In many emergency scenarios, specific equipment is essential to ensure the safety and efficiency of operations. One such tool, often mounted on vehicles, plays a crucial role in alerting nearby pedestrians and drivers. Its loud, distinct tones are designed to cut through ambient noise, ensuring maximum attention during critical moments. These sound-producing mechanisms are both powerful and reliable, making them a staple in various emergency fleets.

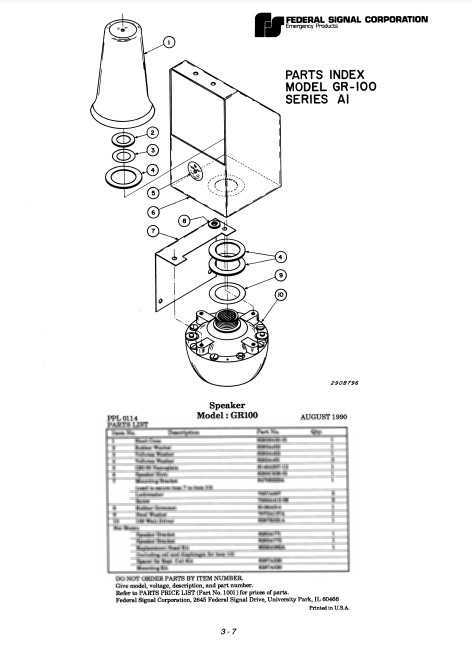

The internal workings of these devices consist of a combination of components, each contributing to the overall functionality. From electrical elements to physical rotors, every part is carefully engineered for durability and performance. Understanding how these mechanisms function and how the individual elements fit together can offer valuable insights for maintenance and repair.

This section provides an overview of the essential components that make up such systems, explaining their role and interconnections within the broader operational framework. With a deeper understanding, one can better appreciate the technology and precision involved in these sound-producing machines.

Key Components of a Q-Siren

The structure of this type of mechanical alerting device is composed of several essential elements that work together to generate its powerful and distinctive sound. These components are specifically designed to enhance the performance, ensuring a reliable and long-lasting operation under various conditions. Understanding the role of each element is crucial for maintaining the effectiveness of the system.

Main Sound Mechanism

The core of the system revolves around a rotating element that produces the unique sound by creating air pressure waves. This spinning component interacts with a stationary frame, amplifying the sound to make it audible over long distances. The balance between these moving and fixed parts is vital for the proper functioning of the entire assembly.

Control and Activation

Another key element involves the system that triggers and controls the sound production. This typically includes an activation switch that allows the operator to engage the mechanism instantly. Additionally, various speed settings may be integrated, offering flexibility in adjusting the volume and tone, depending on the operational need.

Understanding the Internal Mechanism

The structure of the sound-producing device relies on a combination of mechanical and electrical components that work in sync to create a distinctive output. This system is designed to convert energy into audible signals, ensuring both reliability and efficiency in its operation. By exploring its intricate layout, we can gain insights into how each part contributes to the overall function of the unit.

Rotational Element

A central feature in this mechanism is the rotating component. Its primary role is to generate airflow through rapid motion, which, in turn, produces sound waves. The speed and precision of this movement are key to achieving the desired acoustic effect, as the airflow directly influences the volume and frequency of the emitted sound.

Power Delivery and Control

The power system ensures that the necessary energy reaches all internal parts. Through a well-coordinated distribution of electrical currents, the system maintains consistent performance. Additionally, control mechanisms allow for modulation, giving users the ability to adjust the output to meet varying operational requirements.

Exploring the Motor Assembly Structure

The motor assembly plays a crucial role in driving mechanical operations, ensuring efficient performance through its intricate components. Understanding its design and configuration provides insight into the functionality of the entire system, highlighting the relationship between each element.

- The core of the assembly consists of a dynamic rotor that facilitates rotational movement.

- Stator windings generate the necessary magnetic fields, interacting with the rotor to produce motion.

- Brushes and commutators work in tandem to maintain electrical continuity, transferring power to various segments.

- Bearings ensure smooth rotational movement, reducing friction and wear during operation.

Each of these components contributes to the seamless operation of the motor, working together to achieve precise and reliable motion control. Understanding their interactions enhances the ability to diagnose performance issues and optimize efficiency.

The Role of Housing in Durability

The external casing plays a significant role in maintaining the longevity of mechanical systems. A robust enclosure not only protects internal components from external elements like moisture, dust, and impact, but also ensures that the device can perform reliably under various conditions. The quality of the materials and the design of the housing directly influence how well the equipment withstands environmental stress over time.

Material Selection

Choosing the right materials for the casing is crucial to extending the lifespan of any mechanical system. Durable metals, corrosion-resistant alloys, or sturdy plastics are often used to provide both protection and structural integrity. The material must be able to endure wear and tear, as well as resist environmental factors that could weaken it over time.

Design and Protection

Effective design contributes significantly to how well a casing can safeguard the internal workings of the device. A well-engineered enclosure is designed to disperse heat efficiently, protect against mechanical shock, and offer secure sealing from external contaminants. Such features enhance the overall reliability and durability, ensuring that the system can function optimally over an extended period.

Rotor Blades and Their Function

Rotor blades play a key role in generating the distinctive sound associated with certain acoustic devices. Their design and movement are crucial in transforming rotational energy into sound waves, creating a powerful and recognizable output. By spinning at high speeds, these blades interact with the surrounding air, causing vibrations that are amplified to produce the desired auditory effect.

How the Blades Operate

The operation of these components involves precise engineering. As the blades rotate, they cut through the air, generating pressure fluctuations. These variations in pressure are essential for creating the sound waves that form the core of the system’s operation. The faster the rotation, the higher the frequency of the sound produced, which is why adjustments in speed can modify the pitch and intensity.

Materials and Durability

The durability of these components depends heavily on the materials used in their construction. Typically, lightweight yet sturdy metals or high-grade composites are chosen to ensure that the blades can withstand continuous use without compromising performance. Their resistance to wear and

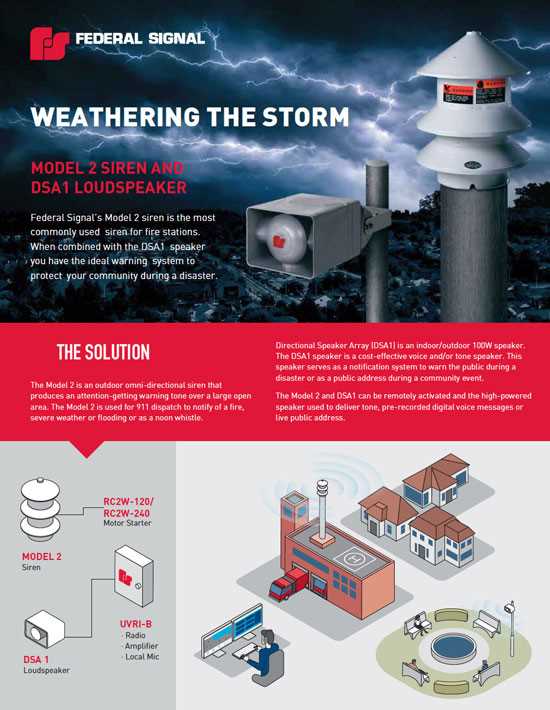

How Sound is Amplified in a Siren

Sound amplification in warning devices involves a series of mechanisms designed to enhance the volume and clarity of emitted signals. This process is crucial for ensuring that alerts can be heard over significant distances and in noisy environments.

At the heart of this amplification is the use of specialized components that convert electrical energy into acoustic energy. Resonators play a pivotal role by vibrating in response to electrical signals, which increases the sound output. The design and materials used in these elements can significantly influence the quality and intensity of the sound produced.

Additionally, the horn structure serves as an important feature that directs and projects the sound waves outward. By focusing the sound in a specific direction, it enhances the overall reach and impact of the alerts. This combination of resonators and projecting elements ensures that the audio signals are not only louder but also more effective in capturing attention.

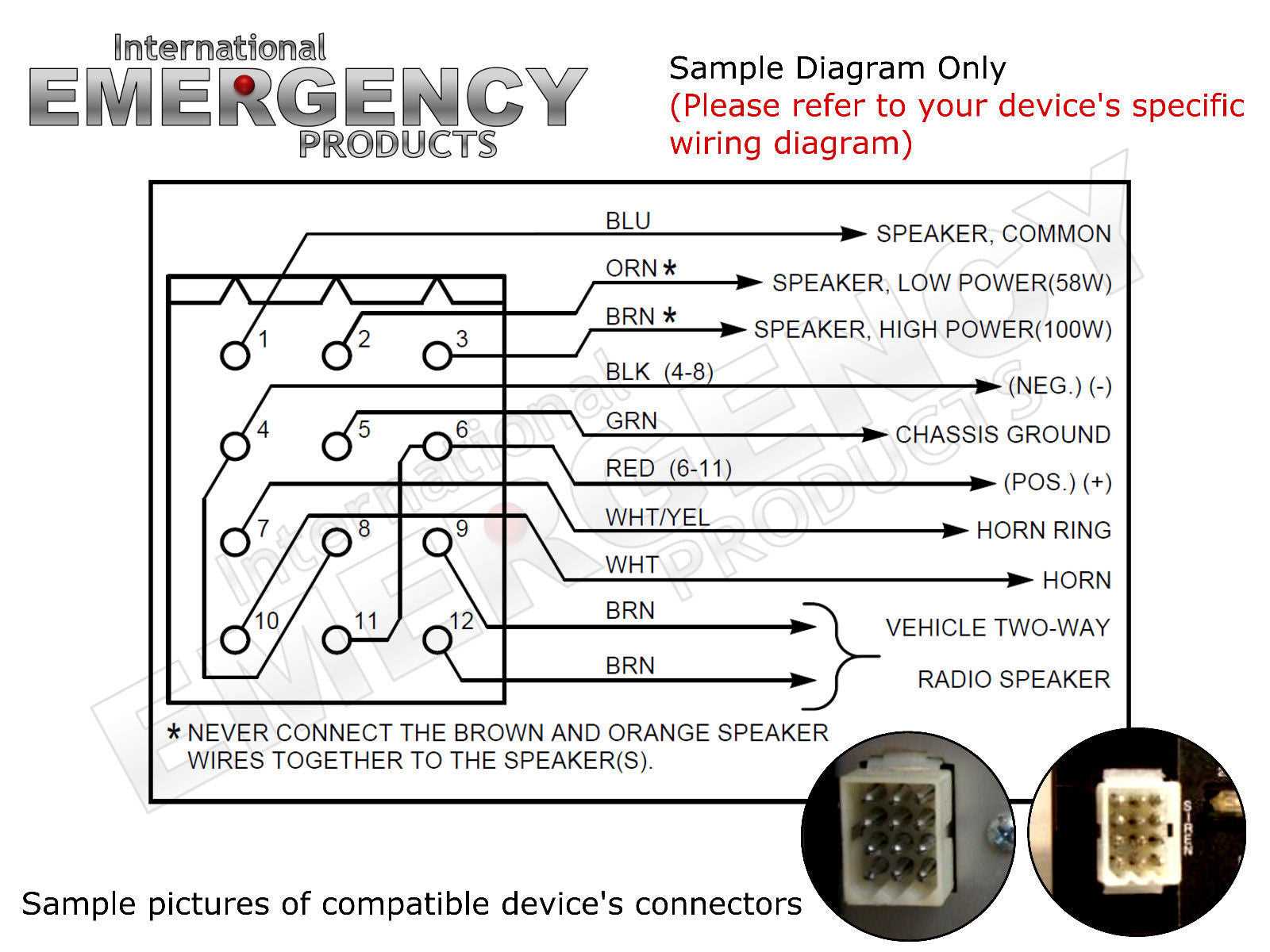

Wiring Setup for Optimal Performance

Achieving peak functionality in audio signaling systems requires a meticulous approach to their connectivity. The arrangement and quality of wiring can significantly influence overall efficiency and sound output. By ensuring proper connections and selecting suitable components, users can maximize the system’s potential.

Choosing the Right Cables

Utilizing high-quality conductors is essential for minimizing signal loss and distortion. Thicker wires with lower resistance facilitate better transmission, ensuring that the audio signal remains intact throughout the setup. Additionally, considering the insulation material is vital, as it helps to prevent interference from external sources.

Connection Techniques

Employing proper connection techniques enhances reliability and performance. Soldering connections is often preferred for its durability and superior conductivity. Alternatively, high-quality connectors can provide flexibility while maintaining effective performance. Regularly inspecting connections for wear and corrosion is also crucial to sustain optimal functionality over time.

Identifying Maintenance Essentials

Proper upkeep is crucial for ensuring optimal functionality and longevity of any complex device. Regular attention to essential components can prevent unexpected failures and enhance overall performance. Understanding the necessary elements involved in maintenance is key for effective service management.

Routine Inspections: Consistent assessments are vital for identifying wear and tear on critical elements. This proactive approach allows for early detection of issues, facilitating timely interventions.

Component Replacement: Some parts may degrade over time, necessitating replacement to maintain efficiency. Keeping track of these components ensures that the system remains in peak condition.

Cleaning Procedures: Accumulation of dirt and debris can hinder performance. Implementing regular cleaning routines helps to maintain optimal operation and prevent damage.

Documentation: Keeping accurate records of maintenance activities aids in tracking performance over time. This information can be invaluable for making informed decisions regarding future service needs.

Protecting the Siren from Environmental Damage

Safeguarding audio alert devices from the elements is crucial to ensure their longevity and reliability. Exposure to harsh weather conditions can lead to malfunctions, decreased performance, and ultimately, failure. Implementing protective measures is essential for maintaining operational integrity and optimal functionality.

To effectively shield these devices from environmental threats, consider the following strategies:

- Weatherproof Enclosures: Utilize specially designed cases that offer resistance to moisture and dust, ensuring that internal components remain protected.

- UV Protection: Select materials or coatings that are resistant to ultraviolet rays to prevent degradation and color fading over time.

- Vibration Dampening: Implement cushioning materials to absorb shocks and vibrations, which can occur during operation, thus preserving structural integrity.

- Temperature Regulation: Incorporate thermal management solutions to prevent overheating or freezing, which can impact performance and longevity.

Regular maintenance and inspections should also be prioritized to identify and rectify any potential issues early. By proactively addressing environmental risks, the durability and functionality of audio alert devices can be significantly enhanced.

Compatibility of Parts in Different Models

Understanding how components function together across various systems is crucial for ensuring optimal performance. Different iterations of a device may incorporate similar elements, yet subtle variations can impact their interoperability. This section explores how components from one model can be utilized or adapted for another, highlighting the importance of cross-compatibility in maintaining efficiency and reliability.

When assessing compatibility, it’s essential to consider the specifications of each model. While certain features may appear identical, differences in voltage, size, or design can lead to discrepancies. Analyzing these factors can guide users in selecting the appropriate components, enabling them to enhance or repair their systems effectively. Furthermore, manufacturers often provide guidelines to assist in identifying suitable replacements, ensuring that users can make informed choices.

In conclusion, the interchangeability of components among various models not only streamlines maintenance but also encourages users to explore upgrades. By understanding the nuances of compatibility, one can make strategic decisions that enhance functionality while minimizing potential issues.

Evaluating Replacement Options and Upgrades

When considering the enhancement or substitution of a signaling device, it is crucial to assess various factors to ensure optimal performance and compatibility. Understanding the specifications and features of potential alternatives can lead to improved functionality and longevity.

Several aspects should be taken into account during the evaluation process:

- Compatibility: Ensure that the new component is compatible with existing systems and meets required operational standards.

- Performance: Look for enhancements in sound output, efficiency, and durability that may provide better service in critical situations.

- Installation: Consider the ease of installation and whether any additional modifications or tools are necessary.

- Cost: Evaluate the overall cost-effectiveness of the upgrade, taking into account both the initial investment and long-term maintenance costs.

By systematically examining these factors, users can make informed decisions regarding the most suitable alternatives and enhancements for their signaling systems.