When working with complex machinery, knowing how various elements interact is crucial for maintaining peak efficiency. The system relies on several interconnected elements that ensure smooth operation and optimal results. By understanding how each element contributes to the overall performance, you can better identify areas that may need attention or replacement.

Proper maintenance of these mechanical components plays a key role in extending the life of your equipment. Regular checks and timely replacements of essential elements help to avoid unnecessary downtime and costly repairs. Familiarizing yourself with the layout of these key parts can greatly improve the ease of upkeep and ensure smooth functioning over time.

In this guide, we will explore the critical elements that contribute to the system’s overall performance. You’ll gain insight into how each component functions and how to keep them in optimal condition for long-lasting, reliable service.

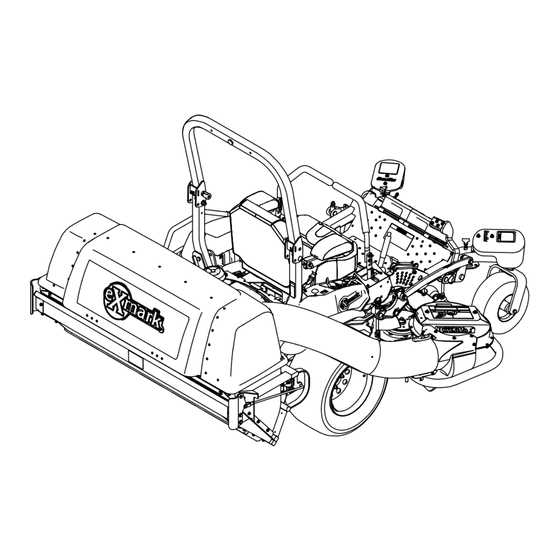

Understanding the Exmark Ultra Vac System

The system in question is designed to effectively manage debris collection during lawn maintenance. It ensures that clippings are collected efficiently, minimizing the need for manual clean-up afterward. This feature is particularly useful for maintaining the cleanliness of lawns, gardens, and other landscaped areas, allowing for a smoother and more streamlined process.

Main Features of the Collection System

- Enhanced airflow for effective debris management

- High-capacity collection that reduces the need for frequent emptying

- Compatibility with a variety of mower models

Benefits of Using the Collection System

- Improves the overall appearance of the lawn by minimizing leftover clippings

- Reduces the time required for post-mowing clean-up

- Helps in preventing the build-up of thatch, which can affect lawn health

By using this efficient collection system, you can ensure that your lawn maintenance routine is not only quicker but also leaves your property looking pristine. The seamless integration with the mower and the capacity for handling large amounts of debris make it an indispensable tool for maintaining a neat and tidy outdoor space.

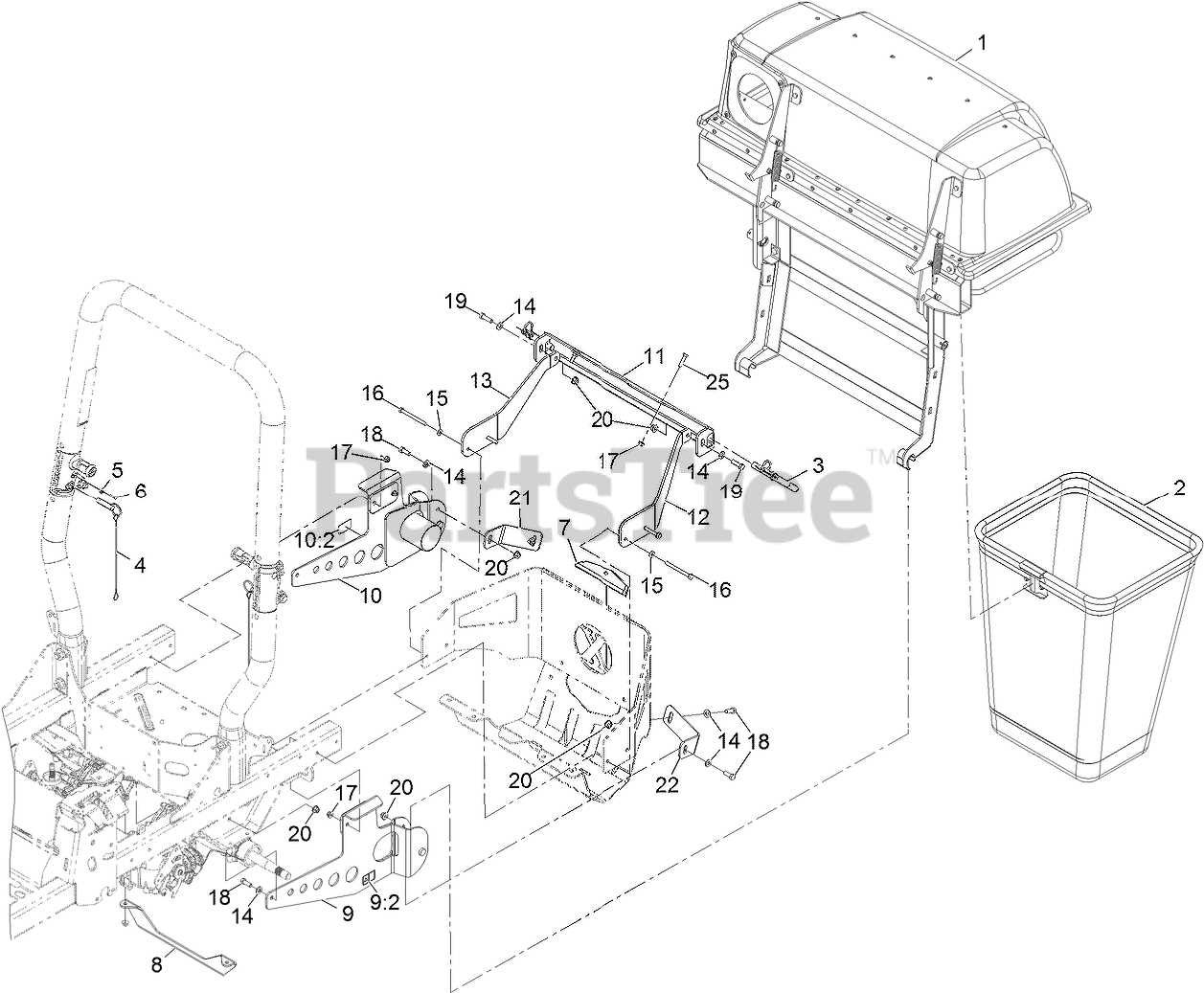

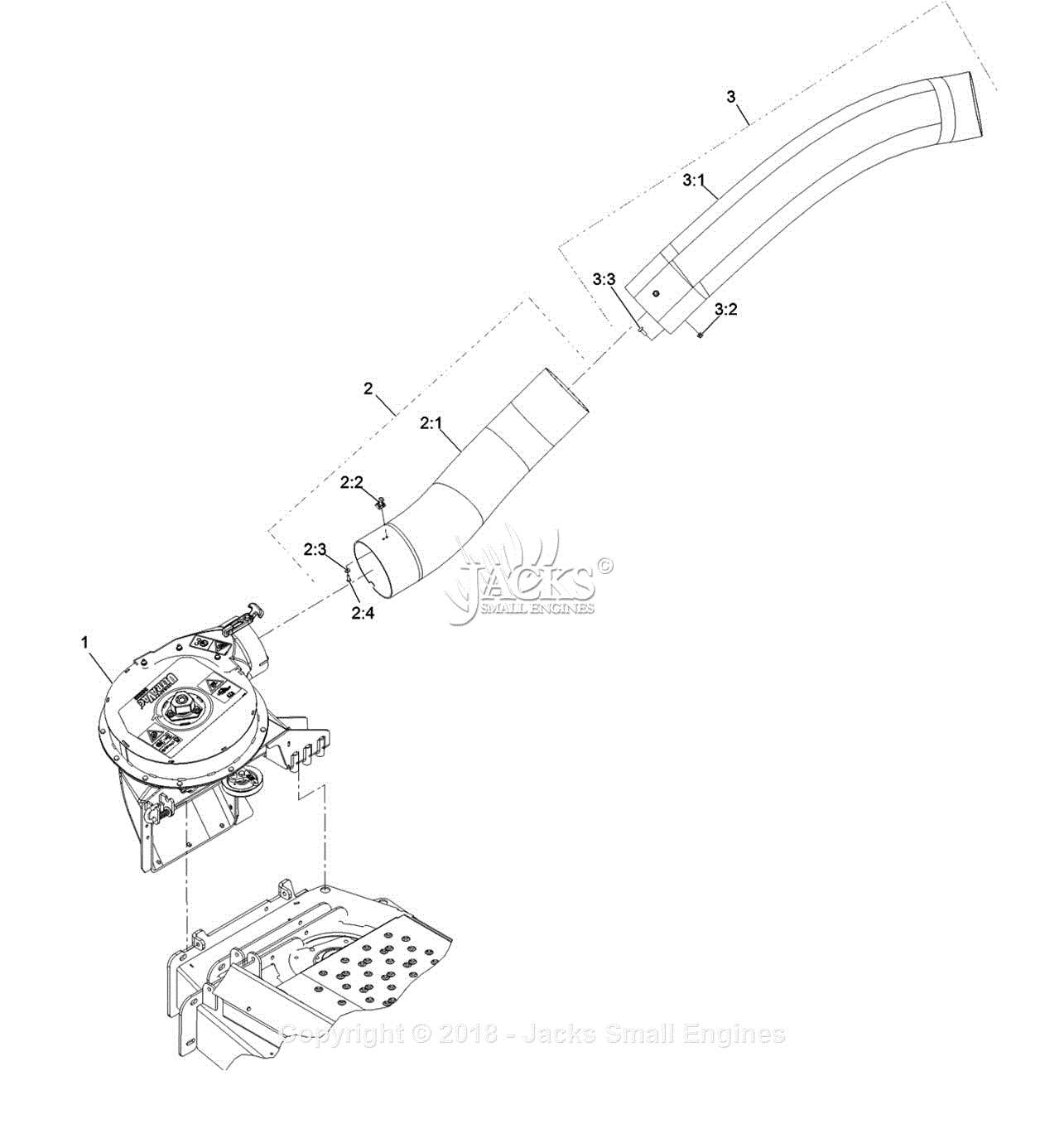

Key Components of the Ultra Vac

The main structure of the collection system relies on several essential elements that work together to ensure efficient debris management. Each part plays a significant role in the overall performance, contributing to effective handling of leaves, grass clippings, and other materials. Understanding the purpose of these components can help maintain optimal functionality and enhance overall durability.

Suction and Collection Mechanism

The system’s power depends heavily on the suction mechanism. This section is responsible for gathering materials and directing them into the collection unit. The efficiency of this process is critical for maintaining a clean working area and ensuring no debris is left behind.

- Suction intake funnel for gathering loose material

- Collection chute that transports debris to the container

- Flexible tubing to adapt to different terrains and conditions

Container and Disposal Unit

The holding container ensures that all collected materials are stored securely until disposal. A well-designed container not only holds more material but also facilitates easy emptying when full, saving time and reducing effort.

- High-capacity container for extended use

- Quick-release mecha

How to Identify Wear and Tear Parts

Over time, frequent use of machinery leads to the gradual degradation of specific components. Recognizing these areas early helps ensure continued performance and avoids more extensive damage. Understanding where to look for signs of wear is crucial for timely maintenance.

Common Signs of Deterioration

The most vulnerable areas typically show visible signs of aging, such as thinning, cracking, or changes in shape. Look out for irregular noises or a decline in the efficiency of certain functions. Physical inspections should be performed regularly, paying close attention to areas with frequent friction or exposure to harsh conditions.

Areas to Inspect Regularly

Certain components naturally experience more strain and may require more frequent replacement. Monitoring these specific sections is key to prolonging the overall lifespan of your equipment.

Component Signs of Wear Recommended Action Belts Cracking, fraying, or loss of tension Replace immediately if signs are visible Bl Replacement Guide for Ultra Vac Blades

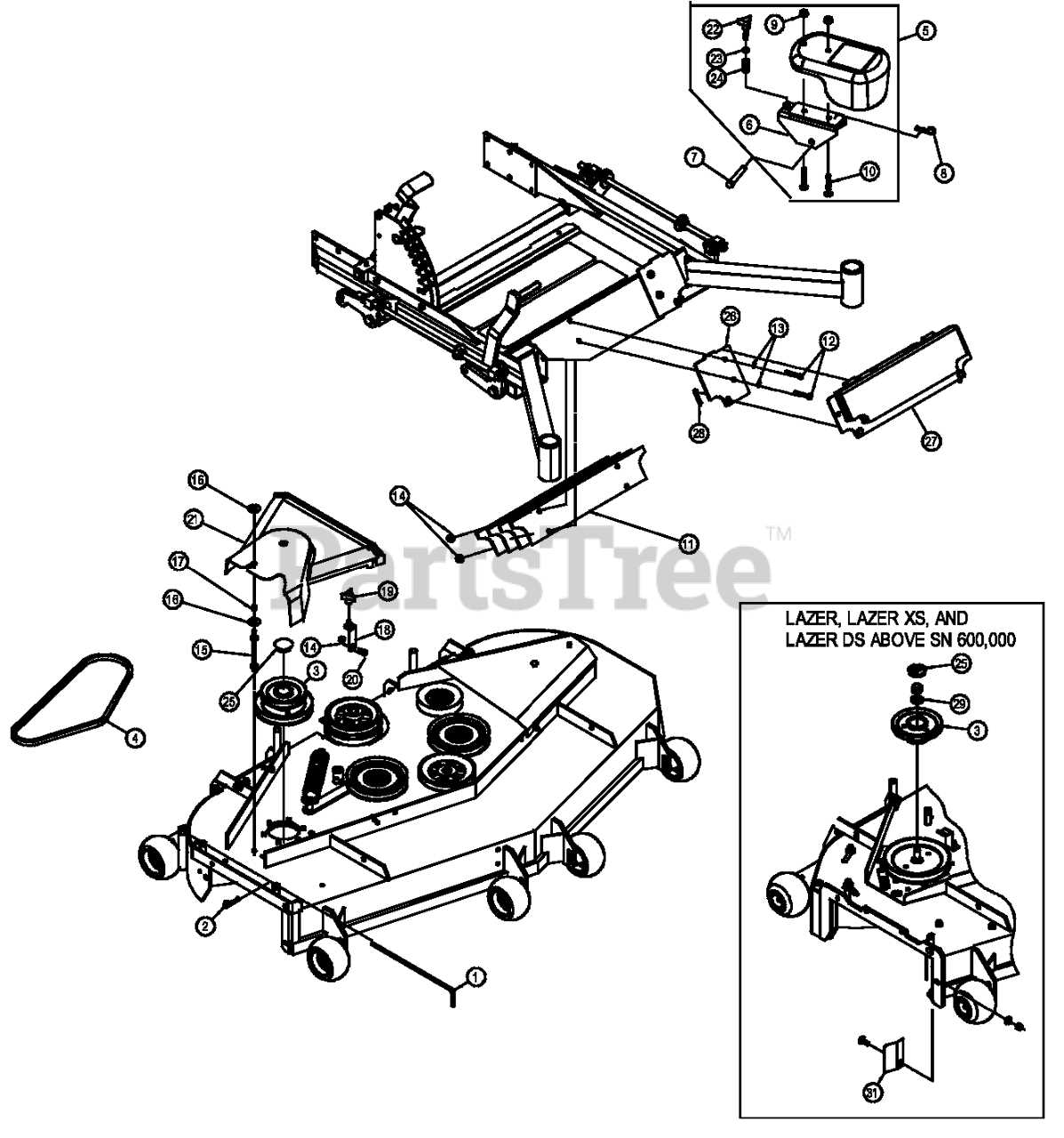

Ensuring your mower operates efficiently requires regular maintenance, including timely blade replacement. Over time, the cutting blades wear down, which can affect the quality of your lawn care. Following a step-by-step approach to replace the blades ensures consistent performance and extends the machine’s lifespan.

Steps to Replace Mower Blades

- Safety first: Disconnect the power source to avoid accidental starts during maintenance.

- Remove the old blades: Use a wrench to loosen the bolts securing the worn blades. Carefully take them off the mower deck.

- Inspect the new blades: Before installation, ensure the replacement blades are sharp and undamaged.

- Install the new blades: Position the new blades on the deck and secure them tightly with the appropriate hardware.

- Test the machine: Reconnect the power and test the mower to verify that the blades are installed correctly and functioning as expected.

Tips for Prolonging Blade Lifespan

- Regularly inspect blades for signs of wear or damage.

- Sharpen blades as needed to maintain optimal cutting performance.

- Avoid mowing over

Proper Maintenance for Longevity

Regular upkeep is essential to ensure that your equipment functions smoothly over an extended period. By adopting a consistent routine of inspection and care, you can prevent unexpected issues and ensure the machine operates at its best. Proactive attention to wear and tear, as well as the replacement of necessary components, can dramatically increase the lifespan of the machinery.

Routine Cleaning

Cleaning the machine after each use is vital to keep it in top shape. Removing debris, dust, and buildup helps prevent blockages and reduces strain on the moving parts. A clean system is less prone to overheating, ensuring it continues running efficiently.

Inspection and Lubrication

Frequent inspections of key components can help identify potential problems before they escalate. Lubricating moving parts on a regular basis ensures smooth operation and reduces friction, which can lead to premature wear. Regularly checking and replacing any worn-out pieces will also extend the life of the equipment.

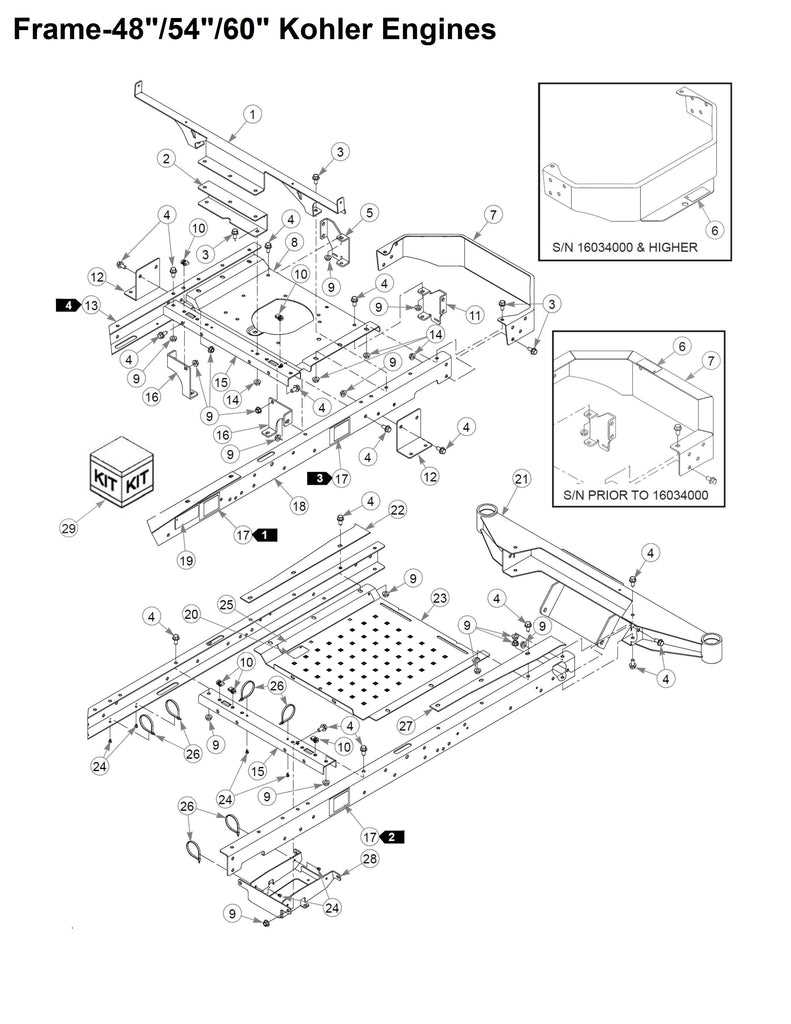

Understanding Belt System Functionality

The belt system plays a crucial role in ensuring the smooth operation of various machinery components. It facilitates the transfer of power between different mechanical parts, allowing for coordinated movement and function. By maintaining the correct tension and alignment, the belt ensures that all parts work together seamlessly, preventing slippage and ensuring efficiency. A well-functioning belt system reduces wear and tear on individual components, contributing to the overall longevity of the machine.

Proper alignment and maintenance of the belt system are essential for minimizing disruptions during operation. When the belt is in good condition, it supports continuous performance without interruptions, enhancing productivity. On the other hand, any issues in the belt’s function, such as loosening or damage, can lead to reduced effectiveness or complete shutdown of the machine.

Understanding how the belt system works helps in diagnosing potential problems early, ensuring that necessary adjustments or replacements are made before they escalate into more significant issues. Regular inspections and timely maintenance are key factors in keeping the belt system reliable and efficient.

Diagnosing Common Issues with the Ultra Vac

When your machine experiences performance problems, it’s essential to identify the root cause quickly to maintain smooth operation. Understanding the symptoms of malfunction and their potential sources can help prevent more significant issues down the line.

Uneven Debris Collection

If you notice inconsistent pick-up or scattered clippings, this may be caused by blockages in the collection system or damage to specific components. It’s important to inspect all intake areas and airflow passages to ensure nothing is obstructing the proper flow of material.

Reduced Suction Power

Weak suction can result from a variety of factors, such as worn-out belts, clogged filters, or improper maintenance. Regularly checking and cleaning the machine’s intake system, replacing worn parts, and ensuring all connections are secure can help restore full performance.

Step-by-Step Installation of New Parts

Replacing components in your equipment can significantly improve its performance and longevity. This guide will walk you through the process of installing new elements efficiently and safely, ensuring everything is properly aligned and functional. By following these steps, you can achieve optimal results without unnecessary complications.

Preparation Before Installation

Before starting, ensure that all necessary tools are available and that the machine is turned off and disconnected from any power sources. Familiarize yourself with the layout of the equipment, identifying the areas where the new pieces will be installed. This preparation step helps to avoid mistakes during the process.

Installing the Components

Begin by carefully removing any old or damaged elements from the equipment. Pay attention to how they are attached, as this will guide the installation of the new parts. Once removed, position the new components in the appropriate slots, ensuring they fit securely. Tighten any fasteners or screws, but avoid over-tightening to prevent damage. After everything is in place, double-check all connections before testing the equipment to confirm proper functionality.

Cleaning and Care Tips for Optimal Performance

Maintaining equipment in peak condition is essential for ensuring efficiency and longevity. Regular cleaning and appropriate care not only enhance functionality but also prevent potential issues that may arise from neglect. This section offers guidance on effective maintenance practices that will keep your equipment operating smoothly.

Routine Cleaning Practices

Establishing a routine for cleaning is vital. After each use, remove debris and residue that may accumulate on surfaces. Utilizing a soft brush or cloth can help in effectively clearing away dirt without damaging the equipment. Additionally, check for any blockages that could hinder performance, especially in air vents or filtration areas.

Proper Storage and Inspection

Storing equipment correctly contributes significantly to its longevity. Ensure that it is kept in a dry, sheltered area away from harsh environmental conditions. Regularly inspect components for signs of wear or damage. Promptly addressing any issues can prevent more extensive repairs in the future and maintain optimal functionality.

How to Optimize Airflow Efficiency

Maximizing the effectiveness of airflow is crucial for ensuring optimal performance in various applications. Proper airflow management not only enhances operational efficiency but also contributes to the longevity of equipment. This section explores strategies to improve airflow dynamics and highlights essential components that influence air movement.

Key Strategies for Enhancing Airflow

To achieve efficient airflow, several practices can be implemented. First, maintaining clean filters is essential, as clogged filters can restrict airflow and reduce performance. Additionally, inspecting and cleaning ducts regularly ensures unobstructed air paths. Another effective approach is to utilize aerodynamic design principles, which can significantly reduce turbulence and improve airflow direction.

Importance of Component Arrangement

The arrangement of various components plays a vital role in airflow efficiency. Strategically positioning fans and vents can create a more streamlined flow, reducing energy consumption and enhancing cooling capabilities. Furthermore, ensuring that all components are properly sealed prevents air leaks that can compromise system efficiency.

Strategy Benefits Regular Filter Maintenance Increases airflow and reduces energy costs Aerodynamic Design Minimizes turbulence and enhances flow Optimal Component Placement Improves cooling and reduces energy waste Choosing the Right Parts for Your Model

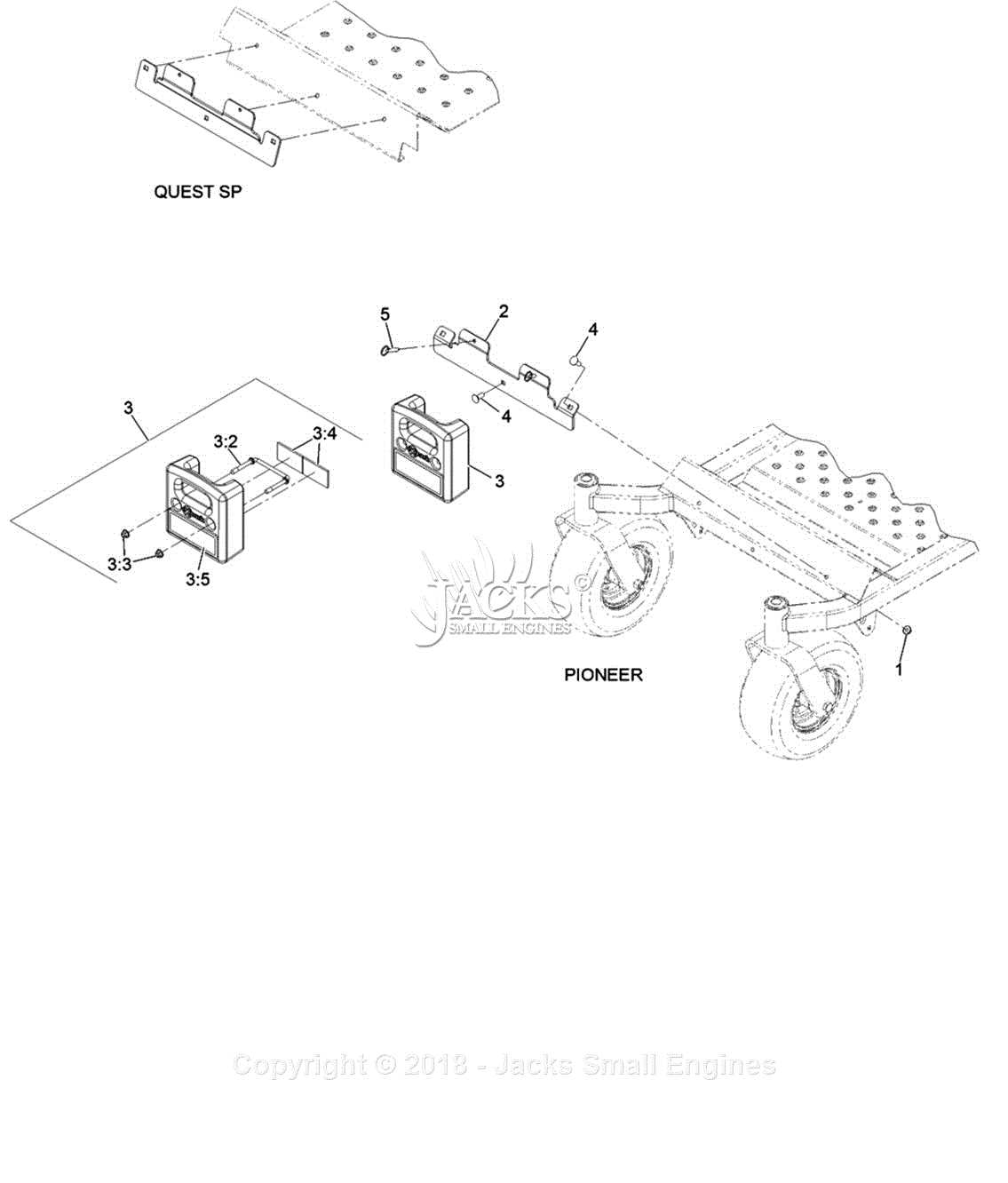

Selecting suitable components for your equipment is crucial for optimal performance and longevity. Understanding the unique specifications of your model will help ensure that you choose the most compatible and effective replacements or enhancements.

When considering which components to acquire, keep the following factors in mind:

- Compatibility: Verify that the items are designed for your specific model to prevent any functional issues.

- Quality: Opt for high-quality alternatives to guarantee durability and reliability during use.

- Functionality: Assess whether the components serve the intended purpose effectively, enhancing the overall operation.

- Availability: Ensure that the components can be easily sourced to facilitate timely repairs or upgrades.

- Cost: Consider your budget while weighing the long-term benefits of investing in quality components against cheaper options.

By carefully evaluating these factors, you can make informed decisions that contribute to the efficient functioning of your machinery.