The efficiency and reliability of any heating unit are heavily reliant on its internal elements. Each component plays a vital role in the overall functionality, working harmoniously to deliver optimal performance. A thorough comprehension of these components can significantly enhance maintenance and troubleshooting efforts.

When examining the structure of a heating device, it is essential to familiarize oneself with the various segments and their specific roles. From ignition mechanisms to control systems, each piece contributes to the system’s operation. Gaining insight into these elements allows for better-informed decisions regarding repairs and replacements.

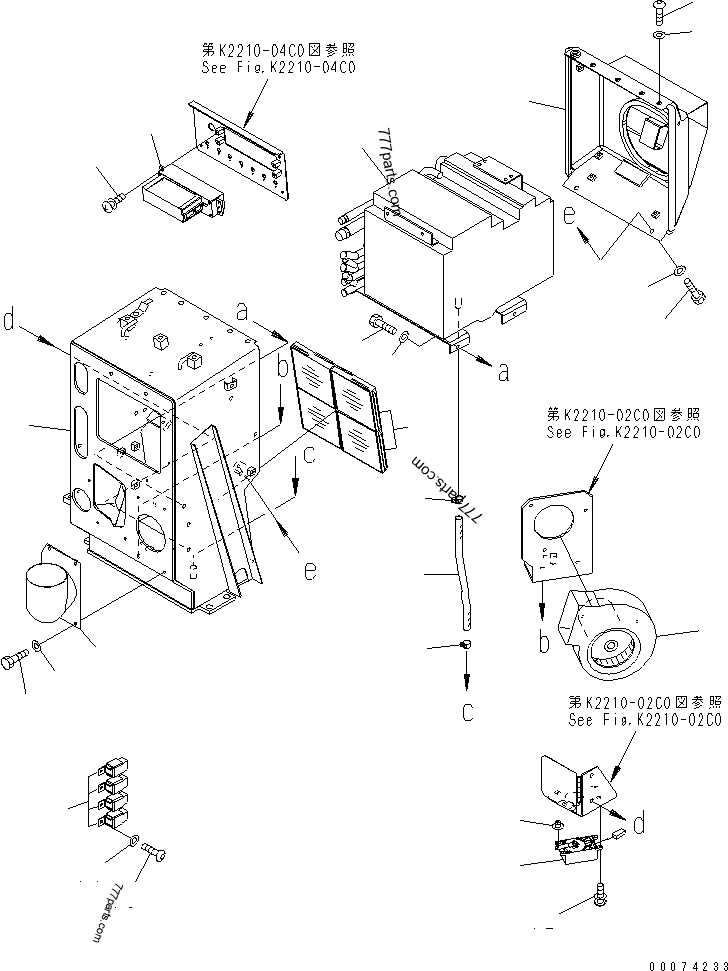

Furthermore, visual aids can be invaluable in this exploration, providing a clear representation of how each segment interacts within the overall framework. This understanding not only facilitates effective servicing but also promotes a deeper appreciation for the technology involved in modern heating solutions.

Understanding Furnace Components

Heating systems consist of various essential elements that work together to maintain a comfortable environment. Each component plays a vital role in the overall functionality, ensuring efficiency and reliability. A thorough understanding of these elements can aid in troubleshooting and maintenance.

| Component | Function |

|---|---|

| Heat Exchanger | Transfers heat from combustion gases to the air circulated in the living space. |

| Blower Motor | Moves air through the system, ensuring even distribution of warmth. |

| Thermostat | Monitors and regulates the temperature by controlling the operation of the heating unit. |

| Ignition System | Initiates combustion, providing the necessary heat for operation. |

| Flue | Ventilates exhaust gases safely outside the building. |

| Filters | Removes impurities from the air before it is circulated, improving indoor air quality. |

Essential Parts of Bryant Systems

Understanding the key components of heating systems is crucial for maintaining efficiency and ensuring optimal performance. Each element plays a vital role in the overall functionality, working together seamlessly to provide comfort and reliability in residential spaces.

| Component | Description |

|---|---|

| Heat Exchanger | Facilitates the transfer of heat from the combustion process to the air circulated throughout the space. |

| Blower Motor | Powers the fan that distributes warm air through the ducts into living areas. |

| Thermostat | Regulates temperature by monitoring the environment and controlling the heating cycle. |

| Flame Sensor | Detects the presence of a flame to ensure safe operation and prevent gas leaks. |

| Control Board | Acts as the brain of the system, coordinating the operation of various components for optimal efficiency. |

Each of these elements contributes to the reliable functioning of the heating mechanism, ensuring that it meets the demands of homeowners while maintaining safety and energy efficiency.

How a Furnace Operates

The functioning of a heating system is a fascinating process that transforms energy into warmth, creating a comfortable environment indoors. Understanding its operation can help homeowners appreciate the complexity and efficiency of these systems.

Key Components

- Heat Exchanger

- Blower Motor

- Thermostat

- Burner Assembly

Operating Cycle

- The thermostat detects the ambient temperature and signals the system to activate.

- The burner ignites, producing heat through combustion.

- Warm air is circulated by the blower motor through the heat exchanger.

- Finally, the heated air is distributed throughout the space via ducts.

Importance of Regular Maintenance

Consistent upkeep of heating systems is essential for ensuring optimal performance and longevity. Neglecting routine checks can lead to inefficiencies, increased energy costs, and unexpected breakdowns. By prioritizing maintenance, homeowners can secure a comfortable living environment while extending the life of their heating equipment.

Benefits of Regular Upkeep

Routine inspections allow for the early detection of potential issues before they escalate into major problems. Regularly servicing equipment not only enhances efficiency but also improves safety by reducing the risk of hazardous situations, such as carbon monoxide leaks. Additionally, a well-maintained system operates more quietly, contributing to a more pleasant atmosphere.

Cost-Effectiveness

Investing time and resources in consistent maintenance can lead to significant savings over time. Efficient operation means lower utility bills and fewer repairs, ultimately resulting in a reduced total cost of ownership. By treating upkeep as a proactive measure, homeowners can avoid the financial strain of emergency repairs and replacements.

Common Issues and Troubleshooting

Understanding frequent malfunctions can significantly enhance the efficiency of heating systems. Identifying these issues promptly can prevent further complications and ensure optimal performance.

Typical Problems

- No heat production

- Unusual noises during operation

- Inconsistent temperature regulation

- Frequent cycling on and off

Troubleshooting Steps

- Check the thermostat settings and ensure they are correct.

- Inspect the power supply and confirm the unit is receiving electricity.

- Examine filters for dirt buildup; clean or replace if necessary.

- Inspect the blower for obstructions or damage.

- Review error codes, if applicable, and refer to the manual for guidance.

Regular maintenance can help mitigate these issues, prolonging the lifespan of the equipment and maintaining a comfortable environment.

Replacement Parts and Compatibility

When maintaining a heating system, understanding the options for components is essential for ensuring optimal performance. Compatibility among various elements can significantly affect the efficiency and longevity of the unit. Selecting appropriate alternatives not only helps in seamless functioning but also minimizes the risk of future issues.

Common Component Types

- Heat Exchangers

- Blowers

- Control Boards

- Igniters

Factors Influencing Compatibility

- Model Specifications

- Manufacturer Recommendations

- Performance Ratings

- Installation Requirements

Ensuring that replacements align with the specifications of the existing setup will enhance functionality. Always consult with professionals or manuals to confirm that selected components will integrate effectively with your current system.

Wiring Diagrams for Bryant Furnaces

Understanding the electrical schematics of heating systems is essential for efficient troubleshooting and maintenance. These visual representations provide insight into the connections and functionality of various components, ensuring that the system operates smoothly and safely.

When examining the wiring layouts, you’ll find that each element is crucial for proper operation. The transformer, thermostat, and blower motor are interconnected, facilitating the flow of electricity necessary for heating. Additionally, these illustrations highlight the importance of following manufacturer specifications to avoid malfunctions.

It’s important to consult these visuals when performing repairs or upgrades. By referencing the appropriate schematics, technicians can accurately identify and resolve issues, thereby enhancing system performance. This attention to detail ensures that the heating equipment functions at its ultimate capacity, providing optimal comfort.

Safety Features in Heating Units

Ensuring the safety of heating systems is paramount for both efficiency and protection. Various mechanisms are integrated into these units to prevent hazards and enhance user confidence. Understanding these features helps in recognizing their importance in daily operations.

Key Safety Mechanisms

- Thermal Limit Switches: These devices monitor temperature levels, shutting down the system if overheating occurs.

- Flame Sensors: Responsible for detecting the presence of a flame, they prevent gas leaks by shutting off the fuel supply if no flame is detected.

- Pressure Switches: These ensure safe operation by monitoring the airflow and pressure within the unit, preventing operation under unsafe conditions.

Additional Safety Considerations

- Regular Maintenance: Periodic inspections and servicing help identify potential issues before they become critical.

- Ventilation: Proper airflow is essential to avoid harmful gas accumulation, making effective ventilation systems vital.

- Emergency Shut-off: Units should be equipped with accessible emergency shut-off controls for immediate action in case of a malfunction.

Energy Efficiency and Performance

Maximizing the effectiveness of heating systems is crucial for both environmental sustainability and cost savings. High-efficiency units utilize advanced technology to minimize energy consumption while ensuring optimal temperature regulation. By leveraging innovative components, these systems achieve significant reductions in fuel usage, resulting in lower utility bills and a smaller carbon footprint.

Performance metrics are essential in evaluating system reliability and responsiveness. Factors such as heat output consistency, operational noise levels, and responsiveness to temperature changes play vital roles in user satisfaction. Enhanced design and quality materials contribute to the longevity and resilience of these systems, providing peace of mind for homeowners.

Regular maintenance is imperative to sustain efficiency and performance over time. Inspections and timely repairs not only preserve the system’s functionality but also ensure it operates at peak efficiency. This proactive approach can lead to improved energy savings and a more comfortable living environment.

Identifying Component Failures

Recognizing the signs of malfunctioning elements in heating systems is crucial for maintaining optimal performance and safety. Understanding the typical indicators of failure can help in timely diagnostics and repairs.

- Unusual Noises: Listen for rattling, buzzing, or humming sounds that may suggest loose or damaged components.

- Inconsistent Heating: Noticeable fluctuations in temperature can indicate a malfunctioning element that fails to operate effectively.

- Frequent Cycling: If the system turns on and off more frequently than normal, it may be a sign of an issue with control elements.

When troubleshooting, it is essential to observe the following:

- Check electrical connections for signs of wear or corrosion.

- Inspect mechanical components for signs of wear or breakage.

- Examine any sensors for proper operation and accuracy.

By staying vigilant and conducting regular checks, potential problems can be identified early, preventing costly repairs and ensuring reliable operation.

Guidelines for DIY Repairs

When tackling home repairs, understanding the components and their functions is crucial for effective troubleshooting. By following some practical steps, you can enhance your skills and approach maintenance tasks with confidence.

Preparation Steps

Before initiating any repair work, ensure you have the necessary tools and safety equipment. Familiarize yourself with the system’s layout and check for common issues. Create a checklist of the components you plan to inspect or replace.

Common Issues and Solutions

| Issue | Potential Solution |

|---|---|

| Inconsistent temperature | Inspect the thermostat and check for any blockages in airflow. |

| Unusual noises | Examine the motor and belts for wear and tear, and tighten loose components. |

| Frequent shutdowns | Check the safety switches and clean or replace filters as needed. |

Resources for Further Information

When seeking to enhance your understanding of components related to heating systems, various sources can provide valuable insights and guidance. These resources range from manuals to online forums, ensuring you have access to a wealth of knowledge that can assist in maintenance and troubleshooting.

Online Platforms

Websites dedicated to HVAC systems often feature detailed articles, community discussions, and expert advice. Engaging with these platforms can help you gather practical tips and solutions from seasoned professionals.

Books and Manuals

Investing in literature focused on heating technology can deepen your comprehension of various elements involved. Manuals, in particular, serve as practical guides for both installation and repair tasks.

| Resource Type | Examples |

|---|---|

| Online Forums | HVAC Talk, Reddit HVAC Community |

| Books | The Complete Guide to HVAC, Modern Refrigeration and Air Conditioning |

| Manufacturer Manuals | Service Manuals, Installation Guides |