For enthusiasts of textile creation, a thorough grasp of a sewing machine’s inner workings is essential. Each element plays a crucial role in ensuring smooth operation and achieving the desired results in various projects.

Identifying these individual parts can significantly enhance your ability to troubleshoot issues, perform maintenance, and make informed upgrades. By gaining insights into the layout and functionality, users can better appreciate the engineering behind these intricate devices.

In this section, we will explore the intricate arrangement of components, providing clarity on their functions and importance. This knowledge not only empowers you in everyday use but also enriches your overall experience with textile crafting.

Understanding Brother XL-5130 Components

Gaining insight into the various elements of a sewing machine enhances user experience and maintenance. Each component plays a critical role in the overall functionality, making it essential for users to familiarize themselves with these parts.

Main Components

- Needle

- Presser foot

- Feed dogs

- Bobbin case

- Thread tension dial

Importance of Each Element

- Needle: Crucial for creating stitches.

- Presser foot: Controls fabric movement.

- Feed dogs: Assists in advancing the material.

- Bobbin case: Holds the lower thread.

- Thread tension dial: Regulates thread tightness.

Understanding these components will ultimately lead to improved sewing efficiency and better outcomes.

Overview of Sewing Machine Parts

Sewing machines are intricate devices composed of various components that work harmoniously to create stitches and perform a multitude of tasks. Understanding these elements is essential for both novice and experienced users, as it enhances the overall sewing experience and maintenance. Each segment serves a distinct purpose, contributing to the machine’s functionality and efficiency.

The main components include the needle, which pierces the fabric to form stitches, and the bobbin, responsible for providing the lower thread. The feed dogs play a critical role by moving the fabric through the machine, while the presser foot holds the material in place during stitching. Additionally, the tension mechanism ensures that threads are pulled evenly, preventing puckering and uneven stitches.

Other important parts include the motor, which powers the machine, and the stitch selector, allowing users to choose from various stitch types. Regular familiarity with these elements not only aids in troubleshooting but also facilitates effective adjustments for different sewing projects. By recognizing each component’s function, users can achieve greater precision and creativity in their work.

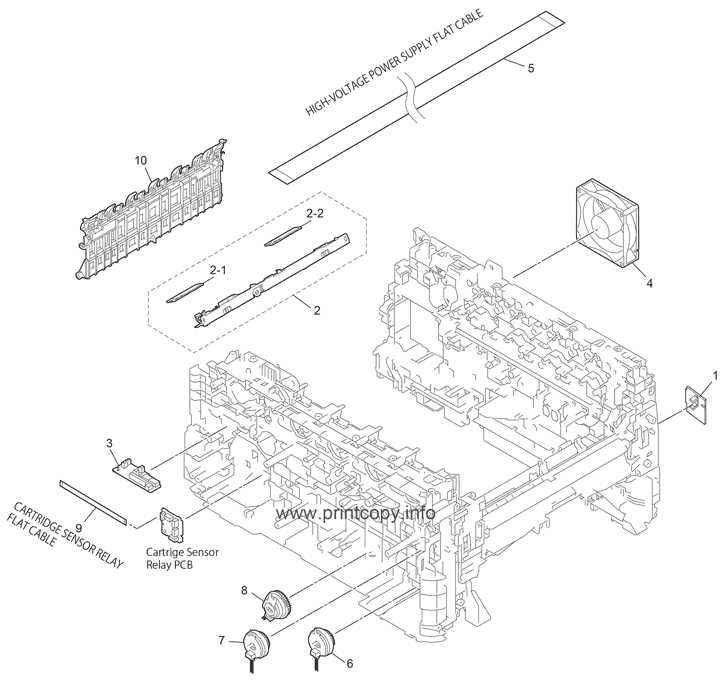

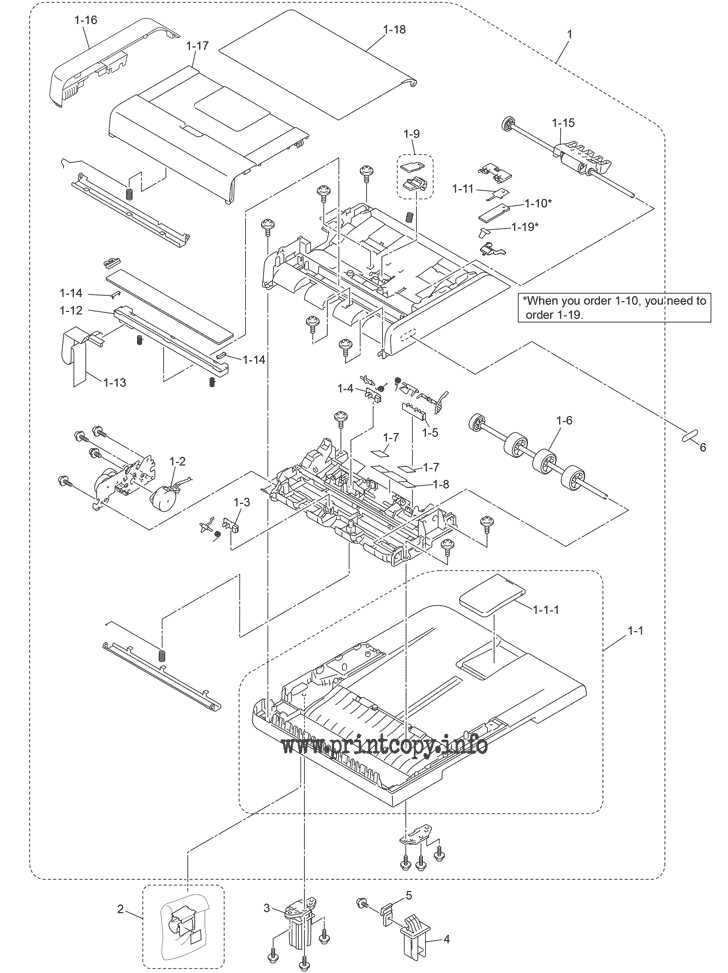

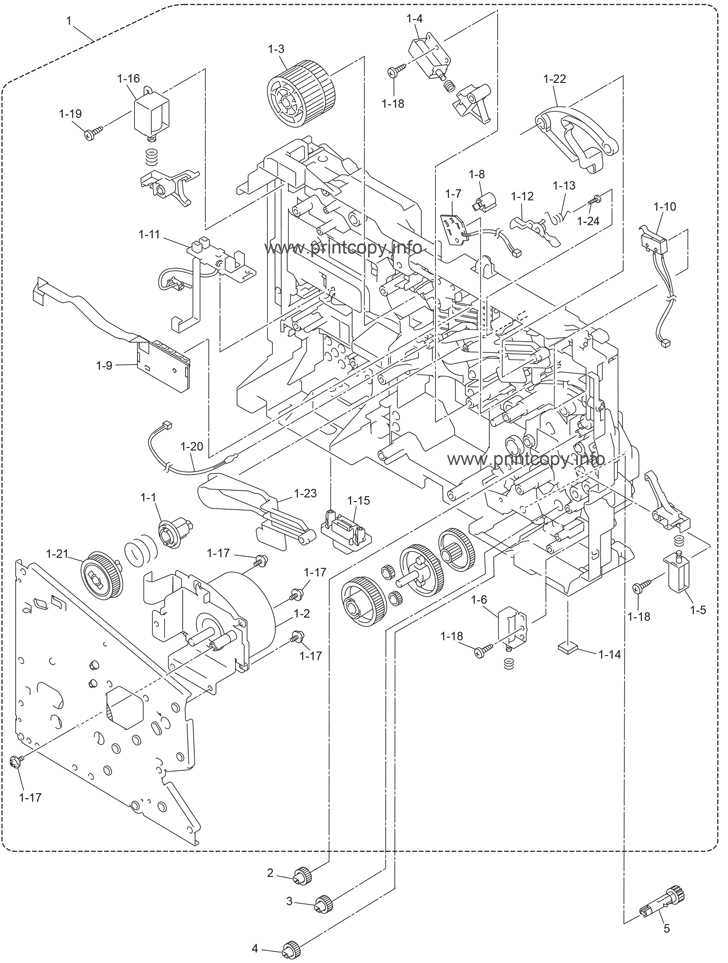

Identifying Key Diagrams for XL-5130

Understanding the essential illustrations related to your device can greatly enhance maintenance and troubleshooting efforts. These visual representations provide a clear view of the components, their arrangement, and connections, facilitating more efficient repairs and replacements. Knowing how to navigate these resources is crucial for optimal operation and longevity.

Components Overview

Key elements in any machine are its individual parts and their relationships. Familiarizing yourself with these features allows for quicker diagnostics and repairs. Below is a summary of critical sections you might encounter in the accompanying visuals:

| Component | Description |

|---|---|

| Motor | Drives the main functions of the device, ensuring proper operation. |

| Feed Mechanism | Controls the movement of materials through the system. |

| Control Panel | Interface for user commands and settings adjustments. |

| Frame | Structural support for all internal components. |

Navigating Visuals Effectively

When consulting these illustrations, focus on key indicators that highlight the layout and functionality of each part. Cross-referencing these visuals with your device’s manual can clarify any uncertainties and ensure you are addressing the correct areas during maintenance.

Common Replacement Parts for Brother XL-5130

When maintaining sewing machines, it’s essential to know the most frequently replaced components. Understanding these elements can enhance performance and prolong the lifespan of your device.

Key Components

- Needles

- Bobbin cases

- Foot pedals

- Belts

Maintenance Tips

- Regularly check and replace needles to ensure smooth operation.

- Keep the bobbin area clean to avoid jams.

- Inspect belts for wear and replace them as needed.

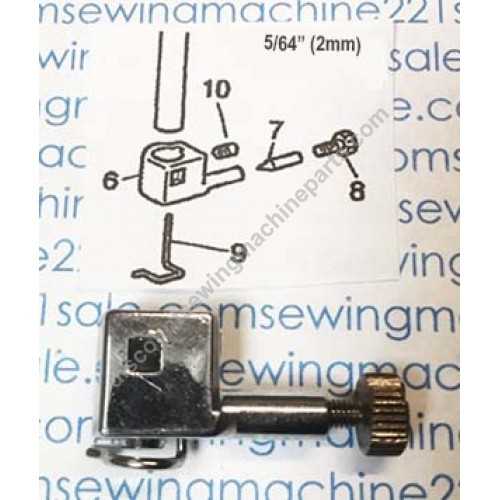

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair devices. These visual guides provide a detailed breakdown of components, helping users identify and locate specific elements within a system.

Familiarize Yourself with Symbols

Each illustration typically uses unique symbols to represent various elements. Recognizing these icons is crucial, as it allows for easier navigation and comprehension of the entire assembly.

Follow the Numbering System

Components are often numbered sequentially, which helps in understanding their relationship to one another. Pay attention to these numbers, as they guide you through the assembly process, ensuring you replace or repair parts correctly.

Maintenance Tips for XL-5130 Components

Ensuring the longevity and optimal performance of your device requires regular upkeep of its essential elements. Proper care not only enhances efficiency but also prevents potential issues that may arise from neglect. Below are some practical suggestions for maintaining the various components effectively.

Cleaning and Dusting

Regular cleaning is vital for maintaining functionality. Dust and debris can accumulate in critical areas, leading to malfunctions. Use a soft, dry cloth to wipe down surfaces and avoid using abrasive materials that could scratch or damage components. Additionally, consider using compressed air to blow out dust from hard-to-reach areas.

Lubrication and Replacement

Some elements require periodic lubrication to function smoothly. Check the manufacturer’s recommendations for suitable lubricants and application frequency. If you notice any parts showing signs of wear or damage, it’s essential to replace them promptly to avoid further complications. Investing in quality replacements can significantly extend the lifespan of your device.

By following these guidelines, you can ensure that your equipment operates at its best, providing reliable performance for years to come.

Where to Find Genuine Parts

When seeking authentic components for your device, it’s crucial to ensure you’re obtaining items that meet high standards of quality and compatibility. This ensures optimal performance and longevity, providing peace of mind in your maintenance efforts.

Authorized Retailers

One of the most reliable sources for genuine components is through authorized retailers. These vendors typically stock original items and are recognized by manufacturers, assuring their legitimacy.

Online Marketplaces

Numerous online platforms also offer authentic parts. It’s advisable to check seller ratings and reviews to avoid counterfeit options.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Retailers | High reliability | Potentially higher prices |

| Online Marketplaces | Wide selection | Risk of counterfeits |

Troubleshooting Issues with Parts Diagrams

Understanding the various components of a device is crucial for effective maintenance and repair. When discrepancies arise during this process, it can be frustrating. Identifying and resolving issues related to schematics can significantly improve your efficiency and outcomes.

Here are some common challenges you might encounter:

- Missing Components: Sometimes, the visual representation may omit essential elements. Verify against multiple sources if possible.

- Incorrect Labels: Labels may not match the actual components. Cross-reference with the device’s specifications for accuracy.

- Obscured Details: In some instances, illustrations may be unclear. Utilizing magnification tools can help clarify fine details.

- Version Discrepancies: Different models may have variations. Always ensure you are referencing the correct version of the schematic.

To effectively troubleshoot these issues, consider the following steps:

- Gather all relevant documentation, including manuals and technical bulletins.

- Cross-reference any unfamiliar components with online resources or forums.

- Consult with experienced technicians or customer support for clarification.

- Document your findings for future reference to streamline the process.

By systematically addressing these challenges, you can enhance your understanding and improve your ability to maintain and repair your equipment successfully.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance performance, longevity, and reliability. These components are designed specifically for compatibility with your equipment, ensuring optimal functionality and reducing the likelihood of issues down the line.

Quality Assurance

One of the primary benefits of OEM components is their guaranteed quality. These parts undergo rigorous testing and adhere to strict manufacturing standards.

- Consistent performance

- Higher durability

- Reduced risk of malfunctions

Warranty Protection

Choosing original parts often means better warranty coverage. Many manufacturers provide extended warranties for products using OEM components, offering peace of mind for the user.

- Increased resale value

- Enhanced support from the manufacturer

- Protection against future repairs

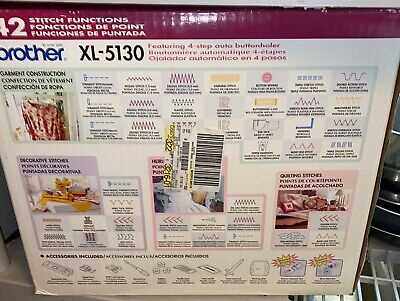

Comparison of XL-5130 with Other Models

This section explores how one specific model stacks up against its counterparts in terms of functionality, features, and user experience. By analyzing various aspects, we can identify strengths and weaknesses that may influence a buyer’s decision.

Performance and Features

When assessing performance, it’s crucial to consider speed, precision, and available functionalities. Some models excel in speed, making them ideal for high-volume tasks, while others focus on intricate designs and superior detail. Users may prioritize specific features like wireless connectivity or specialized stitching options based on their unique needs.

User Experience and Reliability

User experience often hinges on factors such as ease of use and maintenance. Certain models offer intuitive interfaces, making them more accessible for beginners, while others may require a steeper learning curve. Reliability is also a key component, as consistent performance over time is essential for both casual users and professionals alike.

Resources for Further Learning

Enhancing your understanding of machine components and their functions can greatly improve your maintenance skills and troubleshooting abilities. There are numerous resources available that can provide valuable insights, from manuals to online communities, each offering a unique perspective on equipment management.

Manuals and Guides: Look for user manuals and repair guides specific to your equipment. These documents often include detailed information about assembly, disassembly, and common issues, making them indispensable for both beginners and seasoned users.

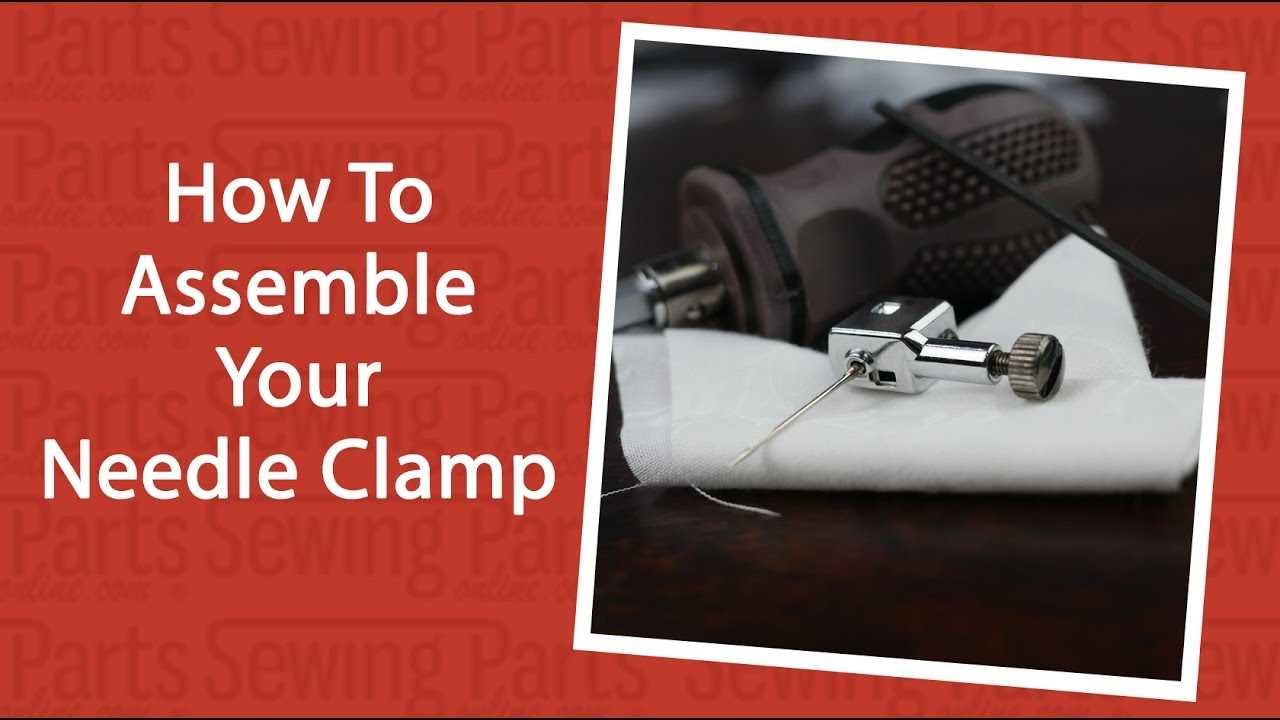

Online Tutorials: Video platforms host countless tutorials that visually demonstrate various repair and maintenance techniques. These can be particularly helpful for visual learners who benefit from seeing processes in action.

Forums and Communities: Engaging with online forums and social media groups dedicated to machinery enthusiasts can provide practical advice and shared experiences. Members often share tips, tricks, and solutions to common challenges, fostering a collaborative learning environment.

Workshops and Webinars: Participating in hands-on workshops or online webinars can deepen your understanding through direct interaction with experts. These sessions often cover advanced topics and provide opportunities to ask questions in real time.

Technical Journals: Subscribing to technical journals or magazines can keep you updated on the latest innovations and research in equipment design and maintenance. This knowledge can enhance your expertise and inform your practices.