Understanding the inner workings of a high-performance engine involves delving into the intricate connections and components that keep everything running smoothly. Whether you’re maintaining, upgrading, or simply analyzing, having a clear visual reference can be invaluable for anyone working on mechanical projects.

The following section offers a detailed look into the various elements that make up the heart of this engine system. By breaking down each segment, you’ll gain insight into the connections that drive the performance, ensuring that all elements work in harmony.

This guide provides a comprehensive overview of the essential components, connections, and their interactions. From fuel management to power distribution, we aim to shed light on the critical elements that make the system efficient and reliable.

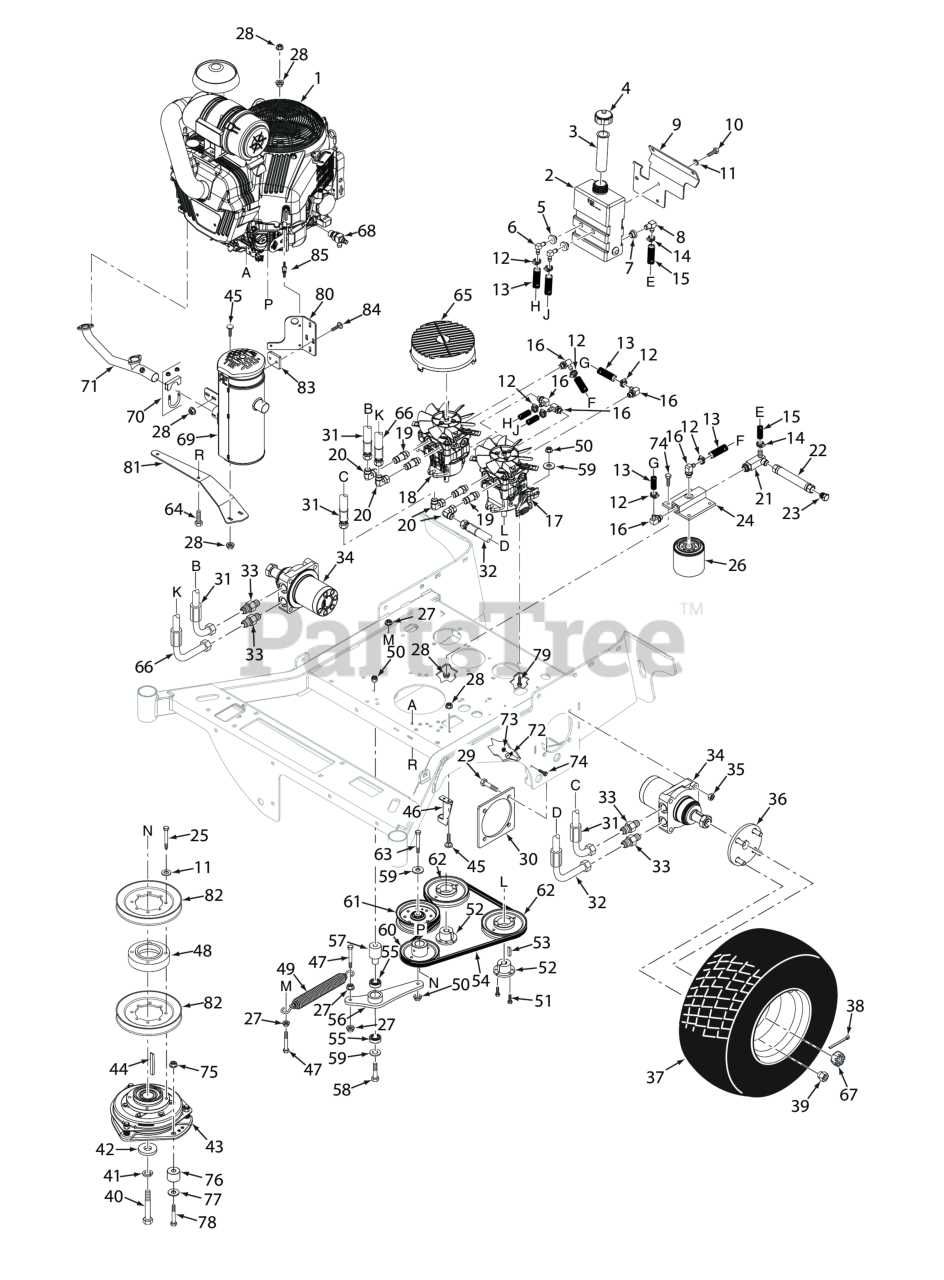

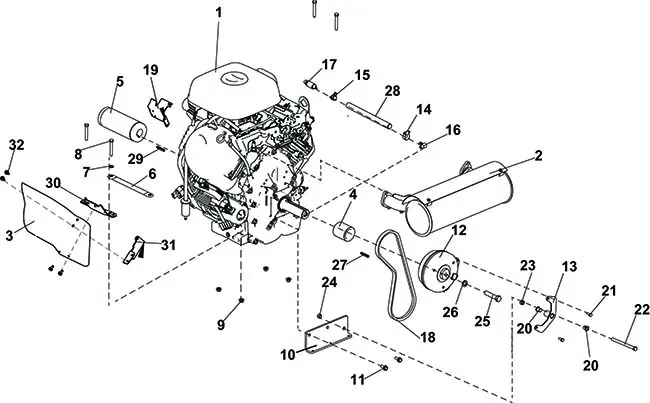

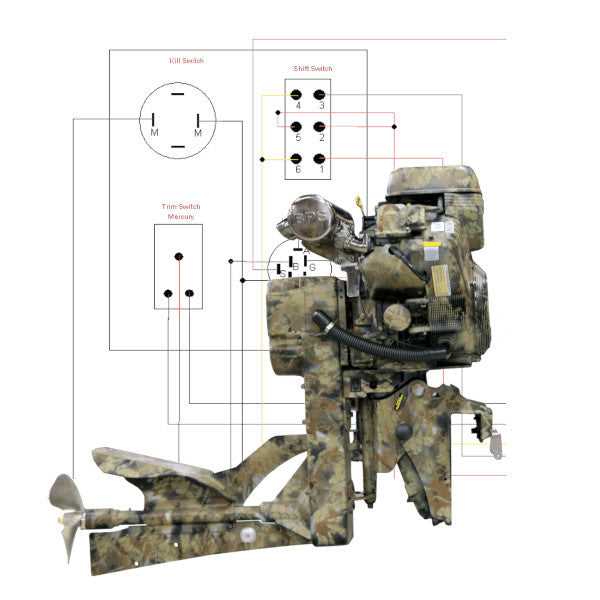

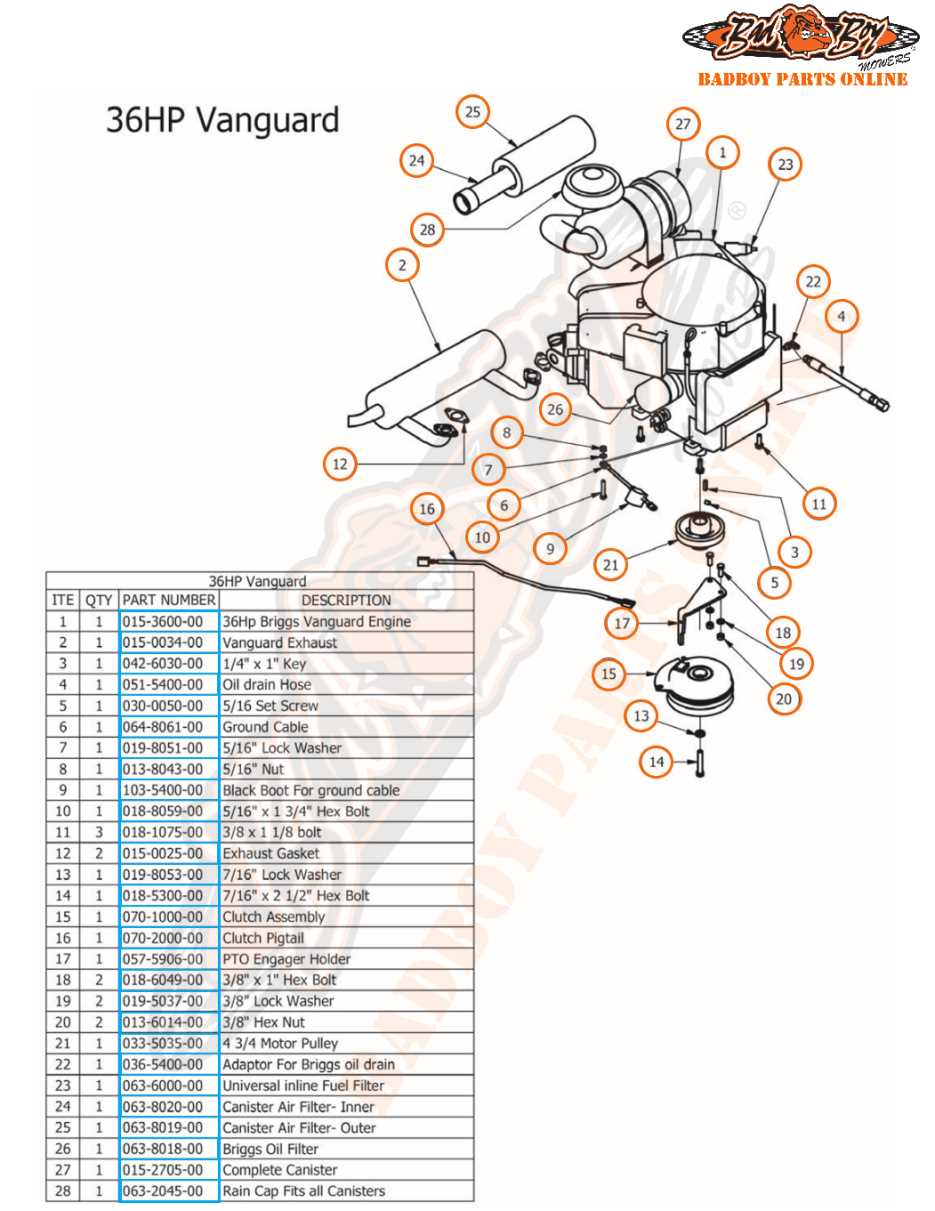

Overview of 37 HP Vanguard EFI System

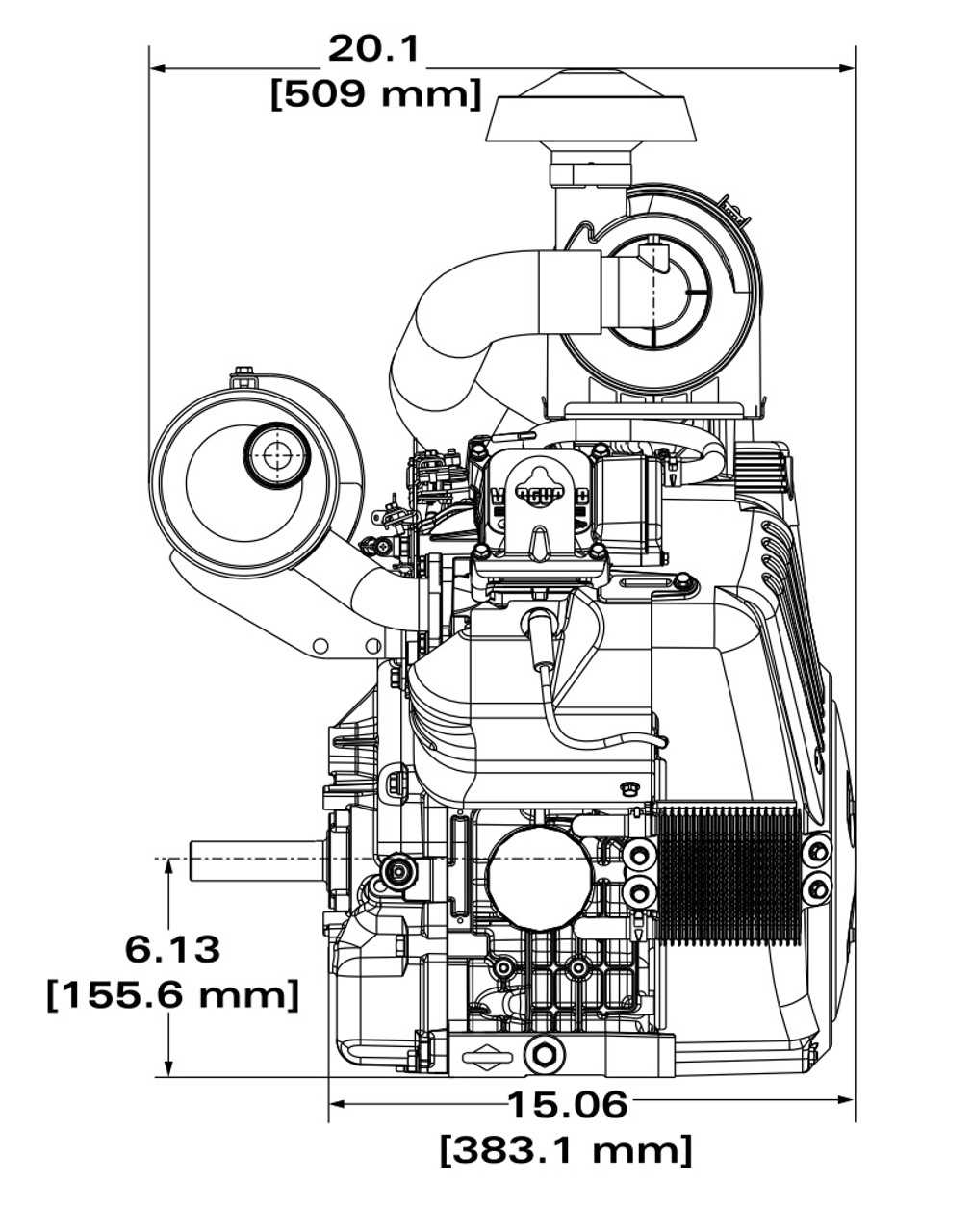

This powerful engine design offers reliable performance and fuel efficiency, ensuring smooth operation across various applications. With advanced components working together, the system manages key functions to deliver optimal power, while maintaining precise control over fuel delivery and combustion. The balance between these elements results in a durable and efficient engine setup that meets modern demands.

Main Features

- Optimized fuel management for enhanced efficiency

- Consistent performance under different conditions

- High adaptability for a variety of uses

Key System Components

- Engine control module that governs essential functions

- Sensors ensuring proper fuel and air mixture

- Precise fuel injectors for controlled delivery

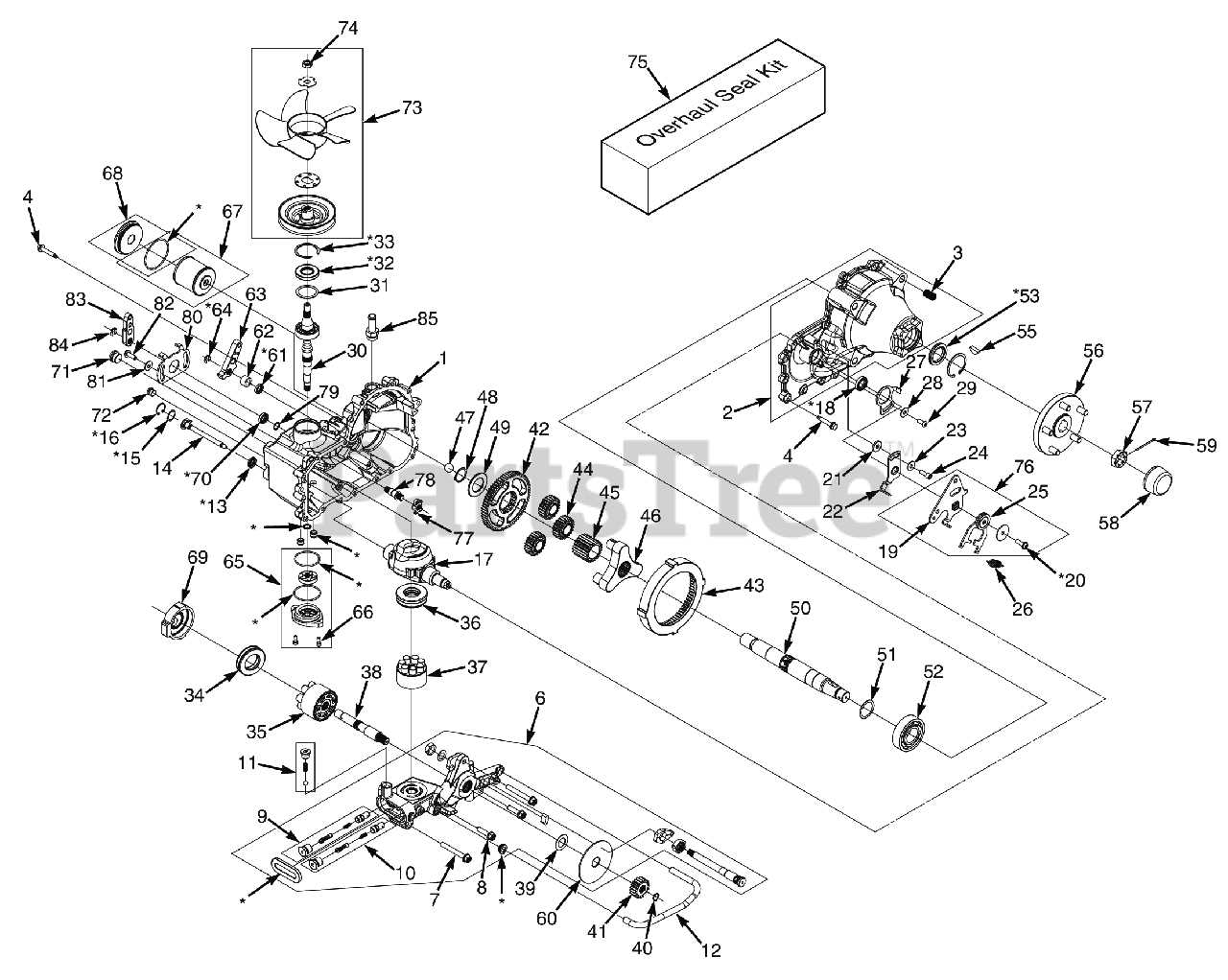

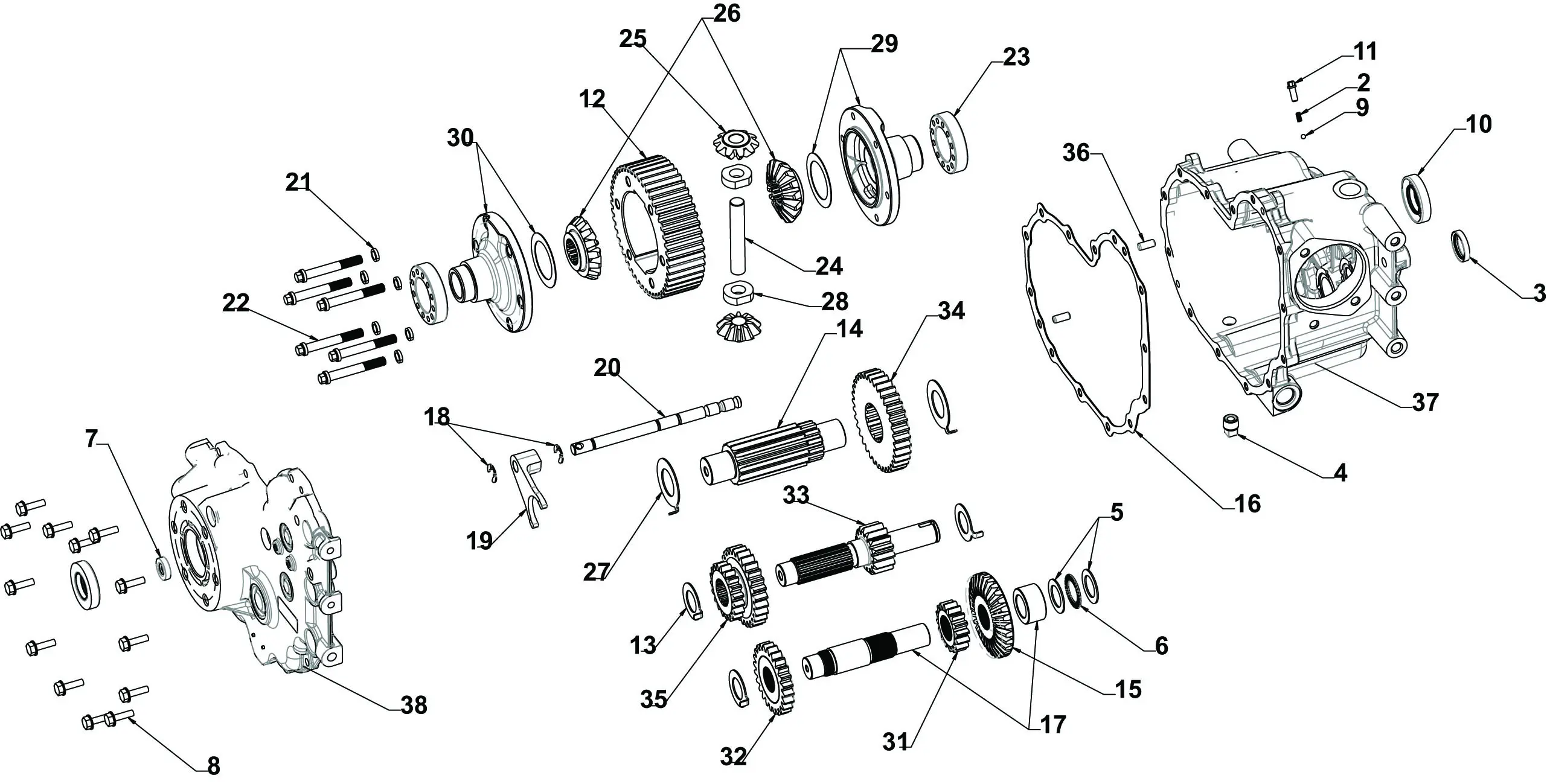

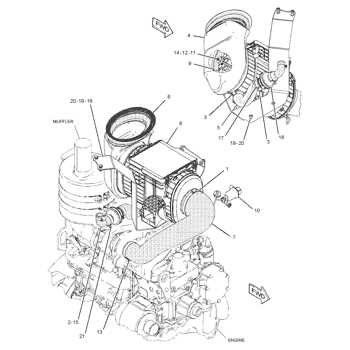

Key Components in Fuel Injection Mechanism

The operation of the fuel system relies on several essential elements that ensure the proper distribution and mixture of fuel. These components work together to optimize the delivery of fuel into the combustion chamber, enhancing performance and efficiency.

Fuel Pump: This crucial element ensures a consistent flow of fuel by transferring it from the tank to the engine. It must maintain the correct pressure to support proper atomization and combustion.

Injectors: Responsible for delivering fuel in fine, controlled amounts, injectors play a pivotal role in determining how efficiently the engine burns fuel. They control both timing and volume, impacting overall engine performance.

Control Unit: Acting as the system’s brain, this module coordinates all aspects of fuel delivery. It monitors various engine parameters and adjusts the injection process accordingly to maintain optimal performance.

Pressure Regulator: The regulator ensures that fuel pressure remains at a specific level, preventing any fluctuations that could disrupt the injection process. Consistent pressure is key to maintaining engine stability and power.

Each of these elements is integral to the fuel system, and together, they form a harmonious mechanism that drives efficient engine function.

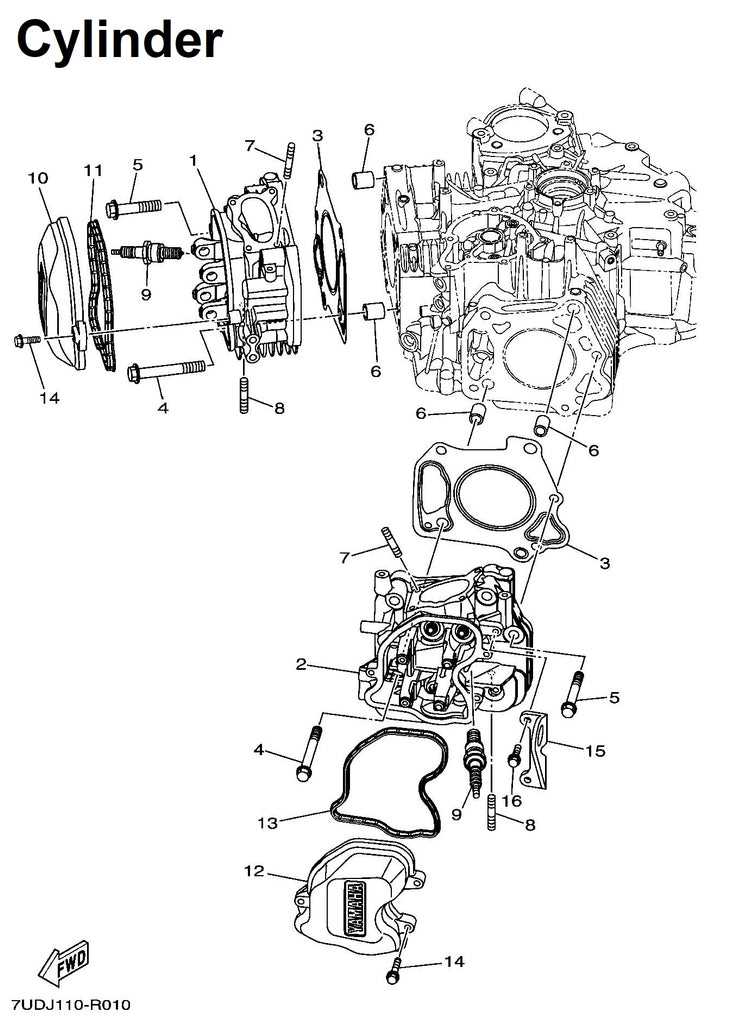

Understanding Engine Performance Optimization

Achieving peak efficiency in engine function requires a delicate balance of multiple factors. By fine-tuning key components, you can ensure smoother operation and improved power delivery. Each adjustment, when correctly implemented, plays a significant role in enhancing overall performance and reliability.

Key Adjustments for Improved Efficiency

Optimizing the airflow, fuel mixture, and ignition timing allows for more efficient combustion, directly impacting the engine’s power output. Precision adjustments in these areas can lead to better fuel economy and more consistent operation. Regular monitoring and fine-tuning help maintain this balance and avoid common issues that may arise from neglect.

The Role of Maintenance in Sustaining Performance

Preventive care is crucial for long-term performance. Regular inspection of critical engine components, replacing worn-out parts, and ensuring everything functions as intended is essential. Keeping the system in optimal condition ensures not only improved output but also extends the life of the engine, reducing the need for major repairs.

Maintenance Tips for EFI System Longevity

Ensuring the long-term reliability of your engine’s fuel management setup requires consistent care and attention. By following essential upkeep practices, you can extend the lifespan of the components responsible for smooth operation, reducing the risk of performance issues.

Regular Inspection of Key Components

Routine checks are crucial for identifying any potential issues before they lead to serious malfunctions. Make it a habit to examine critical elements such as filters and wiring connections to ensure everything is functioning properly. Regular inspection allows for early detection of wear and tear.

Keeping the System Clean

A clean environment is vital for optimal performance. Debris or buildup can interfere with proper functioning, causing inefficiencies. Regular cleaning of the fuel-related sections, including air intakes and connectors, will help maintain peak operation. Preventing blockages ensures smoother engine performance and minimizes potential problems.

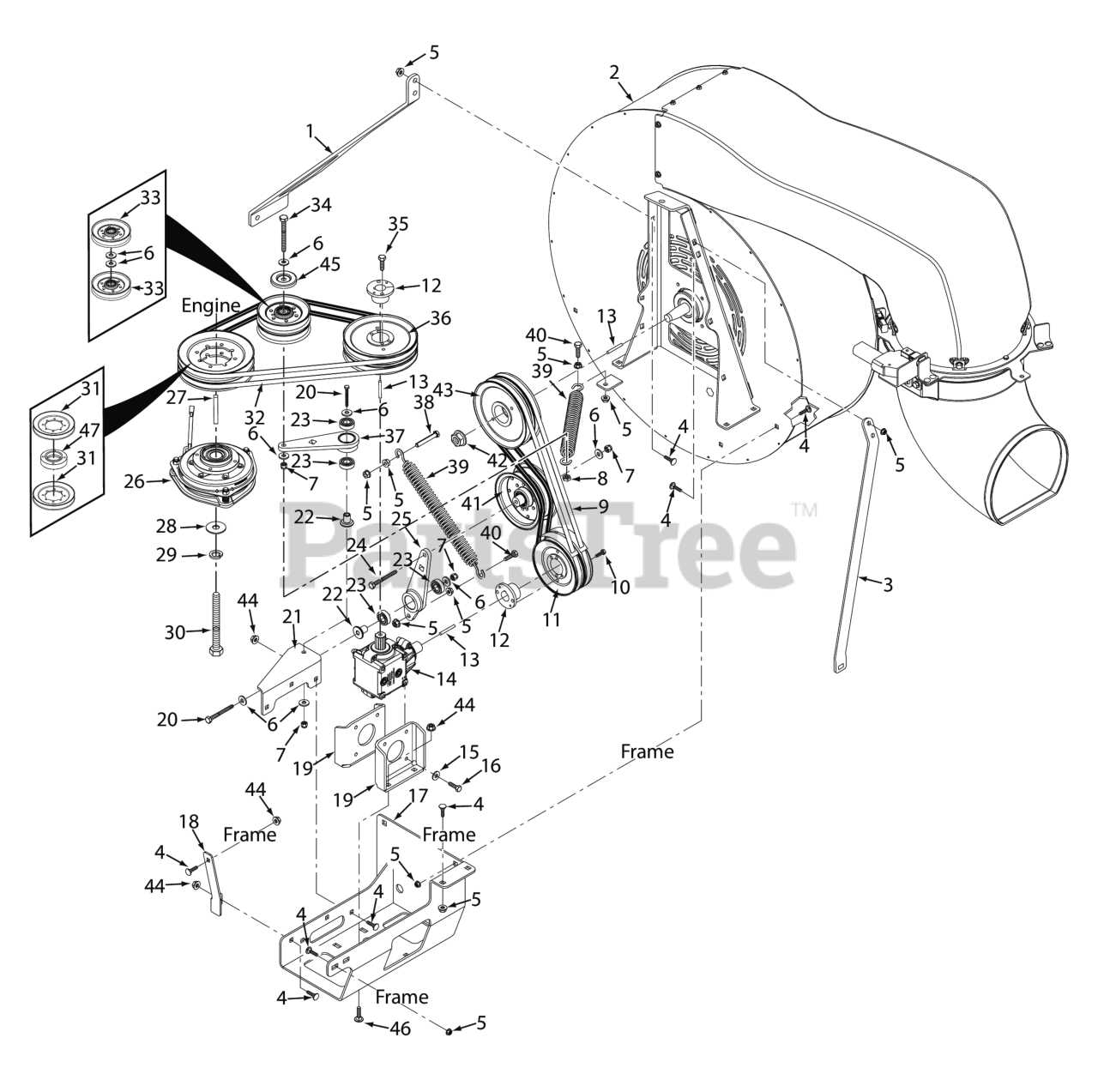

Exploring Fuel Delivery Efficiency

The efficiency of the fuel system plays a crucial role in determining the overall performance of an engine. By optimizing how fuel reaches the engine, one can significantly improve both power output and fuel consumption. Understanding how the various components involved in this process work together allows for a deeper insight into how to enhance efficiency.

Key Factors Influencing Fuel Delivery

- Precise fuel control to ensure optimal combustion.

- The role of injectors in delivering the right amount of fuel.

- Maintaining pressure consistency for smooth engine operation.

Improving System Performance

- Regularly check and replace components to prevent wear-related inefficiencies.

- Ensure the system is free from blockages that could hinder fuel flow.

- Fine-tune the system to maintain proper air-fuel balance for peak performance.

Identifying Common Issues in Vanguard EFI

Understanding typical problems associated with small engine systems can significantly improve their performance and longevity. These issues often manifest in various forms, affecting the overall functionality. By recognizing these common challenges, operators can take proactive measures to ensure smoother operation and maintenance.

Frequent Symptoms

Several indicators suggest that the engine may be experiencing difficulties. Common signs include erratic performance, difficulty starting, and abnormal sounds during operation. These symptoms can stem from various factors such as fuel delivery issues, air intake problems, or ignition system failures.

Troubleshooting Table

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Hard Starting | Fuel starvation or ignition failure | Check fuel lines and spark plugs |

| Rough Idling | Air filter obstruction or improper fuel mixture | Replace air filter and adjust fuel settings |

| Overheating | Insufficient cooling or low oil levels | Inspect cooling system and refill oil |

| Excessive Vibration | Worn components or unbalanced parts | Examine engine mounts and replace worn items |

Enhancing Power Output with Proper Tuning

Optimizing performance is crucial for achieving maximum efficiency in any engine system. By adjusting various components and settings, enthusiasts can significantly increase power delivery and responsiveness. This process involves a careful examination of how different elements interact, leading to a harmonious balance that enhances overall output.

Key factors to consider in the tuning process include:

- Fuel Mixture: Ensuring the right ratio of air to fuel is essential for optimal combustion. Fine-tuning this balance can lead to better throttle response and increased power.

- Ignition Timing: Adjusting when the spark occurs can greatly influence performance. Advancing or retarding ignition timing can help maximize power at different RPM ranges.

- Exhaust Flow: Improving exhaust efficiency allows for better airflow, reducing back pressure and enhancing performance. Consider upgrades that promote a free-flowing exhaust system.

- Intake Modifications: Enhancing the air intake system can improve airflow into the engine, resulting in better performance. Look for components that facilitate increased air volume and speed.

Additionally, regular maintenance plays a vital role in sustaining optimal performance. Keeping components clean and in good condition ensures that the engine operates efficiently, allowing for better results from tuning efforts. Furthermore, using quality parts that match the tuning goals can lead to significant improvements in power output.

In conclusion, meticulous tuning and maintenance can yield impressive enhancements in power and efficiency, leading to a more enjoyable and powerful driving experience.

The Role of Sensors in EFI Operation

Sensors play a crucial part in the efficient functioning of modern fuel delivery systems, enabling precise control and optimal performance. These devices monitor various parameters, providing vital data that helps the engine management system adjust fuel mixtures and timing for enhanced efficiency and reduced emissions. The integration of sensors ensures that the engine operates smoothly under varying conditions, contributing to overall vehicle performance.

Different types of sensors are employed, each serving a specific function. Here is an overview of some common sensors used in these systems:

| Sensor Type | Function |

|---|---|

| Mass Air Flow (MAF) Sensor | Measures the amount of air entering the engine, helping to determine the correct fuel quantity. |

| Throttle Position Sensor (TPS) | Monitors the position of the throttle valve, ensuring proper fuel delivery based on driver demand. |

| Cylinder Head Temperature Sensor | Detects engine temperature, providing feedback for adjustments to fuel flow and ignition timing. |

| Oxygen Sensor | Measures the oxygen levels in the exhaust, helping to optimize the air-fuel mixture for combustion efficiency. |

| Knock Sensor | Detects engine knocking, allowing the system to modify timing for smooth operation. |

The data collected by these sensors is critical for making real-time adjustments, ultimately leading to improved fuel efficiency, enhanced power output, and reduced emissions. By accurately gauging various engine conditions, sensors enable the control unit to respond effectively, ensuring optimal engine performance.

Importance of Regular System Diagnostics

Regular evaluations of machinery play a crucial role in ensuring optimal performance and longevity. By systematically checking the various components, operators can identify potential issues before they escalate, leading to costly repairs or downtime. Consistent assessments not only enhance efficiency but also contribute to overall safety in operation.

Benefits of Routine Inspections

Conducting frequent examinations offers several advantages:

| Benefit | Description |

|---|---|

| Early Problem Detection | Identifying faults before they become serious issues can save time and resources. |

| Improved Efficiency | Regular checks help maintain optimal functioning, leading to better fuel consumption and performance. |

| Enhanced Safety | Ensuring all systems are in working order reduces the risk of accidents or malfunctions. |

Best Practices for Diagnostics

Implementing a structured approach to diagnostics can further enhance outcomes. Utilizing checklists, scheduling routine evaluations, and keeping detailed records of findings will ensure that no aspect is overlooked. By fostering a culture of proactive maintenance, operators can significantly extend the lifespan of their equipment.

How EFI Parts Impact Fuel Economy

Optimizing the components that manage the air-fuel mixture in engines can significantly enhance overall efficiency. By ensuring the correct balance between fuel and air, these elements help maximize power output while minimizing unnecessary fuel consumption. The proper functioning of these systems is crucial for achieving better mileage and reducing emissions.

Key Components Influencing Efficiency

Several critical elements play a role in determining how well an engine utilizes fuel. These components work together to ensure precise delivery and management of the air-fuel blend, which is essential for optimal performance and economy.

| Component | Function | Impact on Fuel Use |

|---|---|---|

| Fuel Injector | Delivers fuel directly into the combustion chamber. | Ensures precise fuel amounts, reducing wastage. |

| Throttle Body | Controls the amount of air entering the engine. | Aids in maintaining the ideal air-fuel ratio. |

| Sensor Array | Monitors various parameters, such as temperature and pressure. | Facilitates adjustments for better combustion efficiency. |

Conclusion

Incorporating advanced technologies and components in engine management systems directly influences fuel efficiency. By enhancing the precision of air-fuel delivery, these elements contribute to lower consumption and improved performance, making them vital for any engine striving for optimal efficiency.

Choosing Replacement Parts for EFI Systems

When it comes to maintaining engine performance, selecting suitable components is crucial. The reliability and efficiency of any internal combustion engine greatly depend on the quality of its individual elements. Understanding the various options available and the specific requirements of your engine can make a significant difference in performance and longevity.

Factors to Consider