When maintaining or repairing an air conditioning system, having a clear understanding of its internal structure is crucial. Knowing how each element works together ensures more efficient troubleshooting and repair. This knowledge helps users identify specific parts that may need attention and contributes to better system performance and longevity.

Detailed schematics and visual guides can be incredibly helpful in breaking down complex systems into understandable parts. These resources provide clear representations of how each component fits within the larger unit, offering insight into potential issues and the steps required to address them. A well-organized guide can also streamline the process of replacing or upgrading individual elements, making the entire operation smoother.

By familiarizing yourself with these technical illustrations, you can gain confidence in handling routine maintenance or addressing malfunctions. Properly interpreting the system’s design allows you to identify problem areas quickly and take action without unnecessary delays or confusion. Whether you’re a homeowner or a professional technician, understanding the internal workings of your cooling system is essential for effective management and upkeep.

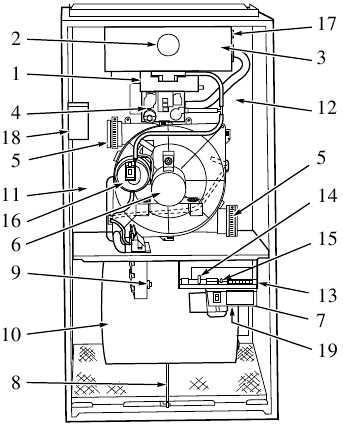

Overview of Carrier Weathermaker 9200 Parts

Understanding the components that make up a heating and cooling unit is essential for both maintenance and troubleshooting. Each system is designed with several key elements that work together to ensure optimal performance and energy efficiency. A deep knowledge of these individual parts can help in identifying issues, performing repairs, and extending the lifespan of the entire unit. The functionality of these systems largely depends on how well the parts interact with each other, ensuring smooth operation for years.

At the heart of these systems, you’ll find critical components such as the heat exchanger, which plays a crucial role in transferring heat, and the blower motor, which ensures that air is properly circulated. In addition, systems also feature safety mechanisms like pressure switches and flame sensors that provide protection against malfunctions, while other parts contribute to the energy efficiency and reliability of the unit. Knowing the location and purpose of each component can significantly improve repair and maintenance processes.

Moreover, understanding the layout of a system’s interior components allows users to identify potential wear and tear. Over time, certain parts may need to be replaced to maintain performance standards. Being familiar with how the components fit together and how they function individually is vital when addressing common issues, such as airflow restrictions or heating/cooling inconsistencies.

Understanding the Importance of Parts Diagrams

In any complex mechanical or electrical system, having a clear visual representation of its components is essential for efficient maintenance, repair, and assembly. Such representations help to identify and locate various elements, ensuring that technicians can work more accurately and quickly. A detailed visual guide not only saves time but also minimizes the risk of errors during troubleshooting or installation processes.

Why Visual References Matter

Visual guides serve as a crucial tool for both professionals and DIY enthusiasts. These references offer a schematic view of how individual components fit together, allowing users to:

- Quickly identify parts and their corresponding functions.

- Understand how elements interact within the system.

- Efficiently locate specific items for repair or replacement.

Enhanced Troubleshooting and Maintenance

When faced with system malfunctions, having access to a comprehensive visual reference can significantly streamline the diagnostic process. By clearly showing the location of each component and its relationship with others, these references enable technicians to quickly pinpoint faulty parts, reducing downtime and improving service efficiency. This organized approach ultimately leads to better overall system performance and longevity.

Key Components in the Weathermaker 9200

The system consists of various critical elements that ensure its efficient functioning. Each part plays a unique role in maintaining optimal performance and longevity. Understanding these components can help with troubleshooting and regular maintenance, ensuring that the unit operates smoothly throughout its lifecycle.

Below are some of the main elements that contribute to the overall efficiency and reliability of the system:

- Compressor: The compressor is responsible for pressurizing the refrigerant, which allows the system to regulate temperature and provide cooling. It is the heart of the entire mechanism, and its operation directly impacts energy consumption and performance.

- Evaporator Coil: This component absorbs heat from the air inside the building, ensuring that the air is cooled before being recirculated. The efficiency of the evaporator coil is crucial to maintaining optimal temperature control.

- Condenser Coil: The condenser coil expels heat absorbed by the refrigerant from the indoor air. It plays a vital role in the heat exchange process and helps in cooling the refrigerant before it circulates again.

- Expansion Valve: The expansion valve regulates the flow of refrigerant into the evaporator, ensuring that the right amount of refrigerant is allowed to enter the coil. This precise control helps in maintaining consistent cooling and energy efficiency.

- Blower Motor: The blower motor circulates air throughout the space, ensuring even cooling and heating distribution. It works in conjunction with the evaporator coil to maintain a comfortable indoor environment.

- Heat Exchanger: The heat exchanger transfers heat between the refrigerant and the air. It is designed to ensure that the system operates efficiently by reducing energy loss and maintaining consistent temperature levels.

- Thermostat: The thermostat controls the temperature settings of the unit. By adjusting the thermostat, users can manage both heating and cooling outputs, ensuring a comfortable indoor climate.

Maintaining these components in top condition is crucial for the longevity and efficiency of the system. Regular inspections and proper maintenance can help identify any issues early, preventing costly repairs and improving overall performance.

Common Issues with Heating and Cooling Units

When it comes to HVAC systems, certain malfunctions and inefficiencies are frequently encountered by homeowners and technicians. These problems can arise due to improper maintenance, wear and tear, or simple component failures. Understanding the most common issues can help in diagnosing problems and ensuring smooth operation of these vital systems.

1. Poor Airflow

One of the most common issues faced by HVAC units is reduced airflow. This can significantly affect the efficiency of the system, leading to uneven temperatures and increased energy consumption. Potential causes include:

- Clogged or dirty air filters

- Blocked ductwork

- Faulty blower motor

- Closed or obstructed vents

2. Inconsistent Temperature Control

Another frequent problem is difficulty in maintaining consistent temperatures throughout the space. Inconsistent heating or cooling could be the result of:

- Faulty thermostat

- Refrigerant leaks

- Malfunctioning sensors or controls

- Improperly sized unit for the space

Addressing these issues early on can prevent further damage and enhance the unit’s longevity and performance. Regular maintenance and prompt repairs are key to ensuring optimal functioning of your heating and cooling system.

How to Use the Parts Diagram Effectively

Understanding the layout of your system is crucial for maintenance and repairs. A visual representation of components allows users to identify specific elements easily, ensuring that troubleshooting and replacements can be executed with precision. Familiarizing yourself with these illustrations not only streamlines the repair process but also enhances your overall knowledge of the unit’s functionality.

Familiarize Yourself with Symbols and Labels

Before diving into the intricacies, take some time to get acquainted with the symbols and labels used in the illustration. Each icon represents a unique component, and knowing what they signify will prevent confusion during your tasks. Pay close attention to any accompanying notes or legends, as these can provide essential insights into the assembly and operation of the entire system.

Utilize the Visual Reference for Troubleshooting

When issues arise, refer back to the visual guide to pinpoint the area of concern. By cross-referencing the depicted elements with your observations, you can narrow down potential problems and devise effective solutions. Additionally, this reference can assist in verifying whether you have all necessary items before starting a repair, reducing downtime and enhancing efficiency.

Steps to Locate Replacement Parts

Finding the correct components for your system is crucial for ensuring optimal performance and longevity. The process involves identifying the right parts, understanding compatibility, and locating trusted sources for procurement. This guide will provide a step-by-step approach to help you efficiently locate the necessary items for your unit.

Step 1: Identify the Model and Specifications

Before searching for components, you must know the exact model and specifications of your system. This includes the manufacturer, unit type, and any specific features that may affect part compatibility. Refer to the unit’s identification plate or manual to gather the relevant details.

Step 2: Search Trusted Sources

Once you have the necessary details, use them to search reliable suppliers, both online and in physical stores. Manufacturer websites, authorized retailers, and certified repair shops are ideal starting points. Be sure to cross-check the part numbers and specifications to ensure they match your requirements.

Identifying Faulty Parts in Your Unit

Proper maintenance and timely identification of malfunctioning components are crucial to ensuring the smooth operation of your equipment. Recognizing early signs of failure can prevent more severe damage and costly repairs down the line. Understanding common indicators of wear and tear, as well as the typical symptoms of specific issues, helps to effectively diagnose the root cause of the problem.

When an appliance begins to show signs of irregular behavior, it’s important to consider a few key symptoms: unusual noises, poor performance, or inefficient energy consumption. These issues often point to specific areas within the system that are underperforming. For example, if the airflow is weak or inconsistent, it may suggest problems with the fan or air ducts. On the other hand, a decrease in temperature regulation could be a sign of a failing compressor or thermostat.

It is important to also observe the system’s overall functionality. An erratic system that frequently cycles on and off, or fails to maintain set conditions, might indicate issues with electrical components or wiring. Visual inspection of critical parts, such as capacitors, coils, and filters, can provide valuable insights into their condition. Any discoloration, damage, or accumulation of dirt and debris may require immediate attention.

Lastly, regular monitoring of performance trends, such as temperature fluctuations or increased energy usage, can signal the need for intervention. Being proactive in identifying these issues can help extend the lifespan of your unit while preventing unexpected breakdowns.

How the Diagram Helps in Troubleshooting

Having a clear visual reference of the system components is essential when diagnosing issues with any complex machinery. Such a reference not only provides a comprehensive overview of the entire setup but also makes it easier to identify malfunctioning parts. It serves as a guide to understanding how each element interacts within the system, which is vital for effective repairs.

Identifying Faulty Components

When faced with a malfunction, being able to quickly locate the malfunctioning part is crucial. A visual layout of the unit allows technicians to identify each element’s position and function. This makes pinpointing the exact location of the issue faster, especially when dealing with multiple interconnected parts. Knowing where to look first can significantly reduce downtime and troubleshooting time.

Understanding System Interactions

Complex systems often consist of numerous parts working together. A detailed schematic can clarify the relationships between these components, showing how one issue can affect others. By understanding these interactions, technicians can avoid unnecessary repairs, ensuring that the actual problem is addressed without disrupting the functioning of other elements.

Overall, such visual aids improve diagnostic accuracy, reduce the likelihood of errors, and help maintain system efficiency. This method of troubleshooting ensures that repairs are done properly and quickly, ultimately extending the lifespan of the equipment.

Ordering Genuine Carrier Parts Online

When it comes to maintaining or repairing your heating and cooling system, securing authentic components is crucial for ensuring optimal performance and longevity. Purchasing high-quality replacements from trusted online retailers provides an efficient and reliable way to get the necessary items directly to your doorstep. This method not only saves time but also guarantees that the components you receive are specifically designed for compatibility with your unit.

Why Choose Authentic Components?

Using original equipment ensures that the system continues to operate at peak efficiency, reducing the risk of malfunction or breakdown. Genuine replacements are engineered to fit seamlessly, offering superior durability and performance compared to aftermarket options. Additionally, they often come with warranties that protect your investment over the long term.

How to Order Components Online

Ordering parts online is straightforward, but it’s important to follow a few key steps to ensure a smooth process. Make sure to have your system’s model and serial number ready, as these details will help you find the right items faster. Many authorized online platforms provide tools to search for specific components by entering this information, simplifying the process for users.

| Step | Action |

|---|---|

| 1 | Identify the part needed by checking your unit’s model and serial number. |

| 2 | Visit an authorized online retailer or the manufacturer’s official website. |

| 3 | Search for the specific component using the model and serial number for precise results. |

| 4 | Add the correct part to your cart and proceed with secure checkout. |

| 5 | Track your order and receive it at your location for installation. |

By following these simple steps, you can easily secure the proper replacement items and maintain your system’s high standards. Make sure to order only from trusted sources to avoid counterfeit products that could compromise the performance of your equipment.

Maintenance Tips for Extending Unit Life

Proper upkeep of your HVAC system is essential to ensure its longevity and efficiency. Regular maintenance can prevent costly repairs, improve energy efficiency, and extend the life of the equipment. Below are key tips for maintaining your unit in peak condition, ensuring it performs optimally for years to come.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean or Replace Filters | Every 1-3 months | Improves airflow, reduces strain on components, enhances air quality |

| Inspect Ductwork | Annually | Prevents leaks, improves energy efficiency, ensures proper airflow |

| Check Refrigerant Levels | Annually | Maintains cooling efficiency, prevents system strain |

| Clean Coils (Evaporator & Condenser) | Every 6 months | Ensures efficient heat exchange, reduces risk of overheating |

| Inspect Insulation | Annually | Prevents energy loss, enhances system performance |

| Test Thermostat | Every 6 months | Ensures accurate temperature control, improves energy savings |

| Check Drainage System | Annually | Prevents water damage, ensures proper system operation |

By adhering to these maintenance practices, you can reduce the likelihood of unexpected breakdowns and keep your unit running smoothly for an extended period. Regular checkups and timely interventions are key to maximizing the efficiency and lifespan of your system.

Signs Your HVAC System Needs Repair

Recognizing when your heating and cooling unit requires maintenance or repair is essential to ensure its efficient performance and avoid costly breakdowns. Early detection of issues can help you prolong the lifespan of the system and maintain a comfortable indoor environment. Below are common signs that indicate your HVAC system may need attention.

1. Unusual Noises

If your system starts making strange sounds such as grinding, rattling, or squealing, it could be a sign that something is wrong. These noises may indicate loose parts, worn-out components, or other internal issues that require immediate attention.

2. Inconsistent Temperature or Poor Airflow

When your system is not providing consistent heating or cooling, or if the airflow from vents is weak, this could point to issues such as blocked ducts, a malfunctioning blower, or problems with the thermostat. Inconsistent performance can cause discomfort and may signal underlying issues that need to be addressed promptly.

- Thermostat not responding

- Inability to reach set temperature

- Cold or hot spots in rooms

3. Increased Energy Bills

If you notice a significant spike in your energy bills without a corresponding change in usage, it may be due to an inefficient system. When your unit struggles to maintain the desired temperature or runs longer than usual, it can consume more energy. This often means there are issues that need fixing.

4. Frequent Cycling

If the system frequently turns on and off without completing its full cycle, it can be a sign of electrical issues, thermostat malfunctions, or a clogged filter. This short-cycling behavior not only reduces comfort but also puts unnecessary strain on the system.

5. Foul Odors

Any strange or musty smells coming from your vents could indicate mold, mildew, or even burnt-out components. Lingering odors may be a sign of an internal issue that needs to be inspected by a professional technician.

Why Regular Inspections Are Crucial

Routine maintenance checks are essential for ensuring that heating and cooling systems operate efficiently and effectively. These inspections help identify potential issues before they become serious problems, minimizing unexpected breakdowns and costly repairs. Regular assessments can also enhance the lifespan of the equipment and ensure it runs at peak performance, saving energy and reducing operational costs.

By performing timely inspections, homeowners and businesses can catch small faults early, preventing them from escalating into major failures. A well-maintained system is more reliable, performs optimally, and operates more efficiently, providing consistent comfort and reducing the likelihood of emergency service calls.

Here are some key benefits of conducting regular inspections:

| Benefit | Description |

|---|---|

| Improved Efficiency | Well-maintained systems use less energy, leading to lower utility bills and reduced environmental impact. |

| Extended Lifespan | Routine checks can identify worn-out components early, extending the overall lifespan of the equipment. |

| Reduced Repair Costs | Addressing minor issues promptly prevents larger, more expensive repairs in the future. |

| Enhanced Safety | Regular inspections ensure the system is operating safely, preventing hazards such as gas leaks or electrical faults. |

Investing in regular inspections provides long-term benefits, enhancing the overall performance and safety of your system while saving time and money down the line.