In the world of machinery and equipment, comprehending the arrangement and function of individual elements is crucial for effective maintenance and troubleshooting. A well-structured visual representation can significantly aid in identifying the roles of various components, enhancing both understanding and efficiency in operations.

This section provides an insightful overview of the specific configuration found in a popular model, illustrating how each piece interacts within the broader system. By analyzing this layout, users can gain a clearer perspective on assembly and disassembly processes, ultimately leading to improved performance and longevity.

Moreover, recognizing the significance of each element fosters a deeper appreciation for the design and engineering behind the equipment. This knowledge empowers operators and technicians to execute repairs and upgrades with confidence, ensuring that the machinery continues to function at its best.

Overview of Component Layout

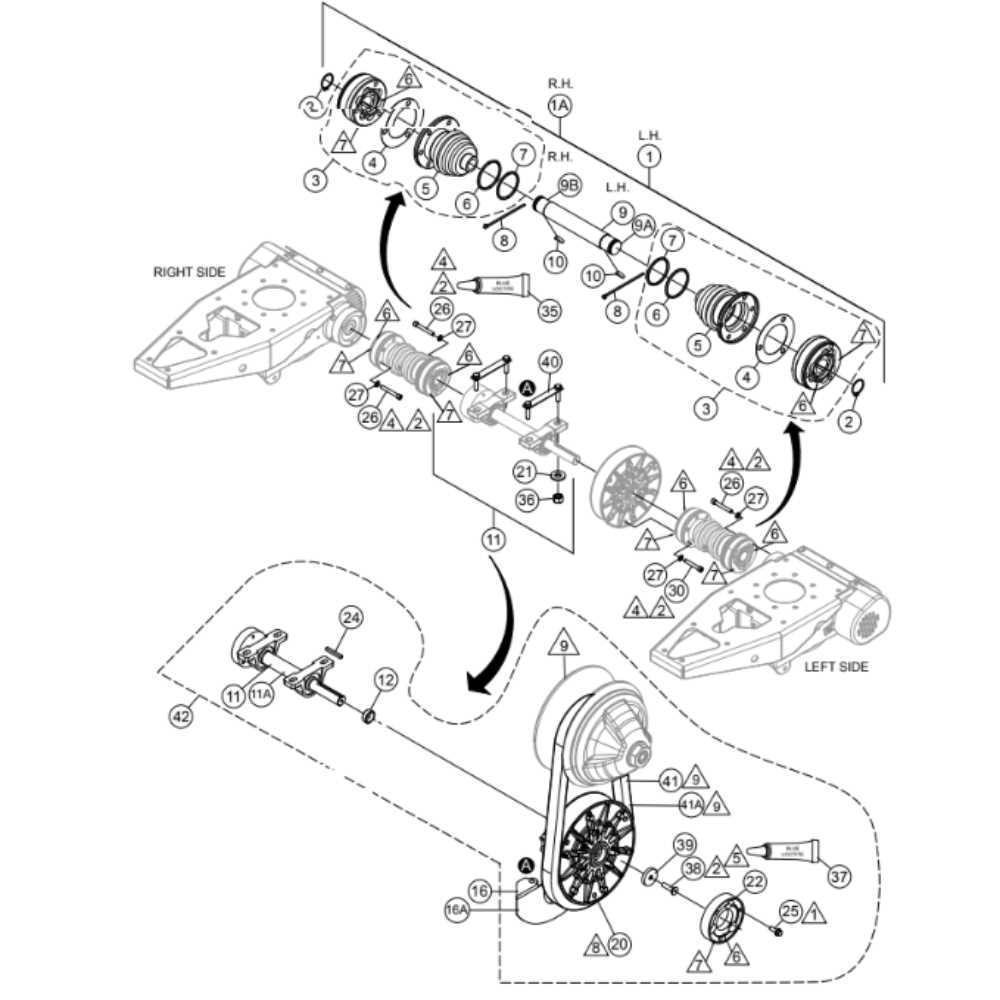

This section provides a comprehensive examination of the assembly structure related to the specified model. Understanding the layout of individual elements is crucial for effective maintenance and troubleshooting. Each part plays a vital role in the overall functionality, contributing to the machine’s performance and efficiency.

Key Elements Explained

The following table outlines the essential components, highlighting their functions and significance within the system:

| Component Name | Function |

|---|---|

| Engine Assembly | Powers the unit and ensures operational efficiency. |

| Control Panel | Allows user interaction and settings adjustment. |

| Fuel Tank | Stores energy source necessary for operation. |

| Cooling System | Prevents overheating during extended use. |

Importance of Understanding the Structure

A thorough understanding of the assembly layout is essential for any user or technician. Familiarity with each element enhances troubleshooting capabilities and ensures proper handling during repairs or modifications, ultimately contributing to longevity and reliability.

Understanding the Dsh 900 Model

This section explores the key features and functionalities of a specific model that serves a variety of applications. Understanding its components and how they interact is essential for both users and technicians, as it allows for better maintenance and efficient operation. A thorough examination of its structure can enhance user experience and extend the longevity of the device.

Key Features

The model is designed with advanced capabilities that cater to various tasks. Its unique elements contribute to performance efficiency, making it a popular choice among users. The integration of innovative technology ensures reliability and ease of use.

Component Overview

Below is an overview of the primary components associated with this model:

| Component | Description |

|---|---|

| Engine | Powers the entire unit, providing necessary force for operation. |

| Control Panel | Interface for users to manage settings and monitor performance. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

| Chassis | Structural framework that houses and protects internal components. |

Key Components and Their Functions

This section delves into the essential elements of a particular system, highlighting their roles and interactions. Understanding these components is crucial for optimal performance and maintenance.

- Power Unit: Provides the necessary energy for operation, ensuring all functions are executed smoothly.

- Control Module: Acts as the brain, managing processes and coordinating responses based on input data.

- Transmission System: Facilitates the transfer of power to different parts, enabling movement and functionality.

- Cooling Mechanism: Regulates temperature to prevent overheating, maintaining efficiency during operation.

- Safety Features: Include various sensors and alarms that monitor performance and prevent accidents.

By comprehensively understanding these elements, users can ensure proper operation and address potential issues effectively.

Benefits of Using Parts Diagrams

Utilizing visual representations of components can significantly enhance the understanding and maintenance of equipment. These illustrations serve as valuable tools for both professionals and enthusiasts, streamlining the repair process and improving overall efficiency.

By providing a clear view of individual elements and their interrelations, these visual aids facilitate easier identification of required components. This ultimately leads to better planning and organization during maintenance tasks.

| Advantage | Description |

|---|---|

| Enhanced Clarity | Visual aids help clarify the layout and function of various elements, reducing confusion. |

| Time Efficiency | Quick reference guides speed up the identification and sourcing of necessary items. |

| Improved Communication | Shared visual resources foster better collaboration among team members and stakeholders. |

| Maintenance Training | Visual tools are effective in educating new personnel on assembly and disassembly processes. |

Common Issues with Dsh 900 Parts

In the realm of machinery components, various challenges can arise that affect overall functionality and efficiency. Understanding these common issues is crucial for effective maintenance and longevity of the equipment. By identifying and addressing these problems promptly, users can ensure optimal performance and reduce the likelihood of major malfunctions.

Wear and Tear

One of the most prevalent concerns is the natural degradation of components over time. Frequent use can lead to friction and stress, causing parts to lose their effectiveness. Regular inspections and timely replacements are essential to mitigate these effects.

Improper Installation

Another significant issue arises from incorrect assembly of components. When parts are not installed as specified, it can lead to malfunctions and inefficiencies. Ensuring that all components are fitted according to the manufacturer’s guidelines is vital for maintaining operational integrity.

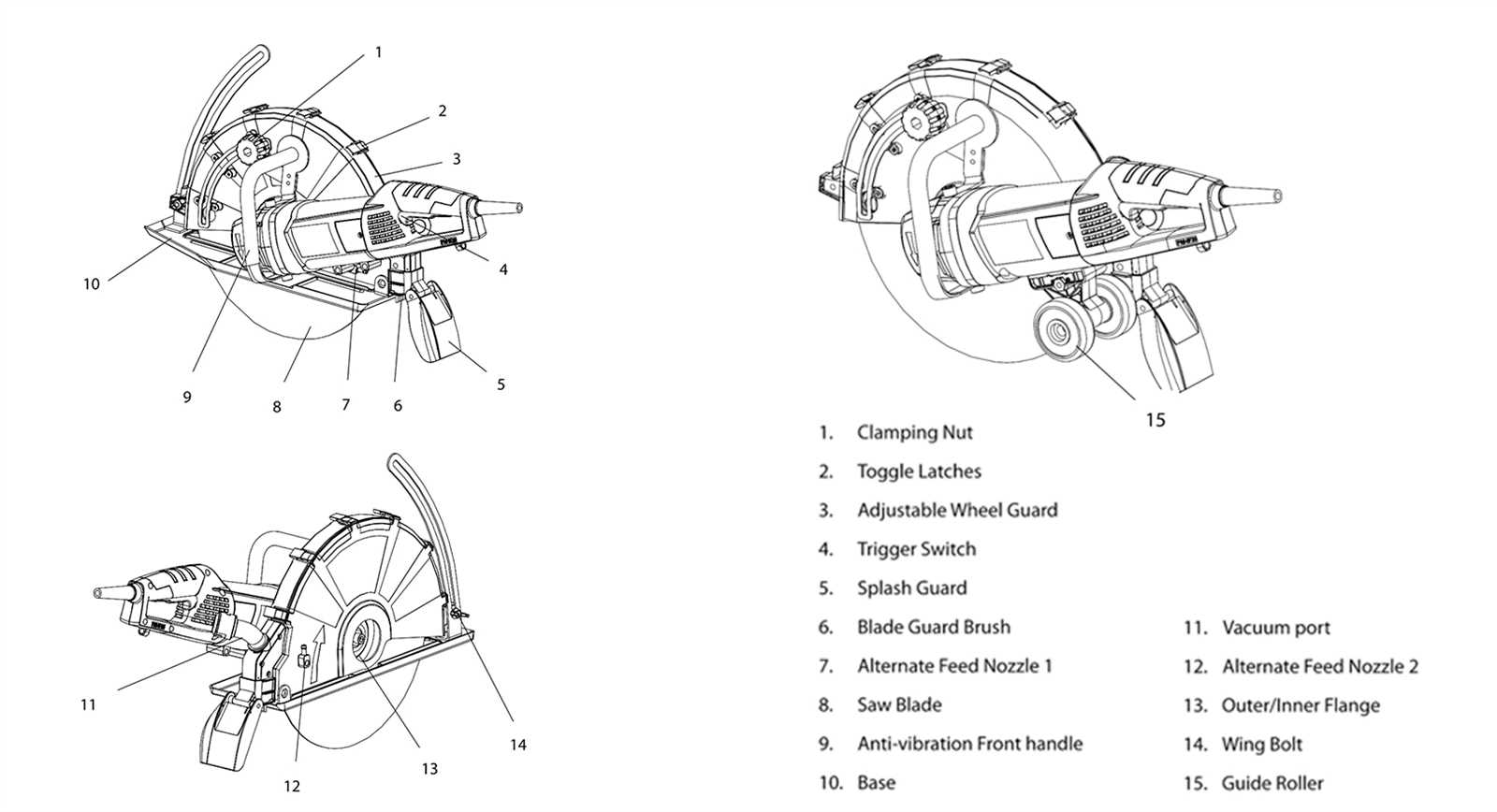

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to assemble, repair, or maintain equipment. This section will guide you through the essential steps to effectively interpret these illustrations, making your tasks more manageable and efficient.

Key Elements to Consider

- Labels: Look for clearly marked identifiers that correspond to each element. These labels often include numbers or letters that you can reference in accompanying documentation.

- Groupings: Components may be organized into sections based on their function or location. Identifying these clusters can simplify your understanding of the overall structure.

- Connections: Pay attention to lines or arrows indicating how different parts interact or connect. This can help you visualize the assembly process.

Steps to Follow

- Begin by reviewing the overall layout to get a sense of the assembly’s complexity.

- Focus on individual labels and cross-reference them with any accompanying text to understand their specific roles.

- Identify any groupings or clusters of components that may work together.

- Examine the connections to understand how each part fits within the larger assembly.

- Take notes or create a checklist of components for easier reference during your work.

Identifying Replacement Parts Easily

When it comes to maintaining equipment, knowing how to locate and recognize necessary components is essential for efficient repairs and replacements. This process can be simplified by utilizing specific resources and tools designed to assist users in identifying the required items without unnecessary hassle.

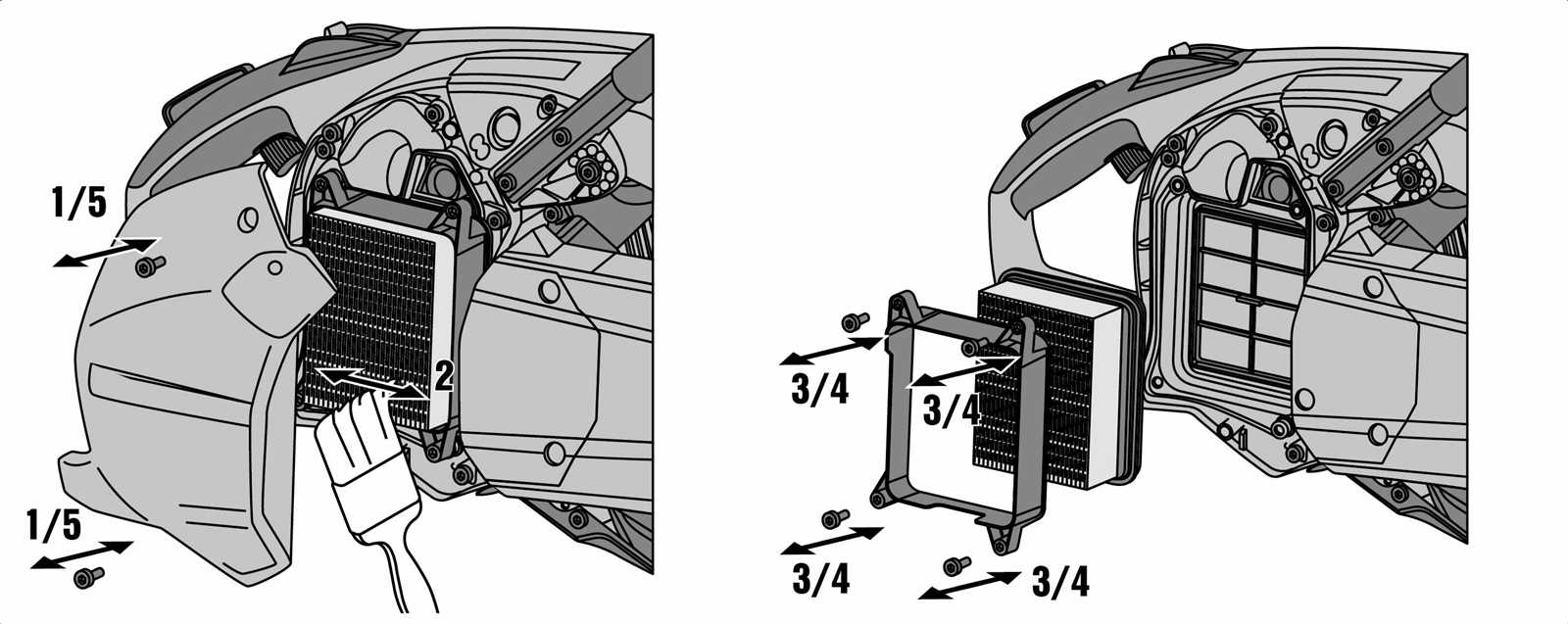

Firstly, utilizing detailed illustrations can significantly enhance your understanding of each component’s layout and functionality. These visuals often highlight various features, making it easier to pinpoint the exact elements that need attention.

Secondly, a thorough review of the manual or user guide can provide crucial information regarding part specifications, compatibility, and identification. These documents usually contain valuable insights, including part numbers and descriptions, which can facilitate the selection of the correct replacements.

Additionally, leveraging online resources, such as forums and manufacturer websites, can connect you with a community of users who may offer firsthand advice and recommendations. Engaging with these platforms allows you to gain further insights and alternative solutions, streamlining the replacement process.

Ultimately, by utilizing various resources and taking the time to understand the equipment’s composition, you can enhance your ability to identify necessary components swiftly and accurately, ensuring that maintenance tasks are completed efficiently.

Maintaining Your Dsh 900 Equipment

Regular upkeep of your machinery is essential for ensuring optimal performance and longevity. Proper maintenance not only enhances efficiency but also minimizes the risk of unexpected failures, thereby saving time and resources. Implementing a consistent care routine will help keep your device in top condition.

Inspecting Components: Routine checks of all essential elements are vital. Look for signs of wear and tear, ensuring each part operates smoothly. Early detection of issues can prevent larger problems down the line.

Cleaning Procedures: Keeping your equipment clean is crucial. Dust and debris can hinder functionality and lead to premature wear. Utilize appropriate cleaning methods to remove contaminants without damaging surfaces.

Lubrication: Regular application of suitable lubricants will reduce friction between moving parts, promoting efficient operation. Follow manufacturer guidelines for recommended products and intervals.

Storage Practices: When not in use, store your machinery in a dry, protected environment. Proper storage prevents rust and other forms of degradation, ensuring your device is ready for use when needed.

Where to Find Authentic Parts

Finding genuine components for your equipment is crucial for maintaining its performance and longevity. Authentic items ensure compatibility and reliability, preventing potential issues that may arise from using inferior alternatives. Here are some trusted sources to consider when seeking original replacements.

Official Distributors

One of the most reliable ways to acquire genuine components is through official distributors. These suppliers are authorized by the manufacturer and offer a wide range of certified items. Always check the manufacturer’s website for a list of approved vendors to ensure you are purchasing quality products.

Reputable Online Retailers

Many online platforms specialize in genuine components for various equipment. Look for websites that provide detailed descriptions, customer reviews, and clear return policies. Verify that the retailer has a solid reputation for selling authentic items to avoid any risks associated with counterfeit goods.

Compatibility with Other Models

Understanding how different models relate to one another is crucial for optimal performance and maintenance. This section explores the interchangeability and shared components among various units, providing insights for users looking to maximize the utility of their equipment.

Many units within the same product line share similar characteristics, making it easier for users to source compatible components. Identifying these relationships can lead to cost savings and enhanced functionality, as parts designed for one model may fit seamlessly into another, allowing for greater versatility.

It is advisable to consult manufacturer guidelines to determine specific compatibility details. By doing so, users can ensure that they select the appropriate components that meet their needs, thereby enhancing the overall efficiency and longevity of their machinery.

Cost Considerations for Repairs

When addressing maintenance needs, evaluating the expenses involved is essential for effective budgeting. Understanding the potential costs helps in making informed decisions regarding whether to undertake repairs or consider alternative solutions. This section delves into various financial factors that influence repair expenditures.

Assessment of Repair Needs

Initially, determining the extent of the damage is crucial. Minor issues may require minimal investment, while significant repairs can lead to higher costs. A thorough examination by a qualified technician can provide clarity on the necessary interventions and their associated fees.

Replacement vs. Repair Costs

Another vital aspect is weighing the costs of replacement components against repair efforts. In some cases, investing in new parts may prove more economical in the long run, especially if the existing items are prone to frequent issues. Careful consideration of both options ensures that resources are allocated wisely.

Frequently Asked Questions

This section addresses common inquiries related to the components and schematics of the equipment. Here, you can find essential information that helps in understanding the structure and functionality of the various elements involved.

General Inquiries

- What are the primary components of the machinery?

- How can I obtain a schematic representation of the assembly?

- Are there specific manuals available for reference?

Maintenance and Troubleshooting

- What routine maintenance should be performed to ensure optimal performance?

- How can I identify issues with the unit?

- Where can I find replacement information for malfunctioning parts?

Tips for Effective Parts Management

Efficient management of components is crucial for maintaining the smooth operation of any machinery or equipment. By implementing strategic practices, organizations can reduce downtime, enhance productivity, and streamline their operations.

1. Organize Inventory – Creating a well-structured inventory system is essential. Use labels and categorize items based on frequency of use, type, or size. This facilitates easy access and reduces the time spent searching for specific elements.

2. Regular Audits – Conduct periodic reviews of your inventory to identify discrepancies and ensure accurate records. Regular audits help in recognizing trends in usage and can inform future purchasing decisions.

3. Utilize Technology – Implementing software solutions can significantly enhance tracking and management processes. These tools can automate inventory counts, provide alerts for low stock levels, and generate reports for analysis.

4. Establish Supplier Relationships – Developing strong partnerships with suppliers can lead to better terms, faster delivery times, and more reliable access to necessary components. Maintaining open lines of communication ensures that any issues can be addressed promptly.

5. Train Staff – Ensuring that all team members understand the management practices and the importance of efficient inventory handling is vital. Regular training sessions can equip them with the knowledge needed to follow established protocols effectively.

6. Implement a FIFO System – Adopting a First In, First Out strategy helps in managing stock efficiently. This approach minimizes the risk of obsolescence by ensuring that older items are used before newer ones.

By focusing on these strategies, organizations can optimize their component management processes, leading to improved operational efficiency and reduced costs.