In the realm of construction and home improvement, the functionality of power tools is paramount for achieving precise results. Familiarity with the internal mechanisms of these devices not only enhances operational efficiency but also empowers users to troubleshoot issues effectively. This section delves into the intricacies of a specific tool’s assembly, providing a comprehensive overview of its essential elements.

By examining the layout and function of each component, users can gain invaluable insights into how their equipment operates. This knowledge fosters a deeper appreciation for the craftsmanship involved and aids in the maintenance and repair processes. Whether for professional use or personal projects, understanding these components is crucial for anyone looking to maximize the potential of their tools.

As we explore the various sections of this instrument, we will highlight key features and their respective roles. This guide serves as a valuable resource for both novices and seasoned users alike, ensuring that all can navigate their tools with confidence and skill.

Bostitch Nail Gun Parts Overview

This section provides a comprehensive understanding of the essential components found in fastening tools. Each element plays a crucial role in the overall functionality and efficiency of the device, ensuring reliable performance during projects.

Key Components

Various elements work together to deliver optimal results. Familiarizing oneself with these pieces can enhance maintenance and troubleshooting skills.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal mechanisms. |

| Piston | Drives the fastening element into materials. |

| Trigger | Controls the activation of the device. |

| Magazine | Holds the fastening elements for quick access. |

| Safety Mechanism | Prevents accidental activation for user safety. |

Maintenance Tips

Regular care of these components can extend the lifespan and performance of the equipment. Inspecting, cleaning, and replacing worn elements is essential for reliable operation.

Understanding the Basic Components

The key to effective tool maintenance and use lies in understanding its fundamental structure. Each element works in harmony to ensure smooth operation and optimal performance. Familiarizing yourself with the main components will allow you to troubleshoot more efficiently and keep the device running smoothly.

Core Structure

At the heart of any such tool is its central mechanism, designed to handle repeated tasks with precision. This includes internal and external parts that contribute to overall stability and functionality. Ensuring these elements are in good condition is essential for consistent use.

Additional Mechanisms

Beyond the core structure, there are supplementary systems that support efficiency. These may include features for adjusting settings or regulating pressure, helping to adapt to different materials and tasks. Paying attention to these components can extend the lifespan of the tool.

Common Tools for Maintenance

Proper upkeep of equipment requires a set of versatile and reliable tools. These instruments simplify routine tasks, ensuring longevity and smooth operation of various systems. With the right tools, even complex issues can be addressed efficiently, minimizing downtime and ensuring continued functionality.

Essential Hand Tools

A well-rounded toolkit should include several hand tools to handle a variety of maintenance jobs. These are foundational for addressing mechanical or technical challenges in day-to-day upkeep.

- Wrenches – Useful for tightening or loosening fasteners of different sizes.

- Screwdrivers – Vital for dealing with screws of various types and sizes.

- Pliers – Helpful for gripping, twisting, or cutting different materials during repairs.

Power Tools for Efficiency

For more demanding tasks, power tools provide the extra force and precision required. These tools save time and reduce effort during repair or installation processes.

- Drill – Ideal for making holes or driving fasteners quickly and efficiently.

- Impact Driver – Provides additional torque, making it

Identifying Worn Parts

Regular maintenance is essential to ensure the smooth operation of any mechanical tool. Over time, various components may begin to show signs of wear, which can affect overall performance. It’s important to regularly inspect these elements to catch potential issues early and avoid bigger problems.

- Visible Cracks or Breakage: Check for any obvious damage, such as fractures or pieces breaking off.

- Loose or Wobbly Components: If certain parts seem unstable or misaligned, this may indicate they are worn down and need replacement.

- Decreased Efficiency: A noticeable drop in performance can often be traced back to components that are no longer functioning as they should.

- Unusual Noises: Strange sounds, such as grinding or clunking, can signal that parts are deteriorating.

By paying attention to these signs, you can address any issues before they lead to major malfunctions, ensuring your tool remains reliable for years to come.

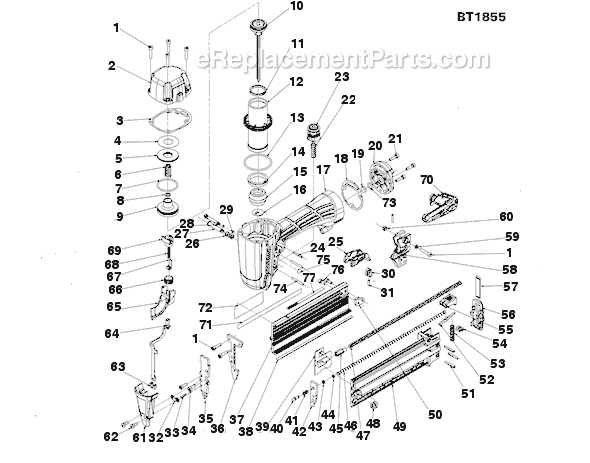

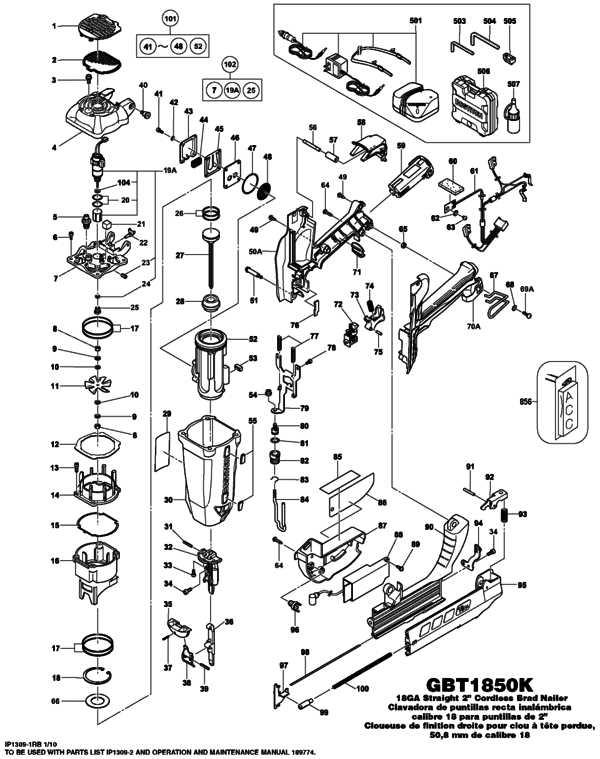

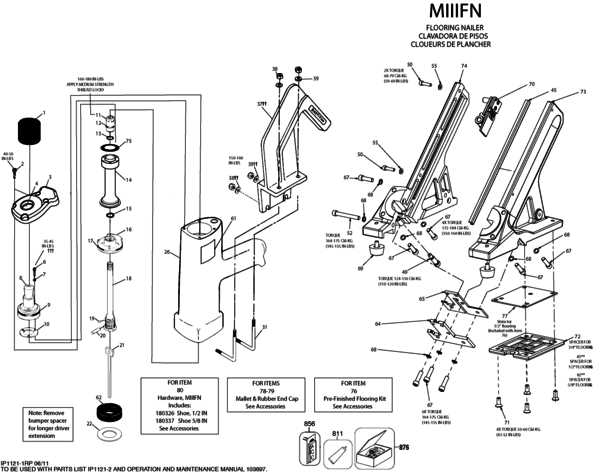

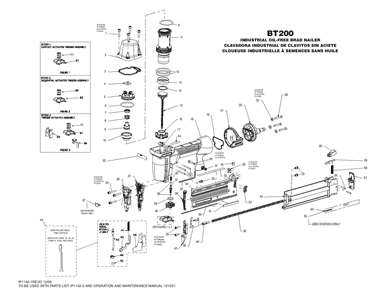

How to Read the Diagram

Understanding a mechanical blueprint requires attention to details and a clear grasp of how various components fit together. These visual representations provide a roadmap, guiding the user through each section and its function. By carefully analyzing the layout, one can see how different elements interconnect, ensuring proper usage and maintenance.

Key Sections

- Component Placement: The layout helps identify the location of each element.

- Connections: Arrows and lines show how the parts interact with each other.

- Labels: Numbers or letters indicate specific parts, referenced in the manual.

Step-by-Step Approach

- Start by locating the major sections to get an overview.

- Follow the connections to see how the elements work together.

- Cross-check the labels with the provided instructions for clarity.

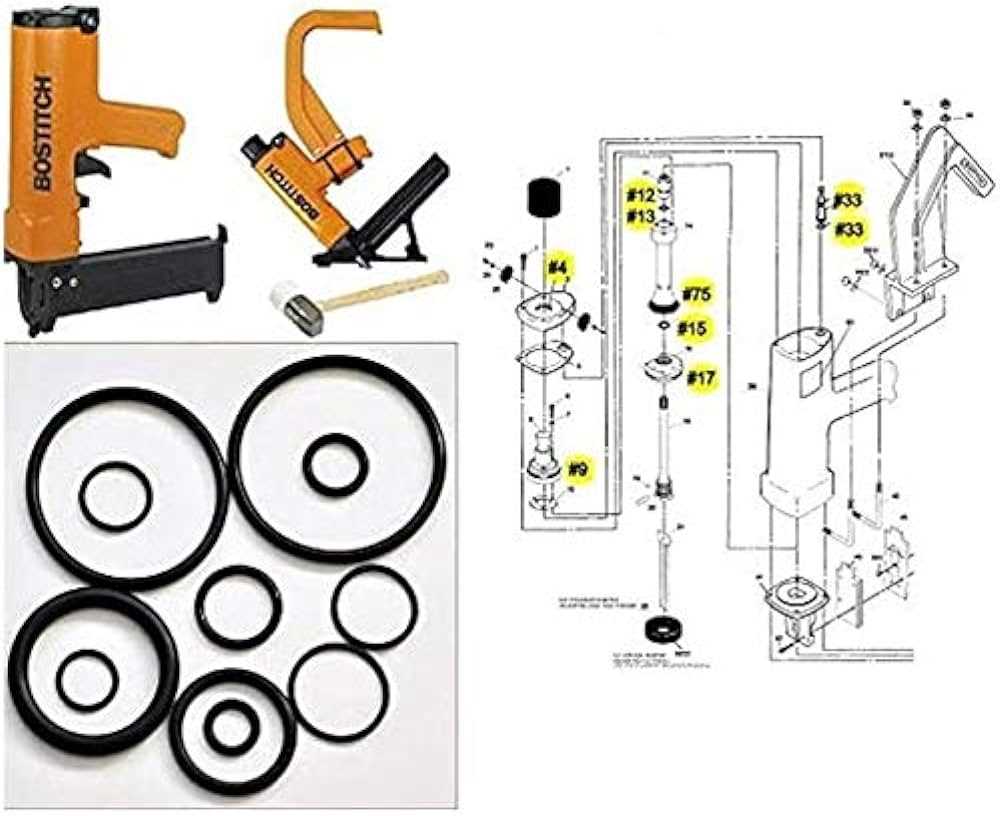

Replacement Parts Availability

When it comes to maintaining the functionality of your tools, having access to compatible replacement components is crucial. Over time, various elements of your equipment may experience wear and tear, making it important to ensure that suitable replacements are readily available to keep everything in working order.

Where to Find Replacement Components

Reliable suppliers and manufacturers often provide detailed catalogs of available replacement components. These catalogs allow users to find the exact element they need based on the tool model or part specifications, ensuring a proper fit and continued performance.

Commonly Available Components

Component Type Usage Availability Fasteners Critical for securing materials Widely available Springs Provides tension for mechanical functions Moderately available O-rings Safety Features of Nail Guns When using power tools, ensuring safety is paramount. Devices that drive fasteners into materials at high speed require multiple safety mechanisms to prevent accidents. These features are designed to protect the user during operation, reduce risks of unintentional use, and improve overall control of the tool.

Trigger Lock Mechanism

A trigger lock is an essential feature that prevents the device from discharging unless it is intentionally activated. This mechanism helps reduce accidental usage, especially when the tool is being handled or carried.

Contact Tip Safety

Another critical feature is the contact tip safety, which ensures that the tool only operates when it is pressed against a surface. This prevents the tool from firing freely in the air and enhances safety by requiring proper contact with the workpiece before activation.

Assembly and Disassembly Instructions

Proper assembly and disassembly of tools is essential for maintenance and ensuring long-term performance. Following clear steps will help in preventing issues during usage and keeping the equipment functioning efficiently.

- First, ensure all power sources are disconnected before starting.

- Remove the fastener holder by releasing the latch.

- Disassemble the front section carefully, checking for any misalignments.

- For reassembly, reverse the steps, ensuring all components fit securely before operation.

Following these guidelines will help in achieving smooth operation.

Repairing vs. Replacing Parts

When it comes to maintaining your equipment, the decision between repairing and replacing components can significantly impact both performance and longevity. Each option has its advantages, and the best choice depends on various factors such as the condition of the component and the overall cost-effectiveness.

Aspect Repairing Replacing Cost Usually cheaper in the short term, especially for minor issues. Higher initial investment but can be more cost-effective over time. Durability Repairs might offer temporary fixes but may not restore full durability. New components tend to provide longer-lasting solutions. Upgrading Your Nail Gun

When it comes to improving your tools, making the right modifications can significantly enhance their performance and durability. Whether you’re looking for more power or greater precision, thoughtful upgrades can make a noticeable difference in your workflow. It’s essential to understand how different components interact, and which adjustments offer the best value for your needs.

Enhancing Performance

Improving efficiency and power output can be achieved by upgrading various internal elements. By focusing on quality enhancements, you can reduce the wear and tear on critical mechanisms, ensuring longer life and smoother operation. Prioritize components that directly affect the tool’s output and handling.

Improving Durability

To extend the lifespan of your equipment, focus on materials that are more resistant to damage and corrosion. Durability enhancements help protect against common issues, ensuring that your tool remains reliable over time. Selecting the right replacements is key to maintaining long-term functionality.

Tips for Troubleshooting Issues

When dealing with a device that isn’t functioning properly, it’s essential to identify common problems and address them efficiently. Whether it’s inconsistent performance or unexpected malfunctions, the key is to understand the root cause and resolve it with simple steps. Knowing how to troubleshoot not only saves time but also prevents future complications.

Check for Obstructions: One of the most frequent causes of issues is blockages. Ensure there’s no debris or material stuck inside, which might hinder the smooth operation of the tool. A quick inspection and cleaning can often resolve performance issues.

Inspect Power Supply: A tool may fail to operate correctly if the power source is unstable or disconnected. Make sure all connections are secure, and if batteries are used, ensure they are fully charged and properly installed.

Regular Maintenance: Keeping the equipment well-maintained is crucial for preventing future breakdowns. Lubricating moving parts, tightening loose components, and cleaning the tool regularly can significantly improve its longevity and efficiency.

Comparison with Other Brands

When evaluating different models from various manufacturers, it’s essential to consider several factors that influence performance and usability. Each brand offers unique features, designs, and technology that cater to distinct user needs and preferences.

Durability is a crucial aspect, as some brands utilize higher quality materials that enhance longevity. In contrast, others might prioritize lightweight designs, affecting overall robustness. Users often find that sturdier tools can withstand rigorous tasks over time.

Another significant element is ergonomics. While some models focus on user comfort, with padded grips and balanced weight distribution, others may not offer the same level of attention to user-friendly design. This difference can greatly impact prolonged usage, making it vital to assess personal comfort alongside functionality.

Performance also varies widely; certain brands are known for their powerful mechanisms that deliver superior results in challenging environments, whereas others may excel in efficiency and speed. Understanding these distinctions helps users choose the right tool for their specific projects.

Finally, customer support and warranty options are aspects that should not be overlooked. Some companies provide extensive support and comprehensive warranties, giving users peace of mind, while others may have limited assistance and shorter coverage periods. This can influence the overall satisfaction and reliability of the product.

Benefits of Using Bostitch Products

Choosing tools from a reputable brand offers numerous advantages for both professionals and DIY enthusiasts. The reliability and innovation associated with these tools enhance the overall efficiency and productivity of any project.

Durability is one of the key features of these products. Crafted with high-quality materials, they are designed to withstand the rigors of frequent use, ensuring long-lasting performance.

Another significant benefit is ergonomics. The thoughtfully designed handles and lightweight construction reduce user fatigue, making it easier to work for extended periods without discomfort.

Moreover, precision is crucial in any construction or repair task. Tools from this brand are engineered to deliver accurate results, minimizing the chances of errors and enhancing the quality of work.

Lastly, investing in reliable tools means less time spent on maintenance and repairs. This cost-effectiveness allows users to focus on their projects rather than dealing with tool issues.