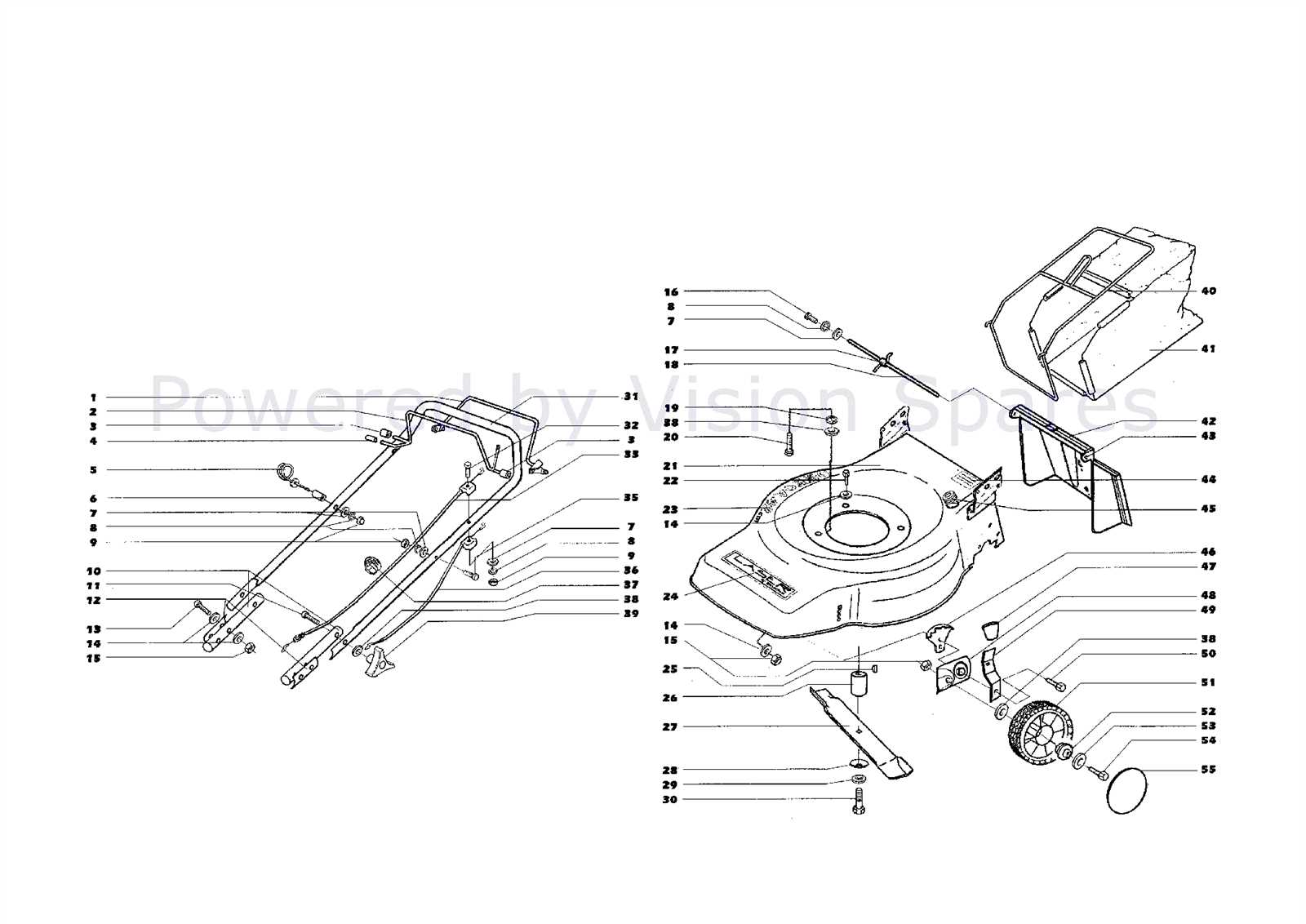

Deck Shell: The m

Key Elements of the Mower’s Engine System

The engine is the core component that ensures the functionality of the mower. Its intricate network of mechanical parts works together to deliver the necessary power for efficient grass cutting. Understanding the essential elements of this system is crucial for maintaining optimal performance and preventing unexpected breakdowns.

Power Generation and Distribution

The heart of the system lies in the power generation, which is achieved through the combustion process. This energy is transferred to various components, ensuring smooth operation. Critical elements such as the cylinder, pistons, and valves play a pivotal role in converting fuel into motion. Proper synchronization between these components ensures consistent and reliable performance.

Cooling and Lubrication

The engine’s ability to maintain a stable temperature is vital to its longevity. A combination of coolant systems and oil circulation ensures that excessive heat is dissipated, preventing damage from overheating. Lubrication also minimizes friction between movi

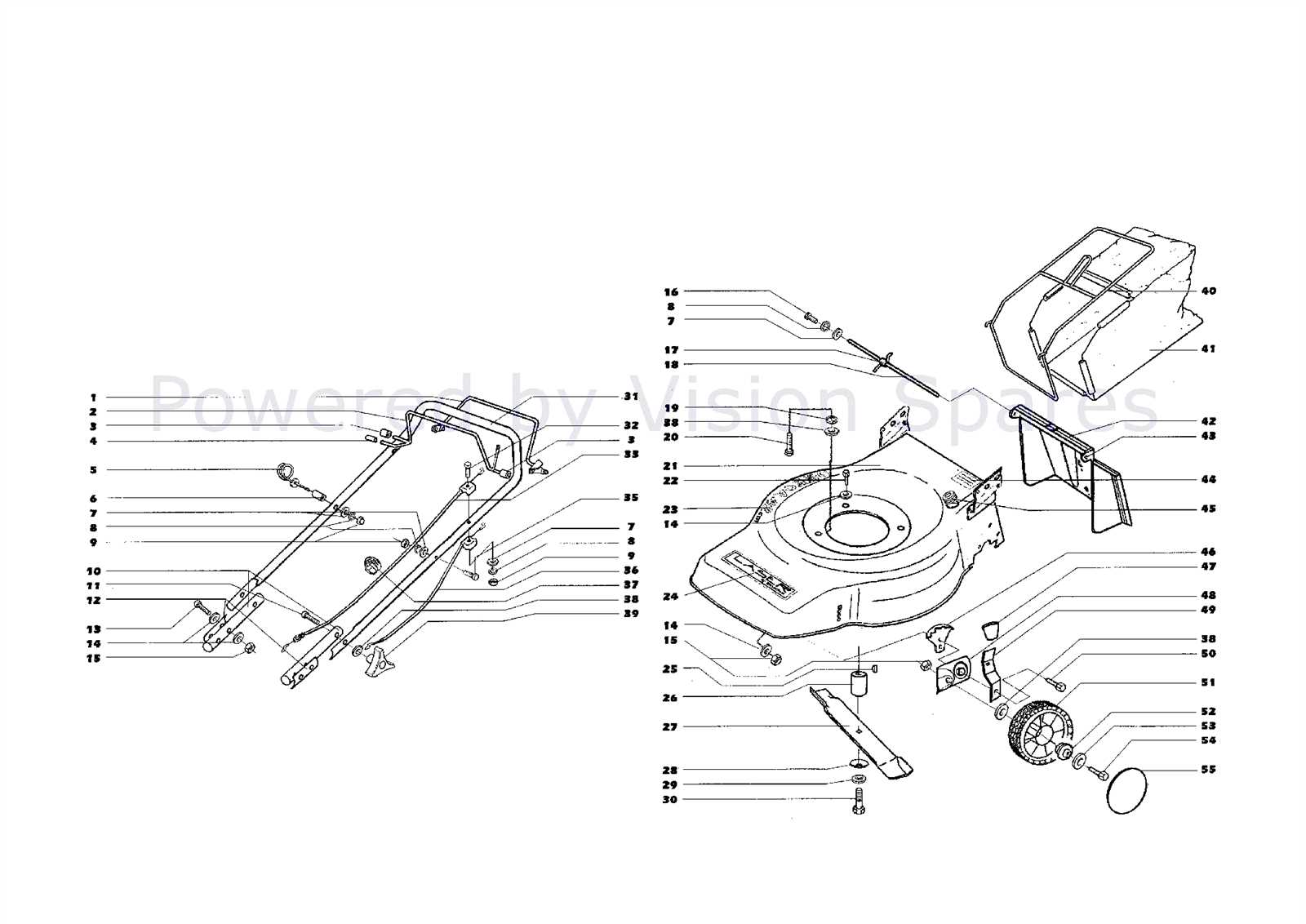

Drive System Layout and Functionality

The drive system in this model is designed to ensure efficient power transmission and control during operation. Its components work in harmony to deliver smooth propulsion, contributing to the overall performance and maneuverability. This section outlines the key elements involved and how they interact to optimize movement and control.

Core Components and Configuration

The system consists of essential mechanical parts that transfer energy from the power source to the wheels. These include a set of pulleys, belts, and motors, all arranged to provide seamless movement. Each component plays a crucial role in maintaining stability and responsiveness during operation, ensuring that the machine can handle various terrains effectively.

Functionality and Control

The drive system offers precise control over speed and direction, thanks to its well-calibrated configuration. The integration of controls allows the operator to adjust speed levels easily, providing the necessary flexibility for different tasks. In addition, the system ensures that power is distributed evenly, reducing wear on

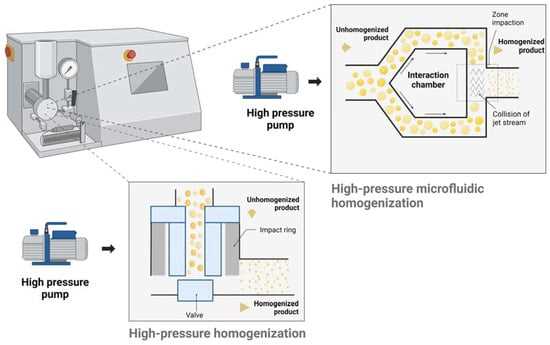

Maintenance Tips for Hydraulic Systems

Ensuring the longevity and efficiency of fluid-powered machinery requires regular attention and care. Proper upkeep not only enhances performance but also prevents unexpected breakdowns, ultimately saving time and resources.

Regular Fluid Checks: Monitor the condition and level of hydraulic fluid consistently. Contaminated or insufficient fluid can lead to system inefficiencies and damage. Always refer to manufacturer recommendations regarding fluid type and replacement intervals.

Inspect Components: Frequently examine hoses, fittings, and connections for signs of wear, leaks, or corrosion. Addressing minor issues promptly can prevent more severe complications down the line.

Clean Filters: Maintaining clean filtration systems is crucial for protecting hydraulic components from debris. Regularly replace or clean filters as needed to ensure optimal fluid flow and prevent contamination.

Monitor Temperature: Keep an eye on the operating temperature of the system. Elevated temperatures can indicate potential problems and can lead to fluid degradation, so ensure that cooling mechanisms are functioning effectively.

Conduct Routine Tests: Implement periodic testing to assess system performance. Pressure tests and flow rate evaluations can help identify inefficiencies and allow for timely corrective actions.

By following these straightforward guidelines, operators can significantly enhance the reliability and performance of their hydraulic systems, ensuring they operate smoothly for years to come.

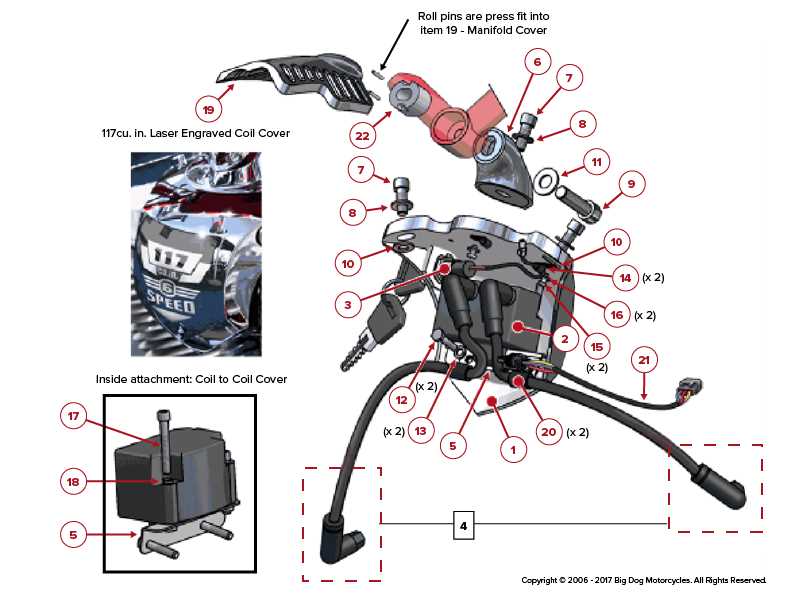

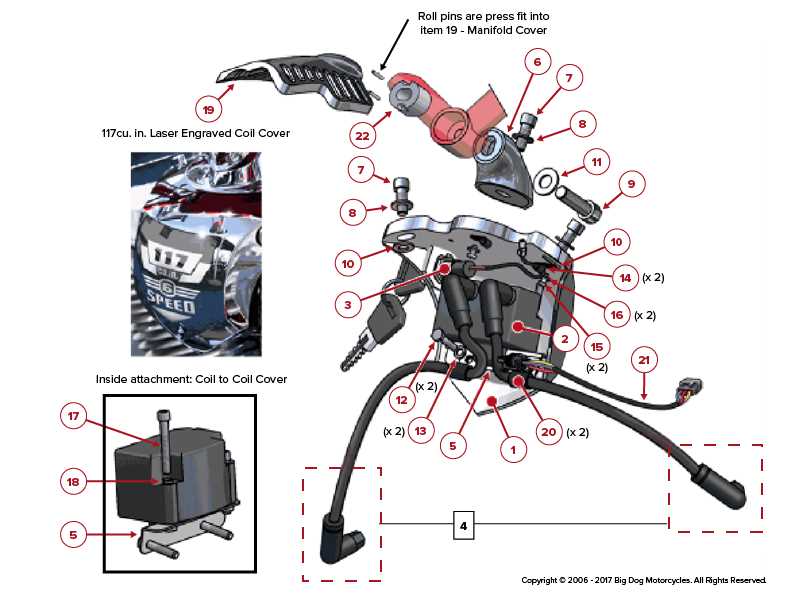

Detailed Breakdown of Steering Mechanisms

This section delves into the intricate components that facilitate directional control in various vehicles. Understanding these mechanisms is crucial for maintaining optimal performance and ensuring safety during operation.

The steering system consists of several key elements, each playing a vital role in achieving precise handling. Below are the primary components:

- Steering Wheel: The interface through which the driver exerts control over the vehicle’s direction.

- Steering Column: A shaft that connects the steering wheel to the gearbox, transmitting the driver’s input.

- Gearbox: Converts the rotational motion of the steering wheel into lateral movement, allowing the wheels to turn.

- Linkage: Connects the gearbox to the wheels, transmitting the steering action and ensuring coordinated movement.

- Wheel Assembly: Comprises the wheels and tires, which are directly influenced by the steering system’s operation.

Each component works in harmony to provide responsive steering. Regular inspection and maintenance of these parts can enhance performance and prolong the lifespan of the vehicle.

In summary, a thorough understanding of steering mechanisms is essential for effective vehicle operation. Each part must be carefully considered to ensure a seamless driving experience.

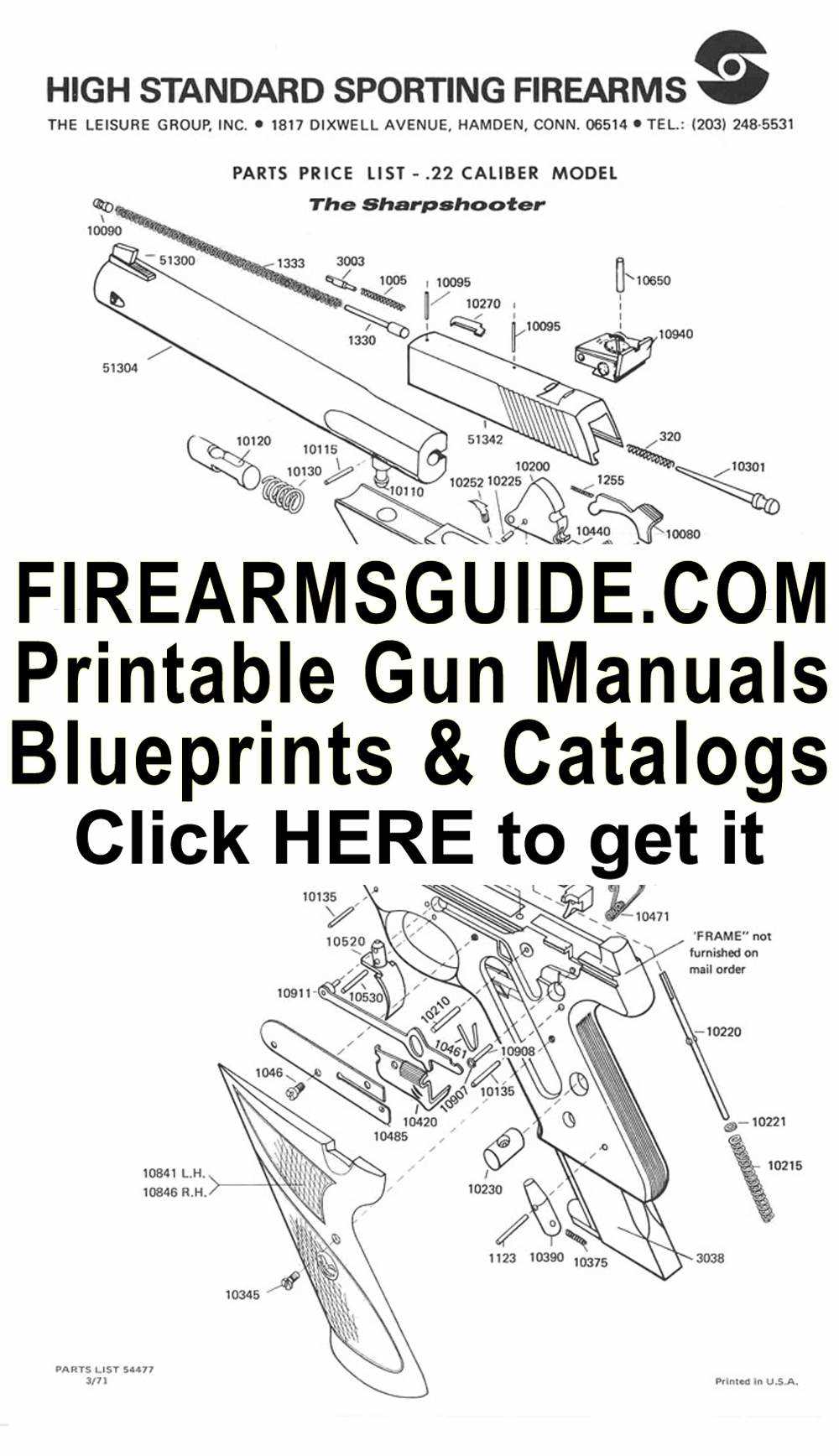

Fuel System Components and Arrangement

The fuel system plays a crucial role in ensuring the efficient operation of any engine. It is designed to manage the storage, delivery, and regulation of fuel, allowing for optimal performance and reliability. Understanding the various elements within this system and their arrangement is essential for troubleshooting and maintenance.

At the core of the fuel system are the fuel tank, fuel pump, and fuel injectors. The fuel tank serves as the reservoir, holding the necessary fuel until it is needed. The fuel pump is responsible for transferring the fuel from the tank to the engine, ensuring consistent pressure and flow. Fuel injectors then deliver the fuel directly into the combustion chamber, where it mixes with air for combustion.

Additionally, various filters, lines, and regulators play pivotal roles in maintaining the integrity and efficiency of the fuel system. Fuel filters are used to remove impurities, ensuring only clean fuel reaches the engine components. The arrangement of these elements is strategically designed to promote effective fuel flow and to minimize the risk of leaks or failures.

In summary, a well-structured fuel system is vital for optimal engine performance. By understanding the individual components and their arrangement, one can better appreciate how they contribute to the overall functionality of the engine.

Electrical Wiring and Safety Features

Understanding the intricacies of electrical connections and their inherent safety measures is crucial for ensuring reliable operation and preventing potential hazards. This section delves into the essential components and practices that contribute to safe electrical systems, emphasizing the importance of proper installation and maintenance.

Wiring configurations are designed to facilitate efficient power distribution while minimizing risks. Utilizing high-quality materials and adhering to recommended specifications are vital for maintaining system integrity. Additionally, incorporating safety devices such as circuit breakers and fuses plays a significant role in protecting against overloads and short circuits.

Regular inspections and adherence to safety protocols are necessary to identify potential issues before they escalate. Understanding the specific requirements for grounding and insulation helps mitigate risks, ensuring that all electrical elements function optimally. By prioritizing these aspects, users can enhance both performance and safety in their electrical systems.

Brake System Design and Parts Overview

The braking mechanism is a critical component in ensuring the safety and performance of any vehicle. Its effective operation relies on various elements that work together seamlessly to provide reliable stopping power. Understanding the fundamental aspects of the braking mechanism is essential for proper maintenance and troubleshooting.

Key Components of the Braking Mechanism

- Brake Pads: These friction materials press against the brake rotor to create the necessary friction for stopping.

- Brake Rotors: These disc-like structures are essential for dissipating heat generated during braking.

- Calipers: The calipers house the brake pads and apply pressure to them when the brake pedal is engaged.

- Brake Lines: These hydraulic tubes transfer brake fluid from the master cylinder to the calipers.

- Master Cylinder: This component generates hydraulic pressure when the brake pedal is pressed.

Functionality and Operation

The braking system operates on the principle of converting kinetic energy into thermal energy through friction. When the operator engages the braking mechanism, hydraulic force is transmitted through the lines to the calipers, which in turn clamp the brake pads against the rotors. This action effectively slows down or stops the vehicle.

Common Replacement Parts and Availability

In the context of maintaining and enhancing the performance of specific machinery, understanding the frequently needed components is essential. These items play a crucial role in ensuring the efficient functioning and longevity of the equipment. Accessibility of these elements can significantly affect repair times and overall user satisfaction.

Among the commonly sought components are those that wear out over time due to regular use. This may include various mechanical and electrical items, which are vital for optimal operation. Availability is a key consideration, as procuring these elements swiftly can minimize downtime and enhance productivity.

Many suppliers and manufacturers provide a wide range of replacements, making it easier for users to find the necessary components. Online platforms and local distributors often stock these essentials, ensuring that customers have access to reliable resources. Furthermore, understanding the specifications and compatibility of each item helps users make informed decisions when sourcing replacements.

Best Practices for Part Installation and Repair

Ensuring the effective installation and maintenance of components is crucial for optimal functionality and longevity. Following systematic approaches and guidelines can significantly enhance the performance and reliability of your equipment. Proper techniques not only help in achieving precise fitting but also prevent potential issues during operation.

Preparation and Planning

Before commencing any work, it is vital to thoroughly assess the situation. Gather all necessary tools and components, ensuring they are compatible with your setup. Creating a detailed plan can facilitate a smoother installation process. Carefully reviewing manufacturer instructions will provide insight into specific requirements, thereby minimizing errors.

Attention to Detail

When performing installations or repairs, meticulousness is key. Pay close attention to alignment and fit, as these factors can impact overall performance. During assembly, utilize appropriate fasteners and securing mechanisms to prevent loosening over time. Regularly inspecting connections and components after installation can help in identifying wear or misalignment early, ensuring reliable operation.