Finding the right technical information for your equipment is crucial for maintaining its functionality and ensuring smooth operation. Having a clear understanding of the specific components and their placement can significantly streamline repairs and maintenance work, reducing downtime and increasing efficiency.

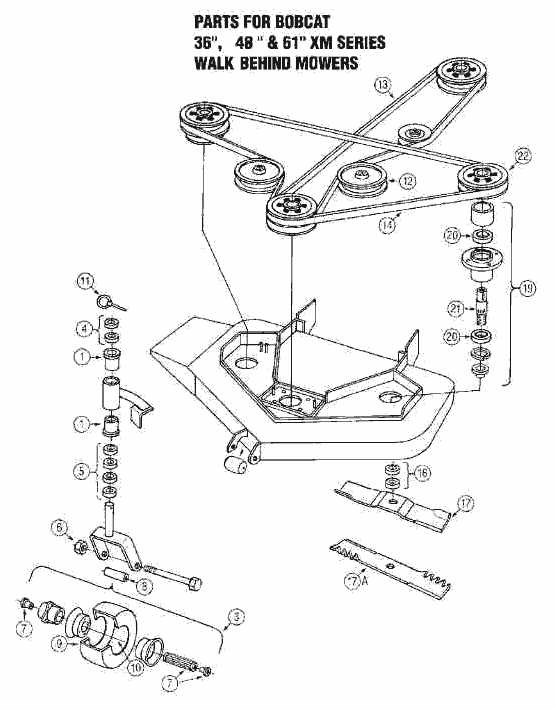

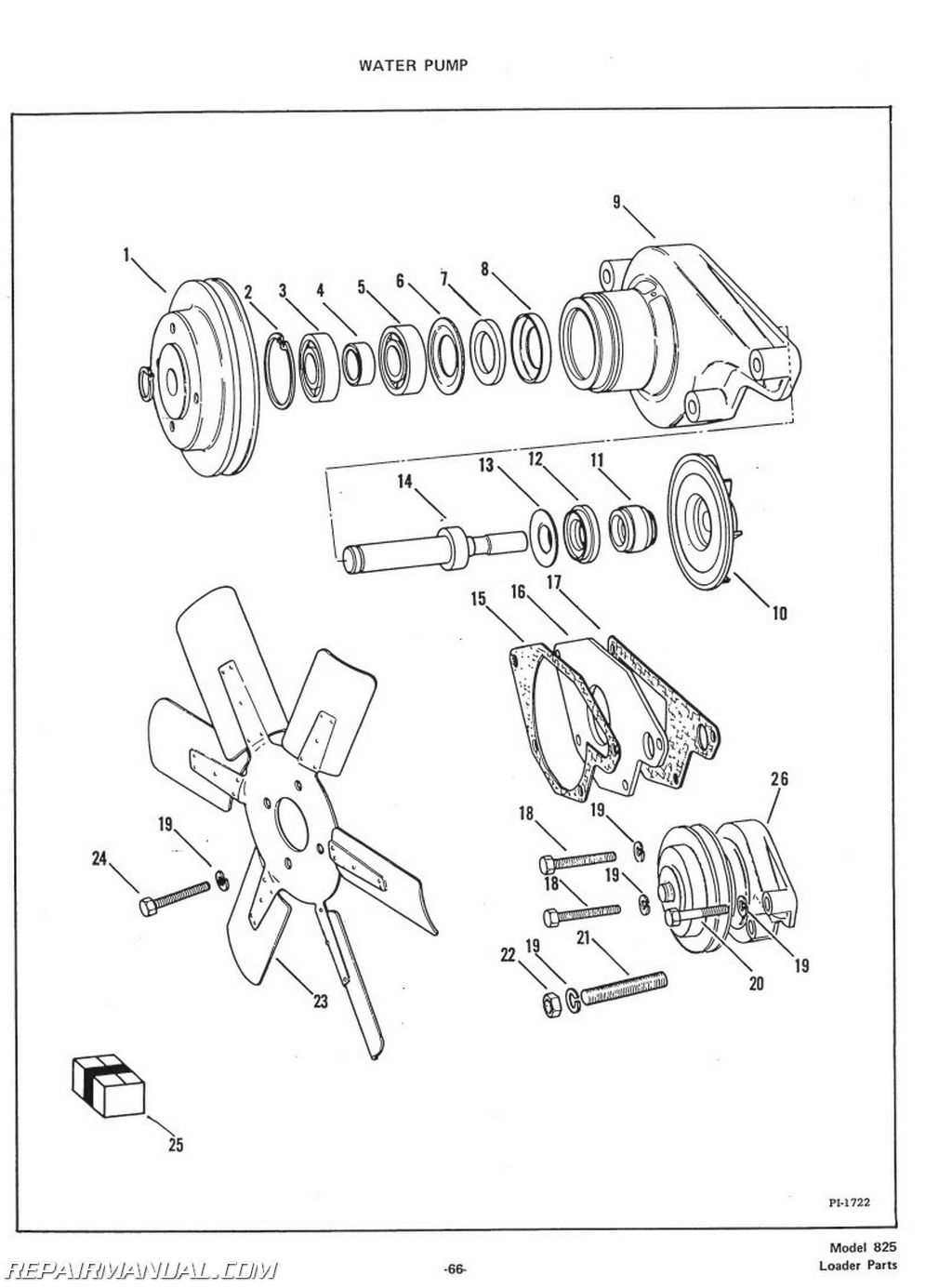

With detailed visual references, it becomes much easier to identify the necessary items and understand their connections. These illustrations allow users to explore complex systems, pinpointing the exact components they need for servicing or replacement. Clear documentation helps ensure that no critical element is overlooked during maintenance tasks.

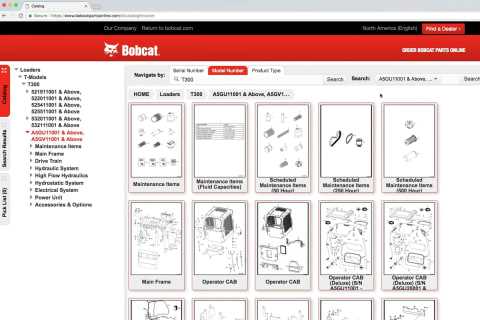

By utilizing a well-structured platform for navigating these resources, users gain quick and easy access to all the necessary technical data, making the process of upkeep and repair far more efficient.

Bobcat Online Parts Diagram

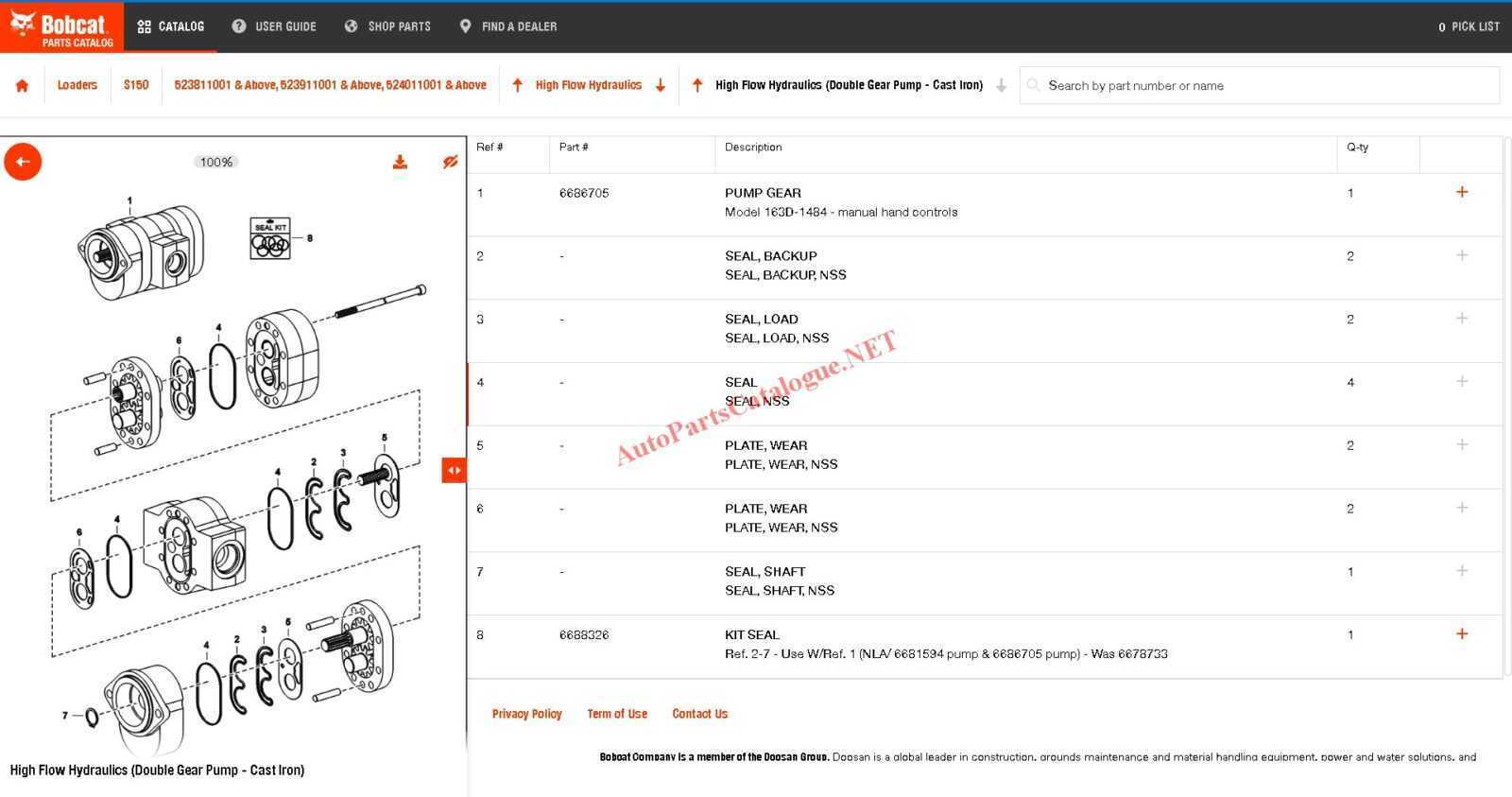

Accessing the right components for machinery repairs or maintenance can significantly enhance productivity and reduce downtime. Understanding how to identify specific elements in detailed visual schematics allows users to quickly locate what they need without confusion. A user-friendly interface simplifies the process of browsing through various sections of complex equipment, ensuring clarity and precision in every search.

- Efficiently identify components using categorized illustrations

- Navigate through sections of mechanical assemblies with ease

- Streamline the ordering process by finding correct items swiftly

By leveraging such tools, it becomes much easier to maintain machines in optimal working condition, ensuring longevity and performance.

Understanding Bobcat Equipment Diagrams

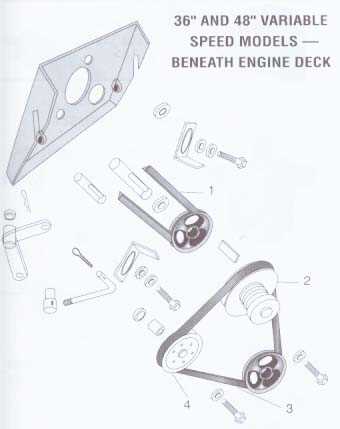

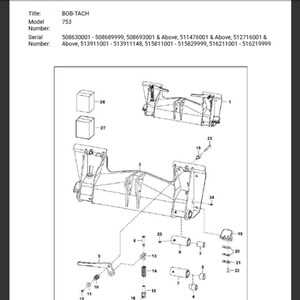

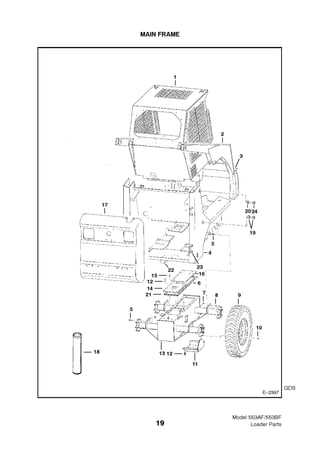

Visual schematics play a crucial role in comprehending the structure and functionality of mechanical systems. These drawings provide a clear representation of the connections and placement of various components, helping users identify parts and their functions. Whether it’s for maintenance or repair, understanding how these elements interact is essential for ensuring smooth operation and resolving technical issues efficiently.

How to Read Machine Schematics

Mechanical blueprints often use standardized symbols to denote different elements, making it easier to follow complex assemblies. Familiarizing yourself with these symbols and understanding the flow of the system can significantly enhance your ability to troubleshoot or maintain machinery. Carefully studying the arrangement of each component ensures that repairs are done correctly and efficiently.

Benefits of Using Equipment Schematics

Detailed visual representations offer a reliable way to avoid errors during the repair process. By following the layout accurately, technicians can prevent common mistakes such as incorrect assembly or misplaced components. In addition, these schematics

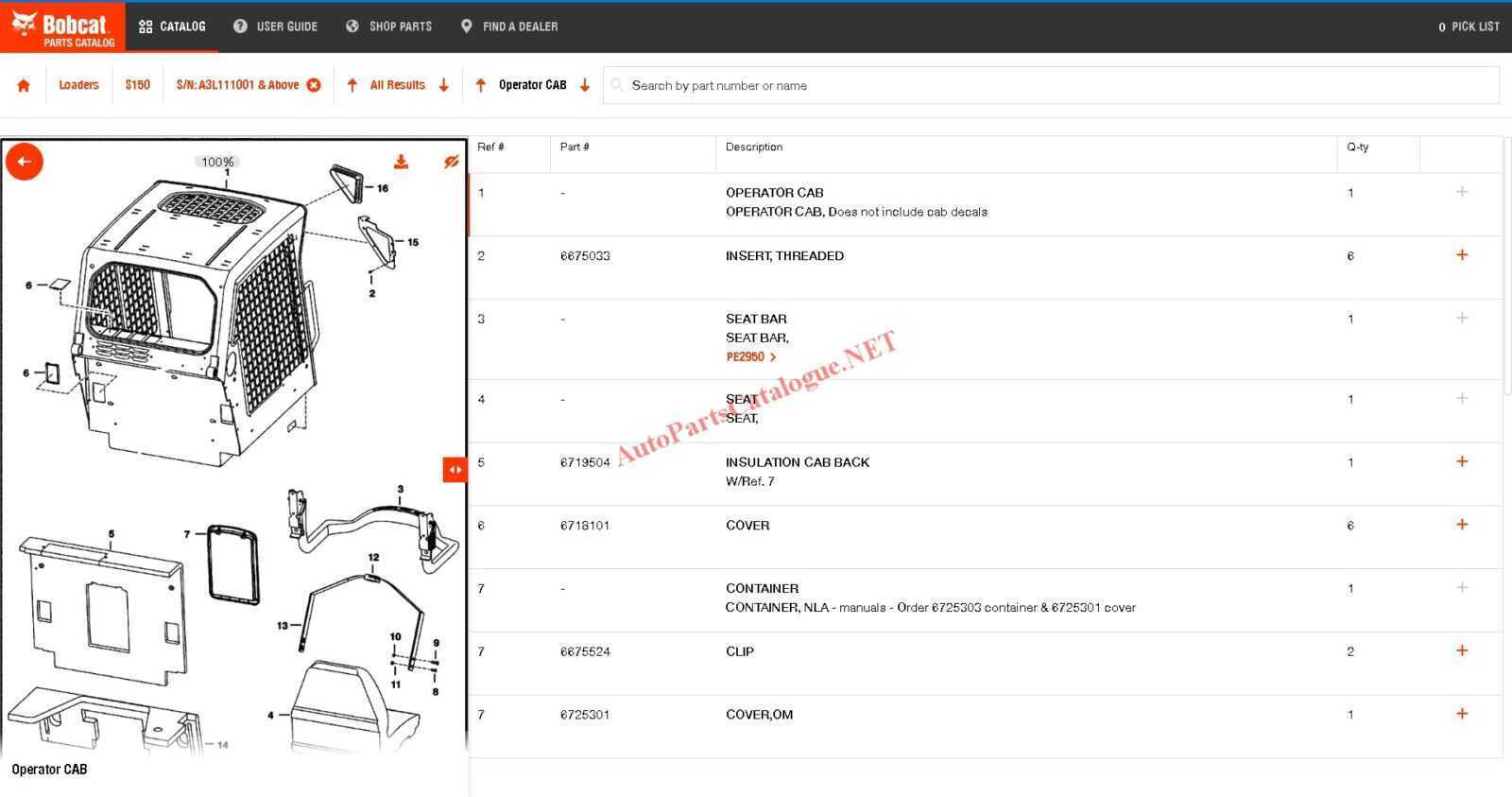

How to Navigate Parts Diagrams Online

Exploring technical illustrations for machine components can be a straightforward process if you know the right approach. This guide will walk you through effective methods for finding the specific components and assemblies you need, ensuring that you can quickly locate relevant information for maintenance or repairs.

Step-by-Step Navigation

- Start by selecting the category or section that corresponds to the type of equipment you’re working on. This could be the engine, hydraulics, or another major system.

- Once in the right category, narrow your search by choosing the specific assembly or part group. This will help you focus on the exact component you need.

- Use zoom and filter features to get a closer look at the detailed illustrations. These tools can help in identifying small but important elements of the system.

Tips for Efficient Search

- Use search tools to input model numbers or component names for faster results.

- If you’re unsure about a s

Locating Specific Bobcat Parts Quickly

Finding the right components for your machinery can be a challenging task, but with the right tools and approach, it becomes much simpler. By utilizing organized systems, you can easily identify the needed item, ensuring efficient maintenance and repairs.

Efficient Search Techniques

To streamline the process, it’s important to know exactly what you’re looking for. Familiarizing yourself with your machine’s structure and the typical wear-and-tear areas helps narrow down the search. Proper categorization further speeds up the process.

Using Search Tools Effectively

Modern tools provide clear navigation options, allowing you to quickly find the required component by category or section. These tools often feature intuitive interfaces that guide you step-by-step through the search process.

Advantages of Online Parts Catalogs

Digital catalogs provide a convenient way to explore and identify necessary components for various machinery. These platforms simplify the search process, offering detailed information that helps users make informed decisions quickly and efficiently. Accessing relevant information becomes faster, reducing time spent on manual research.

Detailed Information at Your Fingertips

One of the primary benefits of digital platforms is the wealth of detailed data available. Users can view descriptions, specifications, and images of each component, ensuring compatibility and fitment. This level of detail minimizes errors and ensures that the right parts are selected.

Ease of Accessibility

With digital catalogs, accessibility is greatly enhanced. Users can browse through various categories and quickly locate the required component from virtually anywhere. This flexibility allows individuals to manage their machinery maintenance and repairs more effectively, saving both time and resources.

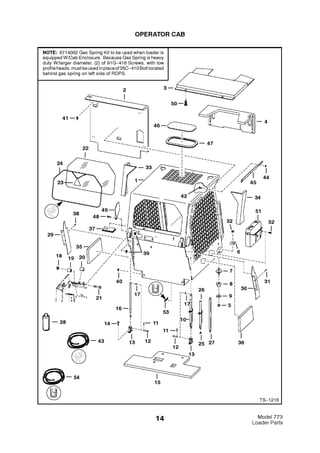

Using Diagrams for Bobcat Maintenance

Visual representations play a crucial role in the upkeep and servicing of machinery. By utilizing detailed illustrations, operators and technicians can better understand the components and systems involved, facilitating a more efficient maintenance process. These resources serve as essential tools for identifying parts, troubleshooting issues, and ensuring proper assembly and disassembly during repairs.

Benefits of Visual References

- Enhanced Clarity: Diagrams provide a clear view of intricate components, reducing ambiguity and improving comprehension.

- Efficient Troubleshooting: Visual aids enable quick identification of problems, allowing for timely interventions and minimizing downtime.

- Streamlined Processes: Step-by-step illustrations guide users through maintenance tasks, ensuring all necessary actions are performed accurately.

Utilizing Diagrams Effectively

- Identify Key Components: Start by familiarizing yourself with the main parts shown in the visual reference.

- Follow Instructions: Adhere to the sequential steps outlined in the diagrams for optimal results.

- Regular Consultation: Refer to the illustrations regularly to reinforce understanding and maintain proficiency in servicing the machinery.

Efficient Ordering through Online Schematics

Utilizing digital blueprints greatly enhances the process of procurement for machinery components. These comprehensive representations allow users to visualize the structure and functionality of various elements, streamlining the selection and acquisition process. By providing detailed illustrations and specifications, individuals can make informed decisions while minimizing errors.

Accessing these resources simplifies the task of identifying the necessary components, ensuring that all requirements are met with precision. Furthermore, this approach facilitates quicker transactions, as users can conveniently navigate through a vast catalog of options. With the help of intuitive interfaces, obtaining essential materials becomes not only faster but also more reliable, fostering a seamless experience.

Adopting this method empowers users to maintain their equipment effectively, promoting longevity and optimal performance. In turn, this contributes to reduced downtime and enhanced productivity, reinforcing the importance of utilizing such innovative resources in today’s fast-paced environment.

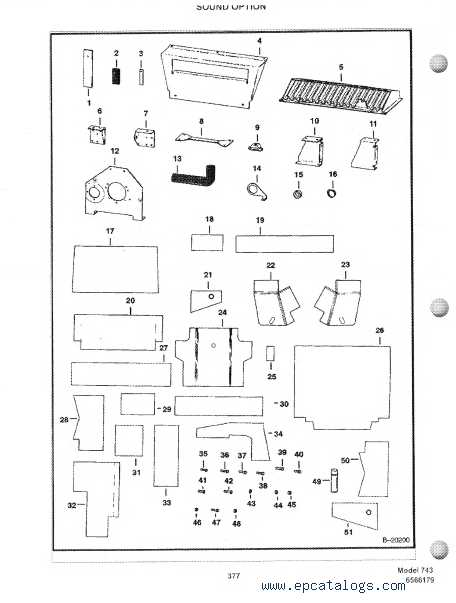

Comparing Parts Across Bobcat Models

When examining the components of various equipment models, it becomes crucial to understand how different versions may utilize similar or unique elements. By analyzing these similarities and differences, one can make informed decisions regarding maintenance, repairs, and upgrades. This section delves into the nuances of comparing these essential elements among different machinery variations.

Identifying Common Components

Many machinery types share core elements that facilitate standardization and compatibility. Recognizing these shared components can simplify repairs and reduce downtime. For instance, engines, hydraulic systems, and electrical assemblies often exhibit similarities across models, allowing for easier sourcing of replacements and maintenance solutions.

Differentiating Unique Features

Despite the commonality of certain elements, specific machinery models may incorporate distinct features tailored to particular applications or operational conditions. These unique components might include specialized attachments, advanced control systems, or modified frames. Understanding these variations is essential for ensuring optimal performance and enhancing the efficiency of each model.

Common Symbols in Bobcat Diagrams

Understanding the various icons used in technical schematics is crucial for effective navigation and comprehension. These symbols serve as a universal language, conveying essential information about components and their functions within machinery. By familiarizing oneself with these representations, users can easily interpret and apply the information provided.

Typically, symbols may denote electrical elements, mechanical parts, or safety warnings. For instance, circuit indicators are often represented by simple shapes, while hazard symbols might include specific alerts for potential dangers. Recognizing these symbols enhances the ability to troubleshoot and maintain equipment efficiently.

Moreover, standardized icons are beneficial for ensuring consistency across various manuals and resources. This uniformity aids operators in quickly identifying the necessary information without confusion. Thus, a solid grasp of these symbols not only improves operational effectiveness but also promotes a safer working environment.

Maximizing Repair Efficiency with Diagrams

Utilizing visual representations can significantly enhance the effectiveness of maintenance and repair tasks. These tools serve as essential guides, offering clear insights into the assembly and components of machinery. By leveraging such resources, technicians can streamline their workflow, reducing downtime and improving accuracy in their work.

Clarity in Communication: Visual aids provide a common language for technicians, enabling them to communicate complex ideas more clearly. This shared understanding helps in minimizing errors during the repair process, as all parties involved can reference the same information.

Time-Saving Benefits: Incorporating visual tools into repair procedures can lead to substantial time savings. By having access to detailed illustrations, technicians can quickly identify parts and their placements, thus expediting the repair process and ensuring that tasks are completed efficiently.

Troubleshooting Bobcat Issues with Schematics

When facing operational challenges with machinery, utilizing detailed schematics can significantly enhance the diagnostic process. These visual representations allow users to understand the intricate relationships between components and identify potential faults efficiently.

Effective troubleshooting involves a systematic approach, including the following steps:

- Identify Symptoms: Recognize the specific issues your equipment is experiencing, such as unusual noises, loss of power, or erratic behavior.

- Consult Diagrams: Use schematics to locate components and understand their functions within the system.

- Trace Circuits: Follow electrical or hydraulic paths to identify potential points of failure.

- Check Connections: Inspect wiring, hoses, and fittings for signs of wear or damage that may affect performance.

- Test Components: Use multimeters or pressure gauges to evaluate the functionality of specific parts as indicated in the schematics.

By adhering to these guidelines, operators can enhance their troubleshooting capabilities, ensuring that machinery operates smoothly and efficiently.

Finding OEM Parts with Diagrams

Locating original equipment manufacturer components can be simplified by utilizing visual aids that illustrate their configuration and placement. These resources enhance the understanding of how different elements interact, making it easier to identify the exact pieces needed for repairs or replacements.

Visual representations serve as valuable tools for users seeking to ensure compatibility and authenticity when sourcing components. They provide clarity on various models and specifications, allowing for informed decisions that contribute to the longevity and performance of machinery.

Component Name Description OEM Number Hydraulic Filter Filters contaminants from hydraulic fluid 123456 Engine Oil Seal Prevents oil leakage from the engine 654321 Air Filter Cleans the air entering the engine 789012