Understanding how various elements come together to form a functional unit is essential for anyone looking to maintain or enhance equipment. Exploring the organization of individual sections within a tool allows for better comprehension and effective troubleshooting. Each section plays a unique role in ensuring the overall system operates smoothly.

Examining the layout of these sections provides insights into their interaction and dependencies. By identifying key sections and their respective roles, users can optimize maintenance routines and increase the efficiency of their equipment’s operation. Proper understanding of these mechanisms can save time and effort during repairs.

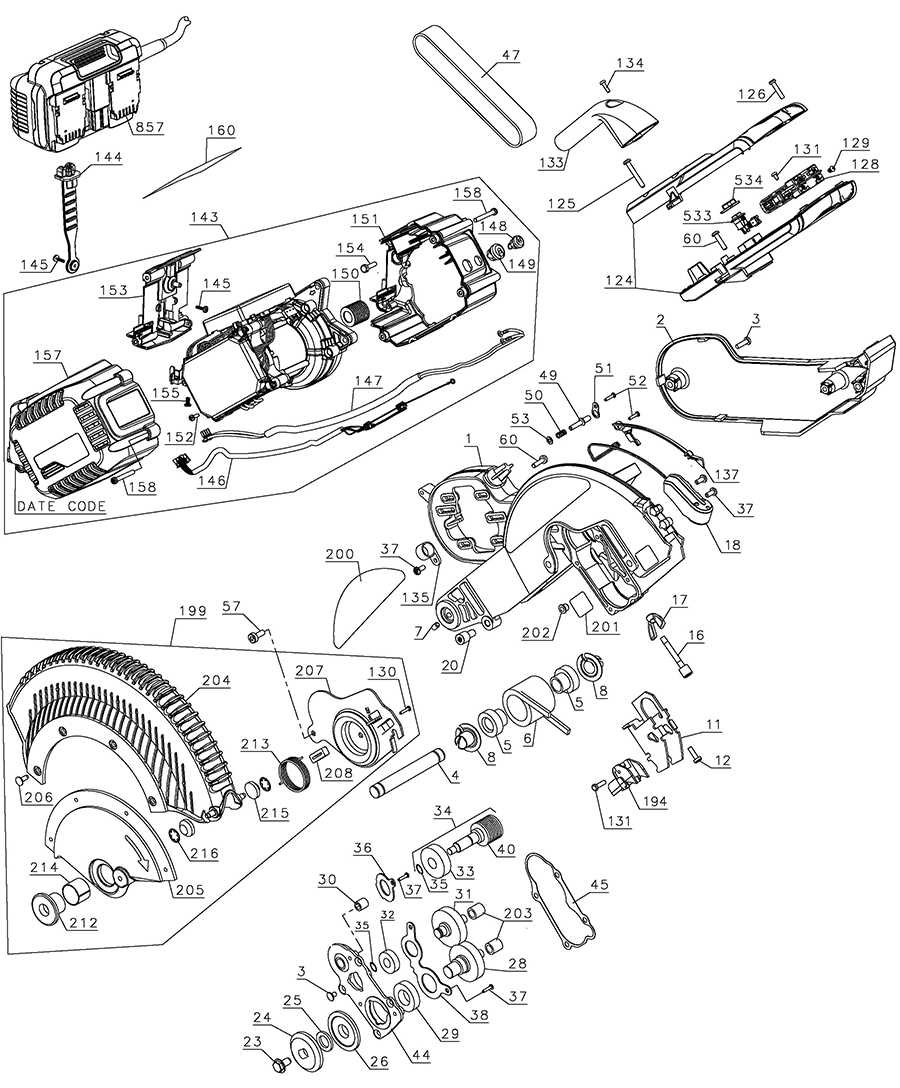

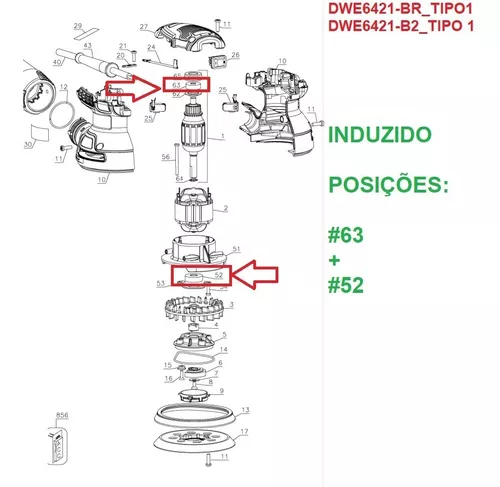

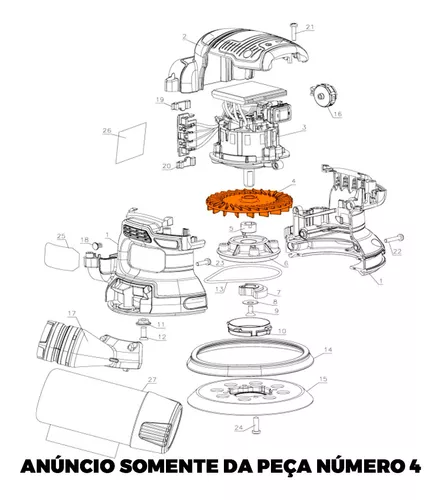

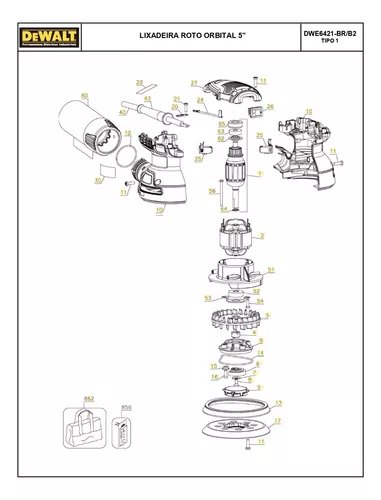

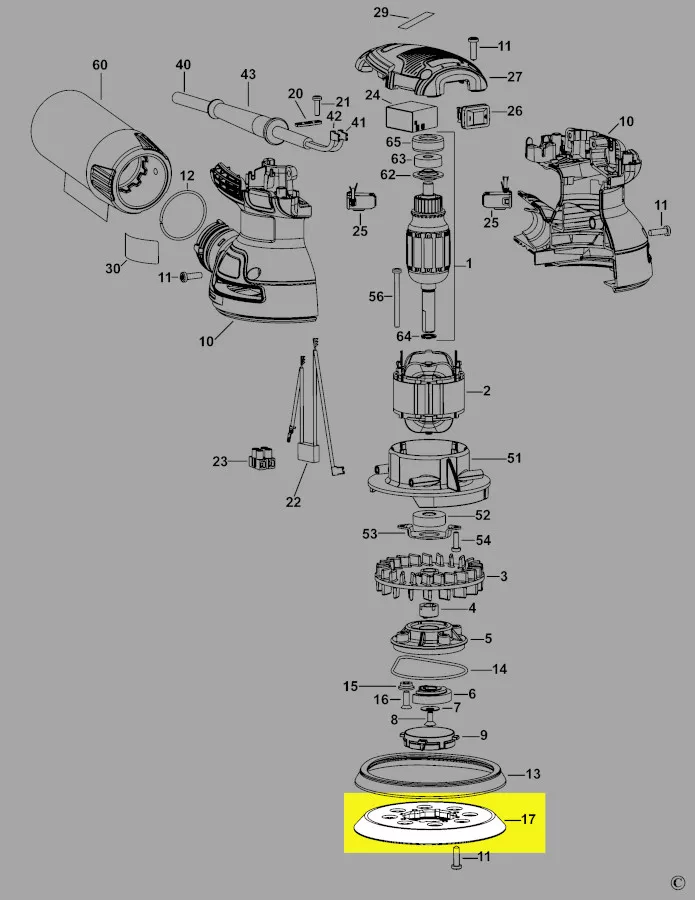

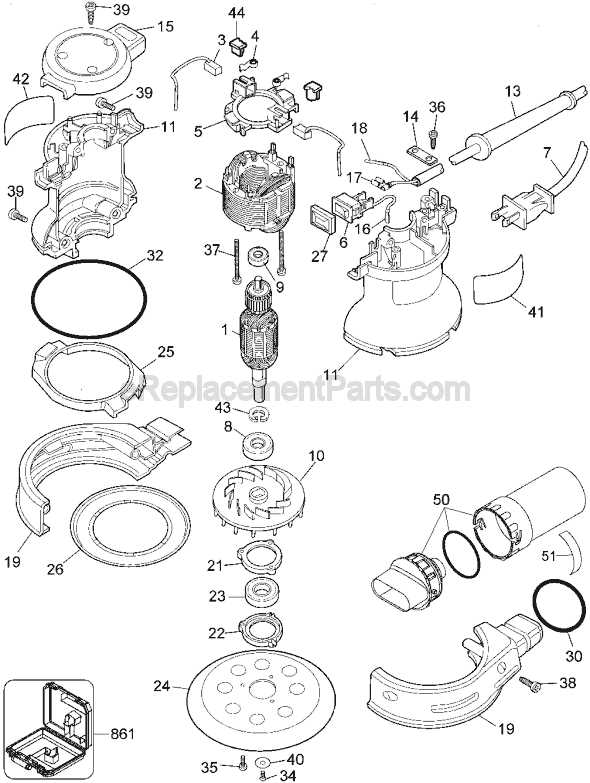

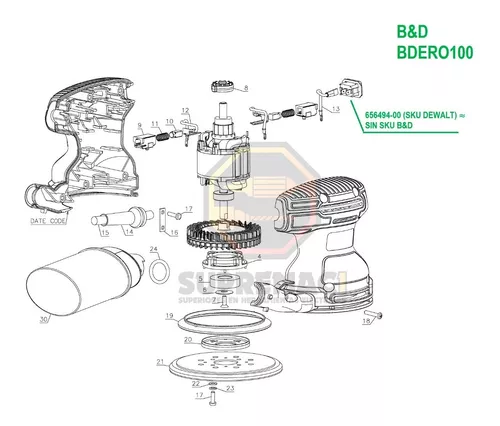

Overview of the DWE6421 Components

The model in question consists of several key elements, each designed to work together to ensure optimal performance and durability. These components have been engineered to provide a seamless user experience, enhancing the tool’s efficiency and ease of use.

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Housing | Protects the internal motor while ensuring heat dissipation and stability during operation. | ||||||||||||||||||||||||||||||

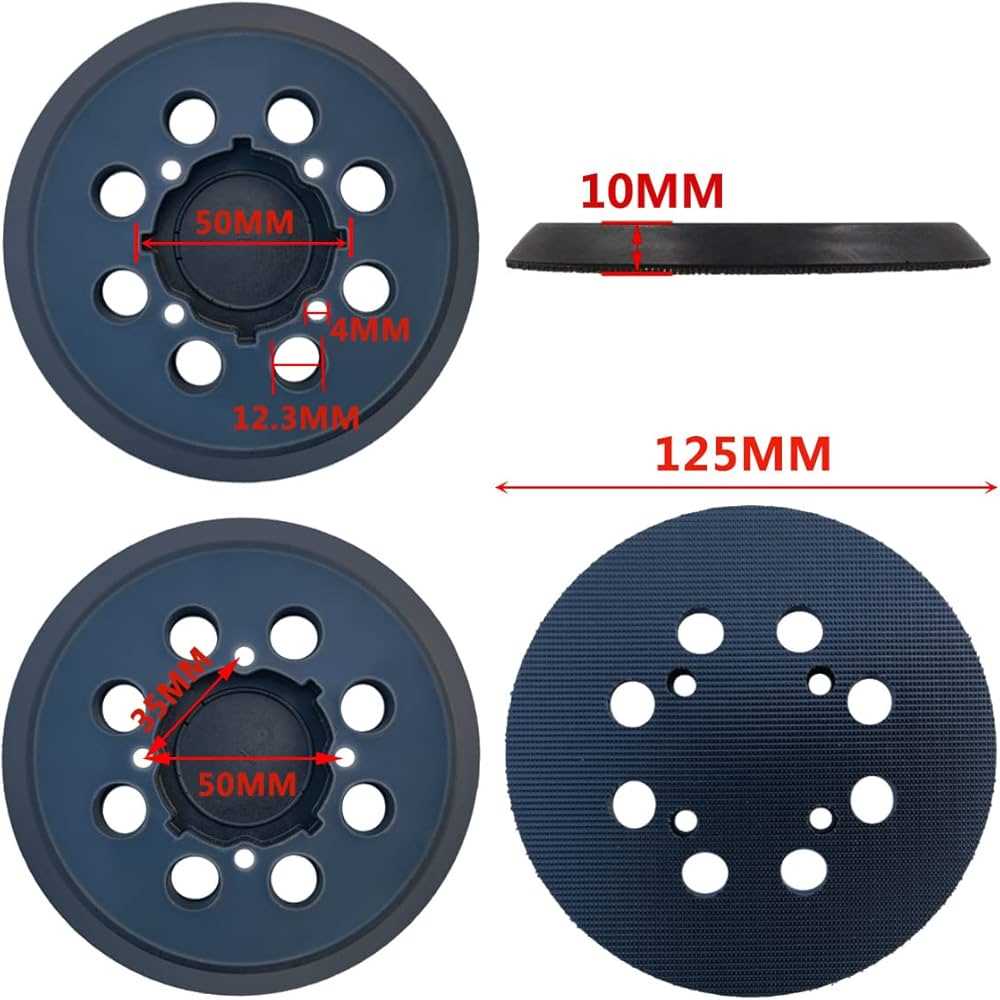

| Base Plate | Serves as the foundation, providing a stable surface for smooth movement and handling. | ||||||||||||||||||||||||||||||

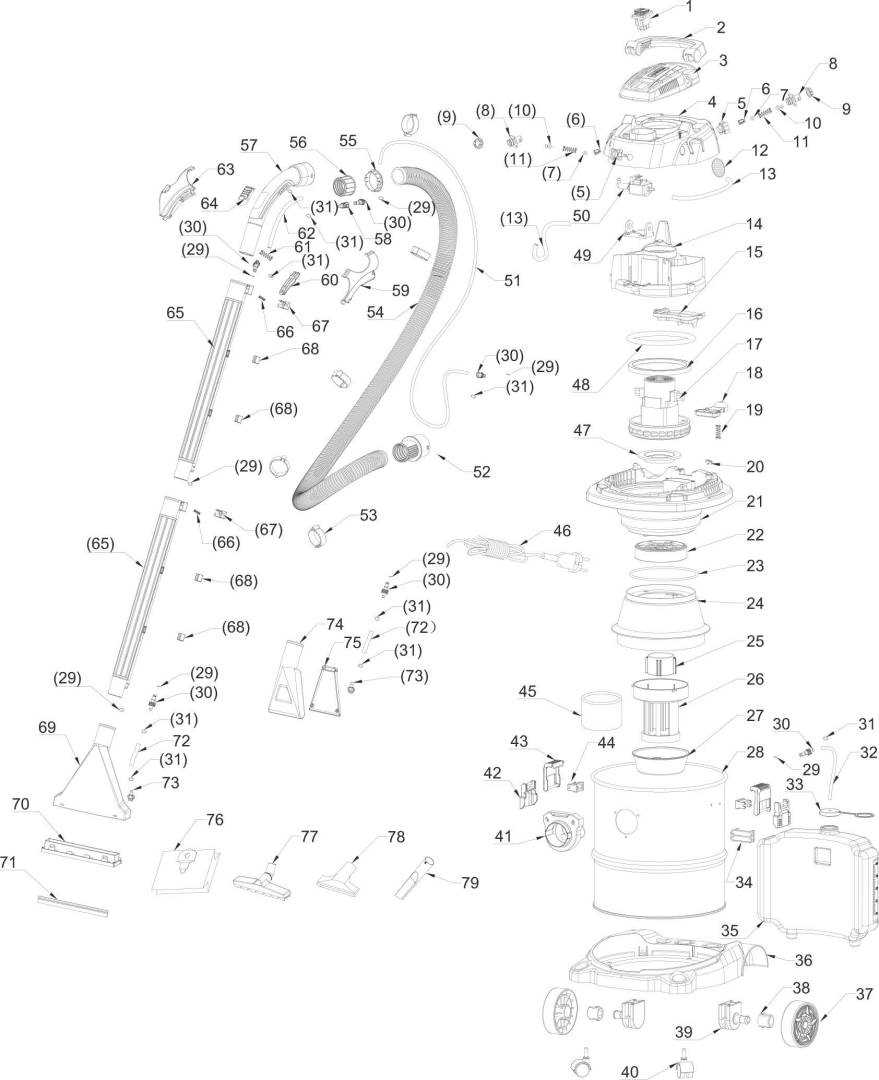

| Dust Collection Port | Facilitates the removal of debris, ensuring a cleaner work environment and reducing clogging risks. |

| Feature | Benefit | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sturdy Materials | Increased durability and protection | ||||||||||||||||||||||||

| Ventilation System | Efficient heat management |

| Type | Description |

|---|---|

| Mechanical Switch | Utilizes physical movement to open or close circuits. |

| Electronic Switch | Operates using semiconductor devices to control current flow. |

| Relay Switch | Uses an electromagnetic coil to open or close a circuit remotely. |

Importance of Functionality

The functionality of a switch mechanism directly impacts the efficiency and safety of a device. A well-designed switch ensures reliable operation, minimizing the risk of failures or hazards. Regular checks and proper maintenance can prolong the lifespan of these components, making them an integral part of any operational system.

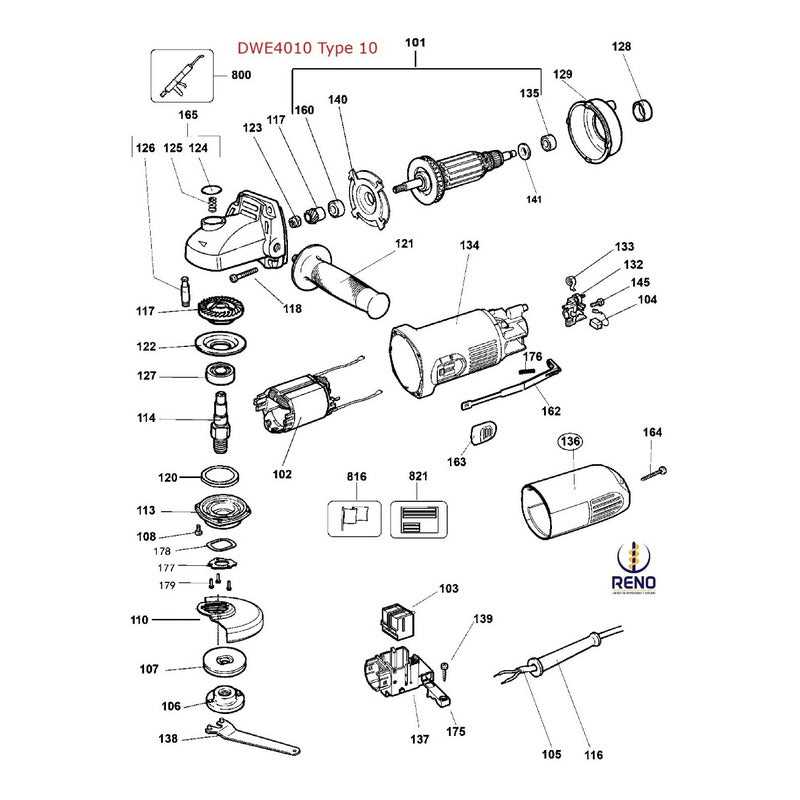

Guard and Shield Component Analysis

The examination of protective elements is crucial for understanding their role in equipment functionality and safety. These components serve as barriers, ensuring that the user remains shielded from potential hazards while enhancing the overall performance of the system. A comprehensive analysis highlights the significance of design, material choice, and structural integrity.

Importance of Protective Elements

Protective elements not only safeguard the user but also contribute to the longevity of the machinery. By preventing damage from external factors, they help maintain operational efficiency. The choice of materials plays a vital role in determining how effectively these components can withstand wear and tear.

Design Considerations

When designing protective features, various factors must be taken into account, including ergonomics and accessibility. A well-thought-out design ensures that the protective components do not hinder the usability of the equipment. Additionally, the integration of these elements should align with the overall aesthetics of the machinery.

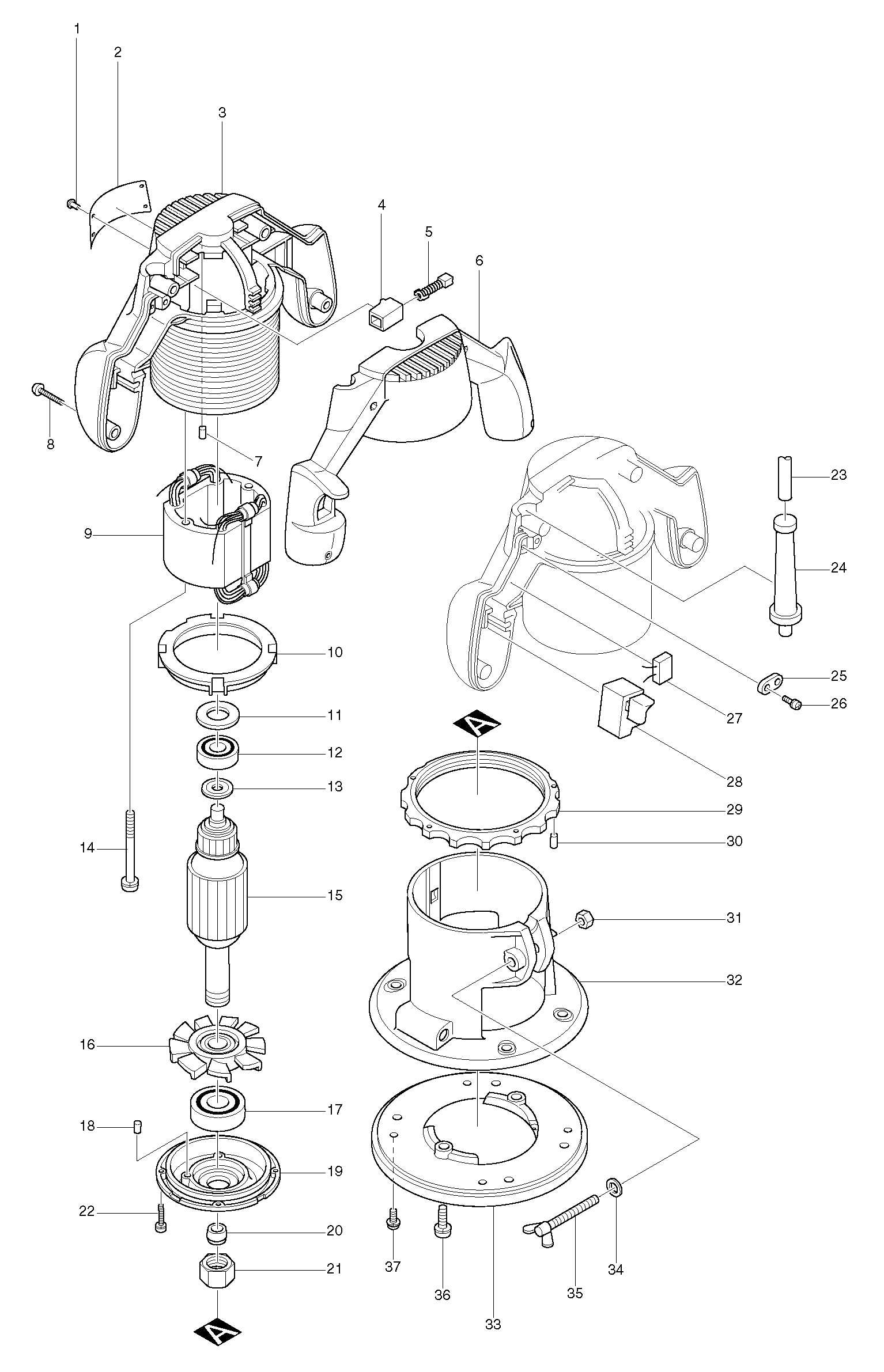

Internal Bearings and Their Role

Internal bearings play a crucial role in the smooth operation of machinery by minimizing friction between moving parts. These components are essential for ensuring the reliability and longevity of equipment, as they facilitate seamless movement and support various mechanical functions.

Functions of Internal Bearings

These elements serve multiple purposes, including:

- Reducing friction, which enhances efficiency

- Supporting loads and maintaining alignment

- Absorbing shocks and vibrations during operation

Types of Internal Bearings

There are several varieties of internal bearings, each designed for specific applications. Understanding the different types is vital for selecting the appropriate bearing for a given situation. Here is a brief overview:

| Type | Description |

|---|---|

| Ball Bearings | Utilize spherical balls to reduce friction between moving parts. |

| Roller Bearings | Use cylindrical rollers for load support and decreased friction. |

| Thrust Bearings | Designed to handle axial loads in rotary applications. |

Vibration Control and Damping Parts

Effective management of vibrations is crucial for enhancing performance and prolonging the lifespan of machinery. Components designed for this purpose play a significant role in mitigating the effects of oscillations and shocks, ensuring smooth operation. By incorporating specialized elements, users can significantly reduce wear and tear, leading to improved functionality and reliability.

Key Components

Among the various components utilized for vibration control, several types are particularly noteworthy. These elements are engineered to absorb energy, preventing excessive movement and stabilizing equipment during operation.

| Component Type | Description |

|---|---|

| Dampers | Devices that dissipate energy from vibrations, converting kinetic energy into thermal energy. |

| Mounts | Supports that isolate vibrations between equipment and its foundation, minimizing transmission. |

| Springs | Elastic elements that store and release energy, providing flexibility and reducing impact. |

Benefits of Vibration Control

Implementing effective vibration control mechanisms not only enhances equipment longevity but also improves operational efficiency. Reduced vibrations contribute to lower noise levels and better overall performance, making machinery safer and more reliable.

Maintenance Tips for Key Parts

Regular upkeep is essential for ensuring the longevity and performance of your equipment. By focusing on critical components, you can prevent issues and enhance the overall efficiency of your tools. Here are some helpful suggestions to maintain these vital elements.

- Cleanliness: Always keep the components clean and free of debris. Use a soft brush or cloth to remove dust and dirt regularly.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure you choose the right type of lubricant for your specific equipment.

- Inspection: Periodically inspect the critical elements for signs of wear or damage. Look for cracks, corrosion, or unusual wear patterns that may indicate a need for replacement.

- Tightening Fasteners: Check all screws, bolts, and other fasteners to ensure they are securely tightened. Loose components can lead to operational issues.

- Temperature Control: Monitor the operating temperature of your device. Overheating can lead to component failure, so ensure proper ventilation during use.

By adhering to these maintenance tips, you can ensure that your equipment operates smoothly and efficiently for a longer period, reducing the risk of unexpected failures.

Ordering Replacement Components Efficiently

When it comes to acquiring necessary items for maintenance or repair tasks, a systematic approach can save both time and resources. Understanding how to effectively order the required elements can streamline the process and ensure that you receive the correct components promptly.

Research and Identify Needed Items

Before placing an order, it is crucial to conduct thorough research to identify the specific items you need. Utilize available resources, such as manuals or online databases, to determine the correct specifications. Taking the time to double-check this information can help avoid any mistakes that may lead to delays or complications in your project.

Choose Reliable Suppliers

Selecting reputable suppliers is essential for ensuring the quality and accuracy of your orders. Look for vendors that specialize in the type of items you require and have positive reviews from previous customers. Establishing a good relationship with your suppliers can also lead to better pricing and faster shipping options, making the entire process more efficient.