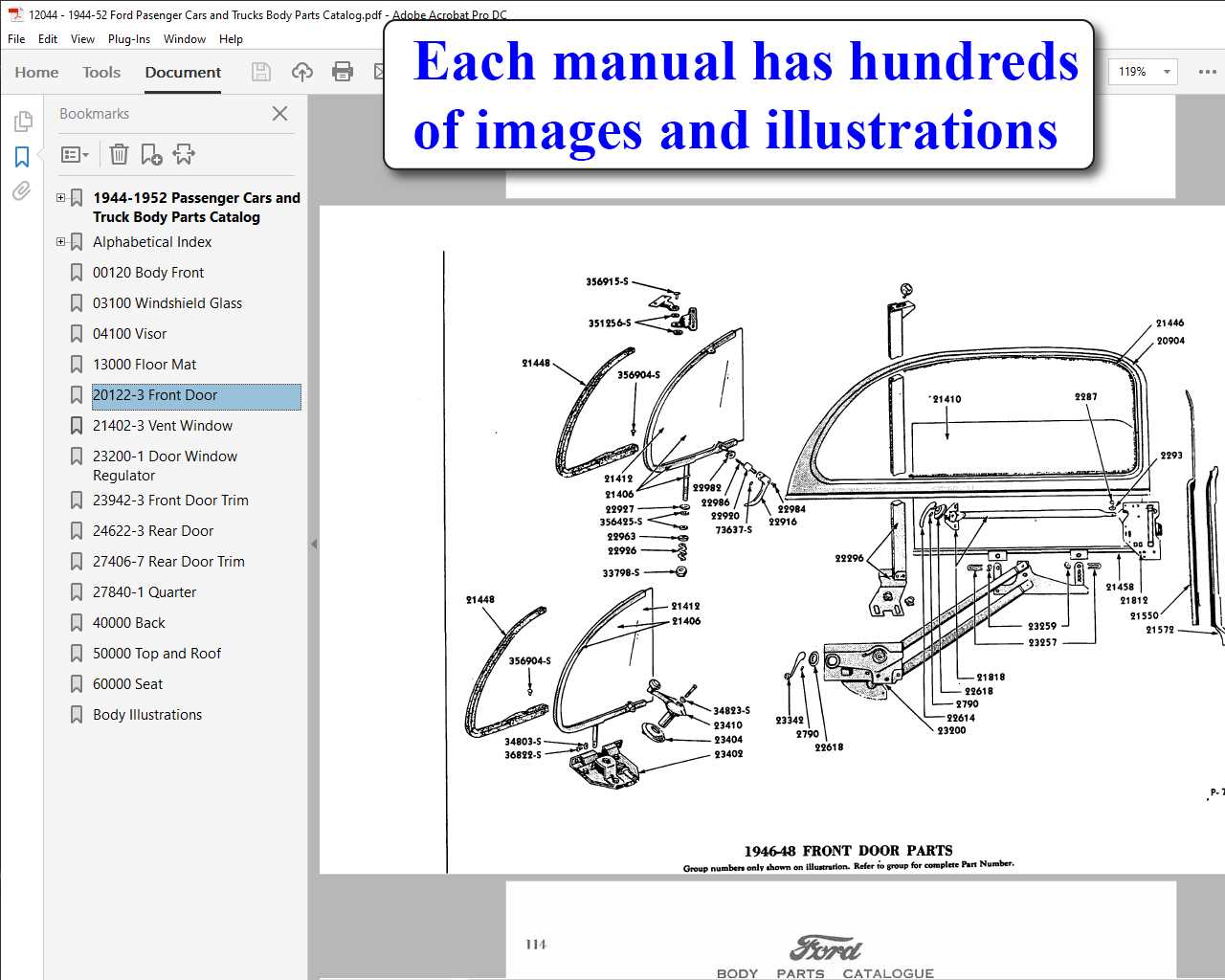

In the realm of heavy-duty machinery, a thorough comprehension of the individual elements that contribute to its functionality is essential. Each segment plays a vital role, ensuring that the entire mechanism operates smoothly and efficiently. Recognizing the significance of these components enhances maintenance practices and overall performance.

From the intricate framework to the robust mechanisms, each element is designed with precision to withstand the demands of challenging environments. Familiarity with these key sections not only aids in troubleshooting but also fosters a deeper appreciation for engineering and design. Exploring these intricacies allows enthusiasts and professionals alike to enhance their expertise and skills in vehicle maintenance.

Furthermore, understanding how these sections interconnect can lead to improved efficiency and longevity of the machinery. This knowledge empowers individuals to make informed decisions when it comes to repairs, upgrades, and overall care. Delving into the specifics of each component reveals the ultimate synergy within the system, paving the way for more effective operation and reliability.

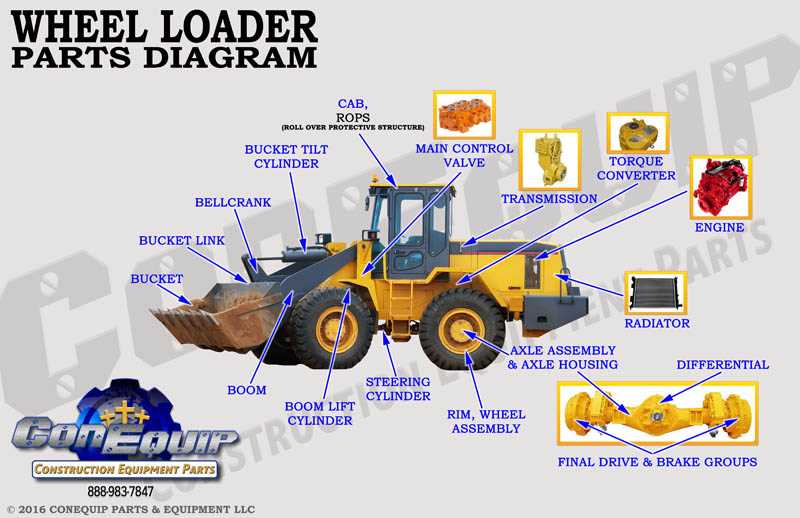

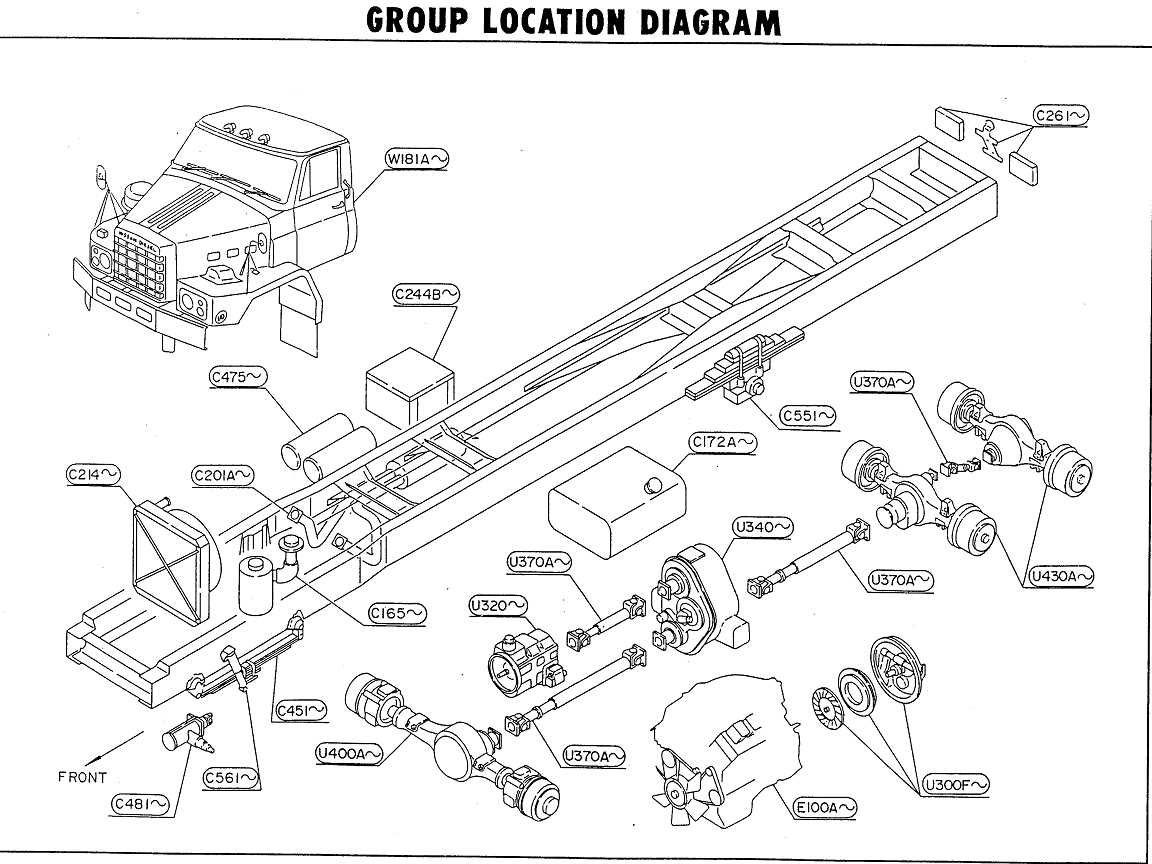

Essential Components of a Truck

This section explores the fundamental elements that constitute a large vehicle designed for transport and logistics. Understanding these components is crucial for ensuring efficient operation and maintenance.

- Chassis: The main frame providing structural support.

- Engine: The power source driving the vehicle.

- Transmission: The system responsible for transferring power to the wheels.

- Suspension: A mechanism that absorbs shocks and maintains stability.

- Braking System: Ensures safe stopping and control of movement.

- Fuel System: Manages fuel storage and delivery to the engine.

- Electrical System: Powers various components, including lights and controls.

Each of these elements plays a critical role in the overall functionality and performance of the vehicle.

Understanding the Engine Layout

The arrangement and configuration of the power-generating unit are crucial for overall performance and efficiency. This section delves into the essential components and their spatial organization, emphasizing how each element contributes to functionality and operation.

Key Components of the Engine

Central to this assembly is the block, which houses the cylinders and is the core of the combustion process. Surrounding it are various elements such as the intake and exhaust systems, each designed to facilitate the flow of air and gases, optimizing the engine’s efficiency. Additionally, the cooling system plays a vital role in maintaining optimal temperatures, preventing overheating and ensuring longevity.

Importance of Layout Configuration

The strategic positioning of components can significantly influence power output and fuel consumption. A well-organized setup not only enhances accessibility for maintenance but also improves the overall balance and stability during operation. Understanding this configuration allows for better diagnostics and repairs, contributing to the reliability of the entire system.

Transmission Types and Functions

In the realm of heavy-duty vehicles, understanding the various methods of power transfer is essential for optimal performance. Each mechanism plays a crucial role in ensuring that the engine’s output effectively reaches the wheels, allowing for seamless movement under diverse conditions.

Manual Transmission involves the driver directly selecting gears using a stick shift, providing enhanced control over the vehicle’s acceleration and power. This type often appeals to enthusiasts who appreciate a more engaging driving experience.

Automatic Transmission simplifies the process by automatically shifting gears based on speed and load. This convenience is particularly beneficial for long hauls, reducing driver fatigue and enhancing comfort.

Continuously Variable Transmission (CVT) offers a unique approach by providing an infinite range of gear ratios, optimizing fuel efficiency and acceleration. This system is increasingly favored in modern vehicles for its smoothness and adaptability.

Each of these transmission types serves distinct purposes, tailoring the driving experience to meet specific operational needs and preferences. Understanding their functionalities aids in making informed decisions regarding maintenance and performance enhancement.

Braking System Overview

The braking mechanism is crucial for ensuring safety and control in large vehicles. It functions to slow down or halt movement, providing the driver with essential responsiveness during operation. Understanding its components and functionality is vital for maintaining optimal performance and preventing malfunctions.

Key Components

At the core of the braking mechanism are several essential elements. The brake pads provide friction against the surface, while the rotors assist in generating the necessary stopping force. Additionally, the hydraulic system plays a significant role in transmitting force from the driver’s input to the braking components.

Functionality and Maintenance

Effective operation relies on regular maintenance and timely inspection of the braking system. Ensuring that all components are in good condition enhances overall safety and performance. Routine checks can prevent issues that may arise from wear and tear, thus prolonging the lifespan of the entire system.

Chassis Structure and Design

The foundation of any heavy-duty vehicle is crucial for ensuring stability, safety, and overall performance. A well-engineered framework not only supports various components but also plays a significant role in how the vehicle interacts with its environment. Understanding the intricacies of this structure is essential for optimizing functionality and durability.

- Material Choices: Different materials are utilized to achieve a balance between strength and weight. Common options include steel for durability and aluminum for reduced mass.

- Configuration: The arrangement of components influences handling and load distribution. Variations can lead to significant differences in performance under various conditions.

- Suspension Integration: The connection between the framework and suspension systems is vital for shock absorption and ride quality, impacting overall comfort and control.

- Load-Bearing Capacity: Engineering considerations ensure that the structure can support the intended weight without compromising safety or integrity.

In summary, a robust design is fundamental to the effectiveness of heavy-duty vehicles. The combination of material selection, configuration, and integration with other systems determines not only performance but also longevity and operational efficiency.

Suspension Systems Explained

The functionality of a vehicle’s structure relies heavily on its ability to absorb shocks and maintain stability while navigating various terrains. This essential mechanism enhances comfort and control for both the driver and passengers.

There are several key components involved in this complex system:

- Springs: These elements are designed to support weight and absorb impacts.

- Dampers: Often referred to as shock absorbers, they control the rebound and compression of the springs.

- Control Arms: These link the wheels to the main body, allowing for controlled movement.

- Stabilizer Bars: They help reduce body roll during cornering.

Understanding the different types of suspension systems is crucial:

- Independent Suspension: Each wheel moves independently, providing improved handling and comfort.

- Dependent Suspension: Wheels are linked, affecting their movement together, which can lead to a rougher ride.

- Air Suspension: Utilizes air-filled bags to adjust ride height and firmness.

Ultimately, the choice of a suspension system influences not only ride quality but also overall performance and safety on the road.

Electrical System Components

The functionality of modern vehicles heavily relies on an intricate network of electrical components that facilitate communication, control, and power distribution. These elements work in harmony to ensure efficient operation and enhanced safety for drivers and passengers alike.

Central to this system are the battery, alternator, and various wiring harnesses, each playing a pivotal role in energy storage and management. The battery serves as the primary energy reservoir, while the alternator generates electricity during operation to recharge the battery and power other systems.

Control units and sensors further augment the performance of these vehicles by monitoring critical parameters and making real-time adjustments. These components contribute to the overall reliability and efficiency of the entire system, making them essential for optimal performance.

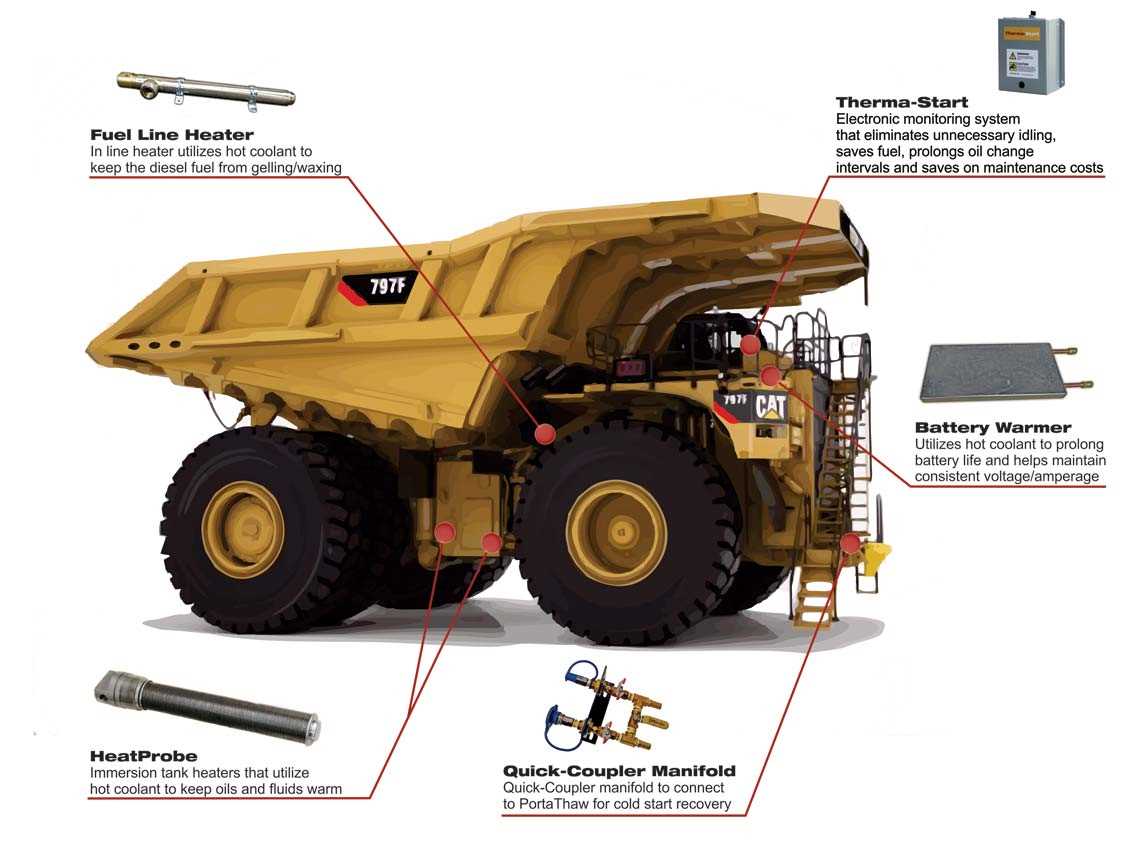

Fuel Delivery Mechanisms

Understanding the various systems that ensure the proper flow of energy is crucial for optimizing performance and efficiency in vehicles. These systems are designed to manage the distribution of fuel, ensuring it reaches the engine effectively.

Key Components

- Fuel Pump: Responsible for transferring fuel from the tank to the engine.

- Fuel Injectors: Sprays fuel into the combustion chamber for optimal mixing with air.

- Fuel Filter: Cleans the fuel before it reaches the engine, removing impurities.

- Pressure Regulator: Maintains consistent fuel pressure throughout the system.

Types of Delivery Systems

- Mechanical Systems: Utilize pumps driven by the engine’s crankshaft.

- Electronic Systems: Rely on sensors and electronic controls for precise fuel management.

- Common Rail Systems: Allow multiple injectors to share a single fuel rail for improved efficiency.

Steering System Functions

The steering mechanism plays a crucial role in ensuring optimal maneuverability and control of a vehicle. It enables the operator to direct the vehicle’s movement with precision, enhancing safety and responsiveness during travel.

This system encompasses several key functions that contribute to its overall effectiveness:

- Direction Control: Allows the operator to change the vehicle’s heading, ensuring it follows the desired path.

- Stability Maintenance: Aids in maintaining balance, especially during turns and while navigating uneven surfaces.

- Feedback Mechanism: Provides the operator with sensory feedback about road conditions and vehicle behavior, improving reaction times.

- Adjustment Capabilities: Enables modifications to steering angle, accommodating various loads and driving conditions.

- Safety Features: Incorporates elements designed to prevent loss of control and enhance overall safety during operation.

Understanding these functions is essential for ensuring proper maintenance and optimizing performance, ultimately leading to a more efficient and secure driving experience.

Importance of Tire Selection

The choice of rolling surfaces is crucial for optimal vehicle performance and safety. Selecting the appropriate type can significantly impact handling, stability, and fuel efficiency. Different environments and operational demands require careful consideration to ensure that the right option is utilized.

Impact on Performance

Utilizing the correct variety enhances traction and braking capabilities, which are vital for maintaining control under varying conditions. A well-matched choice reduces wear and tear, prolonging the lifespan of the equipment and improving overall efficiency.

Safety Considerations

Choosing the right type also plays a vital role in ensuring the safety of operators and cargo. Properly selected surfaces help prevent accidents by providing reliable grip and stability, particularly in adverse weather or challenging terrains.

Cabin Features and Layout

The interior of a large vehicle is designed to prioritize comfort, functionality, and safety for the operator. A well-thought-out arrangement of elements contributes significantly to an efficient driving experience.

Key Components

- Seating Arrangement: Ergonomically designed seats ensure comfort during long journeys.

- Dashboard: An intuitive layout of controls provides easy access to essential functions.

- Storage Solutions: Adequate compartments allow for the organization of tools and personal items.

- Climate Control: Advanced systems maintain a pleasant atmosphere regardless of external conditions.

Spatial Organization

Efficient use of space is crucial. The layout typically includes:

- Driver’s Zone: Contains controls and displays within easy reach.

- Passenger Area: Designed for additional comfort and space.

- Access Points: Well-placed doors and steps facilitate easy entry and exit.

Trailer Attachment Systems

This section explores the mechanisms and methods utilized for connecting towed units, highlighting their significance in ensuring stability and functionality during transport. Understanding these systems is crucial for effective operation and safety on the road.

| System Type | Description |

|---|---|

| Coupling Mechanism | A device that secures the connection between the towing vehicle and the towed unit. |

| Hitch Design | Configurations that determine how the load is distributed and managed during movement. |

| Safety Chains | Additional supports that prevent detachment in case of a primary failure. |

| Electrical Connections | Wiring systems that enable lighting and braking functions across the connected units. |