Exploring the intricate assembly that supports movement and stability is essential for automotive enthusiasts and professionals alike. This system, integral to performance and safety, comprises various elements working in harmony to ensure a smooth ride.

Through a detailed examination of these crucial components, one can gain insights into their functionality and interconnections. Each element plays a significant role in enhancing the overall efficiency of motion, providing both support and flexibility.

By delving into the specifics, we can uncover the ultimate design principles that govern this mechanical marvel. Understanding these features not only aids in maintenance but also deepens appreciation for automotive engineering.

Understanding Car Axle Components

Grasping the essential elements that support vehicle movement is crucial for anyone interested in automotive mechanics. These components play a vital role in ensuring stability, control, and overall performance.

Key components include:

- Housing: This encases the assembly and provides protection for internal mechanisms.

- Shafts: These transmit rotational force from the engine to the wheels, facilitating motion.

- Bearings: Critical for reducing friction, these allow for smooth rotation and enhance durability.

- Joints: These flexible connections enable movement and accommodate changes in angles as the vehicle navigates.

- Differential: This allows for varying wheel speeds, crucial during turns and on uneven surfaces.

Each element works in concert, contributing to the vehicle’s ability to handle various driving conditions effectively. Understanding these components is essential for diagnosing issues and performing maintenance.

Function of the Car Axle

The fundamental role of this crucial component revolves around the transmission of power and the maintenance of vehicle stability. It serves as a vital link between the driving mechanism and the wheels, ensuring smooth motion and efficient handling.

Primarily, it bears the weight of the vehicle, supporting not just the structure but also the occupants and cargo. This support facilitates optimal traction with the ground, enhancing overall performance during various driving conditions.

Additionally, the component enables the wheels to rotate, allowing for directional control. By accommodating the differential motion of the wheels during turns, it contributes to a seamless driving experience. Furthermore, it plays a role in absorbing shocks from uneven surfaces, promoting comfort for passengers.

In essence, this element is indispensable for the harmonious operation of a vehicle, intertwining functionality with safety and driving pleasure.

Main Types of Axles Explained

The various types of supporting structures play a crucial role in the performance and stability of vehicles. Understanding these key components is essential for anyone looking to delve deeper into automotive mechanics and design.

Live Structures: These components actively transmit power to the wheels, contributing to both movement and stability. They are integral to the vehicle’s overall functionality, ensuring a seamless driving experience.

Dead Structures: Unlike their active counterparts, these elements do not transmit power. Instead, they provide support and maintain the vehicle’s alignment and balance, crucial for smooth operation on the road.

Front and Rear Configurations: Each configuration serves distinct purposes, with front structures typically responsible for steering and maneuverability, while rear structures focus on load-bearing and traction.

Single and Dual Structures: The choice between these configurations depends on the vehicle’s design and intended use. Dual structures offer enhanced stability and load capacity, making them ideal for heavier applications.

By exploring these varieties, one gains insight into the intricate balance of design and engineering that ensures optimal performance in diverse driving conditions.

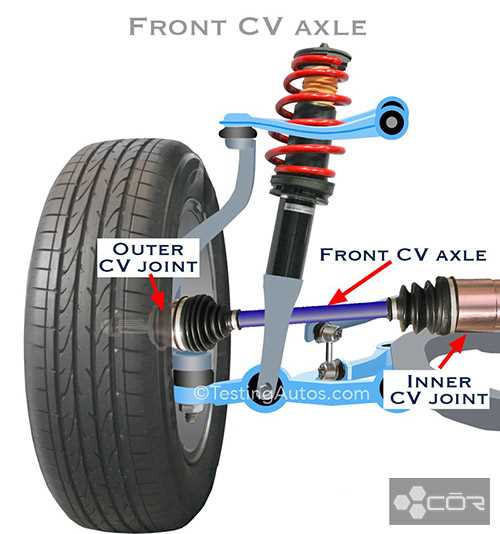

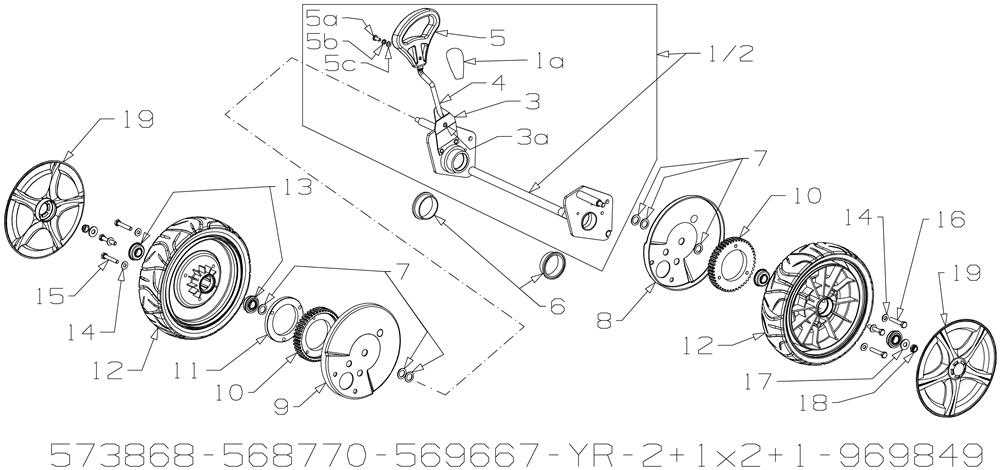

Parts of a Typical Axle Assembly

The assembly that connects the wheels to the chassis plays a crucial role in vehicle dynamics and stability. Understanding its components helps in grasping how vehicles function and maintain balance while in motion.

Key elements of this assembly include:

- Housing: The outer casing that provides structural integrity and houses internal components.

- Shaft: A central rod that transmits power from the engine to the wheels.

- Bearings: Circular elements that allow smooth rotation and reduce friction between moving parts.

- Seals: Components that prevent contamination and fluid leakage from the assembly.

- Support brackets: Structures that secure the assembly to the chassis and maintain alignment.

Each of these elements works together to ensure efficient performance, enhance safety, and provide a comfortable ride. Regular maintenance of these components is essential for optimal operation.

How to Identify Axle Issues

Recognizing problems with the vehicle’s undercarriage components is essential for maintaining optimal performance and safety. Various signs can indicate underlying issues, and timely detection can prevent further damage. Understanding these indicators is key to ensuring a smooth and reliable driving experience.

Common Symptoms of Trouble

Drivers should be vigilant about specific symptoms that may suggest complications. Here are some of the most frequent signs:

| Symptom | Possible Cause |

|---|---|

| Vibrations during driving | Worn bearings or misalignment |

| Unusual noises | Damaged components or loose fittings |

| Difficulty turning | Failure in supporting structures |

| Uneven tire wear | Improper alignment or imbalance |

Steps to Diagnose Issues

When symptoms arise, it is crucial to perform a thorough inspection. Start by examining for visible damage, checking for leaks, and listening for abnormal sounds while the vehicle is in motion. A professional assessment may be necessary for precise diagnosis and repair recommendations.

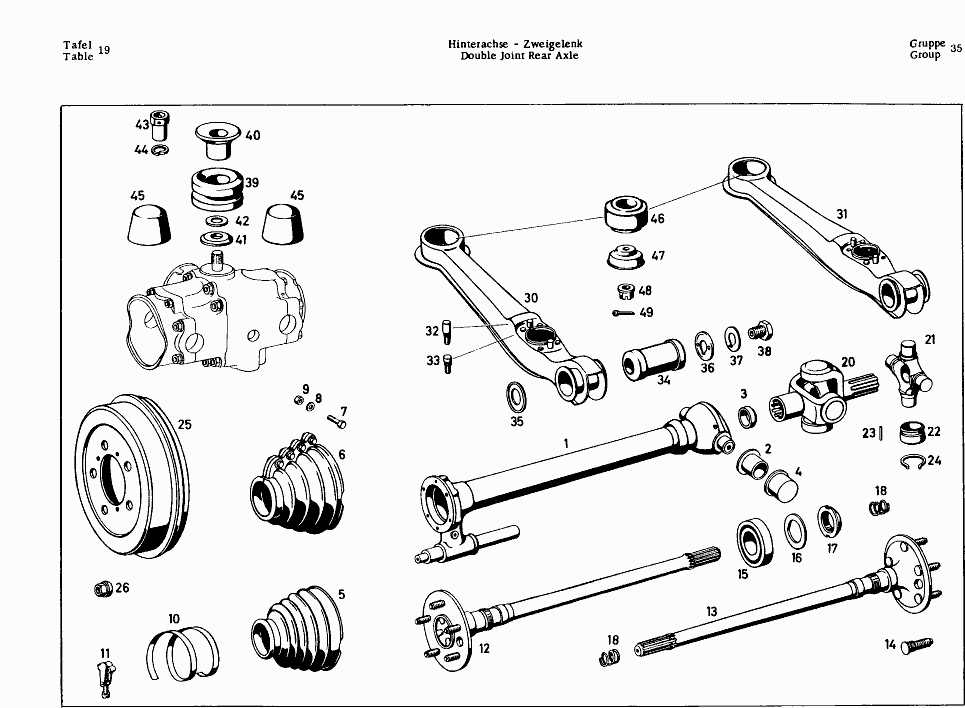

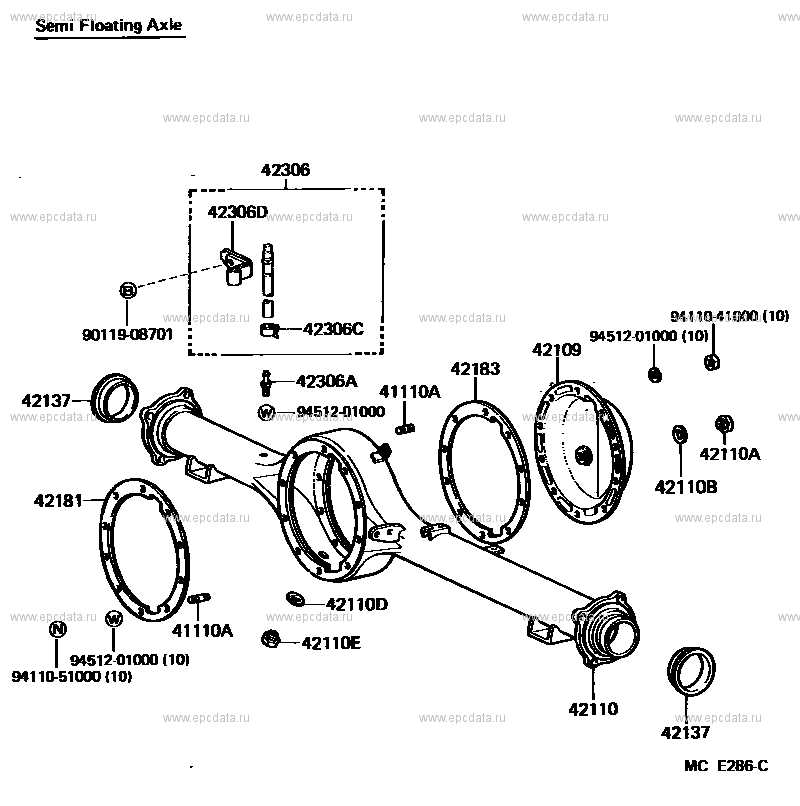

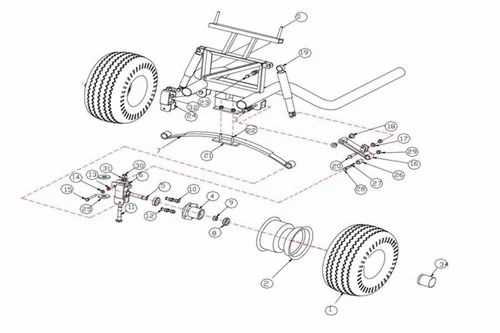

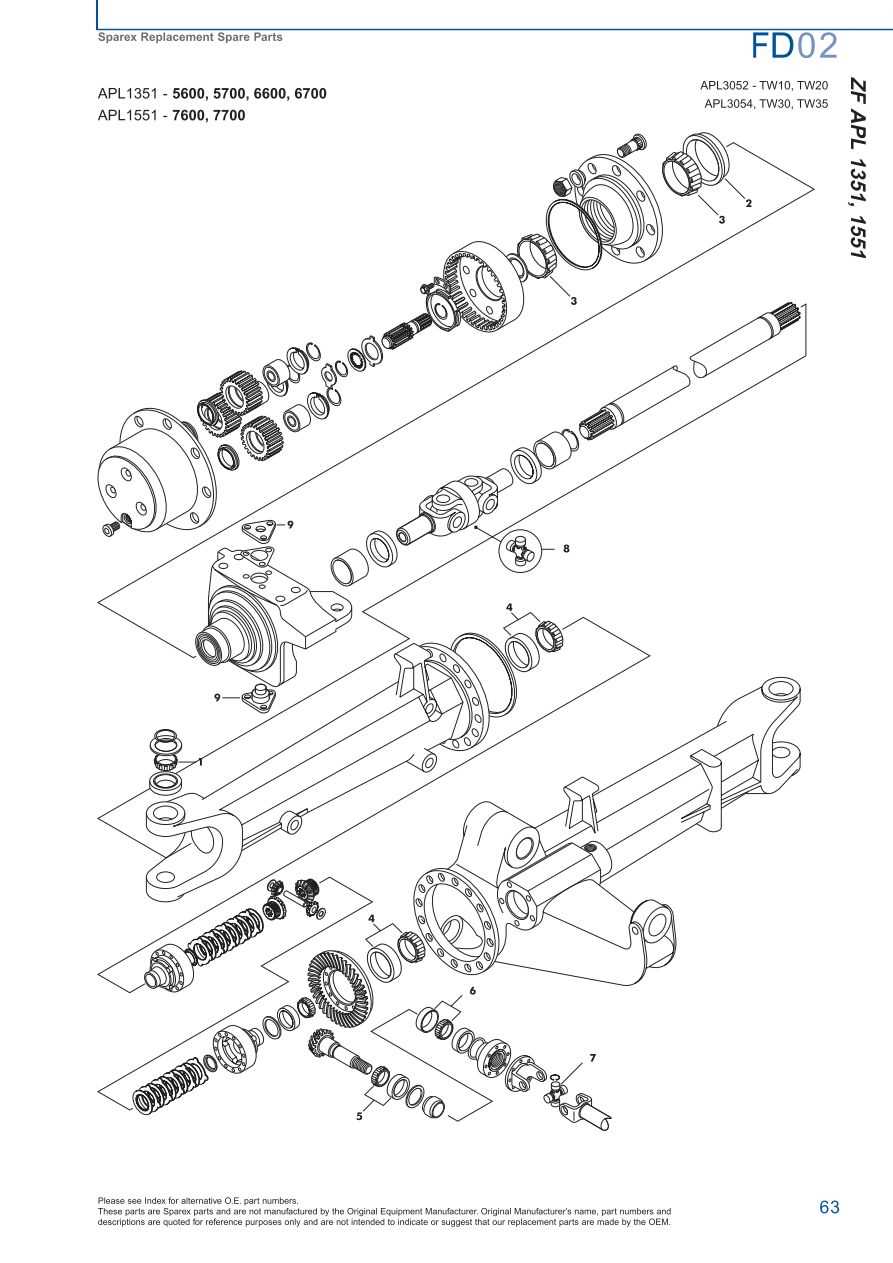

Diagram of a Rear Axle System

This section explores the intricate assembly that plays a crucial role in vehicle dynamics, enabling motion and stability. Understanding the components involved provides insight into their functions and relationships.

Key Components

- Differential

- Drive shafts

- Hub assemblies

- Brake systems

- Suspension links

Functionality Overview

- Transmits power from the engine to the wheels.

- Allows for smooth turns by managing wheel speed differences.

- Supports vehicle weight and absorbs shocks from the road.

- Enables braking and ensures stability during motion.

Understanding these elements is essential for grasping the overall mechanics involved in efficient vehicle operation.

Common Materials Used in Axles

When it comes to the construction of essential support structures in vehicles, the choice of materials plays a crucial role in ensuring durability and performance. Various substances are utilized to achieve the required strength and resilience while also considering weight and cost-effectiveness.

Key Materials

- Steel: Widely favored for its high strength-to-weight ratio, steel provides excellent durability and can withstand heavy loads.

- Aluminum: Known for being lightweight, aluminum is often used in performance applications where reducing weight is essential.

- Cast Iron: This material offers great resistance to wear and deformation, making it suitable for certain heavy-duty applications.

- Composite Materials: Increasingly popular, composites combine different substances to enhance strength and reduce weight, ideal for specialized vehicles.

Considerations in Material Selection

- Weight: Lighter materials can improve fuel efficiency and handling.

- Strength: The ability to bear loads without deformation is critical for safety and longevity.

- Cost: Budget constraints can influence the choice, balancing performance with affordability.

- Corrosion Resistance: Materials that resist environmental factors contribute to a longer lifespan.

Importance of Proper Axle Maintenance

Ensuring the longevity and performance of essential vehicle components is crucial for safe and efficient operation. Regular upkeep not only enhances functionality but also mitigates the risk of costly repairs and potential hazards on the road.

| Benefit | Description |

|---|---|

| Safety | Regular checks prevent failures that could lead to accidents. |

| Performance | Well-maintained components improve handling and ride quality. |

| Cost Efficiency | Preventive care reduces the likelihood of expensive repairs. |

| Longevity | Proper maintenance extends the lifespan of critical systems. |

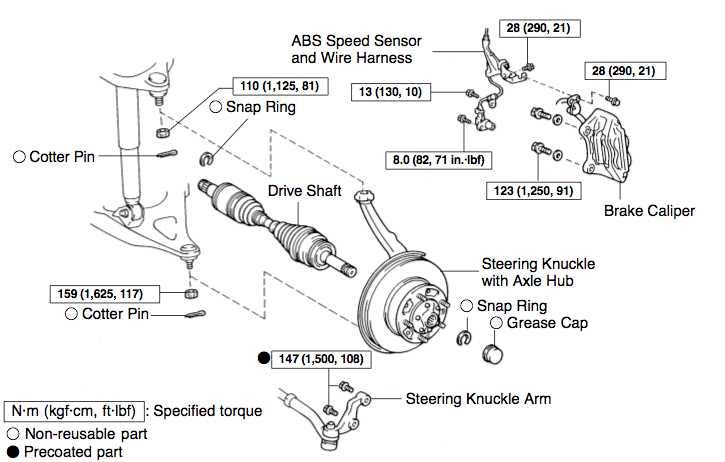

Differences Between Front and Rear Axles

Understanding the distinctions between the forward and rear components of a vehicle’s suspension system is crucial for both performance and safety. Each section is designed to handle specific functions and loads, influencing overall dynamics and handling.

| Feature | Front | Rear |

|---|---|---|

| Primary Function | Steering and control | Stability and support |

| Weight Distribution | Typically carries more load | Balances weight, often lighter |

| Components | Includes steering knuckles and suspension | Includes differential and drive components |

| Tire Wear | More prone to uneven wear | Usually more uniform wear |

| Maintenance | Often requires more frequent checks | Generally less intensive upkeep |

Role of the Differential in Axles

The differential is a crucial component that enables smooth and efficient operation of the drive mechanism in vehicles. Its primary function is to allow the wheels to rotate at different speeds, especially during turns, which enhances handling and stability. By distributing torque appropriately, it ensures that traction is maintained, contributing to overall performance and safety.

Functionality and Importance

This mechanism operates by using gears to accommodate variations in wheel speed. When navigating corners, the outer wheels travel a longer distance compared to the inner wheels. The differential compensates for this difference, preventing tire wear and improving maneuverability. In essence, it plays a vital role in adapting the power delivery to the conditions of the road.

Types of Differentials

Axle Bearings and Their Functions

Bearings play a crucial role in the smooth operation of vehicles, enabling efficient movement and stability. These components facilitate rotation while supporting loads, contributing to overall performance and safety.

Types of Bearings

- Ball Bearings: Commonly used for their ability to reduce friction.

- Roller Bearings: Suitable for handling heavier loads.

- Thrust Bearings: Designed to manage axial loads effectively.

Key Functions

- Reducing Friction: Essential for smooth rotation and enhanced efficiency.

- Load Distribution: Spreads weight evenly to prevent wear.

- Supporting Alignment: Maintains correct positioning of rotating elements.

Upgrading Your Vehicle’s Axle

Enhancing the fundamental components that connect the wheels to the main structure can significantly improve performance, stability, and overall driving experience. This process often involves selecting higher-quality materials and designs tailored to specific needs, whether for off-roading or daily driving.

Benefits of Upgrading

Investing in superior components can lead to better handling, increased durability, and improved power transfer. These enhancements allow for greater efficiency, resulting in a more responsive and enjoyable ride.

Key Considerations

When choosing upgrades, consider factors such as vehicle usage, weight distribution, and desired performance characteristics. Research various options and consult with professionals to ensure the ultimate fit for your vehicle.

Safety Considerations for Axle Repairs

When undertaking repairs on essential components of a vehicle’s drivetrain, it is crucial to prioritize safety. Proper precautions can prevent accidents and ensure a successful maintenance process. Familiarity with the necessary tools and techniques, alongside adherence to safety protocols, significantly reduces the risk of injury.

Personal Protective Equipment

Before beginning any repair work, ensure you are equipped with appropriate personal protective gear. This includes safety goggles to shield your eyes from debris, gloves to protect your hands, and steel-toed boots for foot protection. Wearing reflective clothing is also advisable when working in dim lighting conditions to enhance visibility.

Workspace Safety

Creating a safe working environment is essential. Keep the area clean and free of clutter to minimize the risk of trips and falls. Ensure that all tools are in good condition and properly stored when not in use. Additionally, utilize jack stands to support any lifted equipment, and never rely solely on a hydraulic jack. Understanding how to manage potential hazards is vital for a secure and efficient repair process.