Understanding the layout and configuration of various engine components is essential for anyone involved in automotive repair or customization. By studying the connections and structure of these elements, mechanics and enthusiasts can ensure proper function and maintenance of their machines.

In this section, we will delve into the arrangement of key components within a specific type of engine, offering insight into the setup without relying on overly technical terminology. This will help clarify the interrelationship between different parts and improve understanding for those looking to enhance their knowledge of engine design.

Whether you’re looking to optimize performance or carry out repairs, familiarizing yourself with the layout of these components is crucial. We aim to provide a comprehensive overview that will assist both seasoned mechanics and newcomers alike in their projects.

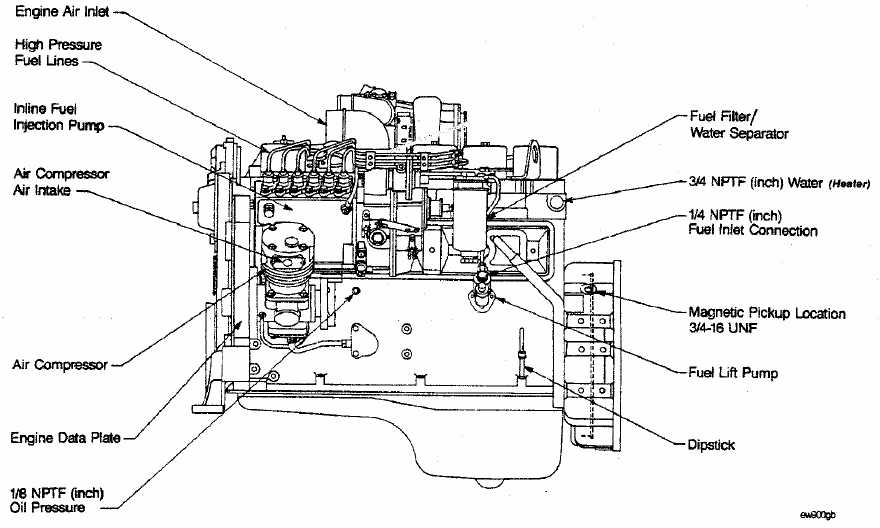

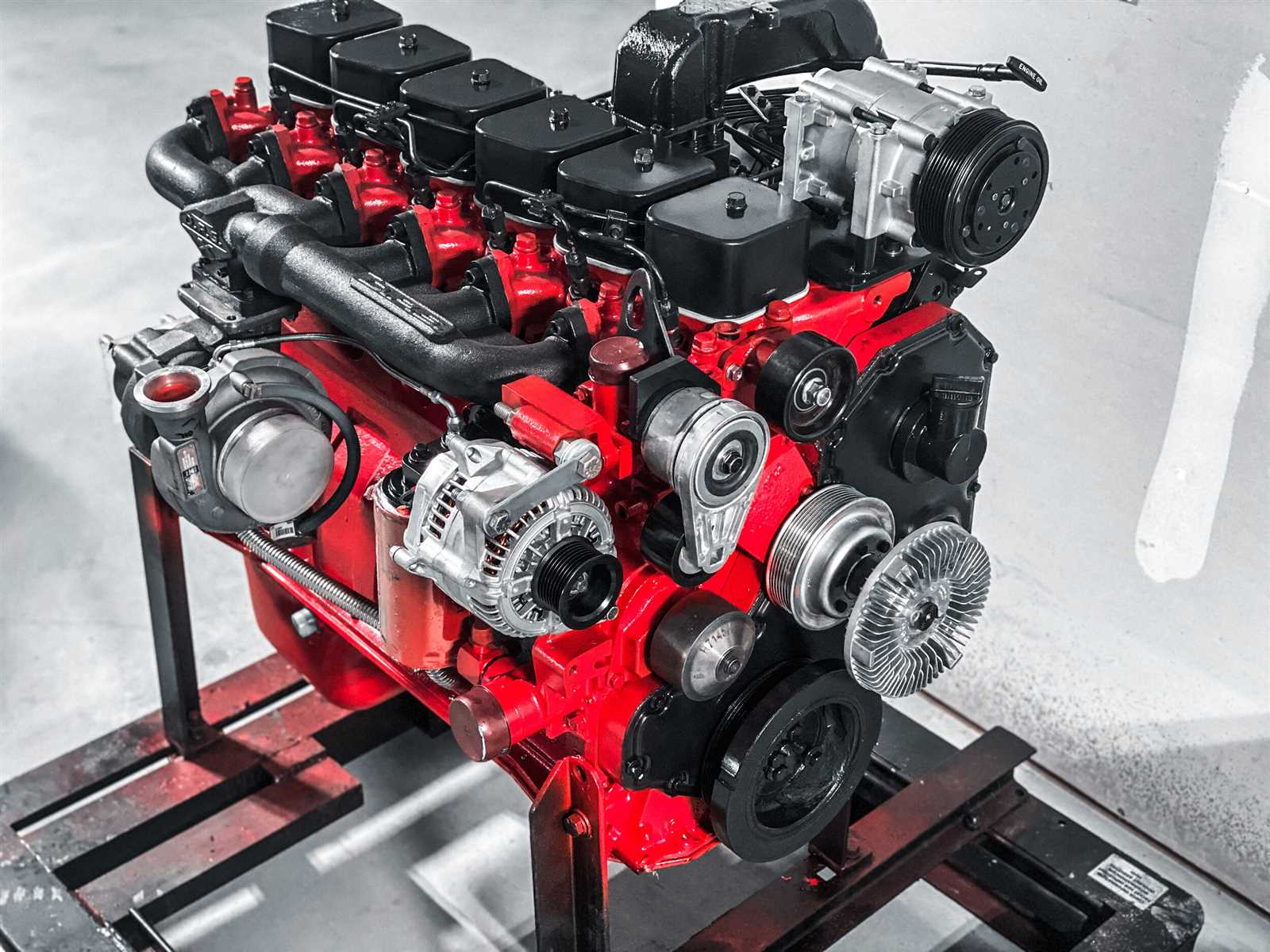

12 Valve Cummins Engine Components Overview

The internal design of this powerful motor has garnered a reputation for durability and exceptional performance. Its straightforward configuration, combined with robust materials, makes it one of the most reliable systems in its class. This section will cover the core elements that contribute to its strength and functionality, exploring how each piece works in harmony to deliver consistent output.

Core Structure

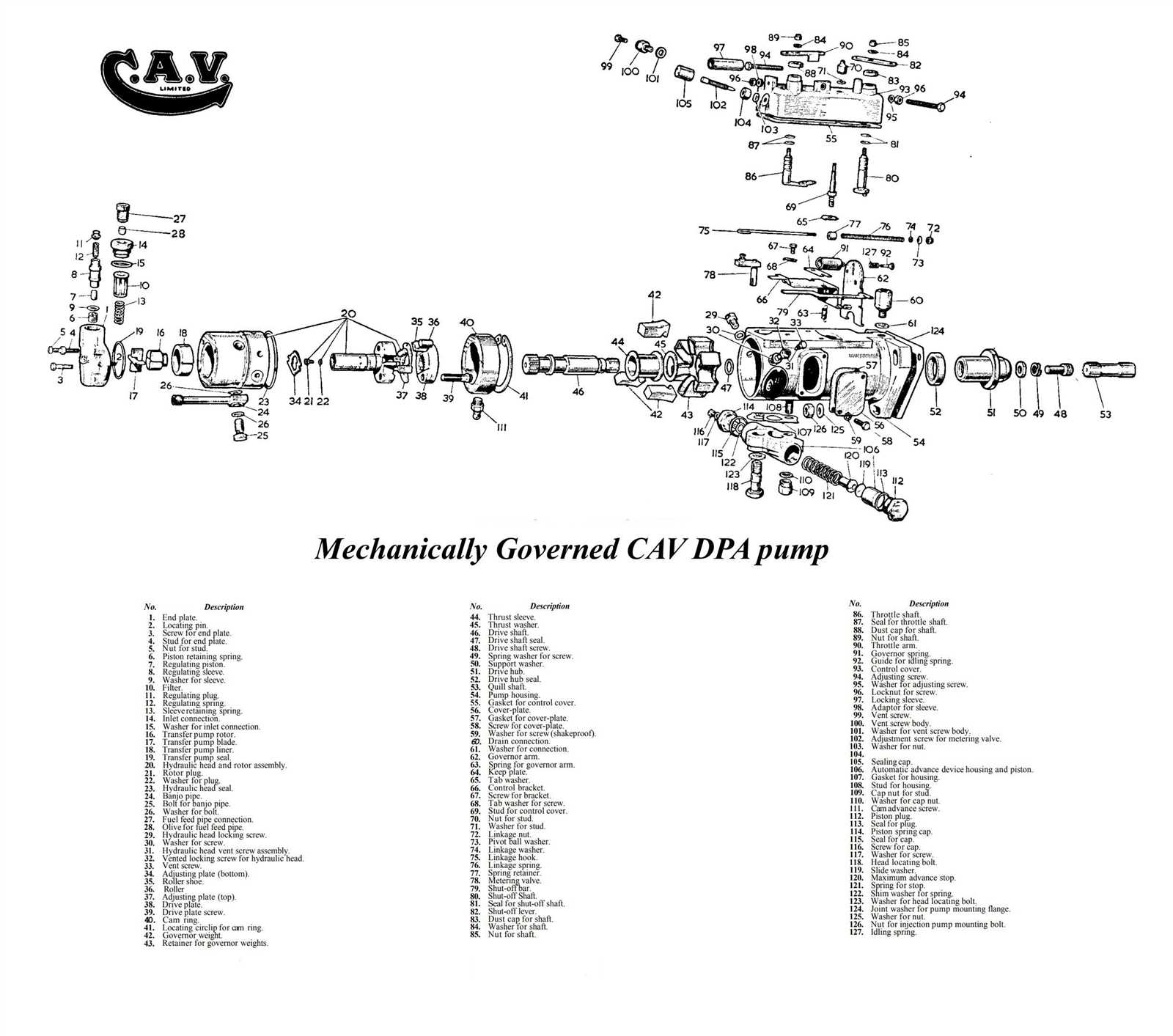

The heart of this engine consists of a series of essential mechanical parts designed to handle high pressure and stress. These elements are constructed to withstand extreme conditions, ensuring efficient operation over time. The interaction between them ensures that fuel is processed effectively, optimizing power output.

Understanding the 12 Valve Cummins Layout

In this section, we explore the arrangement of key components within a well-known diesel engine. The structure of this powertrain is renowned for its simplicity and robustness, contributing to its efficiency and long-term performance. By understanding the positioning of various elements, one can gain deeper insight into how the engine operates seamlessly under different conditions.

| Component | Location | Function | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

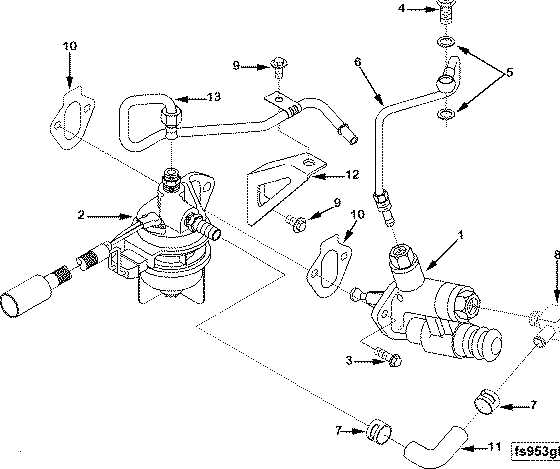

| Fuel Pump | Front-Mounted | Supplies fuel to

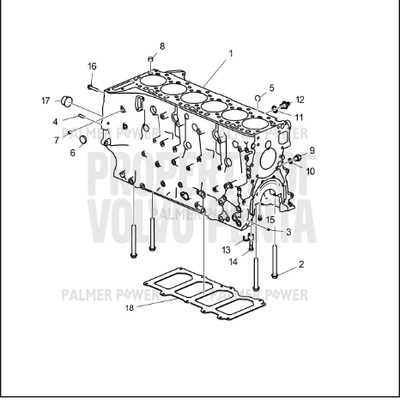

Main Internal Parts of a 12 Valve Cummins

The engine in question features several key components that work together to ensure smooth operation and efficient power generation. These elements are critical for maintaining engine performance and longevity, requiring precision in design and function. Below is a breakdown of some of the most important internal elements that make this engine type renowned for its reliability and strength.

Identifying Key Transmission Parts

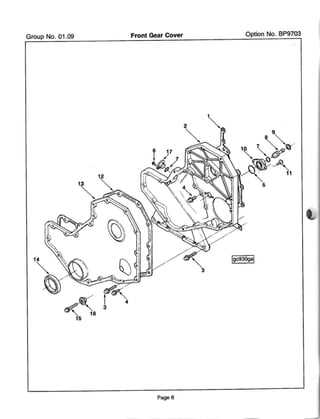

Understanding the essential components of a transmission system is crucial for effective maintenance and repair. This section aims to provide insights into the primary elements that ensure smooth operation and efficiency in heavy-duty machinery.

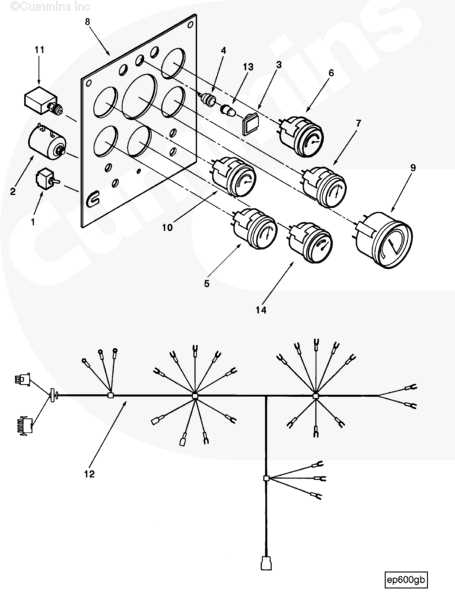

Identifying these key elements is essential for diagnosing issues and ensuring optimal performance in any transmission system. Electrical Components and Wiring LayoutThe efficiency and functionality of an engine greatly depend on its electrical system. Understanding the configuration and connections of these components is essential for proper maintenance and troubleshooting. This section provides an overview of the essential electrical elements, their interconnections, and the importance of a well-organized wiring scheme. Key Electrical ElementsAmong the critical electrical components are the starter motor, alternator, and various sensors. Each part plays a significant role in the overall performance of the engine. The starter motor initiates the engine’s operation, while the alternator ensures the battery is charged and ready for use. Sensors, such as temperature and pressure sensors, provide crucial data to optimize performance. Wiring Connections and Layout

A clear and logical wiring layout is vital for reliable operation. Properly routed wires minimize the risk of shorts and ensure that signals are transmitted accurately. It is essential to regularly inspect wiring for wear and secure connections to prevent electrical failures that could lead to performance issues. Detailed View of the Lubrication SystemThe lubrication system plays a crucial role in ensuring the smooth operation of an engine by reducing friction between moving components. This system circulates oil throughout the engine, providing essential lubrication, cooling, and cleaning functions. A well-designed lubrication system enhances engine performance and longevity by preventing wear and overheating. Key Components of the Lubrication SystemThe lubrication system comprises several vital components that work together to maintain optimal oil flow and pressure. Understanding these components is essential for effective maintenance and troubleshooting.

Importance of Regular MaintenanceRegular maintenance of the lubrication system is essential to ensure optimal engine performance. This includes changing the oil and filter at recommended intervals, checking for leaks, and monitoring oil levels. Proper upkeep prevents potential issues that could lead to significant engine damage. Valve Adjustment Process and ToolsProper calibration of engine components is essential for optimal performance and longevity. This section outlines the procedure and necessary tools for achieving accurate settings in these critical mechanisms, ensuring smooth operation and reliability. Procedure for Calibration

The adjustment process involves several key steps that must be followed meticulously:

Essential Tools

Having the right tools on hand is crucial for an efficient adjustment process:

|