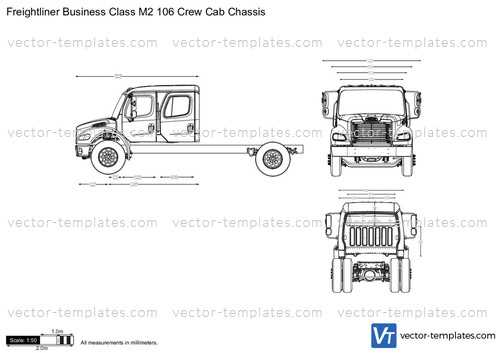

Exploring the intricacies of heavy-duty vehicles involves a detailed examination of their structural elements. Having a comprehensive overview of how different components are arranged not only enhances maintenance efficiency but also aids in troubleshooting potential issues that may arise during operation.

Visual representations of these arrangements serve as invaluable resources for mechanics and technicians alike. By utilizing clear illustrations, one can easily identify the various sections and understand how they interact within the overall framework of the vehicle.

Such resources play a crucial role in ensuring optimal performance and longevity of the machinery. Familiarity with the specific arrangements of various components empowers users to make informed decisions regarding repairs and upgrades, ultimately leading to improved functionality and reliability.

Regular upkeep of vehicles is crucial for ensuring their longevity and optimal performance. Neglecting maintenance can lead to unforeseen breakdowns and costly repairs. By adhering to a routine maintenance schedule, vehicle owners can enhance reliability, safety, and overall efficiency.

Benefits of Regular Upkeep

Consistent maintenance practices contribute to various advantages, including improved fuel efficiency, reduced emissions, and enhanced safety features. Additionally, a well-maintained vehicle can have a higher resale value, making it a worthwhile investment for owners.

Common Maintenance Tasks

To maintain peak performance, several routine tasks should be prioritized. These include checking fluid levels, inspecting tire conditions, and ensuring that all essential systems are functioning correctly. Below is a table outlining key maintenance tasks and their recommended frequency:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 – 7,500 miles |

| Tire Rotation | Every 5,000 – 7,500 miles |

| Brake Inspection | Every 10,000 miles |

| Fluid Checks | Monthly |

| Battery Inspection | Every 6 months |

Common Issues and Solutions

In the realm of commercial vehicles, various challenges may arise that can affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality. This section explores typical concerns encountered in heavy-duty trucks and provides practical solutions to address them effectively.

Engine Performance Problems

Engine-related issues often manifest as reduced power or unusual noises. These symptoms can result from factors such as poor fuel quality, air intake restrictions, or malfunctioning sensors. Regular maintenance, including timely oil changes and air filter replacements, can mitigate these concerns. Additionally, utilizing high-quality fuel can enhance engine performance and longevity.

Brake System Failures

The braking system is crucial for safety and operational efficiency. Common symptoms of brake problems include unusual noises, reduced responsiveness, or warning lights. These issues may stem from worn brake pads, air leaks in the system, or hydraulic fluid contamination. Regular inspections and prompt replacement of worn components are essential practices to ensure the brake system functions reliably.

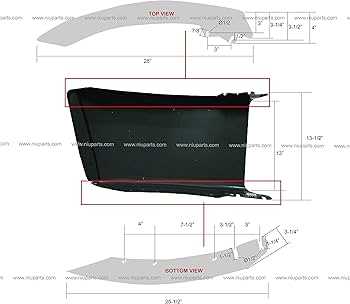

Replacement Part Identification

Identifying the correct components for vehicle maintenance is essential for ensuring optimal performance and longevity. This section will guide you through the process of recognizing and selecting appropriate replacement elements for your vehicle.

When looking for suitable substitutes, consider the following factors:

- Specifications: Always verify the technical specifications of the component to ensure compatibility with your vehicle’s system.

- Manufacturer Guidelines: Consult the manufacturer’s recommendations for approved alternatives to maintain warranty coverage.

- Quality Standards: Opt for components that meet or exceed industry quality standards to avoid premature failures.

To streamline your search, follow these steps:

- Identify the specific element that requires replacement.

- Locate the part number or model reference associated with the component.

- Research authorized distributors or online platforms that specialize in automotive components.

- Cross-reference the identified part with available alternatives to confirm compatibility.

By following these guidelines, you can ensure that the replacement components you choose are suitable and reliable, ultimately enhancing your vehicle’s functionality.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer (OEM) components offers numerous advantages that enhance the overall performance and reliability of vehicles. These components are specifically designed to fit seamlessly and function effectively, ensuring optimal operation.

One significant benefit of choosing OEM components is their superior quality. Crafted to meet rigorous standards, these parts provide a level of durability and dependability that aftermarket alternatives often cannot match. Additionally, OEM components come with a warranty, which gives vehicle owners peace of mind knowing that their investment is protected.

Another advantage is the precise compatibility with the vehicle. Since OEM components are made specifically for a particular make and model, they ensure a perfect fit and function. This compatibility can lead to improved efficiency and reduced chances of malfunctions, ultimately saving time and money on repairs.

Furthermore, using OEM components can help maintain the vehicle’s resale value. Prospective buyers often prefer vehicles equipped with original parts, recognizing the quality and reliability they represent. Thus, investing in OEM components can contribute to a higher resale price in the future.

In conclusion, selecting original equipment manufacturer components is a wise choice for those seeking reliability, quality, and value in their vehicles. By opting for these superior options, owners can ensure their vehicles perform at their best and retain their worth over time.

Tools for Parts Replacement

Replacing components in vehicles requires a specific set of instruments to ensure efficiency and precision. Having the right tools not only simplifies the process but also minimizes the risk of damage to the vehicle or the new components. Below is an overview of essential tools needed for effective replacement tasks.

Essential Hand Tools

Basic hand tools are indispensable when it comes to component replacement. These tools allow for the disassembly and assembly of various parts with ease. Here are some crucial hand tools to consider:

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening or tightening bolts and nuts. |

| Wrenches | Essential for gripping and turning fasteners. |

| Screwdrivers | Used for inserting or removing screws. |

| Pliers | Helpful for holding, bending, and cutting wires. |

Specialized Equipment

In addition to standard hand tools, specialized equipment may be necessary for certain tasks. These tools help to perform specific functions that standard tools cannot handle effectively. Consider the following specialized tools:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Diagnostic Scanner | Used to read and clear error codes from the vehicle’s computer. |

| Impact Wrench | Provides high torque output for heavy-duty fasteners. |

| Brake Bleeder Kit | Assists in removing air from the brake system. |

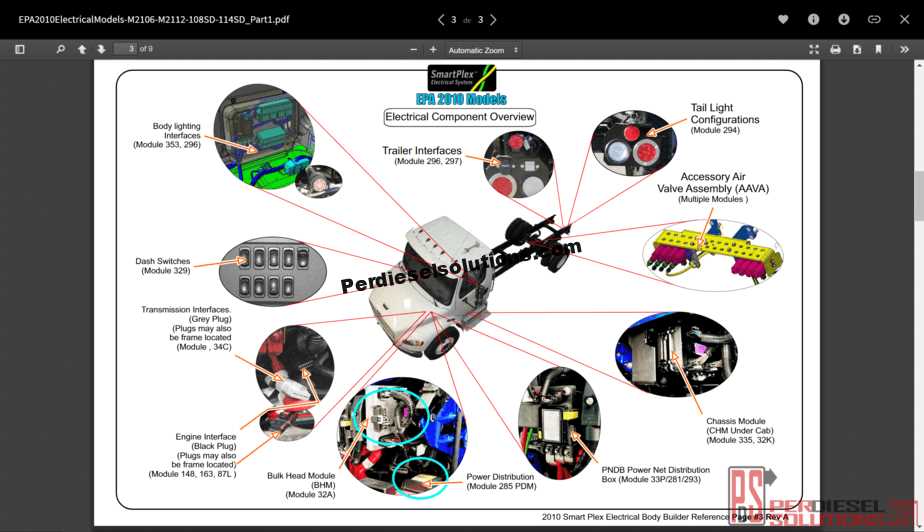

Detailed Wiring Diagram Analysis

This section delves into the intricate analysis of electrical schematics, providing a comprehensive understanding of the connections and components involved. By examining the layout and relationships between various elements, one can gain insights into the functionality and troubleshooting of the electrical system.

A thorough exploration of these schematics reveals essential information regarding power distribution, signal pathways, and component interdependencies. Understanding how each part interacts within the network is crucial for effective maintenance and repair. This knowledge not only enhances the ability to identify potential issues but also aids in optimizing overall performance.

By dissecting the wiring configuration, one can pinpoint critical areas that require attention or upgrading. Whether it involves inspecting for wear and tear or ensuring proper connections, a detailed analysis of the wiring structure is vital for ensuring reliability and safety in operations.

Accessing the Parts Catalog

To effectively maintain and repair your vehicle, having access to a comprehensive catalog is essential. This resource provides vital information on various components, facilitating informed decisions during servicing or upgrades. Understanding how to navigate this catalog will enhance your repair experience and ensure proper functionality.

Online Resources

Many manufacturers offer digital catalogs that can be easily accessed through their websites. Here are some steps to follow:

- Visit the official website of the manufacturer.

- Locate the section dedicated to support or resources.

- Search for the catalog or database specific to your vehicle model.

- Utilize filters to narrow down components based on categories.

Printed Manuals

In addition to online resources, printed manuals are also valuable. These documents often contain detailed illustrations and part numbers. Consider the following:

- Check with authorized dealers for availability of printed manuals.

- Ensure the manual corresponds to your vehicle model for accurate information.

- Keep the manual accessible for quick reference during maintenance tasks.

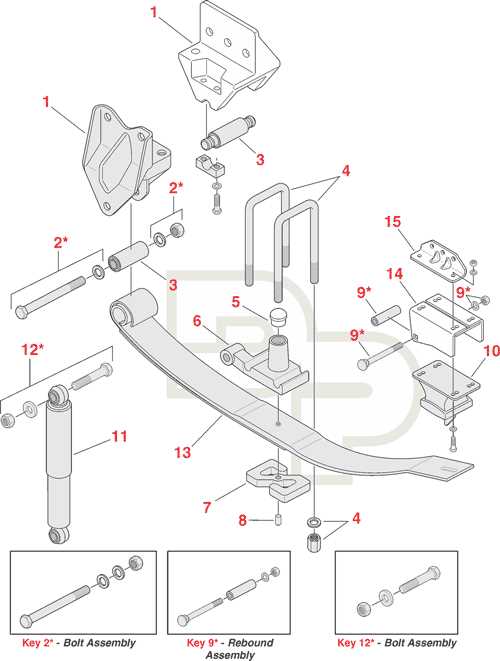

Step-by-Step Repair Guide

This section provides a comprehensive approach to effectively addressing maintenance and repair tasks for commercial vehicles. Following a structured process ensures that every issue is resolved efficiently, enhancing the longevity and performance of the vehicle.

To facilitate a successful repair, it is crucial to follow specific steps. Begin by identifying the problem, gathering necessary tools, and ensuring a safe working environment. The following table outlines the key steps involved in the repair process:

| Step | Description |

|---|---|

| 1 | Assess the situation and identify the malfunction. |

| 2 | Gather the required tools and replacement components. |

| 3 | Ensure the vehicle is in a secure and safe position. |

| 4 | Proceed with the disassembly of necessary parts for access. |

| 5 | Perform the required repairs or replacements. |

| 6 | Reassemble the components in the reverse order of disassembly. |

| 7 | Test the vehicle to ensure proper functionality. |

By adhering to this structured repair guide, individuals can tackle maintenance challenges with confidence and expertise, leading to improved vehicle reliability.

Upgrades and Customization Options

When it comes to enhancing your vehicle’s performance and aesthetics, various modifications and enhancements can significantly improve its functionality and visual appeal. These upgrades not only elevate the driving experience but also allow for personalization to meet individual preferences.

Consider the following options for upgrading and customizing your vehicle:

- Performance Enhancements: Improving the engine’s efficiency and power can be achieved through aftermarket exhaust systems, turbochargers, or performance chips.

- Suspension Upgrades: Enhancing ride quality and handling can be accomplished by installing upgraded shock absorbers, springs, or air suspension systems.

- Exterior Modifications: Customizing the look of your vehicle can involve adding new paint, body kits, or specialized lighting.

- Interior Customization: Upgrading the cabin with premium upholstery, advanced infotainment systems, or enhanced sound insulation can create a more comfortable and enjoyable driving environment.

- Wheels and Tires: Swapping out the factory wheels for custom designs and high-performance tires can improve both aesthetics and handling.

Each of these upgrades provides an opportunity to tailor the vehicle to your specific needs, enhancing both its performance and style.