Understanding the intricate elements that contribute to the functionality of a cooling system is essential for both maintenance and troubleshooting. Each component plays a vital role in ensuring the efficient operation of the entire mechanism. By examining these elements, one can gain insights into how they work together to regulate temperature effectively.

In this section, we will explore the various sections involved in the system’s operation. This knowledge not only aids in recognizing potential issues but also empowers users to make informed decisions regarding repairs and replacements. With a clear understanding of each segment, users can better appreciate the engineering behind efficient temperature control.

Familiarity with the assembly allows for a more profound comprehension of its operation, making it easier to identify problems when they arise. Whether for personal or professional use, this knowledge is invaluable for maintaining optimal performance and longevity.

This section outlines a structured approach to understanding the intricate components of a cooling unit. By exploring various elements, readers can gain insight into their functions and significance, enhancing overall comprehension of the entire system.

1. Overview of Cooling Units

Understanding the fundamentals of cooling systems is essential. Here are some key aspects:

- Purpose of cooling systems

- How they operate

- Importance in various applications

2. Key Elements of Cooling Mechanisms

Explore the vital components that contribute to the efficiency of cooling systems:

- Refrigerant flow

- Heat exchange process

- Pressure regulation

3. Functionality of the Main Components

Each part has a unique role. Here’s a brief overview:

- Understanding refrigerant management

- Role of the expansion valve

- Importance of the evaporator

4. Maintenance Practices for Longevity

Regular upkeep ensures optimal performance. Consider these practices:

- Scheduled inspections

- Cleaning routines

- Monitoring refrigerant levels

5. Troubleshooting Common Issues

Identifying problems early can save time and resources. Common signs include:

- Unusual noises

- Inconsistent temperature

- Frequent cycling on and off

6. Safety Considerations

Prioritize safety when working with cooling units. Key guidelines include:

- Proper handling of refrigerants

- Understanding electrical hazards

- Use of protective equipment

7. Innovations in Cooling Technology

Stay updated on the latest advancements:

- Smart technology integration

- Energy-efficient designs

- Eco-friendly refrigerants

8. Environmental Impact

Understand the broader implications of cooling systems:

- Effects on energy consumption

- Contribution to climate change

- Importance of sustainable practices

9. The Role of Insulation

Effective insulation plays a crucial role in efficiency. Key points include:

- Types of insulation materials

- Impact on energy savings

- Installation best practices

10. Comparison of Different Systems

Evaluating various types of cooling units can aid decision-making:

- Central vs. portable systems

- Window units vs. split systems

- Cost-effectiveness considerations

11. Understanding System Ratings

Familiarize yourself with performance metrics:

- SEER ratings

- BTU capacity

- Energy Star certification

12. Future Trends in Cooling Solutions

Anticipate upcoming developments that may influence the industry:

- Automation and smart controls

- Advancements in energy storage

- Increased focus on sustainability

Understanding Compressor Functionality

In the realm of refrigeration and air conditioning, the device in question plays a vital role in regulating temperature and maintaining optimal conditions. It operates by manipulating the flow of refrigerant, transforming it from gas to liquid and back again. This process is essential for heat exchange and ensures that systems run efficiently.

At its core, this mechanism relies on a cycle of compression and expansion. When the refrigerant is compressed, its pressure and temperature rise, enabling it to transfer heat effectively. Subsequently, as it moves through the system, it releases heat before entering a cooling phase. This cyclical process not only facilitates climate control but also enhances energy efficiency, making it indispensable for various applications.

The operational efficiency of this device is influenced by several key components working in harmony. Each element plays a significant role in the overall function, ensuring that the refrigerant is properly managed throughout the cycle. Understanding the interactions among these components is crucial for diagnosing issues and optimizing performance.

Ultimately, grasping the fundamental principles behind this mechanism equips users and technicians alike with the knowledge necessary for effective maintenance and troubleshooting. A solid understanding of how this integral device functions can lead to improved reliability and longevity of refrigeration and air conditioning systems.

Key Components of the System

The functionality of an air conditioning system relies on several crucial elements that work together to regulate temperature and ensure comfort. Understanding these essential components can provide insight into how the entire mechanism operates efficiently.

Refrigerant Flow Control

This element is vital for managing the circulation of the cooling substance throughout the system. It regulates the pressure and temperature, ensuring that the cooling process is consistent and effective. Proper control is essential for optimal performance and energy efficiency.

Heat Exchange Mechanism

Another significant component is responsible for transferring heat between the indoor and outdoor environments. This mechanism facilitates the absorption and release of heat, playing a critical role in the overall cooling cycle. The efficiency of this process directly impacts the system’s effectiveness and operational costs.

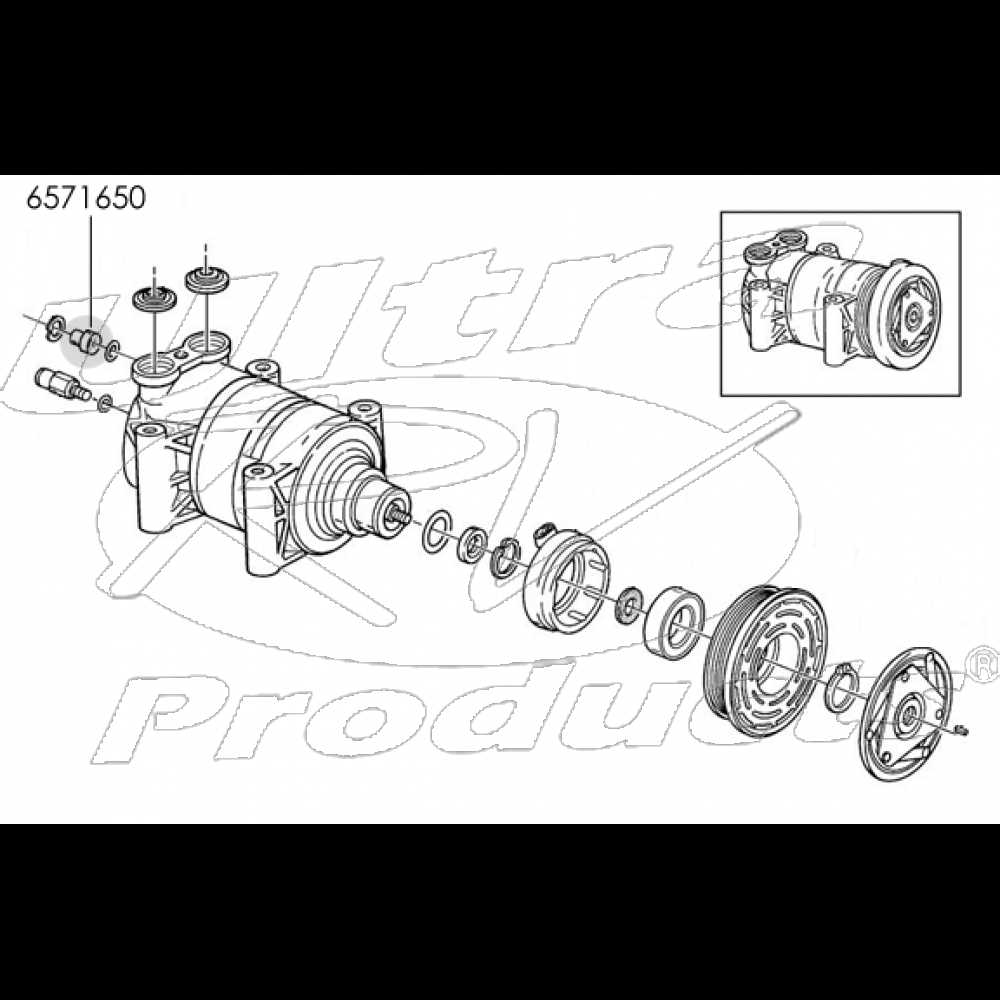

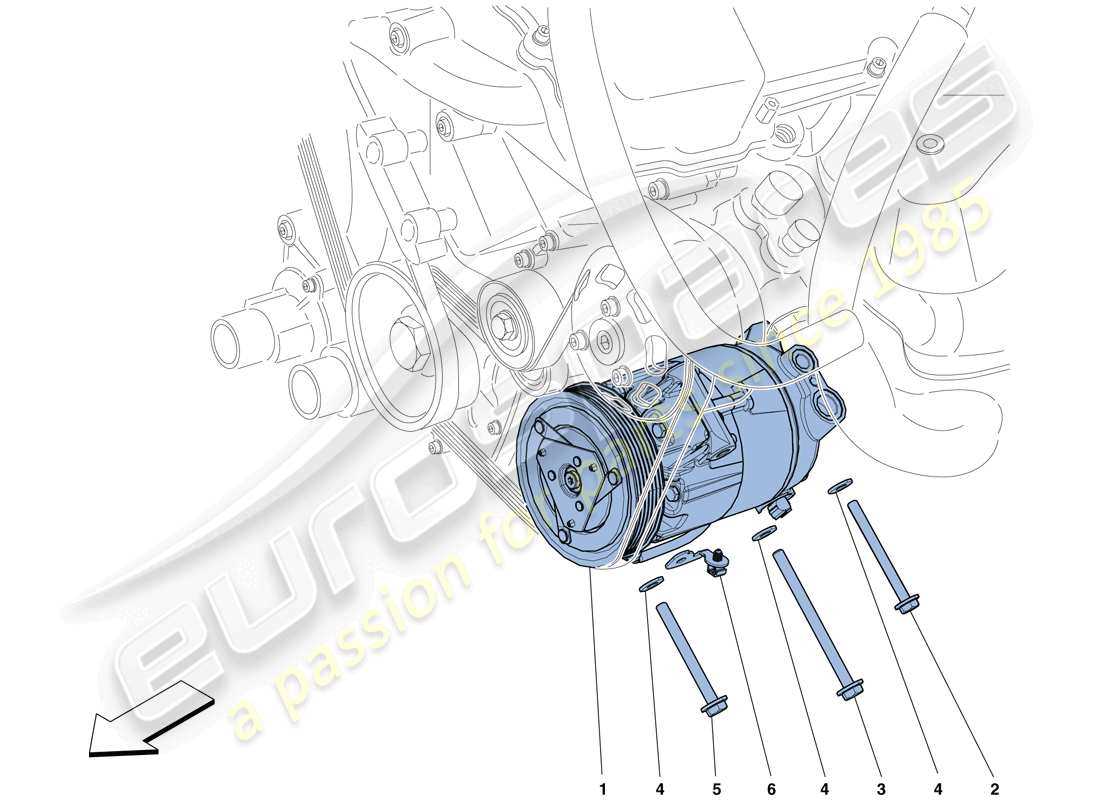

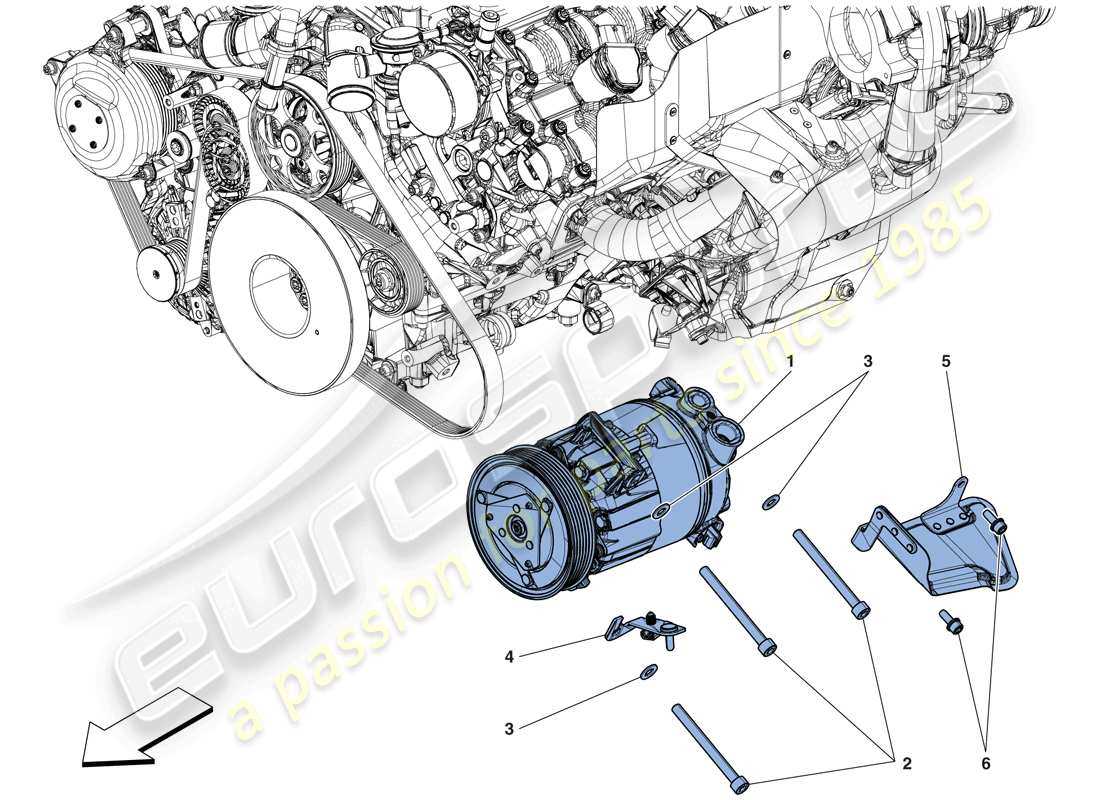

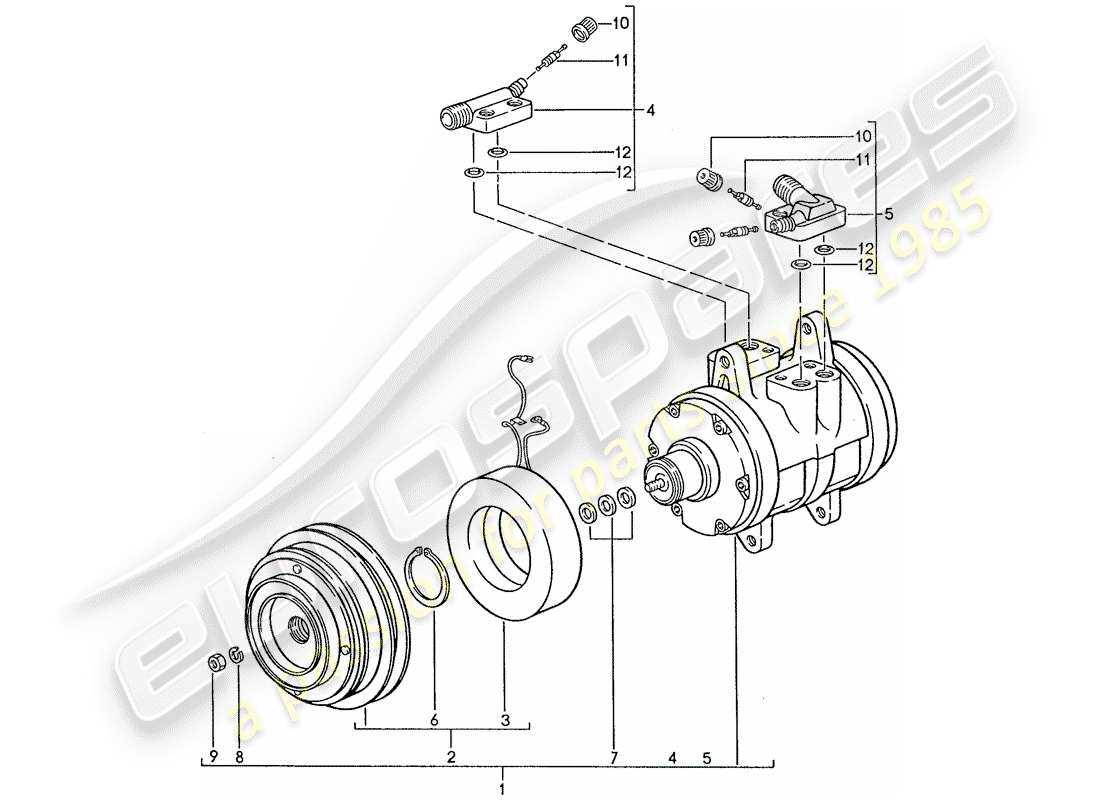

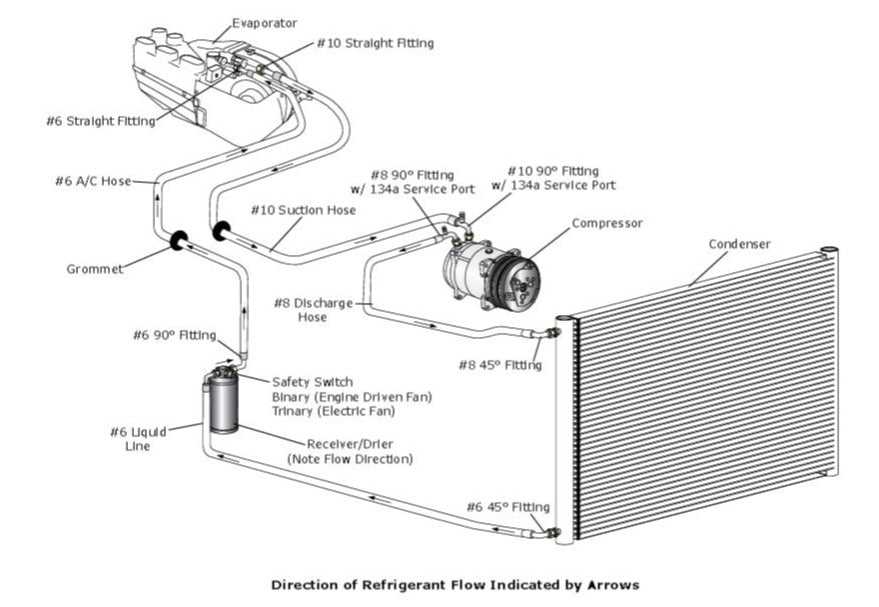

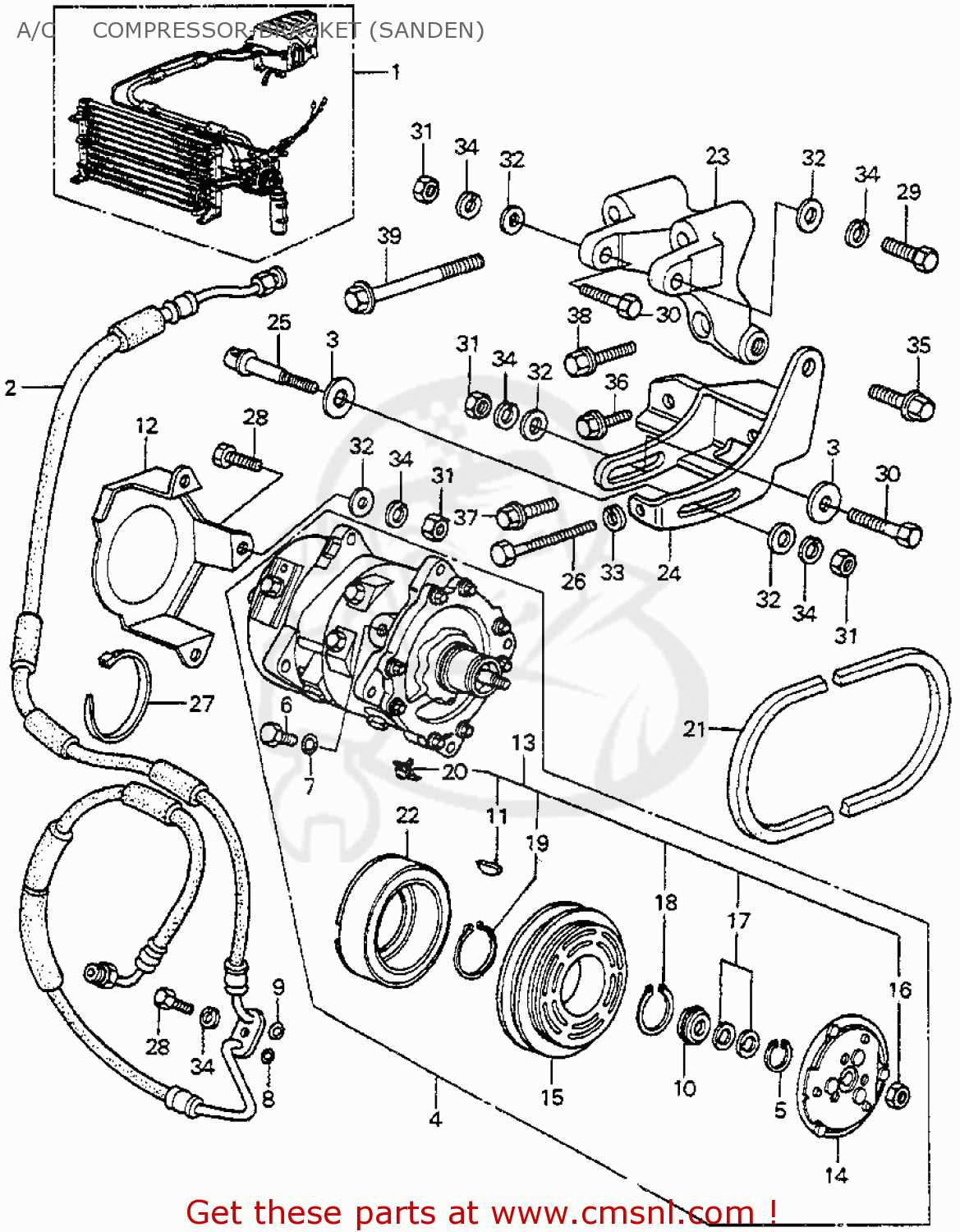

Diagram Overview and Labels

This section provides a comprehensive insight into the illustration showcasing various components of the cooling system. Understanding the layout is crucial for effective maintenance and troubleshooting.

The visual representation is typically divided into multiple sections, each highlighting specific elements. Here’s a breakdown of the labels commonly found within the illustration:

- Refrigerant Flow Path: Indicates the movement of the cooling substance throughout the system.

- Expansion Device: Marks the area where the pressure is reduced, allowing the refrigerant to expand.

- Condenser Location: Shows where heat is dissipated, transforming gas back into a liquid state.

- Evaporator Section: Highlights the zone where the liquid refrigerant absorbs heat, converting back to gas.

Familiarity with these labels enhances the understanding of how each section contributes to the overall function of the system.

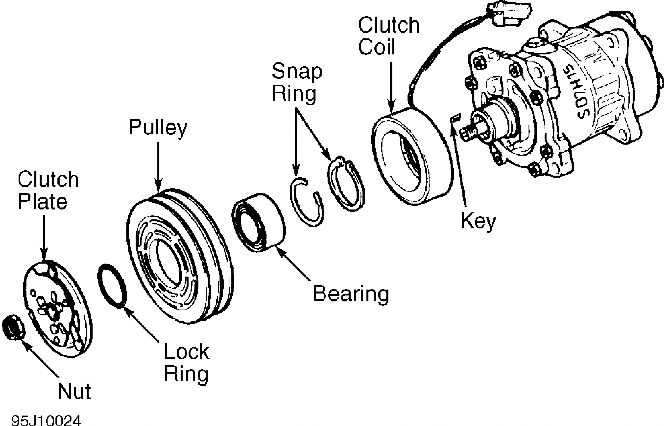

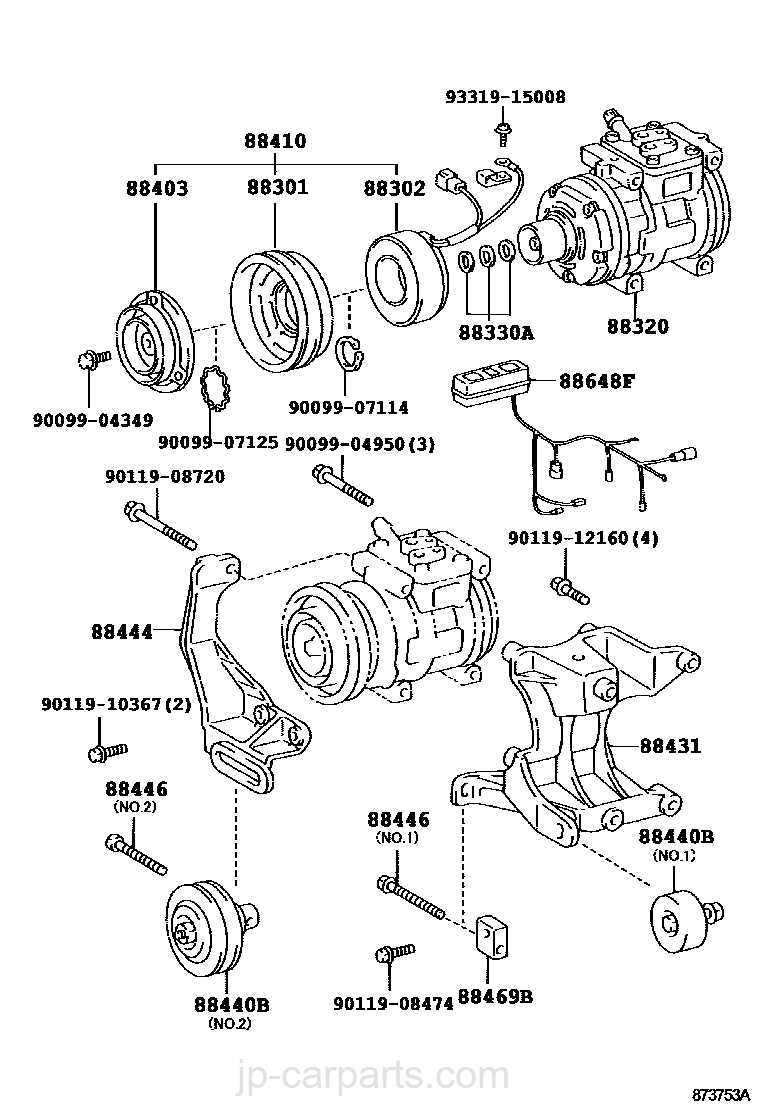

Identifying Major Parts

Understanding the key components of a cooling system is essential for effective maintenance and troubleshooting. Each element plays a significant role in ensuring optimal performance, and recognizing these elements can aid in identifying potential issues. This section will outline the primary features that contribute to the efficient operation of the unit.

Core Components

The core features of the system include a motor that drives the mechanism, a shell that houses the entire assembly, and an internal mechanism responsible for compressing the refrigerant. Each of these elements works in tandem to facilitate the cooling process, making it crucial to comprehend their functions and interactions.

Supporting Elements

Supporting elements include valves that regulate the flow of refrigerant, as well as filters designed to remove impurities. These components not only enhance the efficiency of the cooling cycle but also prolong the lifespan of the entire unit. Familiarity with these supporting elements will enable better diagnostics and maintenance practices.

How Each Part Works

This section delves into the functionality of various components within the cooling system. Understanding the role of each element is crucial for grasping how they collectively contribute to the overall operation.

The initial stage involves the suction mechanism, which draws in low-pressure gas from the surrounding environment. This gas then enters a chamber where it undergoes compression, resulting in a temperature increase. Following this, the heated gas is directed to a coil, where it dissipates heat and transforms into a liquid state. The next phase features an expansion device, which reduces the pressure of the liquid, allowing it to expand and cool down.

Once the substance reaches a lower temperature, it re-enters the system, where it absorbs heat from the environment, effectively cooling the surrounding air. This cycle continues, ensuring a consistent temperature regulation. Each element plays a vital role in maintaining efficiency and performance throughout this process.

Maintenance Tips for Longevity

Ensuring the extended life of your cooling system requires regular attention and care. Implementing a few straightforward practices can significantly enhance its efficiency and durability, minimizing the likelihood of unexpected breakdowns.

Regular Inspection

Consistent evaluations of the unit are essential. Look for any signs of wear or damage and address them promptly. Key areas to focus on include:

- Check for unusual noises that may indicate a problem.

- Inspect the housing for cracks or leaks.

- Examine the electrical connections for any signs of fraying.

Proper Cleaning

Keeping the unit clean is vital for optimal performance. Dust and debris can hinder functionality. Follow these cleaning tips:

- Ensure that the surrounding area is free of obstructions.

- Regularly clean filters to maintain airflow.

- Use a soft brush or vacuum to remove dust from the exterior surfaces.

Common Issues and Solutions

This section highlights frequent challenges encountered in the operation of refrigeration units and provides effective remedies to address them. Understanding these common complications can help in maintaining optimal functionality and prolonging the lifespan of the equipment.

Insufficient Cooling Performance

A prevalent issue is inadequate cooling, which can arise from various factors such as low refrigerant levels, blocked airflow, or malfunctioning temperature controls. Regular inspections and maintenance can help identify leaks or blockages, ensuring efficient heat exchange.

Unusual Noises

Unusual sounds during operation often signal underlying problems. Rattling or grinding noises may indicate loose components or wear and tear. Conducting routine checks can assist in tightening or replacing affected elements, leading to quieter performance.

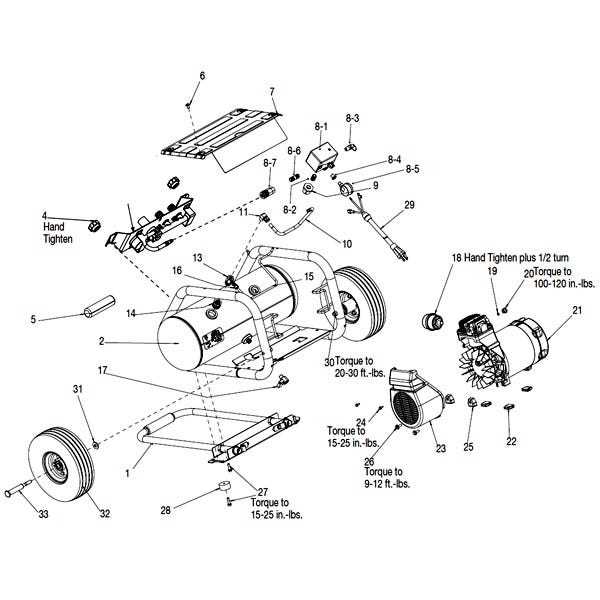

Importance of Proper Installation

Ensuring that equipment is correctly set up is crucial for its efficient operation and longevity. A meticulous installation process minimizes potential issues and enhances overall functionality. Proper placement and secure connections are essential for optimal performance and reliability.

Benefits of Correct Setup

- Reduces the risk of operational failures.

- Enhances energy efficiency, leading to cost savings.

- Improves the lifespan of the equipment.

- Ensures safety by preventing leaks and other hazards.

Common Mistakes to Avoid

- Inadequate sealing of connections, leading to air or fluid leaks.

- Incorrect alignment that can cause undue stress on components.

- Neglecting to follow manufacturer guidelines and specifications.

- Overlooking necessary adjustments during the setup process.

In summary, taking the time to install equipment correctly not only promotes optimal functioning but also safeguards against future complications. Attention to detail during this phase is key to ensuring a smooth operational experience.

Choosing Quality Replacement Parts

When it comes to maintaining and restoring your system, selecting high-quality components is crucial for optimal performance and longevity. The right choices can prevent premature failures and ensure that your unit operates efficiently, saving you time and money in the long run.

Factors to Consider

Several aspects should be taken into account when looking for suitable components. It’s essential to evaluate compatibility with your existing setup, the materials used in manufacturing, and the reputation of the manufacturer. Additionally, warranties and customer support can play significant roles in your decision-making process.

Comparison of Component Types

| Type | Pros | Cons |

|---|---|---|

| OEM | Guaranteed fit and performance | Higher cost |

| Aftermarket | Cost-effective options | Variable quality |

| Rebuilt | Environmentally friendly | Possible reliability issues |

Impact on Overall Efficiency

The functionality of a specific system significantly influences its overall performance. Each component plays a vital role in ensuring optimal operation, which ultimately affects energy consumption and effectiveness. Understanding how these elements interact can lead to better maintenance practices and improved energy management.

Role of Key Components

Main elements contribute to the seamless functioning of the system. Their design and efficiency directly impact how well the system operates under varying conditions. Ensuring that these components are in optimal condition is essential for maximizing productivity and minimizing energy waste.

Optimization Strategies

Implementing best practices for regular checks and updates can enhance performance. This includes monitoring the condition of critical elements and making necessary adjustments to maintain peak efficiency. Proper care not only extends the lifespan of these parts but also promotes a more sustainable operational environment.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right tools is essential to ensure efficiency and effectiveness. A well-equipped toolkit can significantly simplify the repair process and help achieve the desired results. Below is a comprehensive list of necessary instruments to facilitate the task at hand.

| Tool | Purpose |

|---|---|

| Wrench Set | To loosen or tighten various fasteners. |

| Screwdriver Set | For removing or securing screws of different sizes. |

| Multimeter | To measure electrical values and diagnose issues. |

| Pliers | To grip, twist, and cut wires or other materials. |

| Vacuum Pump | To remove air and moisture from the system. |

| Refrigerant Scale | To measure the quantity of refrigerant being added or removed. |

| Safety Goggles | To protect eyes from debris and chemicals. |

When to Seek Professional Help

Understanding the workings of your cooling system can sometimes be challenging, especially when issues arise that may require specialized knowledge. Knowing when to consult an expert can save you time, effort, and potential complications. If you notice persistent problems that affect performance, it may be time to reach out for professional assistance.

Signs of Malfunction

Watch for indicators such as unusual noises, inadequate cooling, or noticeable leaks. These symptoms often suggest that the system is not functioning optimally and may require the attention of a skilled technician. Attempting to resolve complex issues without proper expertise could lead to further damage or safety concerns.

Complex Repairs

In situations where repairs involve intricate components or require specific tools and knowledge, seeking professional help is advisable. Experts possess the necessary training and experience to diagnose problems accurately and implement effective solutions. Relying on their expertise ensures that your system operates efficiently and safely.