When it comes to making the perfect cup of coffee, the internal mechanisms of your appliance play a vital role. Each element is designed to work in harmony, ensuring that the beans are processed and brewed to perfection. To fully comprehend how everything operates, it’s essential to explore the key elements that make up the device. These components, while often overlooked, are the backbone of any efficient system.

By familiarizing yourself with the layout and function of each segment, you can better maintain your equipment and troubleshoot any issues that may arise. Whether you’re experiencing inconsistent results or simply want to enhance your understanding, knowing how these individual pieces fit together is crucial. A comprehensive overview of these vital sections will empower you to get the most out of your appliance, ensuring a long-lasting and enjoyable experience.

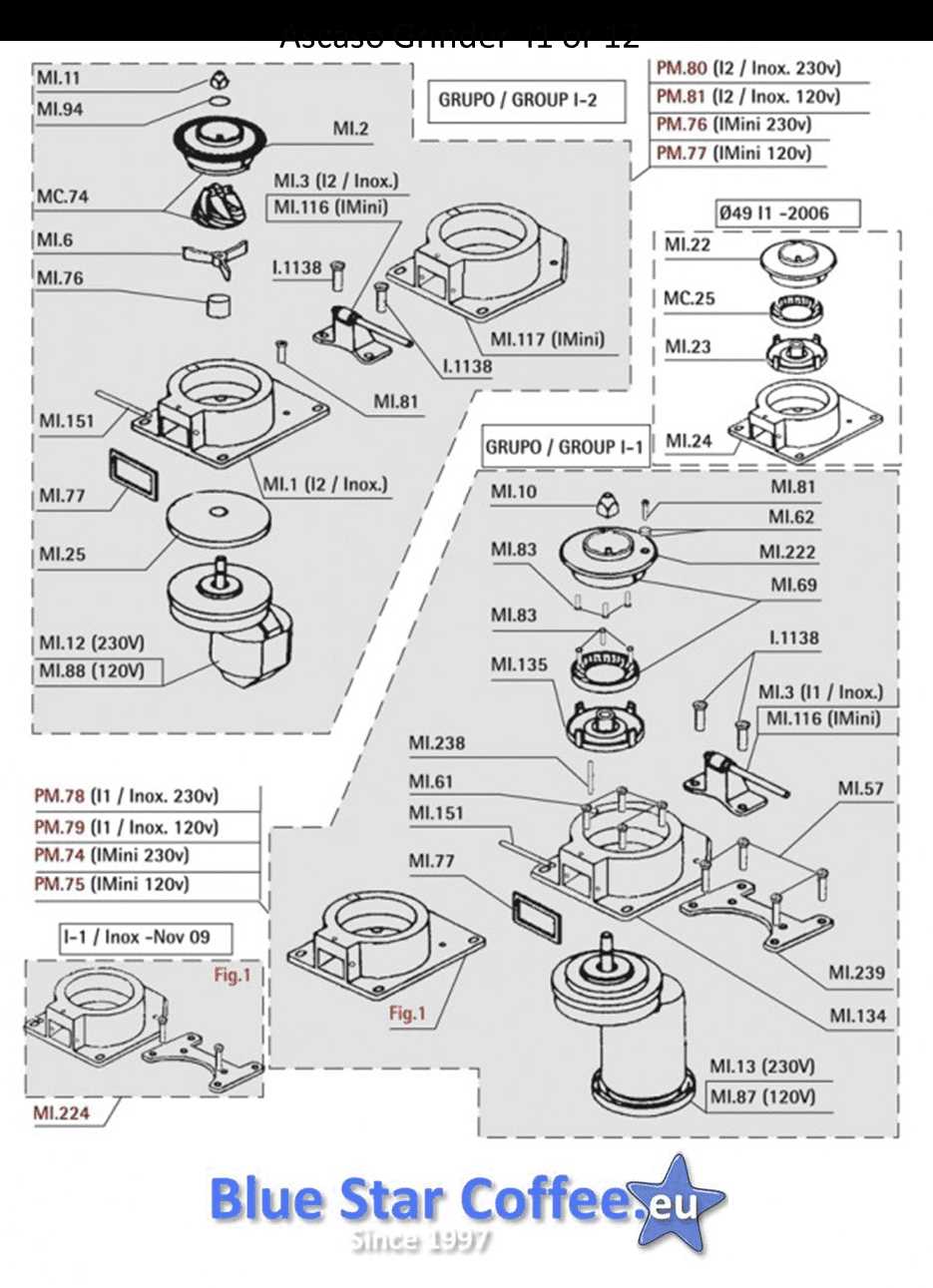

Breville Grinder Key Components Overview

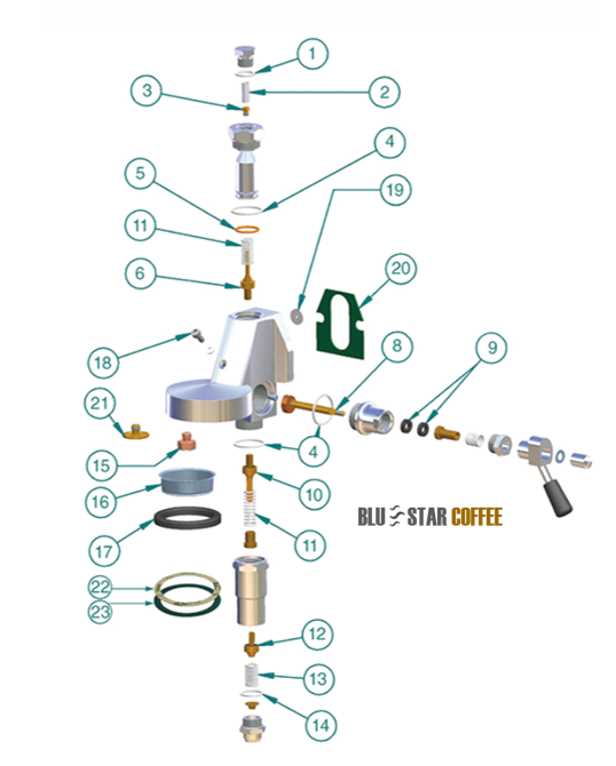

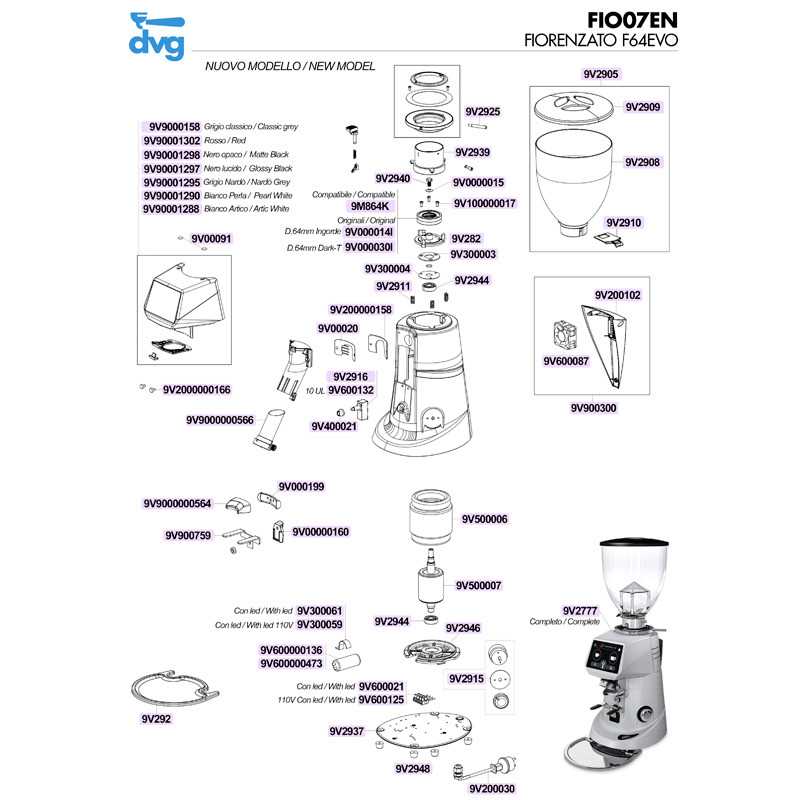

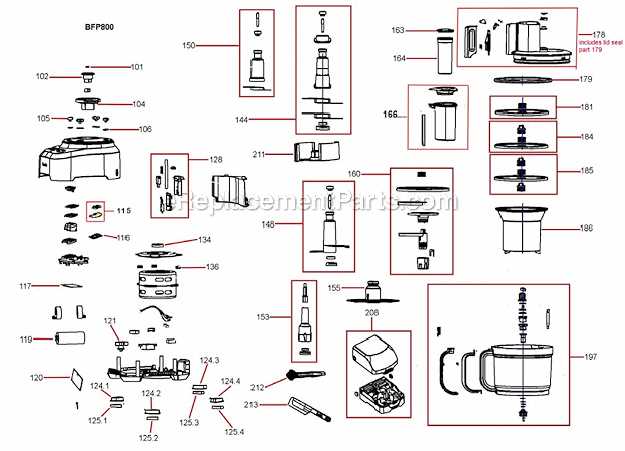

Understanding the essential elements that contribute to the functionality of a coffee preparation device is crucial for both enthusiasts and professionals. These devices consist of several critical components, each playing a pivotal role in ensuring smooth operation and consistent results. While these parts vary in design and complexity, their primary purpose remains the same: to deliver an optimal grinding experience for various brewing methods.

Motor Assembly: The motor is at the heart of the system, responsible for driving the rotation of the internal mechanisms. It needs to be both powerful and efficient to ensure even grinding and a long service life.

Burrs: The grinding mechanism is typically composed of two key elements that crush the beans into a consistent texture. Whether flat or conical, these pieces are essential for determining the grind size and uniformity.

Hopper: This container holds the raw coffee beans before they enter the grinding process. The design and capacity of the hopper can affect the amount of beans processed and the efficiency of the system.

Adjustment Mechanism: Many devices offer the ability to modify the grind size, which is achieved through a simple dial or more sophisticated electronic settings. This adjustment affects the speed and precision with which the beans are ground.

Collecting Chamber: Once the beans are ground, they are collected in this chamber, which can vary in size and design depending on the device’s intended use. Its function is to store the ground coffee before it is used for brewing.

Essential Parts of Breville Grinders

When it comes to ensuring optimal performance and longevity, understanding the key components of your appliance is crucial. Each unit is composed of several integral elements that work together to deliver consistent results. These components are responsible for controlling the consistency of the grind, the ease of use, and overall durability.

- Motor: The driving force behind the entire mechanism, it powers the movement of the internal elements, converting electrical energy into motion.

- Grinding Mechanism: This is where the action takes place, using a set of rotating blades or burrs to process the material. Precision in this area ensures uniformity in the final product.

- Hopper: The container where the material is placed before processing. It holds the beans or other items, feeding them into the grinding system in a controlled manner.

- Adjustment Mechanism: A crucial feature that allows users to modify the fineness or coarseness of the output. This is typically controlled by a dial or lever that fine-tunes the operation.

- Catch Tray: After processing, this component collects the ground material, often with a compartment that helps to prevent spills or messes.

- Housing: The outer shell of the unit that protects the internal components while ensuring proper ventilation and safety during operation.

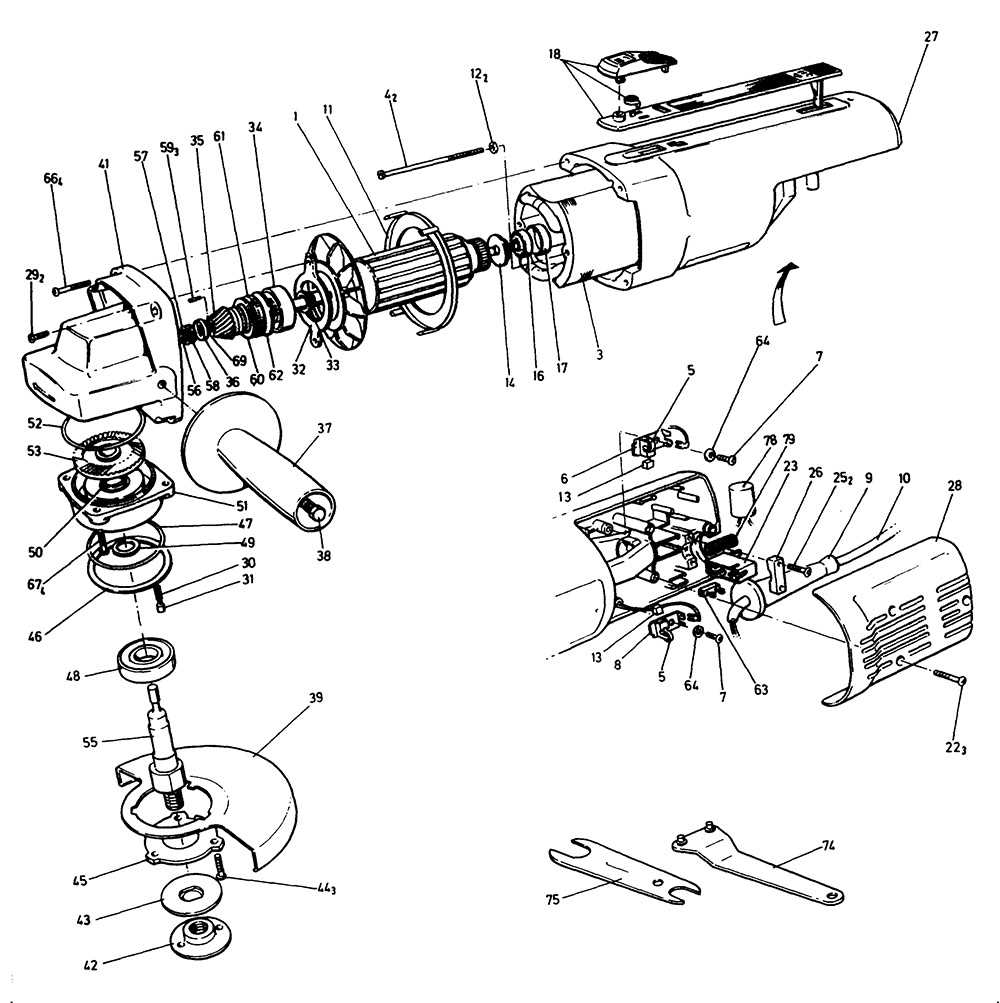

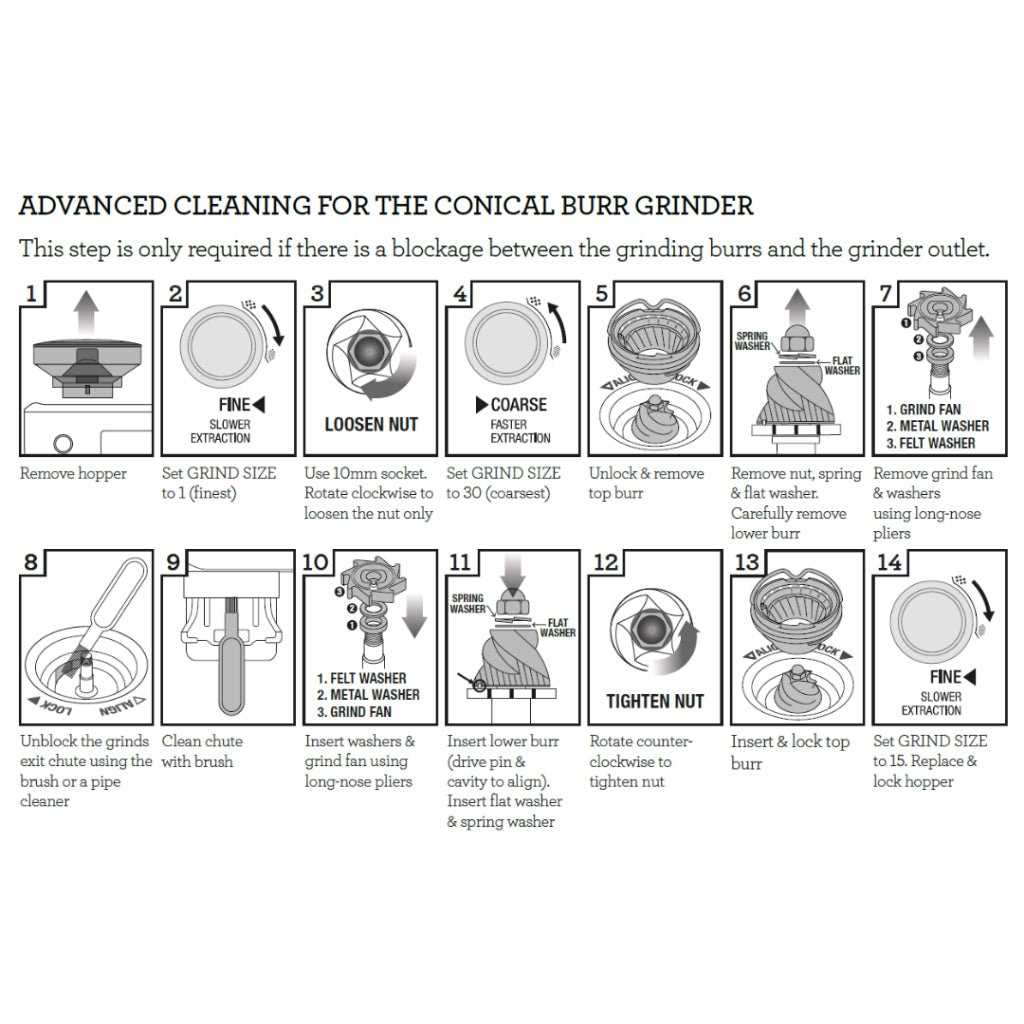

How the Burrs Work in Grinding

The burrs are essential components in the process of transforming beans into a fine, uniform texture. They function by applying consistent pressure to the coffee beans, breaking them down into small particles. This method ensures an even grind size, which is critical for achieving a balanced extraction and optimal flavor during brewing.

Types of Burrs

- Flat Burrs: These burrs consist of two parallel discs that crush beans between them. The result is a consistent grind size, but it may produce more heat during the process.

- Conical Burrs: These burrs feature a cone-shaped inner burr that fits inside a larger outer burr. The grinding action is more efficient, producing less heat and friction.

How Burrs Operate

- The coffee beans are fed between the burrs, where they are crushed and ground into particles of varying coarseness depending on the setting.

- As the burrs rotate, the beans are steadily pushed through the grinding chamber, ensuring that the grind remains even throughout the process.

- Both burr types aim for precision and control, minimizing the amount of fine particles or boulders in the final output.

Understanding the Motor and Its Role

The motor is a crucial element in any device that processes food, particularly when it comes to mechanical systems designed for grinding or milling. This component is responsible for generating the power necessary to operate the mechanism that performs the main task. It drives the motion of key parts, ensuring smooth and consistent performance, which directly impacts the efficiency and quality of the output.

In essence, the motor functions as the heart of the system, providing the energy required to initiate movement and sustain it over time. The strength and durability of the motor can determine how effectively the device handles different materials and how long it can be used before maintenance is needed. The motor’s speed and torque are vital factors that influence the overall performance and functionality, ensuring that each process is carried out with precision and reliability.

Without a well-designed motor, even the most advanced mechanical systems would struggle to operate at their peak potential. Understanding how the motor works and what it needs to perform optimally is essential for maintaining the longevity and efficiency of the device. Proper care and attention to this key component can prevent unnecessary wear and tear, ensuring that the system remains in top condition for longer periods.

Exploring the Hopper Design and Functionality

The hopper plays a crucial role in the overall operation of a coffee preparation system, acting as the reservoir where beans are stored before being processed. Its design and functionality are key to ensuring a smooth, efficient, and consistent flow of beans into the grinding mechanism, allowing for optimal results in every batch.

Design Features

The hopper typically features a spacious container with a secure lid to hold the coffee beans. The material used for the hopper is often transparent, providing a clear view of the remaining beans. Some designs incorporate a locking mechanism to prevent spillage when removing or refilling the hopper.

- Capacity: Adequate space to hold a large amount of beans.

- Material: Transparent plastic or glass for easy monitoring of bean levels.

- Seal: A lid that ensures freshness by protecting the beans from air and moisture.

Functionality Considerations

Beyond its physical design, the hopper’s functionality is equally important. A well-designed hopper ensures that beans move smoothly into the grinding chamber without clogging or uneven distribution. The size of the opening and the angle of the funnel can affect how beans are fed into the system, ultimately influencing the quality of the grind.

- Even Bean Distribution: Ensures all beans flow consistently into the grinding mechanism.

- Minimal Waste: Optimized design to minimize leftover beans.

- Convenience: Easily removable for cleaning and refilling.

The Importance of the Grind Settings Dial

Adjusting the coarseness of the ground material is a crucial step in achieving the perfect brew. The dial that controls this adjustment plays a key role in influencing the texture and quality of the final product. Whether it’s a fine or coarse grind, the precision of this tool can make a noticeable difference in flavor and aroma.

Having a well-calibrated mechanism for controlling the grind size allows you to tailor your preparation to suit different brewing methods, from espresso to French press. A uniform and consistent grind ensures optimal extraction, while improper adjustments may lead to under-extraction or over-extraction, affecting the taste.

- Finer settings are ideal for espresso and other pressure-based methods.

- Coarser settings work better for drip coffee makers and French press brewing.

- Intermediate settings are useful for pour-over or aeropress techniques.

Therefore, a functional and easy-to-use dial is essential for enthusiasts aiming to fine-tune their experience and enjoy every cup to its fullest potential.

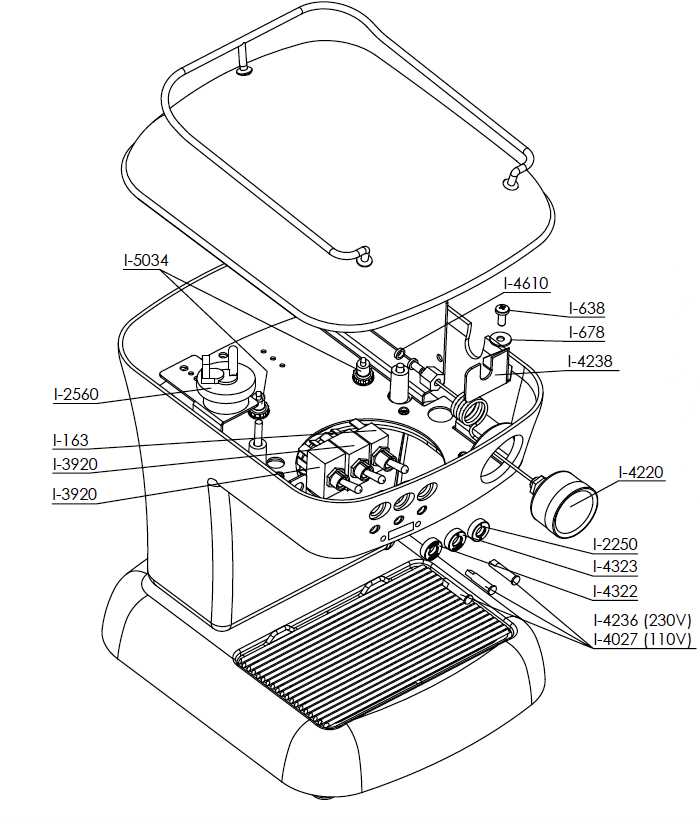

Analyzing the Power Switch and Controls

The power switch and control mechanisms are essential components that govern the operation of any electrical appliance. Understanding the functionality of these elements helps users to troubleshoot issues and ensure proper usage. These components serve as the interface through which the machine is turned on, adjusted, and monitored during its operation.

When examining the power switch, it is important to focus on the following aspects:

- Durability: The switch should be robust and able to withstand frequent use. Poor-quality switches can wear out quickly, causing intermittent operation or complete failure.

- Ease of use: The switch design should be intuitive, allowing users to turn the device on and off without difficulty. Some designs include illuminated indicators to show the active status.

- Location: The positioning of the power switch should be convenient and easily accessible. Ideally, it should be within reach of the user’s natural hand movements, avoiding awkward adjustments.

Next, consider the control mechanisms that allow for the adjustment of settings, such as speed or intensity:

- Functionality: The control knobs or buttons should provide smooth feedback, ensuring the user can make precise adjustments. A lack of responsiveness may indicate mechanical issues.

- Variety of settings: Advanced models typically offer multiple settings, allowing the user to choose between different modes for various tasks. Ensuring that each setting is clearly marked helps avoid confusion during operation.

- Reliability: Just like the power switch, the control system must remain functional after prolonged use. Any inconsistencies in operation may suggest faulty wiring or components.

In conclusion, evaluating the power switch and control system is a critical step in understanding the overall functionality and longevity of an appliance. Proper maintenance and awareness of these elements can prevent potential issues and improve the user experience significantly.

Cleaning and Maintaining the Grinder Parts

Proper maintenance is essential for ensuring the longevity and optimal performance of your equipment. Regular cleaning helps to prevent the buildup of residue and ensures that each component operates smoothly. Keeping the internal mechanisms clean not only improves the efficiency of the machine but also contributes to the quality of the output. Understanding how to maintain these essential elements is key to avoiding issues and prolonging the lifespan of your device.

Cleaning the Internal Mechanisms

The internal components of your equipment require routine cleaning to remove any leftover debris. Start by carefully disassembling the device according to the manufacturer’s guidelines. Use a soft brush to sweep away any remaining residue from the crevices and other hidden areas. For more stubborn dirt, a damp cloth may be used, but ensure that moisture does not come into contact with electrical parts. Regularly removing built-up particles will prevent clogging and ensure that your equipment remains in top condition.

Maintaining the External Housing

The exterior of your machine is just as important to maintain. Wipe down the surface with a clean, dry cloth to remove dust and dirt. Avoid using harsh chemicals or abrasive materials that could damage the finish. For deeper cleaning, a mild detergent solution can be applied, but always ensure that the unit is thoroughly dried before reassembling. Regular care of the outer casing not only keeps the machine looking clean but also protects against wear and tear.

Important note: Be sure to follow the specific guidelines provided for your equipment to avoid any damage during cleaning. Regular maintenance will help maintain the integrity of each component and improve the overall functionality of your device.

How the Dosing System Impacts Your Brew

The dosing mechanism plays a critical role in the overall quality of your coffee. It ensures that the correct amount of coffee grounds is dispensed, influencing the extraction process and, ultimately, the flavor profile. Precision in this area is essential for achieving consistency and optimal results with every cup.

When the dosing system is well-calibrated, it provides several benefits:

- Ensures uniformity in each shot, preventing under or over-extraction.

- Helps maintain a balanced brew ratio, which is essential for the right flavor balance.

- Minimizes waste, ensuring that you get the most out of your beans.

A dosing system that dispenses uneven portions can lead to:

- Inconsistent taste from one cup to another.

- Difficulty in fine-tuning the extraction process.

- Increased waste, as too much or too little coffee may be used.

Overall, the accuracy of this system has a direct impact on how well the coffee beans are extracted, which ultimately shapes the character and strength of your drink. Fine-tuning the dosing system allows for greater control, letting you achieve the perfect balance for your personal taste.

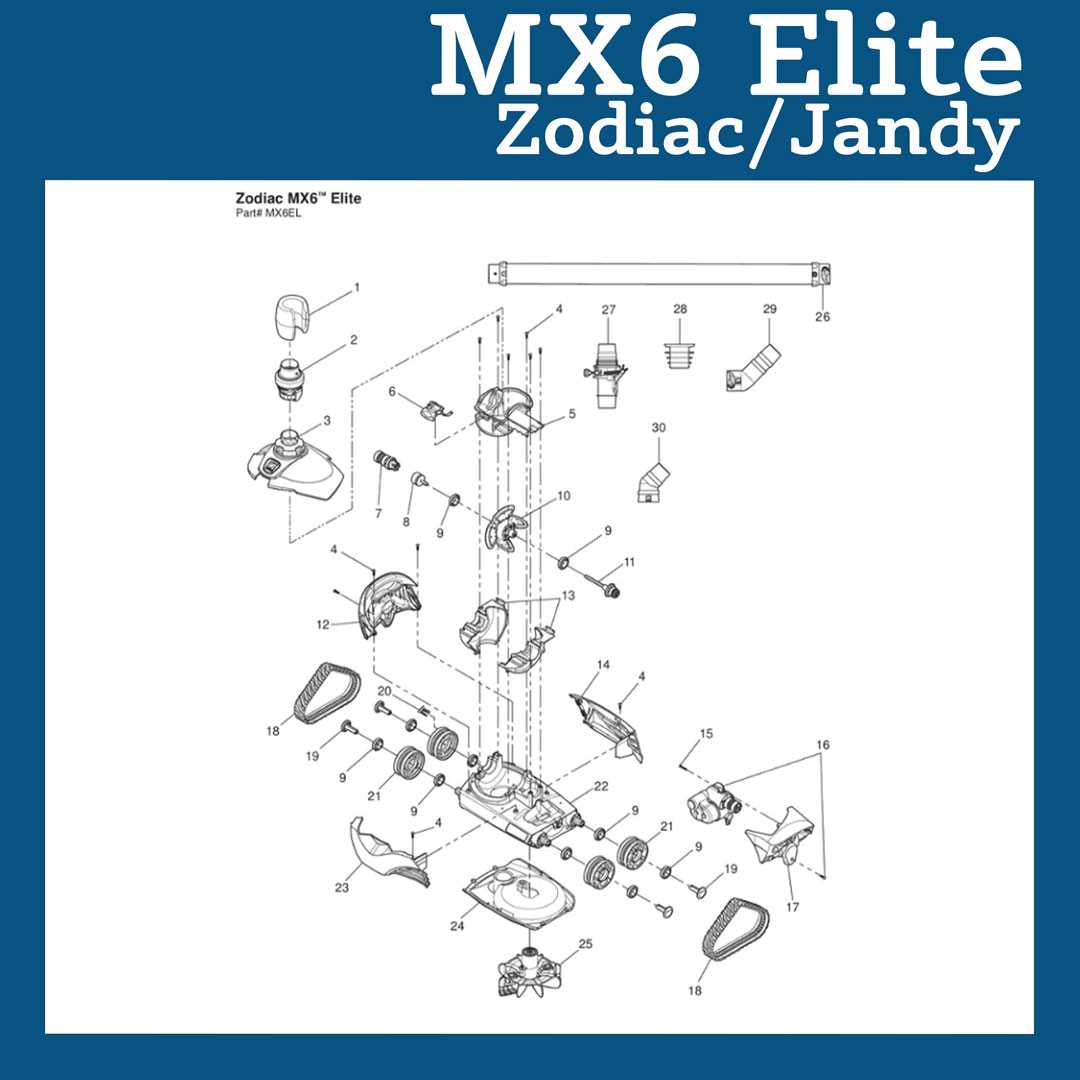

Troubleshooting Tips for Your Coffee Milling Machine

When your coffee mill starts malfunctioning, it can be frustrating. Understanding the common issues and knowing how to troubleshoot can help restore your device to optimal performance. This guide covers the most frequent problems and practical solutions to ensure your coffee preparation experience remains smooth and enjoyable.

It’s important to regularly maintain your equipment and address issues early to avoid more significant repairs. The following troubleshooting tips should help resolve minor malfunctions and get your device back on track.

| Issue | Possible Cause | Solution |

|---|---|---|

| Unusual noise | Debris or foreign object inside the machine | Turn off the machine, unplug it, and check the grinding chamber for any obstructive items. Clean it thoroughly. |

| Inconsistent grinding | Worn-out burrs or insufficient cleaning | Replace the worn burrs and perform a deep clean of all internal components. Regular maintenance is key. |

| Machine does not turn on | Electrical issue or power supply interruption | Check the power cord, ensure the outlet is working, and inspect any fuses or circuit breakers. |

| Sluggish operation | Motor overheating or clogged mechanism | Allow the motor to cool down. If clogging is suspected, carefully disassemble and clean the affected parts. |

Upgrading Breville Grinder Parts for Better Performance

Enhancing the key components of your coffee equipment can lead to significant improvements in its overall efficiency and output quality. By replacing outdated or low-quality elements with high-performance alternatives, you can optimize the functionality and longevity of your appliance. This process not only elevates the user experience but also allows for more precise control over grinding consistency and speed.

Improving the Burr Set is one of the most effective upgrades. Upgrading to a higher-grade burr set ensures more even and consistent grounds, which directly impacts the flavor and aroma of your coffee. Whether you’re looking for ceramic or stainless steel burrs, each type has its unique advantages in terms of heat retention and durability.

Enhancing the Motor System can also make a remarkable difference. A more robust motor reduces the time it takes to process coffee beans, which can prevent overheating and maintain optimal extraction temperatures. This upgrade is crucial for those who value precision and consistency in their daily brewing routine.

Lastly, upgrading the housing or internal components like springs and gears can result in smoother operation and fewer maintenance needs. These seemingly small adjustments contribute to a more enjoyable and hassle-free coffee-making process.

Identifying Common Wear and Tear Issues

Over time, certain components in coffee preparation machines can experience wear due to frequent usage. Recognizing the signs of deterioration early can help extend the lifespan of the appliance and improve its performance. Regular inspection is essential to avoid larger, more expensive issues down the line.

The most common signs of wear include:

- Decreased Efficiency: If your machine takes longer than usual to process or produces inconsistent results, it could be a sign that key elements are worn.

- Unusual Noises: Grinding or processing noises that differ from the usual operational sounds may indicate misalignment or worn-out mechanisms.

- Clogging or Jamming: Blockages during use can occur when internal components are no longer functioning properly, leading to a buildup of residue.

- Irregular Output: A decrease in the quality or consistency of the output could be due to worn-down internal systems that affect the final result.

Addressing these issues early by performing routine maintenance and replacing faulty components can prevent further damage and maintain optimal function.