In the realm of motorized vehicles, comprehending the arrangement of various elements is essential for effective maintenance and repair. This section aims to provide an overview of how these components interact and are organized within the machine. A clear understanding of this layout can enhance the overall functionality and longevity of the equipment.

By delving into the specifics of each component’s location and relationship to others, operators can make informed decisions regarding repairs and upgrades. Such insights not only facilitate troubleshooting but also empower users to optimize their machinery for better performance.

Through a detailed exploration of these configurations, enthusiasts and professionals alike can appreciate the intricate design that underlies efficient operation. Gaining familiarity with these structures fosters a deeper connection to the machinery and encourages proactive care.

When it comes to older snow machines, various complications can arise that affect performance and reliability. Understanding these typical problems can help owners maintain their vehicles more effectively and ensure a smoother ride.

- Engine Performance: Issues such as poor acceleration or stalling can often be traced back to fuel system complications or ignition failures.

- Suspension Concerns: Over time, suspension components may wear out, leading to a rough ride and decreased handling capabilities.

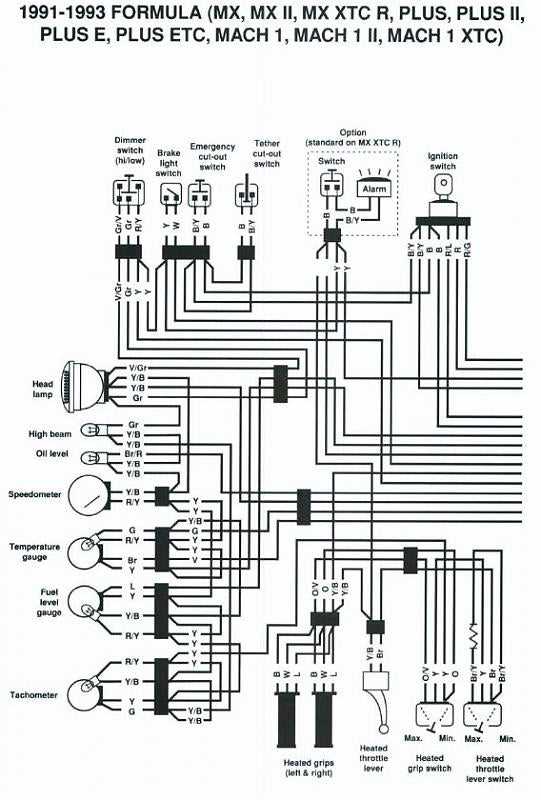

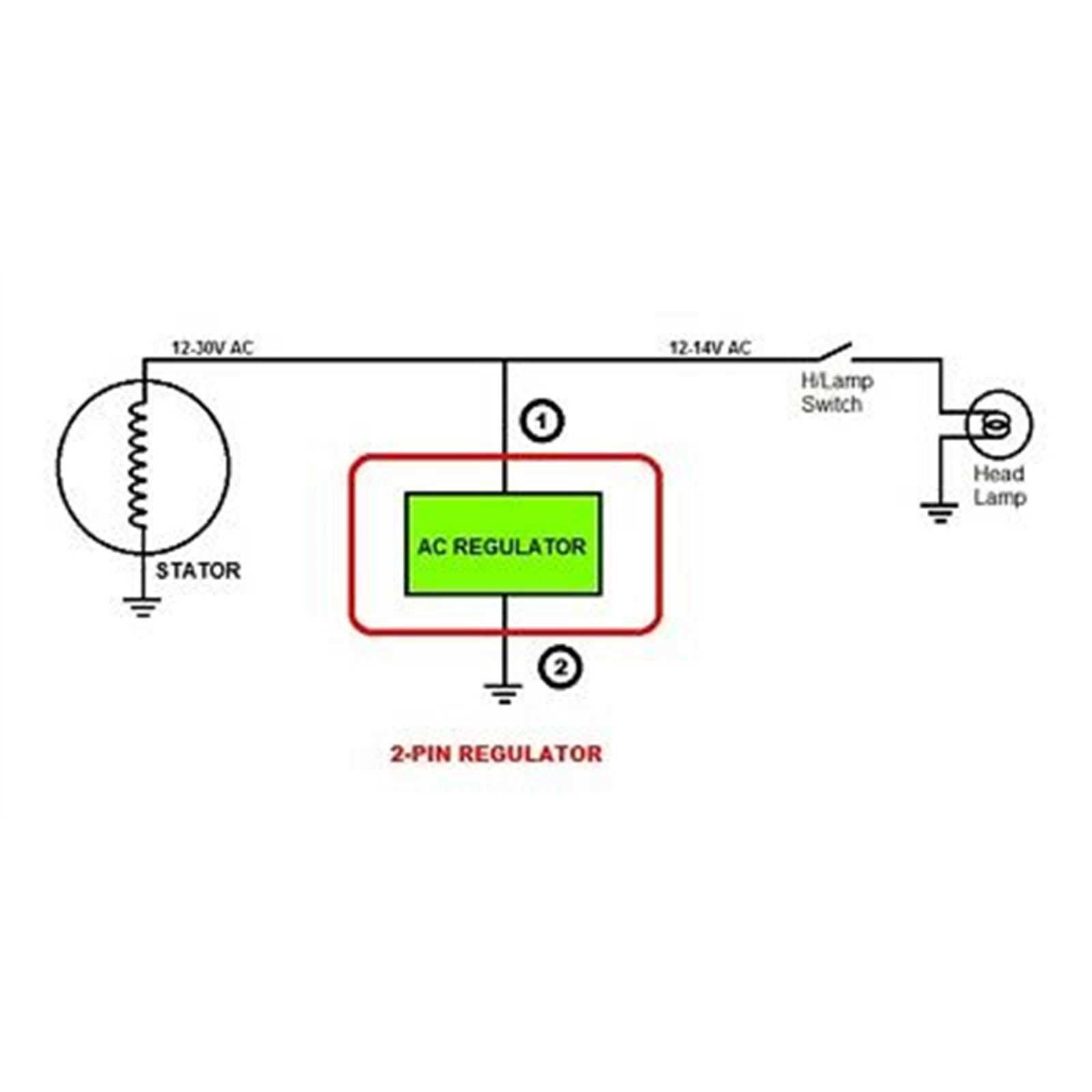

- Electrical System: Problems with wiring or connectors can result in electrical failures, affecting lights and starting systems.

- Cooling System: Overheating is a common issue, often due to clogged lines or malfunctioning thermostats.

- Track Wear: Tracks can become worn or damaged, impacting traction and stability during operation.

Regular maintenance and prompt attention to these concerns can enhance the longevity and functionality of these machines, allowing enthusiasts to enjoy their winter activities without hassle.

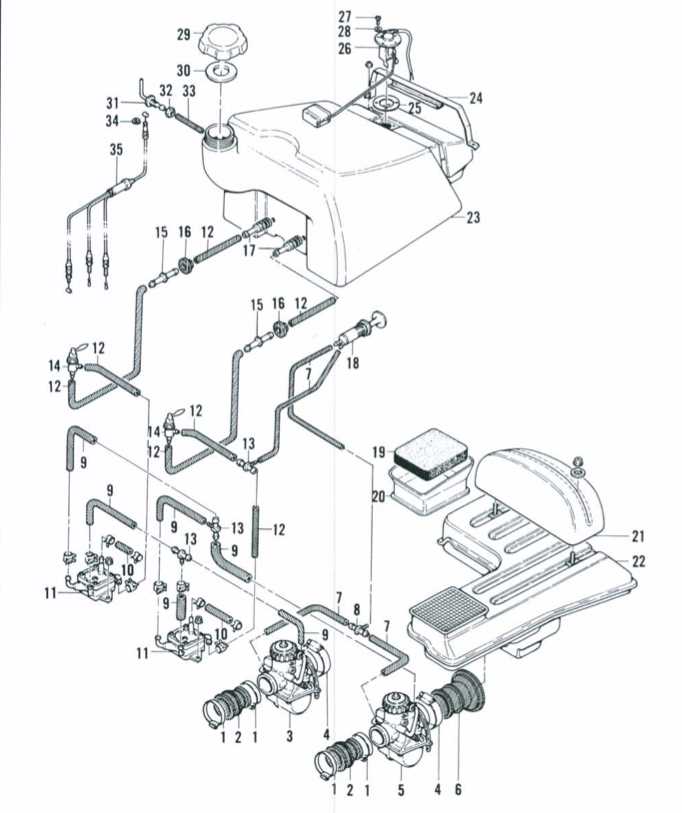

How to Read Parts Diagrams

Understanding the layout of component illustrations is crucial for effective maintenance and repairs. These visual guides offer a clear representation of each element, making it easier to identify and source necessary items. By familiarizing yourself with the symbols and organization used in these schematics, you can enhance your troubleshooting skills and streamline the repair process.

Understanding Symbols and Notations

Each illustration typically includes specific symbols and annotations that convey essential information about each component. Familiarizing yourself with these markings will significantly aid in accurately interpreting the visuals. Common symbols may indicate the type of attachment, connection points, or the sequence in which parts are assembled.

Step-by-Step Approach

To effectively utilize these visual aids, follow a systematic approach:

| Step | Description |

|---|---|

| 1 | Begin by identifying the main assembly you are working on. |

| 2 | Locate the relevant visual representation that corresponds to your assembly. |

| 3 | Examine the symbols used, taking note of the key provided, if available. |

| 4 | Cross-reference the illustration with your actual components to ensure correct identification. |

Sources for Genuine Parts

When it comes to maintaining a vehicle, finding authentic components is crucial for ensuring optimal performance and longevity. Utilizing original pieces not only enhances reliability but also guarantees compatibility with your machine. Below are some reliable avenues to consider when searching for these essential elements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides direct access to genuine components, along with specifications and compatibility information. |

| Authorized Dealers | Local dealers are trained to assist in sourcing original items and can offer advice on installation and maintenance. |

| Online Retailers | Reputable e-commerce platforms may stock genuine items, but it is essential to verify the seller’s credibility. |

| Specialty Shops | Stores focusing on specific vehicle types often carry a range of original components and can provide expert advice. |

Aftermarket vs. OEM Components

When it comes to maintaining or upgrading your vehicle, the choice between aftermarket and original equipment manufacturer (OEM) components can significantly impact performance and longevity. Understanding the differences between these options is crucial for making informed decisions that align with your needs and budget.

Aftermarket components are produced by third-party manufacturers, often offering a range of options that may enhance performance or provide cost savings. On the other hand, OEM components are made by the original manufacturer and are designed to meet specific standards and specifications.

Here are some key considerations when choosing between these two types of components:

- Quality: OEM parts typically guarantee a standard of quality consistent with the original design, while aftermarket parts can vary widely in quality.

- Price: Aftermarket components often present a more affordable option, but this can come at the cost of durability and performance.

- Compatibility: OEM parts are designed to fit perfectly with your vehicle, whereas aftermarket options may require modifications.

- Warranty: Many OEM parts come with a warranty, providing peace of mind, while warranty options for aftermarket parts can differ significantly.

- Availability: Aftermarket components may be more readily available, especially for older models, while OEM parts might need to be ordered from manufacturers.

Ultimately, the decision between aftermarket and OEM components depends on individual priorities, including budget constraints, desired performance, and the importance of maintaining original specifications.

Upgrading Your Ski Doo

Enhancing your snowmobile can significantly improve its performance, comfort, and overall enjoyment during rides. Whether you’re looking to boost speed, increase stability, or enhance the aesthetic appeal, there are various modifications available to suit your needs.

Consider focusing on key areas such as the engine, suspension, and track systems. Each upgrade can contribute to a more enjoyable experience on the trails. Below is a table outlining some popular enhancement options and their potential benefits:

| Upgrade Option | Description | Benefits |

|---|---|---|

| Performance Exhaust | Upgrading to a high-flow exhaust system. | Improves engine efficiency and sound. |

| Suspension Kit | Enhanced suspension components for better handling. | Increases stability and comfort on rough terrain. |

| High-Performance Carburetor | Replacing the stock carburetor with a more efficient model. | Increases throttle response and power delivery. |

| Track Upgrades | Switching to a wider or studded track. | Improves traction and handling in various snow conditions. |

Before making any upgrades, it’s important to research compatibility and potential impacts on warranty and safety. A well-planned enhancement strategy can lead to a more enjoyable and exhilarating experience on your next outing.

Repairing vs. Replacing Components

When it comes to maintaining machinery, two primary approaches emerge: fixing existing components or substituting them with new ones. Each method has its own set of advantages and considerations that can influence the overall performance and longevity of the equipment.

Benefits of Repairing

Repairing damaged or worn elements often provides several benefits, including:

- Cost-Effectiveness: Repairs typically require a smaller financial investment compared to purchasing new items.

- Preservation of Original Quality: Maintaining original components can ensure the equipment retains its intended performance characteristics.

- Reduced Waste: Fixing items contributes to environmental sustainability by minimizing waste and reducing the demand for new resources.

Advantages of Replacement

On the other hand, opting for new components may be the better choice in certain situations:

- Enhanced Performance: New items may offer improved efficiency and functionality, especially if advancements have been made since the original was manufactured.

- Warranty and Support: Replacing with new components often comes with manufacturer warranties, providing peace of mind and support.

- Time Savings: In some cases, it might be quicker to install new parts rather than invest time in repairs.

Ultimately, the decision to repair or replace will depend on various factors, including budget, availability, and specific circumstances surrounding the issue at hand.

Where to Find Diagrams Online

Locating visual guides for specific mechanical components can greatly aid in understanding assembly and disassembly processes. Various online resources offer comprehensive illustrations that can enhance your knowledge of equipment structure and functionality.

Online Retailers and Manufacturer Websites

Many manufacturers provide detailed schematics on their official sites. These resources often include:

- Interactive diagrams that allow you to zoom in on specific parts

- Downloadable PDFs for offline access

- Instructions on how to order replacement items based on the visuals

Specialized Forums and Community Groups

Engaging with online communities can also yield valuable insights. Popular platforms include:

- Discussion boards where enthusiasts share their own resources

- Social media groups focused on maintenance and repair topics

- Dedicated websites offering user-generated content, including illustrations