In the realm of farming and land management, the significance of robust equipment cannot be overstated. Efficient cultivation relies on various tools designed to optimize soil preparation and enhance crop yields. This guide delves into the intricacies of one such implement, shedding light on its essential components and their functions within the machinery.

Exploring the structural elements of this implement reveals a well-thought-out arrangement that ensures effective performance. Each segment plays a crucial role in the overall operation, contributing to the implement’s efficiency and longevity. Understanding how these elements interact not only aids in maintenance but also empowers operators to maximize their use during the cultivation process.

By familiarizing oneself with the configuration of this equipment, users can gain insights into troubleshooting common issues, facilitating smoother operations in the field. This exploration aims to provide clarity on the various aspects of the implement, ultimately enhancing the user’s experience and effectiveness in agricultural practices.

Understanding Allis Chalmers Disc Harrows

In the realm of agricultural equipment, specific implements play a crucial role in soil preparation and cultivation processes. These tools are designed to enhance the efficiency of land management by breaking up soil and facilitating proper seedbed preparation. Familiarity with the components and functionalities of these implements is essential for optimal operation and maintenance.

The effectiveness of these tools is largely influenced by their design and construction. Each element works in concert to achieve the desired results, ensuring that the soil is adequately aerated and conditioned for planting. Recognizing the significance of each component aids operators in troubleshooting and enhancing the overall performance of the equipment.

| Component | Function |

|---|---|

| Frame | Provides structural support and stability during operation. |

| Blades | Cut through the soil, breaking up clumps and mixing organic material. |

| Axle | Enables rotation of the blades, facilitating efficient tilling. |

| Hitch | Connects the implement to the towing vehicle, allowing for movement. |

| Adjustable Settings | Allows operators to modify depth and angle for varying soil conditions. |

Understanding these components empowers users to make informed decisions regarding their maintenance and operation, ultimately leading to more successful agricultural practices.

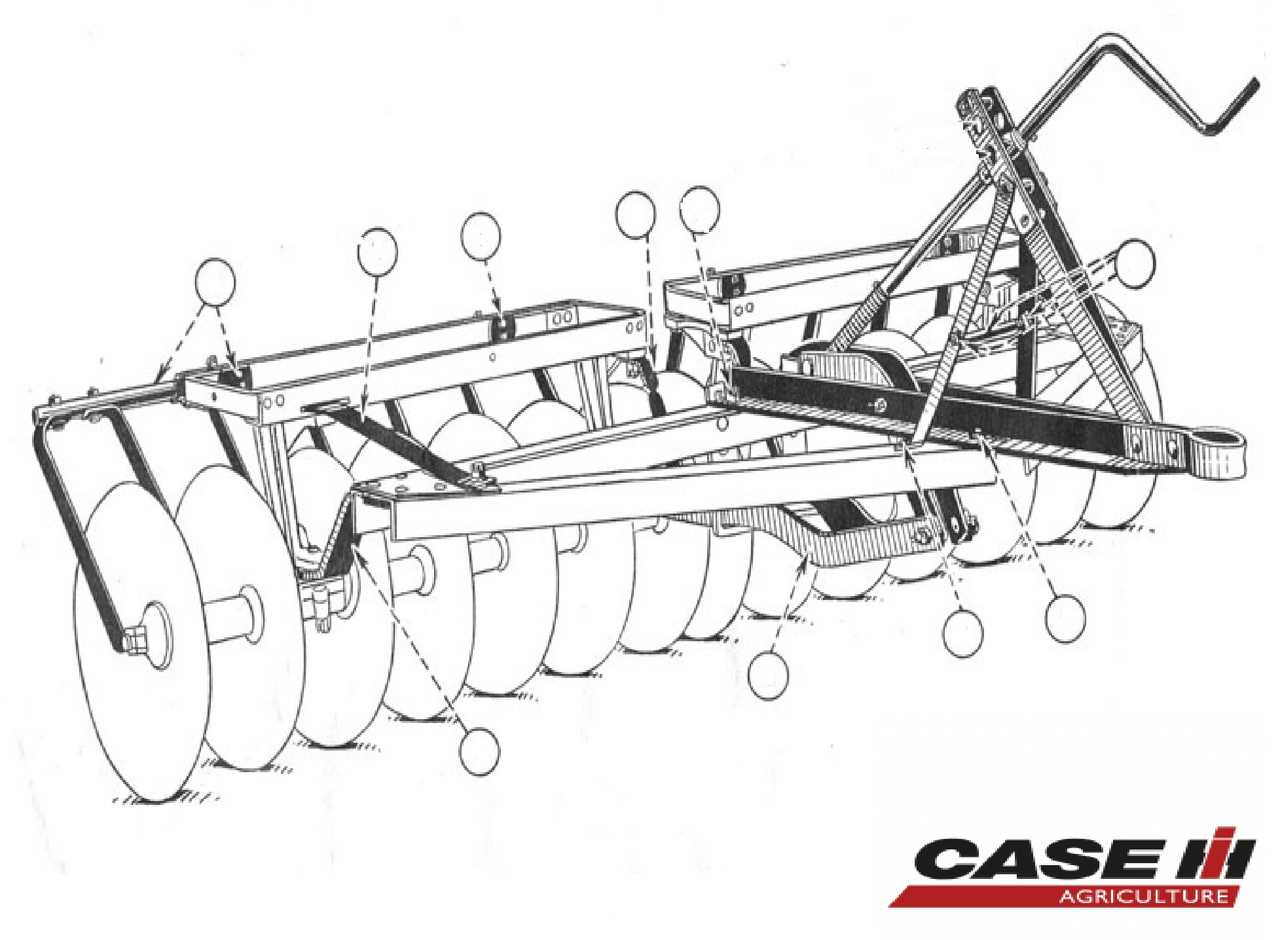

Components of the Disc Harrow

The efficient functioning of agricultural implements relies heavily on their individual components. Each element plays a crucial role in ensuring optimal performance during soil preparation tasks. Understanding these elements is essential for effective maintenance and operation.

Frame: The structure that supports all other components, providing stability and strength. A robust frame is vital for handling the stresses encountered during operation.

Blades: The cutting tools that penetrate the soil, breaking it up and preparing it for planting. These tools come in various shapes and sizes, depending on the specific requirements of the task.

Hitch: The connection point that links the implement to the towing vehicle. A well-designed hitch ensures smooth operation and easy maneuverability in various field conditions.

Bearings: These components allow for the smooth rotation of blades, reducing friction and wear. Properly maintained bearings are essential for the longevity and efficiency of the implement.

Depth Control: This system allows operators to adjust the working depth of the blades. Accurate depth control is crucial for achieving consistent soil conditions across the entire field.

Transport Wheels: Used for moving the implement from one location to another, these wheels provide stability and support when the implement is not in operation.

Functionality of Each Part

This section delves into the roles and contributions of various components within the tilling implement. Understanding these functions enhances the ability to maintain, repair, or optimize the equipment for effective soil preparation.

Key Components and Their Roles

- Frame: The central structure provides stability and support, ensuring that all other elements operate in harmony.

- Blade Assemblies: These elements penetrate and cut through the soil, facilitating effective mixing and turning.

- Hitch Mechanism: Connects the implement to the towing vehicle, allowing for controlled maneuverability.

- Transport Wheels: Assist in easy movement of the implement when not in use, preventing damage to the soil.

- Depth Adjustment Controls: Enable operators to modify the working depth, tailoring the tillage process to specific requirements.

Additional Features

- Blade Spacing: Proper spacing enhances the efficiency of soil processing, affecting the uniformity of tillage.

- Wear Parts: Components such as scrapers and shims reduce wear on primary blades, extending the implement’s lifespan.

- Maintenance Access: Design features that allow easy access for servicing promote longevity and consistent performance.

Maintenance Tips for Longevity

Proper upkeep is essential for enhancing the lifespan of agricultural equipment. Regular maintenance ensures that machinery operates efficiently and minimizes the risk of unexpected breakdowns. By adhering to a consistent maintenance routine, operators can maximize performance and maintain optimal functionality.

Regular Inspections

Conducting routine examinations of machinery can help identify potential issues before they escalate. Focus on the following areas during inspections:

- Check for signs of wear and tear on components.

- Ensure all bolts and connections are secure.

- Inspect for any leaks in hydraulic systems.

Lubrication and Cleaning

Keeping machinery well-lubricated is crucial for reducing friction and preventing damage. Implement the following practices:

- Use high-quality lubricants recommended by the manufacturer.

- Clean debris and residue from moving parts to prevent blockages.

- Regularly replace lubricants as specified in the maintenance schedule.

Common Issues and Solutions

In agricultural machinery, various challenges can arise during operation and maintenance. Understanding these common problems, along with their solutions, is essential for optimal performance and longevity. Addressing these concerns promptly can prevent more significant issues and ensure efficient functionality.

1. Uneven Tillage Results

One frequent issue is uneven soil preparation, which can stem from improper adjustment of the equipment. Solution: Regularly inspect the alignment and settings to ensure consistent depth and coverage. Calibrating the machinery according to manufacturer recommendations can enhance effectiveness.

2. Wear and Tear on Components

Another common challenge is the deterioration of specific components, which can lead to reduced performance. Solution: Implement a routine maintenance schedule that includes checking for signs of wear. Replacing worn parts promptly can prevent further damage and maintain operational efficiency. Regular lubrication and cleaning can also extend the life of various elements.

Parts Replacement Guidelines

Ensuring the longevity and efficiency of agricultural equipment often hinges on timely replacements of its components. Proper maintenance not only enhances performance but also minimizes downtime and repair costs. Following structured procedures for swapping out elements can significantly improve operational effectiveness.

Before embarking on the replacement process, it is essential to gather all necessary tools and materials. Familiarizing oneself with the specific requirements of the equipment will aid in executing replacements smoothly. Below are some recommended steps and considerations:

| Step | Description |

|---|---|

| 1 | Identify the component that requires replacement. Ensure accurate diagnosis to avoid unnecessary changes. |

| 2 | Acquire the correct substitute that matches the specifications of the original. Verify compatibility to ensure optimal performance. |

| 3 | Utilize appropriate tools to safely remove the worn or damaged item. Follow safety protocols to prevent injuries. |

| 4 | Install the new component carefully, ensuring that it is securely fastened and properly aligned. |

| 5 | Test the equipment post-replacement to confirm that it operates correctly and efficiently. |

Regular inspections and proactive replacements will contribute to the overall health of your machinery. Adhering to these guidelines fosters a culture of maintenance that is essential for achieving peak performance in agricultural operations.

Choosing Quality Replacement Parts

When it comes to maintaining agricultural equipment, selecting high-quality replacement components is essential for optimal performance and longevity. The right elements ensure that machinery operates efficiently and reduces the likelihood of unexpected breakdowns. Investing in durable and reliable substitutes not only enhances productivity but also saves time and money in the long run.

Assessing Material and Construction

One of the critical factors to consider is the material and construction of the substitutes. Components made from robust materials such as hardened steel or high-grade composites tend to withstand wear and tear better than their lower-quality counterparts. Always verify that the materials used in the replacements meet industry standards to guarantee resilience and performance.

Compatibility and Fit

Ensuring that replacements are compatible with existing machinery is vital. Proper fit reduces the risk of malfunction and promotes smoother operation. Before purchasing, it is advisable to consult the equipment’s specifications and, if necessary, seek expert advice to confirm that the chosen items will integrate seamlessly into your setup.

Comparative Analysis of Models

This section provides an in-depth examination of various machinery designs, focusing on their unique features and operational efficiencies. By evaluating different configurations, users can make informed decisions based on their specific agricultural requirements and preferences.

Key Features to Consider

- Construction Materials: Different models utilize various materials that affect durability and weight.

- Operational Width: The width of the equipment can significantly impact the speed and efficiency of land preparation.

- Adjustability: Some designs offer enhanced flexibility in settings to accommodate diverse soil types.

- Maintenance Requirements: The ease of servicing varies, influencing long-term operational costs.

Performance Metrics

- Soil Penetration: Analyze how well each model can penetrate different soil densities.

- Fuel Efficiency: Compare the fuel consumption rates of various designs under similar working conditions.

- Operating Speed: Review the optimal speeds for each configuration to maximize productivity.

Understanding these aspects will aid in selecting the most suitable equipment for enhancing agricultural productivity.

Assembly Instructions for New Parts

Proper installation of replacement components is crucial for maintaining the efficiency and longevity of your equipment. This section provides essential guidelines to ensure that each new element is integrated seamlessly into the existing framework. Following these instructions will help you avoid common pitfalls and enhance overall performance.

1. Preparation: Before beginning the assembly, gather all necessary tools and components. Ensure that your workspace is clean and organized to facilitate a smooth installation process. It is advisable to review the provided manual to familiarize yourself with the specific features of the new components.

2. Step-by-Step Installation: Start by removing any old or damaged components. Take care to follow any disassembly instructions to prevent unnecessary damage. Once the old parts are removed, align the new components with their corresponding slots, ensuring a snug fit. Secure them using the appropriate fasteners, making sure not to overtighten, as this could lead to damage.

3. Final Checks: After installation, inspect the assembly for any misalignments or loose connections. It is recommended to perform a thorough check before operating the equipment to confirm that everything is correctly secured. Any adjustments should be made at this stage to avoid complications during usage.

By adhering to these assembly instructions, you can ensure a successful integration of new components, resulting in improved functionality and reliability of your machinery.

Safety Considerations During Use

Ensuring safety during equipment operation is paramount to prevent accidents and injuries. Proper awareness and adherence to safety protocols can significantly reduce risks associated with using agricultural machinery. Users must remain vigilant and informed about best practices to promote a safe working environment.

Pre-Operation Checks

Before engaging the machinery, it is crucial to conduct thorough inspections. Verify that all components are securely fastened and free from wear or damage. Additionally, ensure that safety guards are in place, and fluid levels are adequate. This proactive approach can help identify potential hazards and prevent malfunction during operation.

Operator Training

Only trained individuals should operate heavy equipment. Comprehensive training programs should cover not only how to use the machinery but also emergency procedures. Familiarizing operators with the equipment’s features and limitations will enhance their ability to respond effectively to unforeseen situations.

Impact on Soil Preparation

The efficiency of tillage equipment significantly influences the quality of soil management practices. Properly designed implements enhance the physical characteristics of the ground, facilitating better aeration, moisture retention, and nutrient distribution. This process is crucial for promoting healthy plant growth and optimizing crop yields.

Soil Structure Improvement

Utilizing effective tools allows for the breaking up of compacted layers within the earth, which improves drainage and root penetration. When the soil structure is well maintained, it fosters a more conducive environment for microbial activity, essential for nutrient cycling. As a result, the overall fertility of the ground is enhanced, benefiting future harvests.

Weed Control and Residue Management

Another critical aspect of soil cultivation is the management of weeds and crop residues. The right implements can efficiently incorporate organic matter back into the ground, reducing competition from unwanted plants. This not only aids in maintaining soil health but also minimizes the need for chemical herbicides, promoting sustainable agricultural practices.

Where to Find Parts Diagrams

Locating accurate schematics for agricultural machinery components can significantly enhance maintenance and repair tasks. Understanding the layout and relationships between various elements ensures efficient troubleshooting and replacement. There are several reliable sources for obtaining these essential visuals, which can aid in keeping your equipment in top condition.

Online Resources

The internet is a vast repository of information. Many websites specialize in machinery documentation, offering detailed visuals and descriptions. Manufacturer websites often provide downloadable manuals that include comprehensive layouts and component listings. Additionally, online forums and community groups can be invaluable, as enthusiasts frequently share resources and experiences.

Local Dealers and Suppliers

Your local machinery dealer or supplier can be an excellent resource for acquiring printed materials. These professionals typically have access to official manuals and can assist in sourcing specific visuals. Engaging with them can also lead to discovering alternative options that may not be readily available online, ensuring you have all the necessary information for effective equipment care.