This section delves into the intricate arrangements of various elements essential for optimal functionality. Understanding how each piece interacts within the system is crucial for efficient operation and maintenance. By visualizing these layouts, users can enhance their familiarity with the intricate network of components.

In the pursuit of mastering the assembly and disassembly processes, it becomes imperative to grasp the connections and roles of each element. This knowledge not only aids in troubleshooting but also empowers individuals to make informed decisions during upgrades or repairs. A well-structured representation serves as a valuable reference for both enthusiasts and professionals alike.

Ultimately, this exploration aims to provide clarity and insight into the composition of mechanical structures, facilitating a deeper understanding of their functionalities. Whether for educational purposes or practical applications, having access to organized layouts enhances one’s ability to engage effectively with the subject matter.

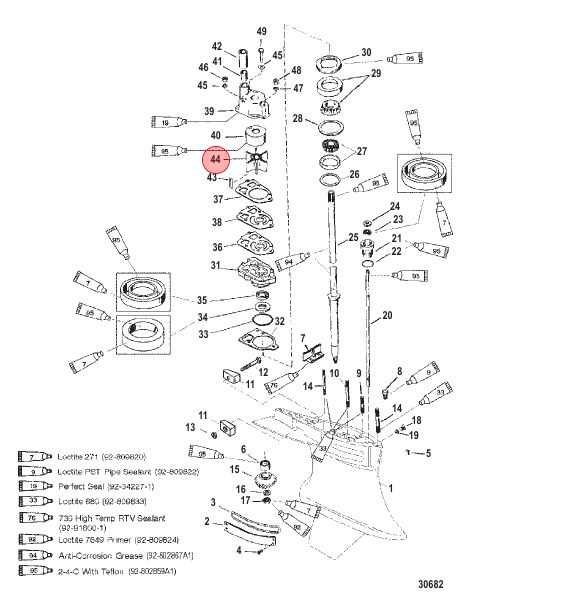

This section delves into the essential elements that constitute the mechanism, providing insight into their roles and functionalities. Understanding these components is crucial for anyone looking to grasp the intricacies of the system.

| Component | Description |

|---|---|

| Drive Unit | The central element responsible for converting energy into motion, facilitating propulsion. |

| Gearbox | This component regulates speed and torque, enabling efficient performance under various conditions. |

| Hydraulic System | A system that utilizes fluid power to drive various functions, ensuring smooth operation. |

| Control Module | This unit processes inputs and manages the overall operation, enhancing user experience and functionality. |

| Steering Mechanism | Essential for directional control, allowing the operator to navigate with precision. |

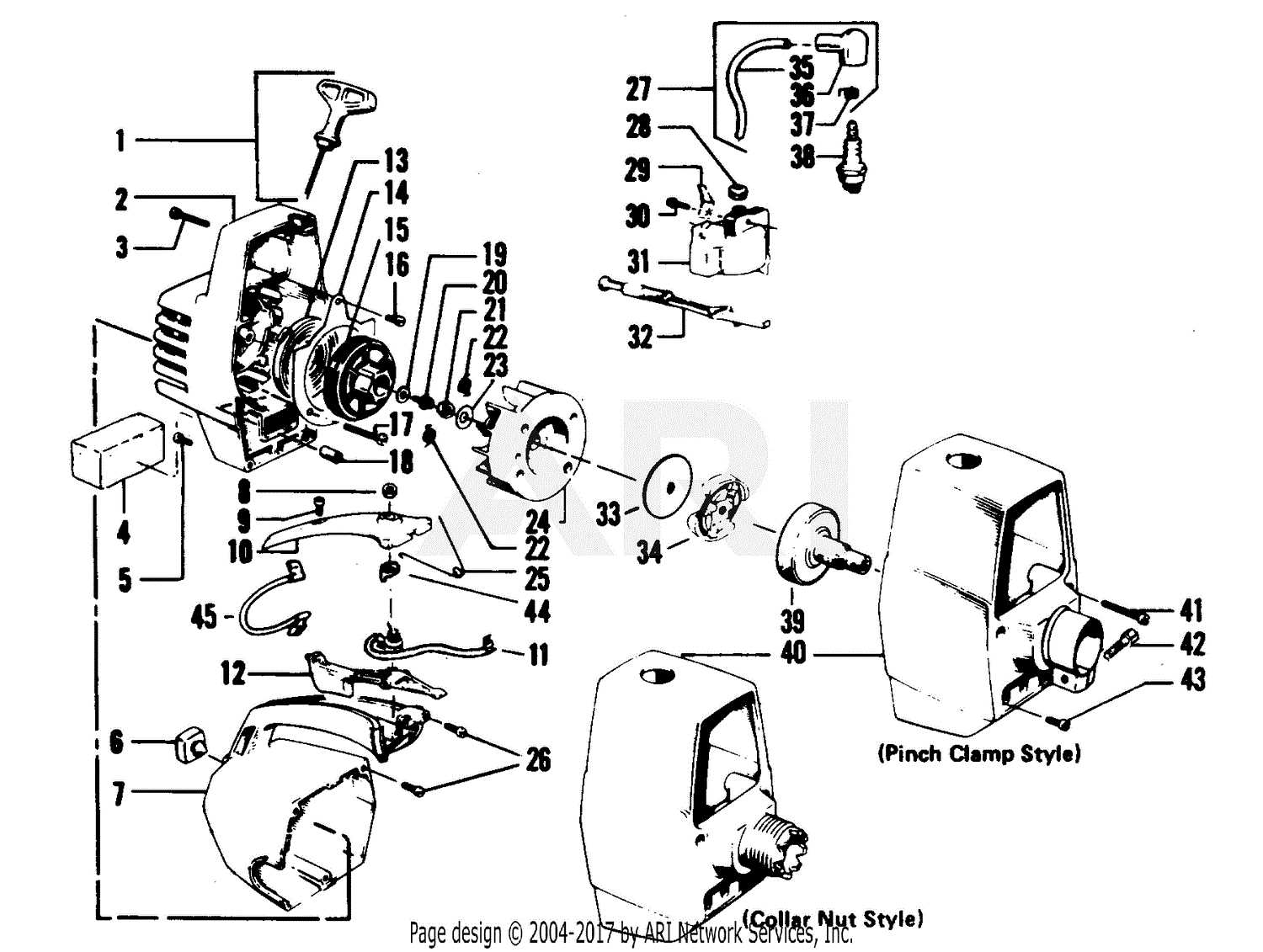

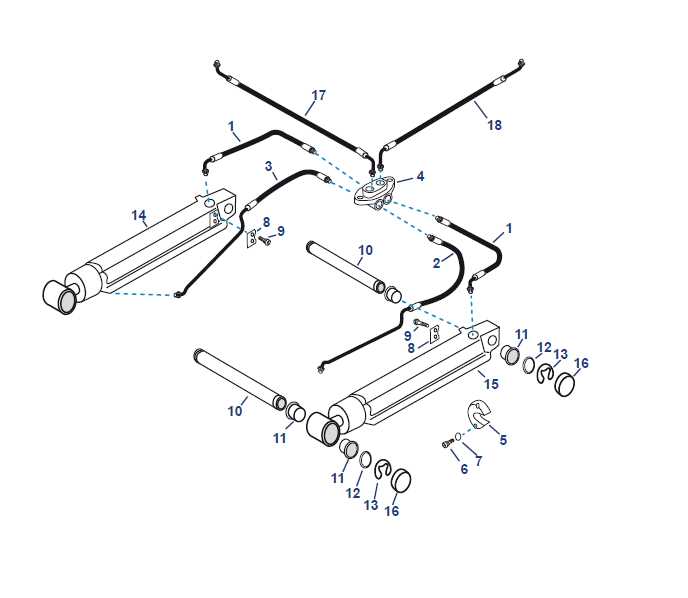

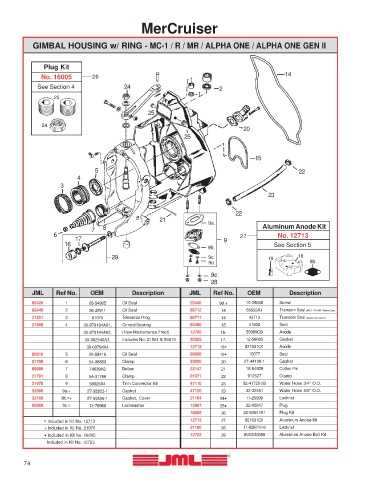

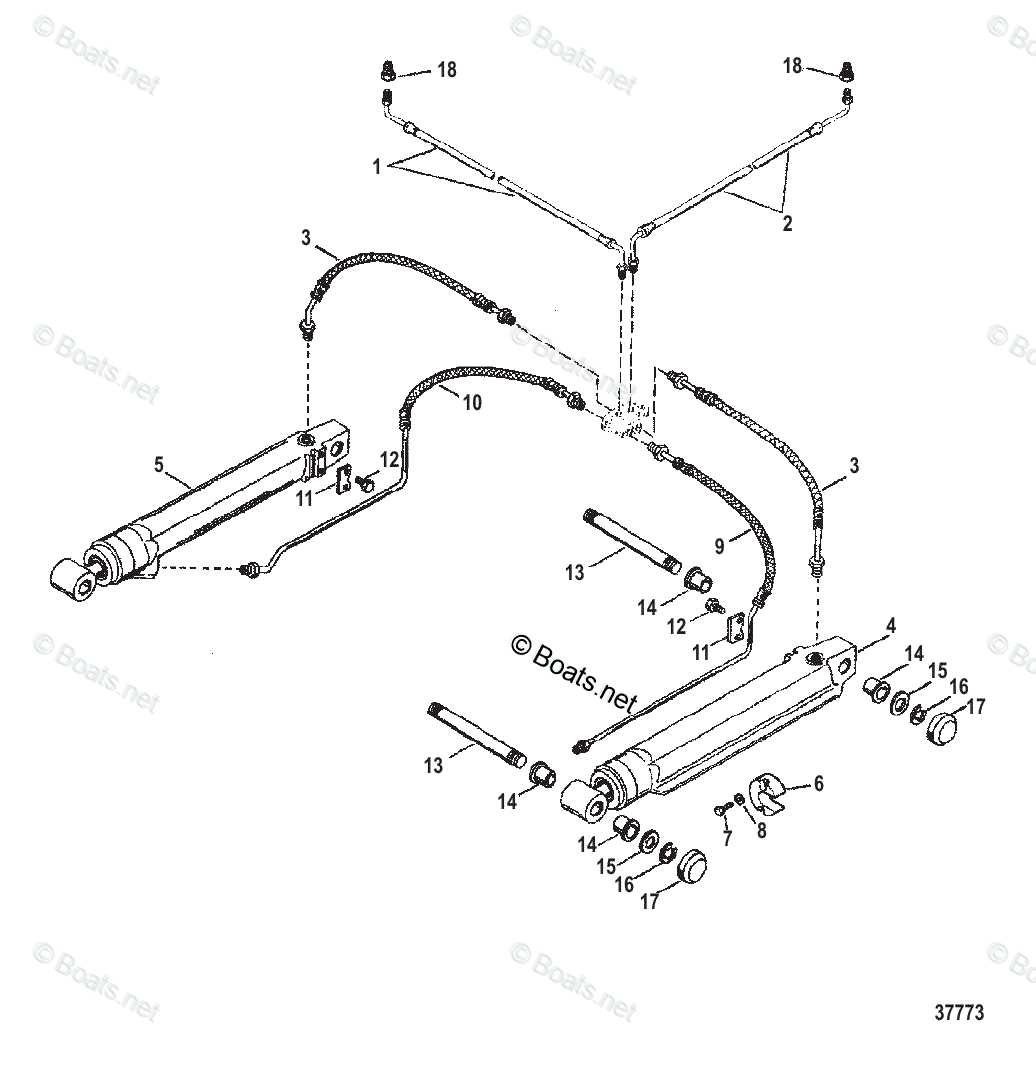

Understanding the Parts Diagram

Gaining insight into the components of a mechanical system is essential for effective maintenance and repair. Familiarity with the arrangement and function of each element enables users to identify issues more efficiently and ensure optimal performance.

To effectively navigate the schematic, it is important to recognize key aspects:

- Component Identification: Recognizing each individual piece and its specific role within the assembly is crucial for troubleshooting and repair.

- Connection Relationships: Understanding how different components interact helps in diagnosing problems and planning upgrades.

- Maintenance Practices: Knowing which elements require regular attention or replacement can enhance the longevity of the entire system.

By thoroughly exploring these aspects, users can achieve a comprehensive understanding of their equipment, leading to more informed decision-making regarding repairs and enhancements.

Benefits of Detailed Diagrams

Having comprehensive visual representations can significantly enhance understanding and efficiency in various fields. These illustrations serve as essential tools, allowing individuals to grasp complex structures and processes quickly. They provide clarity and facilitate communication, making it easier for team members to collaborate effectively.

Enhanced Clarity

Well-crafted visuals eliminate ambiguity by providing a clear view of components and their interrelations. This clarity helps users identify specific elements and understand their functions, resulting in improved problem-solving and decision-making abilities.

Increased Efficiency

When users have access to precise representations, they can navigate tasks more swiftly. This efficiency minimizes errors and reduces the time needed for training and onboarding, allowing teams to focus on achieving their objectives with confidence.

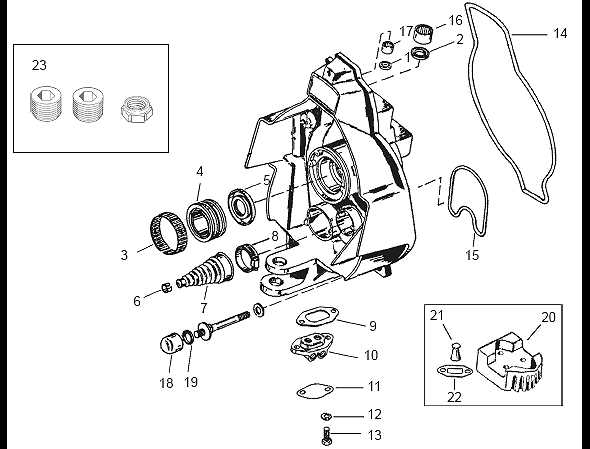

Identifying Essential Components

Understanding the crucial elements of any mechanical system is vital for effective operation and maintenance. Each component plays a significant role, contributing to the overall functionality and performance of the assembly. By recognizing these key parts, users can ensure proper usage and troubleshoot any issues that may arise.

In any advanced system, components are typically categorized based on their function and significance. Structural elements provide stability and support, while functional units facilitate specific operations. Moreover, control mechanisms play an integral role in regulating performance and ensuring efficiency.

Familiarity with these essential parts enhances the ability to identify potential areas for improvement and maintenance. By gaining insights into how each element interacts, one can better appreciate the complexity and precision of the entire assembly.

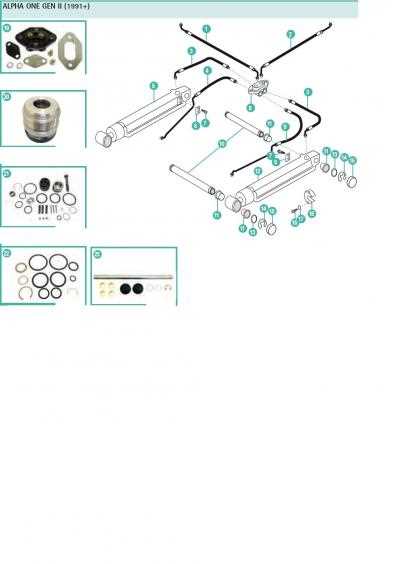

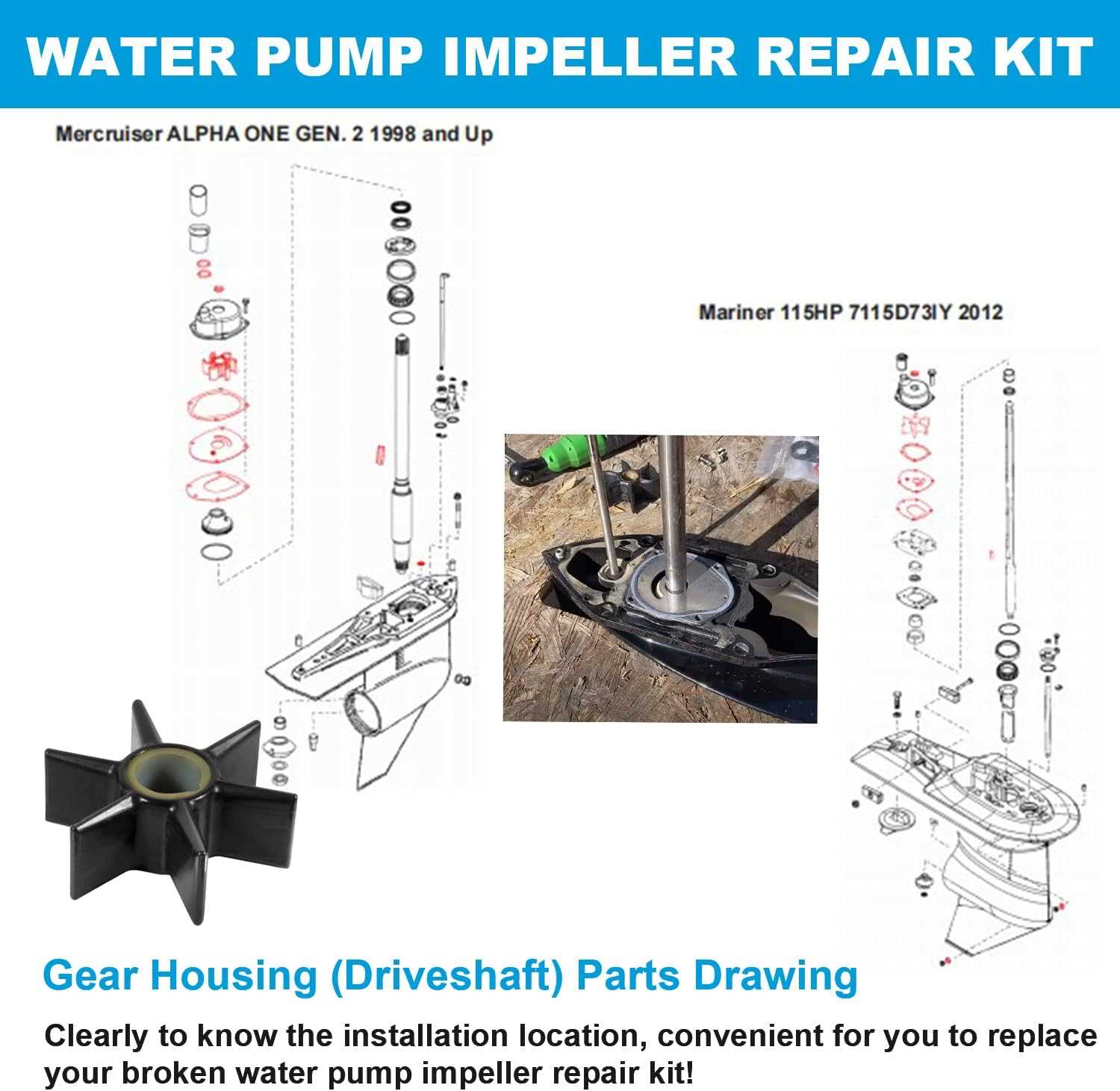

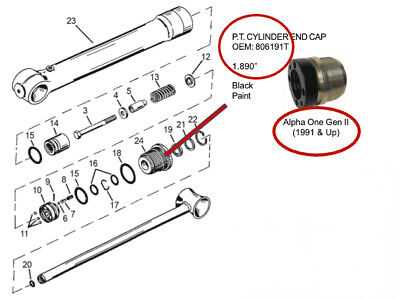

Maintenance Tips for Alpha One Gen 2

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few straightforward guidelines, you can prevent issues and enhance the reliability of your system.

1. Routine Inspections: Periodically check all components for signs of wear and tear. Look for any leaks, corrosion, or loose fittings that could compromise functionality.

2. Lubrication: Ensure all moving parts are properly lubricated to reduce friction and wear. Use the recommended lubricants and follow the manufacturer’s guidelines for application frequency.

3. Cleaning: Keep the unit clean by removing debris and dirt buildup. A clean environment prevents overheating and promotes efficient operation. Use non-abrasive cleaning agents to avoid damaging surfaces.

4. Fluid Levels: Regularly check and maintain appropriate fluid levels. This includes checking oil, coolant, and other essential liquids. Low levels can lead to overheating and damage.

5. Seasonal Maintenance: Before and after peak usage periods, conduct a thorough maintenance check. This helps address any issues that may arise due to seasonal changes or heavy usage.

6. Professional Servicing: Schedule regular professional inspections to ensure all systems function correctly. Technicians can identify potential issues before they become major problems.

By incorporating these maintenance practices into your routine, you can significantly extend the lifespan and efficiency of your equipment.

Common Issues and Solutions

This section addresses frequently encountered challenges and their respective remedies in relation to the components of the specified system. Understanding these common problems can enhance performance and longevity, ensuring optimal functionality.

| Issue | Description | Solution |

|---|---|---|

| Electrical Malfunctions | Intermittent power loss or malfunctioning features. | Check wiring connections and replace any damaged components. |

| Mechanical Wear | Components exhibiting signs of wear over time. | Regular maintenance and timely replacement of worn parts are essential. |

| Fluid Leaks | Unexpected fluid discharge from the system. | Inspect seals and gaskets for damage and replace as necessary. |

| Performance Issues | Reduced efficiency or responsiveness during operation. | Conduct a thorough cleaning and recalibrate as needed. |

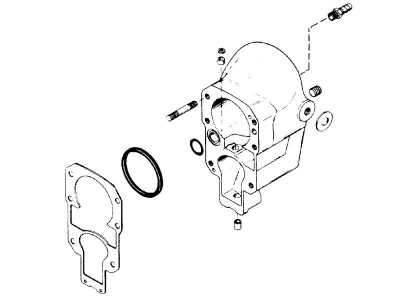

Upgrading Parts Effectively

Enhancing components is a crucial step for improving performance and longevity. It involves careful consideration of the elements being replaced and the benefits that come with modern alternatives. This process not only boosts efficiency but also aligns your setup with the latest technological advancements.

Assessing Compatibility

Before embarking on the enhancement journey, it’s essential to evaluate the compatibility of new components with your existing configuration. Researching specifications and consulting manuals can provide valuable insights. Ensure that the selected items fit seamlessly into your system, avoiding potential issues down the line.

Prioritizing Quality

When upgrading, always prioritize quality over cost. Investing in high-quality replacements can lead to superior performance and durability. Reliable brands often offer warranties and support, ensuring peace of mind with your enhancements. Aim for well-reviewed products to guarantee that your upgrades deliver the desired improvements.

Comparison with Previous Models

The latest iteration of this marine propulsion system showcases significant advancements over its predecessors. By integrating innovative technology and enhanced engineering, it provides improved performance, reliability, and user experience. This section highlights the key differences and similarities, allowing users to understand the evolution of this system and its features in relation to earlier versions.

Key Features of the Current Model

The modern variant introduces several noteworthy enhancements that distinguish it from earlier iterations. Among these are:

- Optimized fuel efficiency

- Advanced electronic control systems

- Improved weight distribution for better handling

Comparison Table

| Feature | Previous Model A | Previous Model B | Current Model |

|---|---|---|---|

| Fuel Efficiency | Moderate | Good | Excellent |

| Control System | Basic | Standard | Advanced |

| Weight Distribution | Even | Uneven | Optimized |

This comparison underscores the remarkable strides made in design and technology, positioning the latest model as a superior choice for users seeking enhanced performance on the water.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right instruments is essential for achieving successful outcomes. The proper tools not only facilitate efficient work but also ensure safety and precision throughout the repair process.

Essential tools include a variety of hand tools, power tools, and specialized equipment tailored to the specific job at hand. For instance, a good selection of screwdrivers, wrenches, and pliers is crucial for loosening and tightening components. Additionally, using precision tools can enhance accuracy, especially when dealing with intricate mechanisms.

Investing in quality equipment will make repairs more manageable and contribute to the longevity of the items being serviced. It’s advisable to familiarize oneself with each tool’s proper use to maximize efficiency and minimize the risk of damage during the repair process.

Safety Precautions During Maintenance

Ensuring safety while conducting maintenance tasks is paramount for preventing accidents and ensuring efficient operation. It is essential to adopt various measures to protect both personnel and equipment throughout the maintenance process.

Before initiating any maintenance activity, it’s crucial to familiarize oneself with the specific equipment involved. Understanding its functionality and potential hazards can significantly reduce risks. Proper personal protective equipment (PPE) should be worn at all times to minimize exposure to harmful elements.

| Precaution | Description |

|---|---|

| Wear Appropriate PPE | Use gloves, goggles, and masks to safeguard against debris and hazardous substances. |

| Disconnect Power Sources | Ensure all electrical connections are turned off to prevent accidental start-ups. |

| Keep Work Area Clean | A tidy workspace reduces the risk of slips, trips, and falls. |

| Follow Manufacturer Guidelines | Refer to the provided manuals for specific safety instructions and recommended practices. |

| Report Hazards Immediately | Inform supervisors of any dangerous situations to ensure prompt resolution. |

By adhering to these safety guidelines, individuals can significantly mitigate risks associated with maintenance tasks, ensuring a safer work environment for all involved.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a challenging task. Whether you’re looking to replace a damaged item or enhance the performance of your device, knowing where to search is essential. Various sources offer a wide range of options to ensure you can restore your gear to its optimal state.

Online Retailers

One of the most convenient ways to locate replacement items is through online marketplaces. Numerous websites specialize in providing a vast selection of components, often with detailed descriptions and customer reviews. This allows you to compare options and make informed decisions based on quality and price.

Local Dealers

If you prefer a hands-on approach, visiting local dealers or specialty shops can be beneficial. These establishments often stock common components and can provide personalized assistance. Additionally, you may find that they offer installation services or advice on maintenance.

| Source Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive pricing | Shipping times may vary |

| Local Dealers | Immediate access, expert advice | Potentially higher prices |

| Manufacturer Websites | Authenticity, warranty options | Limited availability |