The operation of a snow clearing device relies heavily on its individual elements, each playing a critical role in ensuring efficiency and reliability. A comprehensive understanding of these components not only enhances maintenance practices but also aids in troubleshooting potential issues that may arise during use.

By examining the arrangement and functionality of each segment, users can gain insights into how to optimize performance and extend the lifespan of their equipment. This exploration of the machine’s intricate assembly will guide both novices and seasoned operators in navigating the complexities involved.

Whether you are looking to replace a worn-out component or simply want to familiarize yourself with the mechanics of your equipment, a detailed overview of its construction can be invaluable. The following sections will illuminate the key features and their interrelations, offering a roadmap for effective management and repair.

Understanding Ariens Razor 21 Components

Grasping the intricacies of this cutting-edge machine requires an exploration of its essential elements. Each component plays a critical role in ensuring optimal performance, making it vital for users to familiarize themselves with their functions and interactions.

Key Elements of the Device

The core assembly consists of a powerful engine, durable frame, and precision blades, all working together to deliver efficiency. Understanding how these major elements function individually and collectively enhances user experience and maintenance practices.

Maintenance and Troubleshooting

Regular upkeep of these integral parts is crucial for longevity. Identifying common issues, such as blade dullness or engine performance, can help maintain peak operation. Knowledge of these components enables users to address challenges effectively.

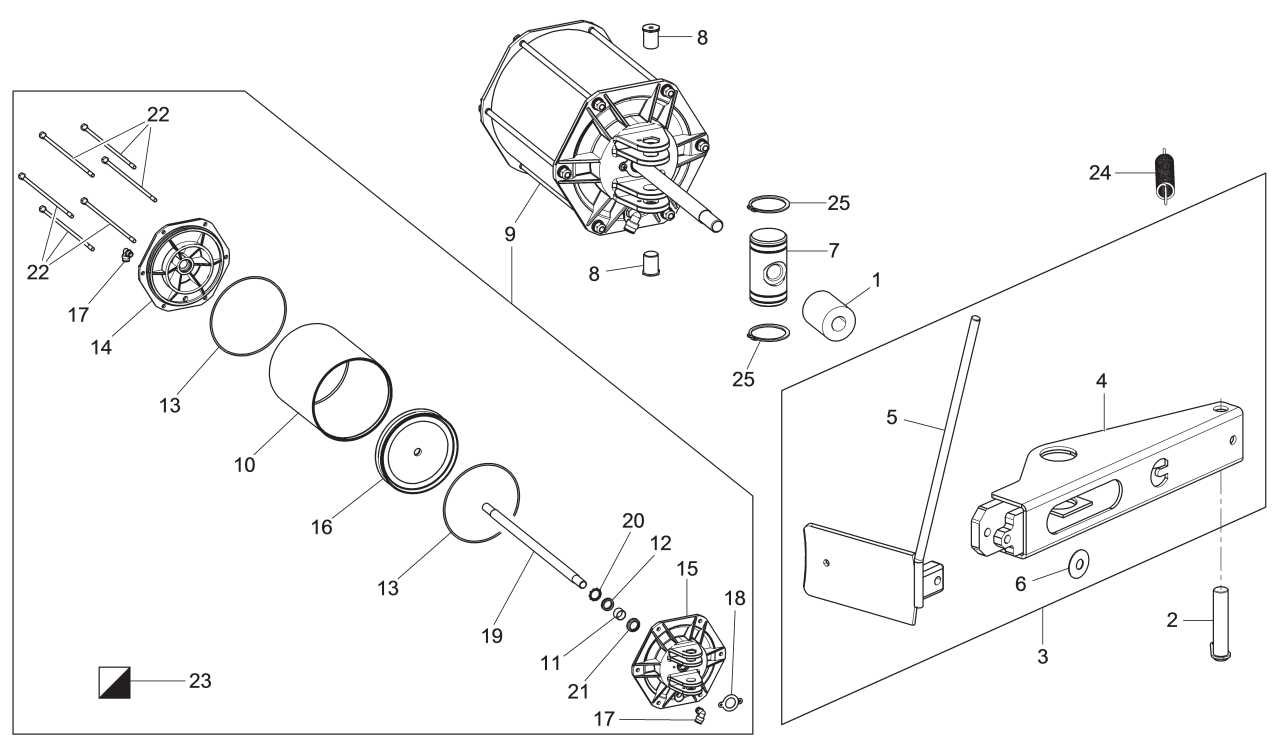

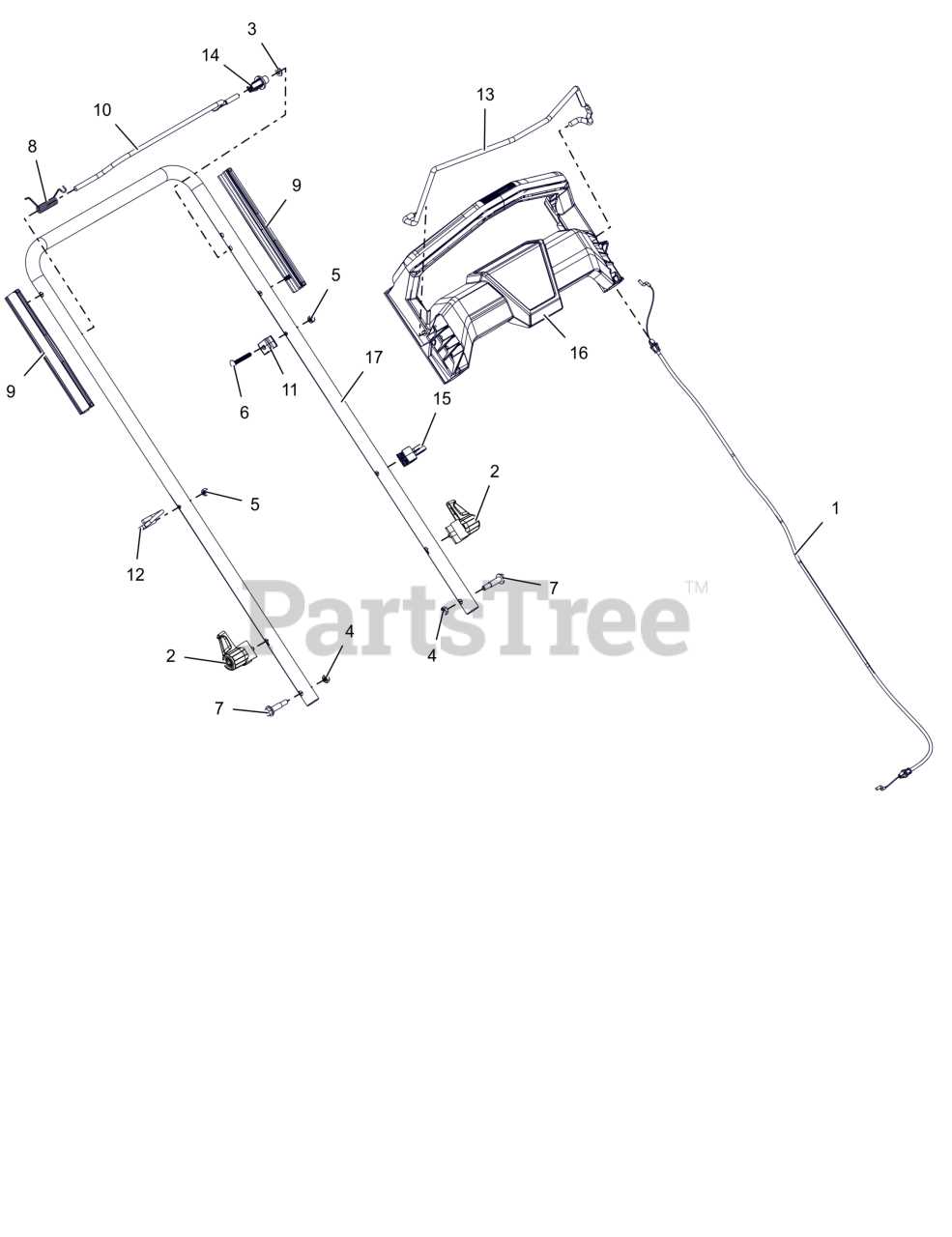

Importance of Parts Diagrams

Understanding the intricate layout of machinery components is essential for effective maintenance and repair. Visual representations serve as a valuable tool for users, enabling them to identify and access necessary elements with ease. Such illustrations not only enhance comprehension but also streamline the troubleshooting process, ensuring that users can efficiently address issues as they arise.

Moreover, these visual guides play a critical role in ensuring that each element is correctly assembled or replaced, minimizing the risk of errors that could lead to malfunctions. By offering clarity in structure and function, they assist both novice and experienced users in navigating complex systems.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Provides a clear view of how components interact, promoting better knowledge of the overall system. |

| Efficient Repair | Facilitates quick identification of needed elements, speeding up the repair process. |

| Minimized Errors | Reduces the likelihood of incorrect assembly or replacement, ensuring reliable operation. |

| Training Tool | Serves as an educational resource for new users, helping them learn about system functions. |

Key Features of Ariens Razor 21

This section highlights the essential characteristics of a high-performance machine designed for efficient operation and user satisfaction. Understanding these features will help users appreciate the value and functionality provided, ensuring optimal results in various tasks.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust motor that delivers reliable performance and ample torque for tackling tough jobs. |

| Durable Construction | Built with high-quality materials to withstand wear and tear, ensuring longevity and resilience. |

| Compact Design | Engineered to be lightweight and easy to maneuver, making it suitable for various terrains and spaces. |

| User-Friendly Controls | Features intuitive controls that enhance the overall user experience, promoting ease of use for all skill levels. |

| Versatile Attachments | Compatible with a range of accessories, allowing users to adapt the machine for different tasks and applications. |

| Enhanced Safety Features | Incorporates safety mechanisms to protect users during operation, minimizing risks and ensuring a secure working environment. |

Common Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any equipment. By adhering to specific care practices, users can extend the life of their machines and optimize performance.

- Regularly check and change the oil to ensure smooth operation.

- Clean air filters frequently to maintain airflow and prevent damage.

- Inspect blades for wear and sharpen or replace as necessary.

- Examine belts and cables for fraying and replace them promptly.

- Keep the machine clean and free from debris after each use.

Implementing these simple practices can significantly enhance the longevity of your equipment, providing ultimate reliability for years to come.

How to Identify Each Part

Understanding the various components of your equipment is crucial for maintenance and repair. By familiarizing yourself with the different elements, you can enhance performance and prolong its lifespan. This guide will help you distinguish each section effectively.

Visual Characteristics

Begin by examining the visual features of each component. Look for unique shapes, sizes, and colors that differentiate one element from another. For example, blades often have a sharp edge, while housing units may appear more robust and solid. Noting these characteristics will aid in quick identification.

Functional Roles

Understanding the functionality of each element can further assist in identification. Each section serves a specific purpose; some are designed for propulsion, while others are responsible for control and stability. Familiarizing yourself with these roles will not only help you identify parts but also understand their importance in the overall operation.

Replacing Worn-Out Components

Maintaining the efficiency and functionality of your equipment often requires the timely replacement of aged or damaged elements. Recognizing when components have reached the end of their usable life is essential for ensuring optimal performance and preventing further issues. This section will guide you through the process of identifying and substituting these critical parts.

Identifying Signs of Wear

It’s crucial to regularly inspect your machinery for indications of deterioration. Look for signs such as unusual noises, reduced efficiency, or visible damage. Components that are cracked, frayed, or excessively worn should be replaced immediately to avoid more severe malfunctions. Regular maintenance checks can help catch these problems early.

Steps for Replacement

Once you’ve identified a component that requires replacement, follow these steps to ensure a smooth process:

- Gather Necessary Tools: Make sure you have all the required tools and new components before starting the replacement process.

- Power Down: Always disconnect the power supply to avoid any accidents during the procedure.

- Remove the Old Component: Carefully take out the worn piece, taking note of how it is installed for reference.

- Install the New Component: Position the new part correctly, ensuring it fits securely.

- Test the Equipment: Once everything is back in place, restore power and conduct a test run to ensure everything operates smoothly.

By promptly replacing outdated elements, you can significantly extend the lifespan of your equipment and maintain its efficiency.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for ensuring efficiency and effectiveness. A well-organized toolkit not only simplifies the process but also enhances safety and precision. Below are the key implements you will require for successful repairs.

Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts. Ensure you have a variety of sizes on hand to accommodate different fittings.

Screwdrivers: A set of both flathead and Phillips screwdrivers will enable you to tackle various fasteners. Magnetic tips can add convenience by holding screws in place.

Multimeter: This device is crucial for diagnosing electrical issues. It helps measure voltage, current, and resistance, allowing for informed troubleshooting.

Pliers: Needle-nose and regular pliers are useful for gripping and manipulating small parts. They provide the ultimate control in tight spaces.

Lubricants and Cleaners: Keeping components clean and well-lubricated prolongs their lifespan. Use suitable products to prevent wear and tear during repairs.

Having these tools readily available will empower you to delve into your maintenance projects with confidence and precision.

Where to Find Replacement Parts

When your equipment needs new components, locating reliable sources is essential for restoring its functionality. Several options are available for sourcing these crucial elements, ensuring your machine operates smoothly once more.

Authorized Dealers

Visiting certified distributors is one of the best ways to obtain authentic components. These outlets often maintain an extensive inventory and can offer guidance on the most suitable items for your specific model.

Online Marketplaces

The internet provides a vast array of platforms where you can purchase necessary items. Websites dedicated to outdoor machinery frequently feature detailed listings and user reviews, helping you make informed decisions. Always check the credibility of the seller before making a purchase.

Understanding the Assembly Process

The assembly process of machinery involves a series of precise steps that ensure all components work together seamlessly. By grasping the intricacies of this method, one can enhance both the efficiency and reliability of the final product. Each segment plays a critical role, and understanding their interconnections is essential for successful assembly.

Firstly, it is crucial to familiarize oneself with the individual elements and their functions. Each piece is designed to fit perfectly with others, creating a cohesive unit. Recognizing the purpose of each component not only simplifies the assembly but also helps troubleshoot any issues that may arise during operation.

Next, following the correct sequence during assembly is vital. Skipping steps or altering the order can lead to complications that may affect performance. Adhering to established guidelines ensures that everything aligns as intended, minimizing the risk of malfunctions.

Finally, meticulous attention to detail is paramount throughout the process. Ensuring that every connection is secure and every piece is properly aligned can prevent future breakdowns and extend the lifespan of the equipment. By embracing a careful approach, one can significantly improve the overall functionality and durability of the assembled unit.

FAQs About Ariens Razor 21

This section addresses common inquiries related to a specific lawn maintenance device, providing clarity on its functionality, maintenance, and user experiences. Below are some frequently asked questions that can help potential and current users understand their equipment better.

What are the key features of this lawn tool?

The equipment is designed with user-friendly controls, robust build quality, and various cutting heights, ensuring efficient grass trimming. Its powerful engine enhances performance, making it suitable for both small and larger yards.

How can I maintain my machine for optimal performance?

Regular upkeep is essential. Ensure to check the oil levels, clean the air filter, and inspect the blades for sharpness. Following the manufacturer’s guidelines will ultimately prolong the lifespan and efficiency of your equipment.

Exploring User Experiences and Reviews

This section delves into the insights and perspectives shared by users regarding their experiences with the product. Understanding these personal accounts can provide valuable context and help potential buyers make informed decisions.

Positive Feedback

- Durability: Many users praise the longevity of the device, noting its ability to withstand various conditions.

- Ease of Use: Reviewers often highlight the straightforward setup and user-friendly features.

- Performance: Numerous comments reflect satisfaction with its efficiency and effectiveness in achieving tasks.

Constructive Critiques

- Maintenance: Some users mention the need for regular upkeep to maintain optimal performance.

- Weight: A few reviews express concerns about the device’s heaviness, affecting maneuverability.

- Noise Levels: Some users note that it operates louder than expected, which may be an issue for certain environments.