In the realm of machinery and equipment, a clear visualization of individual elements is essential for effective maintenance and repair. Understanding how each component fits together can significantly enhance operational efficiency and simplify troubleshooting processes. This section aims to provide a comprehensive overview of various components and their relationships within a specific assembly.

By analyzing the layout of these essential elements, users can better appreciate their functionality and interconnectivity. This insight not only aids in identifying potential issues but also empowers operators to make informed decisions during servicing. The intricate design of machinery often requires a detailed exploration to ensure optimal performance and longevity.

Furthermore, having access to a detailed overview fosters confidence in both novice and experienced users alike. By demystifying the complex relationships between components, individuals are equipped to tackle repairs with greater assurance and precision. Emphasizing a thorough understanding of these intricate systems ultimately leads to enhanced reliability and productivity.

This section aims to provide a comprehensive overview of the components and their arrangement within a specific model. Understanding how each piece interacts within the overall structure is essential for effective maintenance and repair. By delving into the specifics, readers can gain valuable insights into functionality and troubleshooting.

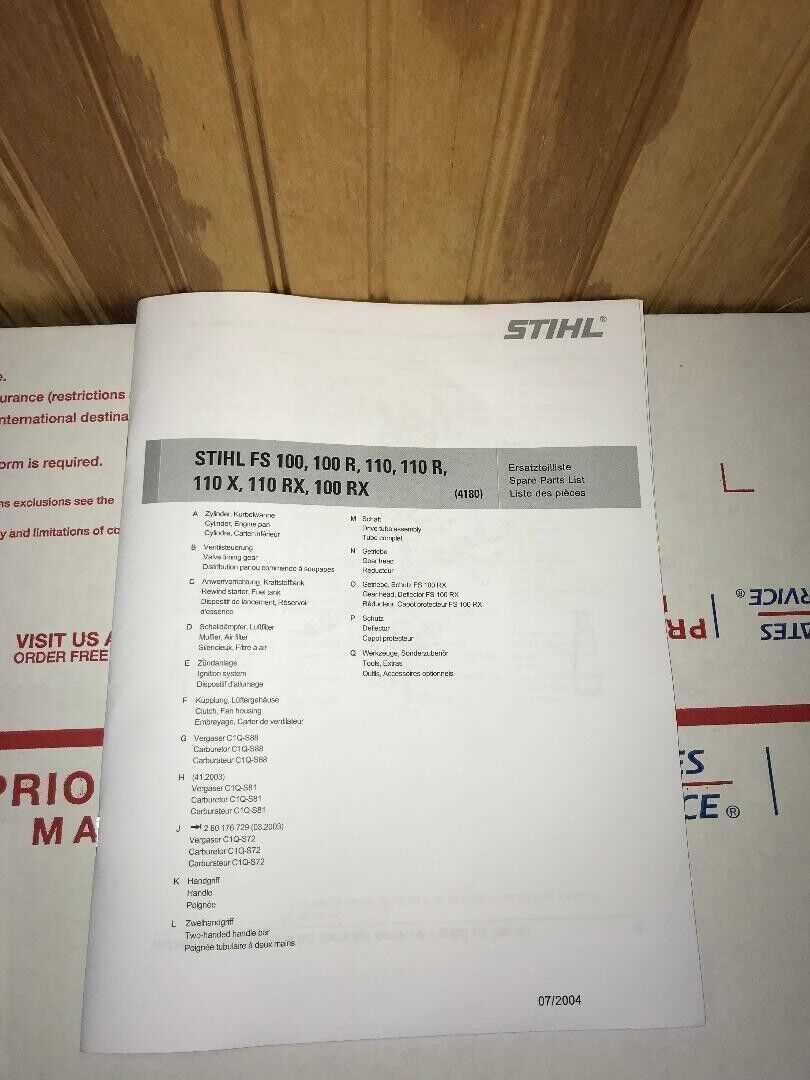

1. Introduction to the Model

This part will introduce the subject matter, emphasizing its significance and common applications.

2. Key Components Overview

Here, we will outline the primary elements that make up the unit.

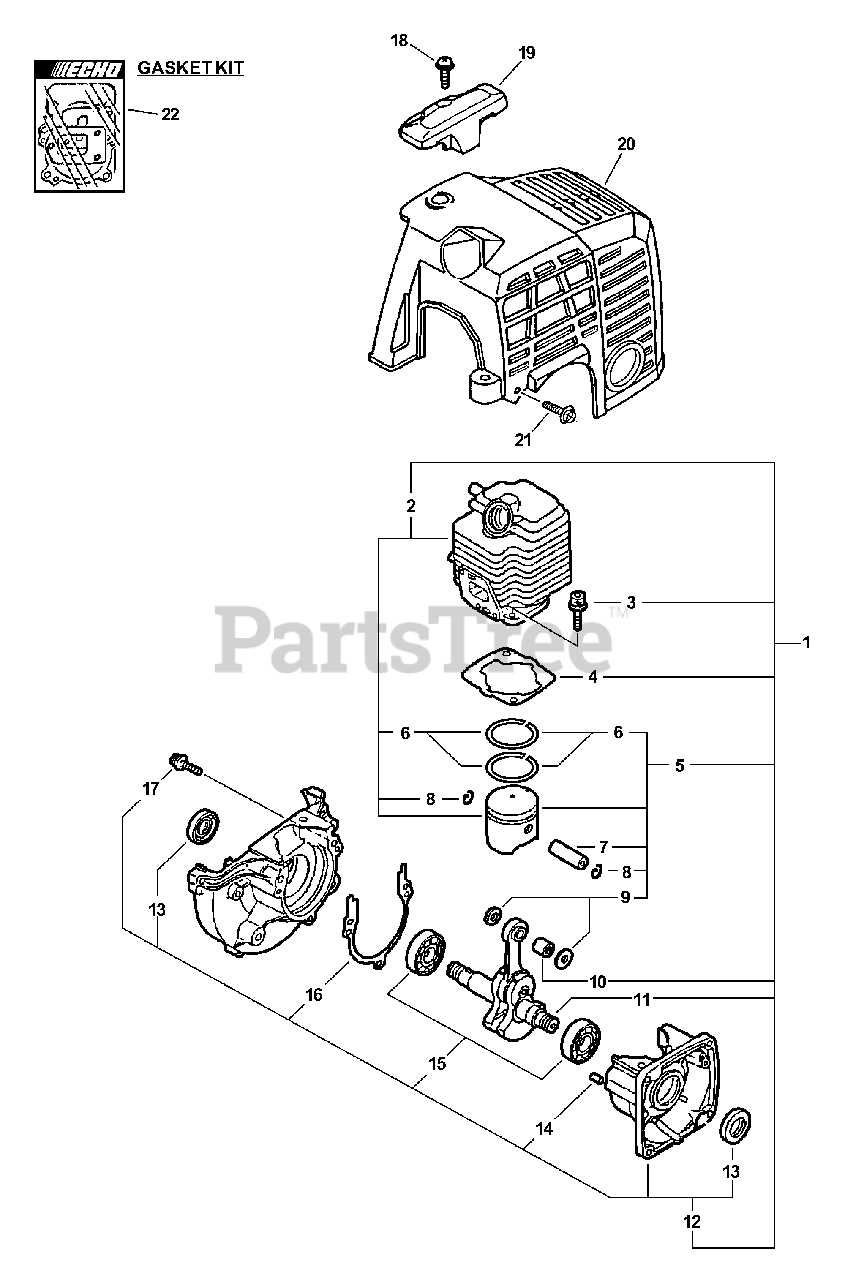

- Engine Assembly

- Control Panel

- Drive Mechanism

3. Understanding the Engine Assembly

This section will explain the critical role of the engine assembly in performance and efficiency.

4. Importance of the Control Panel

We will discuss the functionality of the control panel and its user interface.

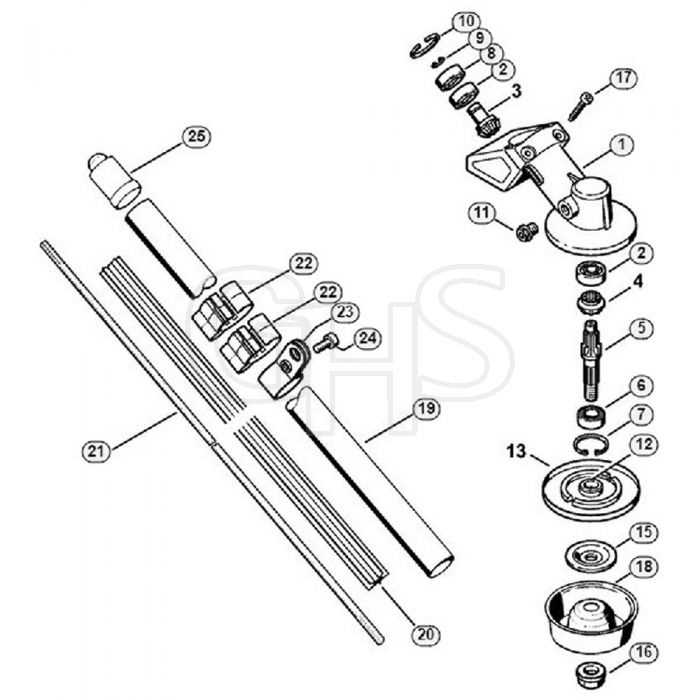

5. Drive Mechanism Details

An exploration of the drive mechanism and how it powers the unit.

6. Maintenance Tips

Essential practices to ensure longevity and optimal performance.

- Regular inspections

- Lubrication schedules

- Part replacements

7. Common Issues

A review of frequent problems encountered and their possible solutions.

8. Troubleshooting Guide

Steps to diagnose and address various faults.

9. Repair Techniques

Methods for effectively addressing and fixing common issues.

10. Safety Precautions

Critical safety measures to follow when working with the model.

11. Conclusion

A summary of the importance of understanding the arrangement and functionality of components for improved maintenance practices.

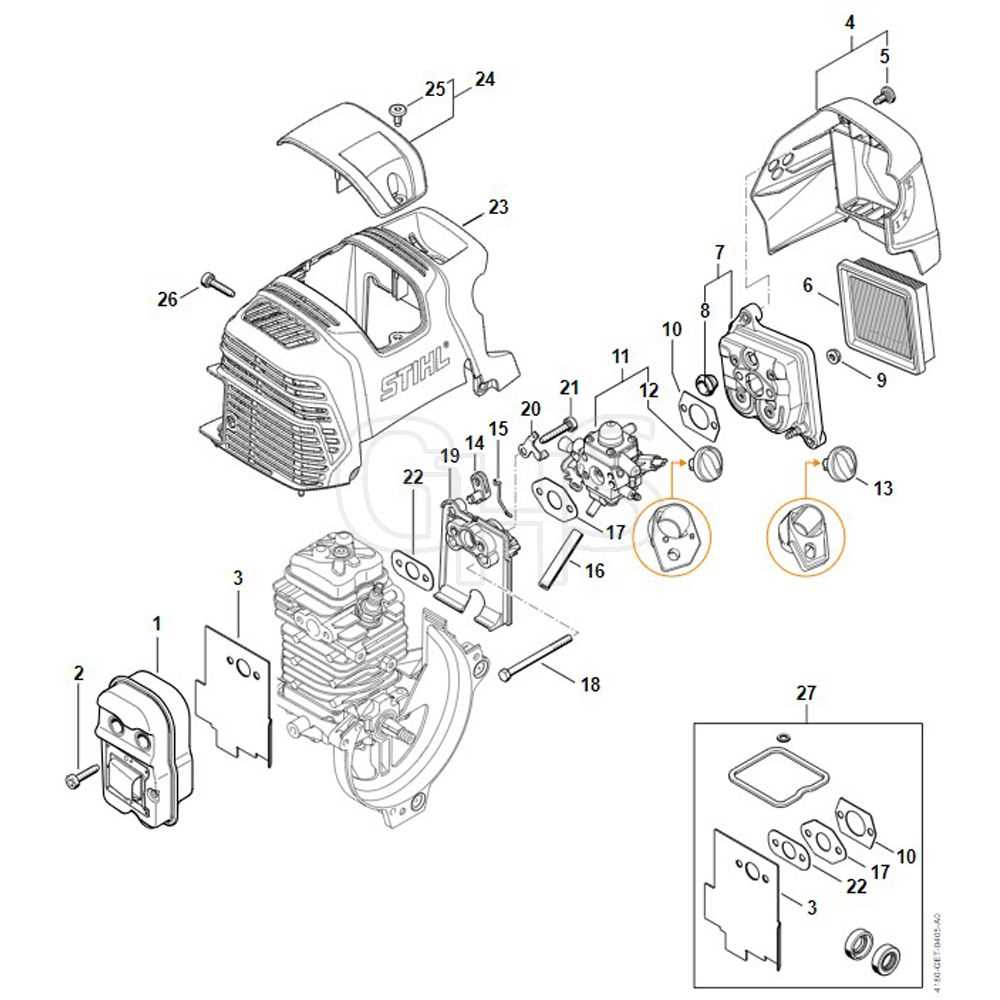

Key Components of FS110 System

The functionality of any sophisticated system relies on its essential elements, which work in unison to deliver optimal performance. Understanding these crucial components is vital for efficient operation and maintenance. This section delves into the primary features that constitute the system, highlighting their roles and interconnections.

| Component | Description |

|---|---|

| Engine | The powerhouse responsible for driving the entire mechanism, providing the necessary energy for operation. |

| Control Unit | This element manages the various functions, ensuring that the system responds accurately to user inputs. |

| Transmission System | Facilitates the transfer of power from the engine to other components, enabling seamless movement and function. |

| Fuel System | Handles the storage and delivery of fuel, crucial for sustaining engine performance. |

| Cooling System | Prevents overheating by regulating temperatures, ensuring the system operates within safe limits. |

| Frame | The structural foundation that supports all components, providing stability and durability. |

Importance of Accurate Parts Diagram

An accurate representation of components is essential for effective maintenance and repair. It enables technicians to quickly identify individual elements and understand how they interact within the overall system. This clarity helps prevent errors during assembly or disassembly, ultimately enhancing efficiency and reducing downtime.

Facilitating Troubleshooting

Clear visuals simplify the process of diagnosing issues. When professionals can easily locate each part, they can swiftly pinpoint the source of a malfunction. This speed not only saves time but also minimizes disruption in operations, making the overall repair process more efficient.

Enhancing Training and Knowledge

Detailed schematics serve as valuable educational tools for new technicians. They provide a visual guide that complements theoretical knowledge, fostering a deeper understanding of the equipment’s structure and function. This foundational knowledge is crucial for developing skilled professionals who can perform repairs and maintenance competently.

| Benefits | Description |

|---|---|

| Efficiency | Reduces time spent on repairs by providing clarity. |

| Accuracy | Minimizes the risk of errors during maintenance. |

| Training | Supports the education of technicians through visual aids. |

Common Issues with FS110 Parts

When dealing with machinery components, several challenges may arise that can affect performance and efficiency. Understanding these potential problems can help in timely maintenance and effective resolution.

Frequent Problems

- Wear and Tear: Over time, components can degrade due to constant use, leading to decreased functionality.

- Improper Installation: Incorrect assembly can cause malfunctions and affect the overall operation.

- Material Fatigue: Repeated stress on materials can result in cracks or breaks, compromising reliability.

Signs of Trouble

- Unusual Noises: Any strange sounds during operation may indicate an underlying issue.

- Decreased Performance: A noticeable decline in efficiency is often a red flag for component-related problems.

- Visible Damage: Cracks, dents, or other physical defects should prompt immediate inspection.

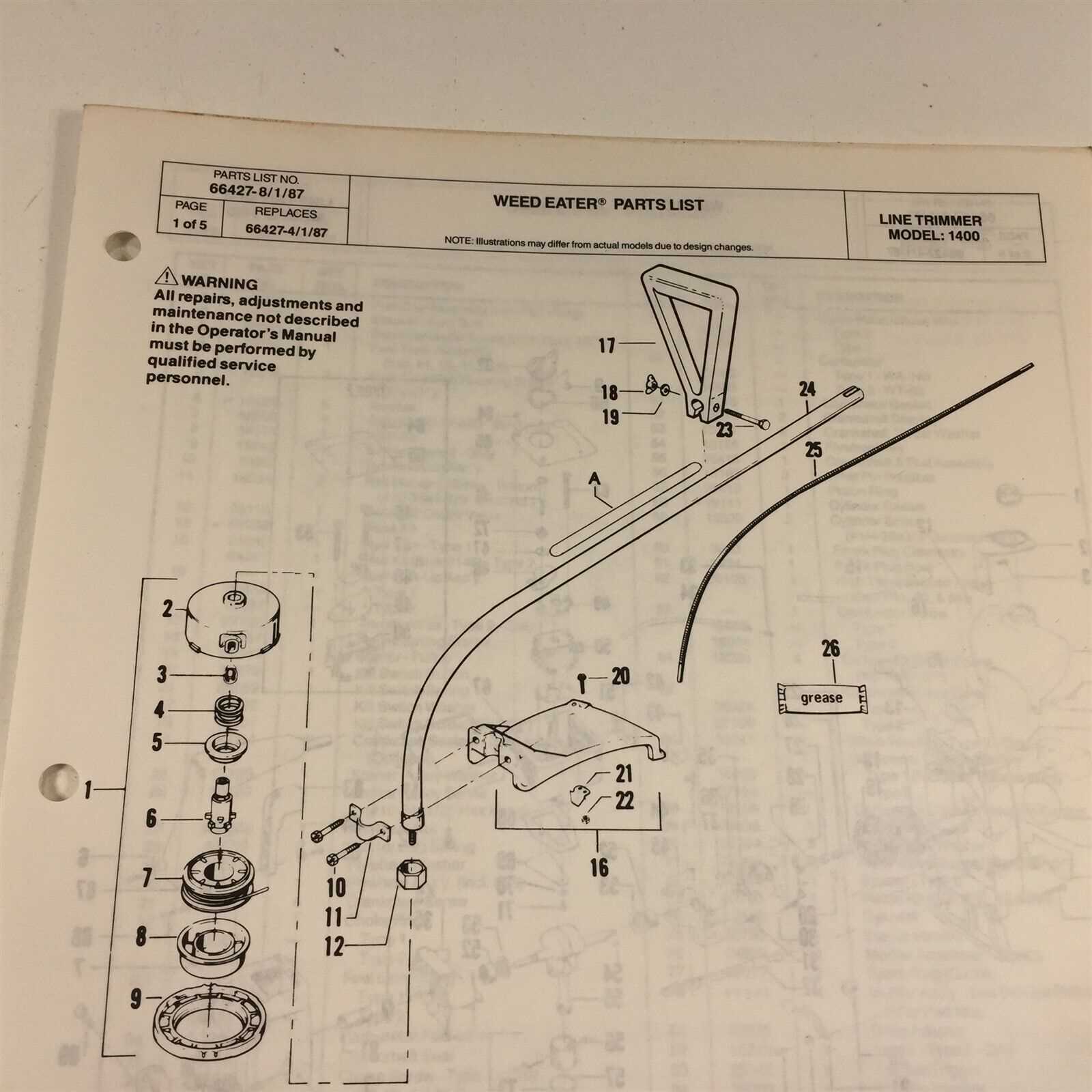

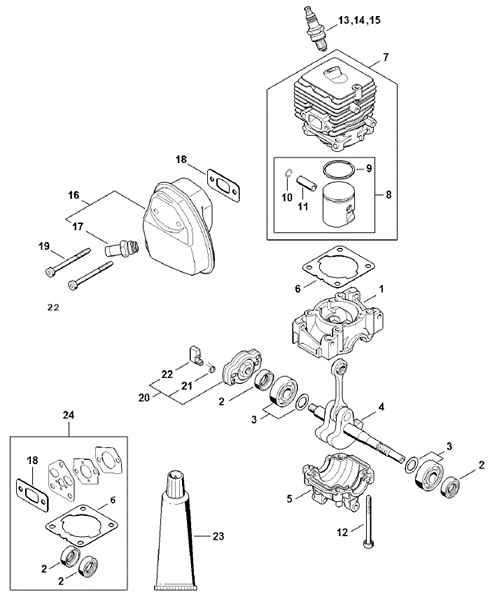

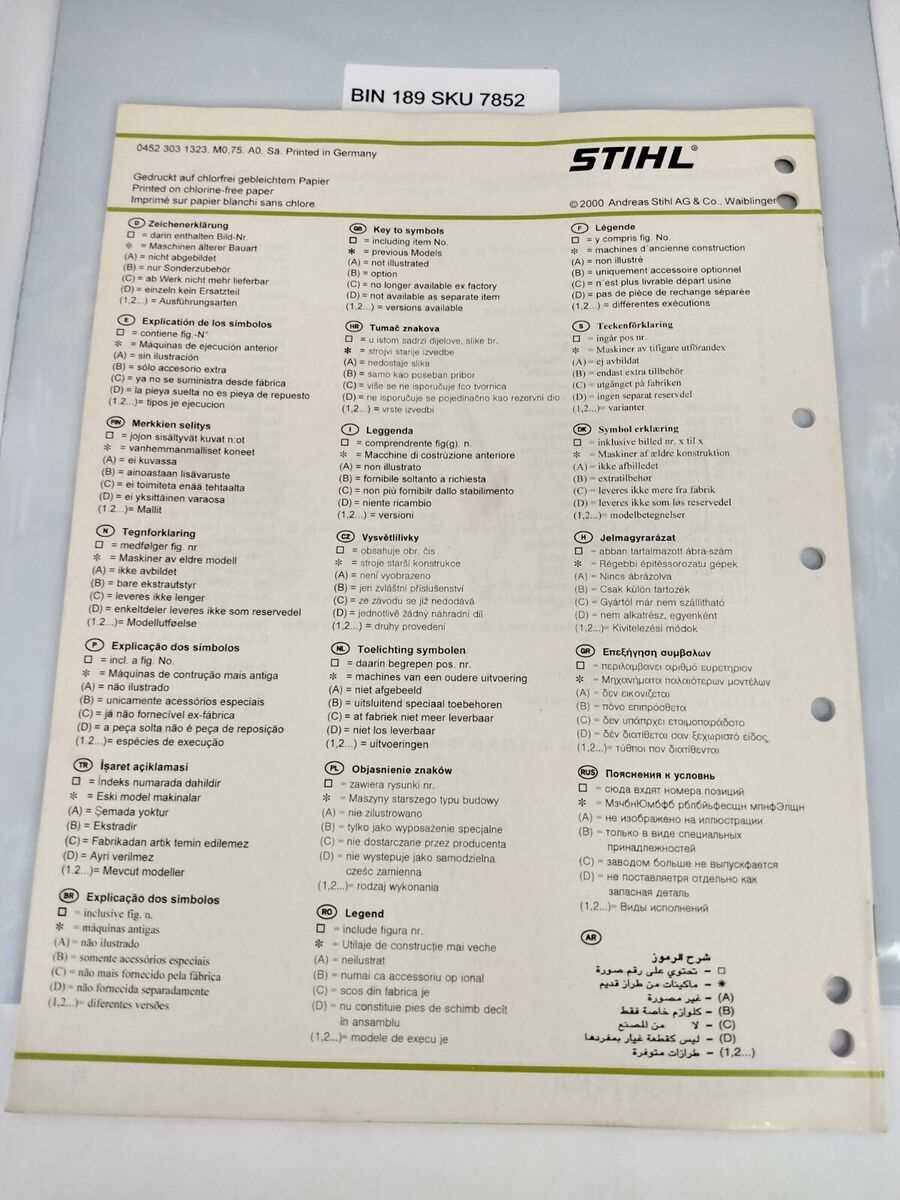

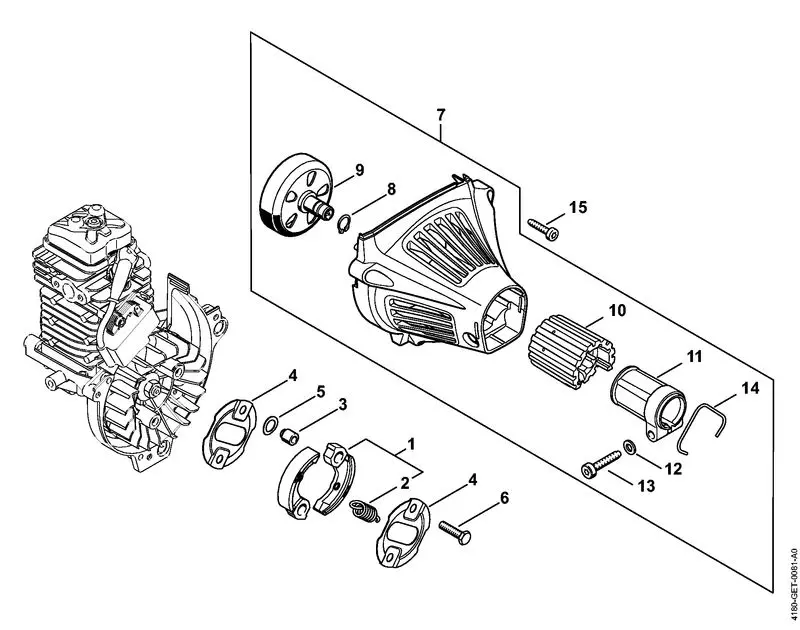

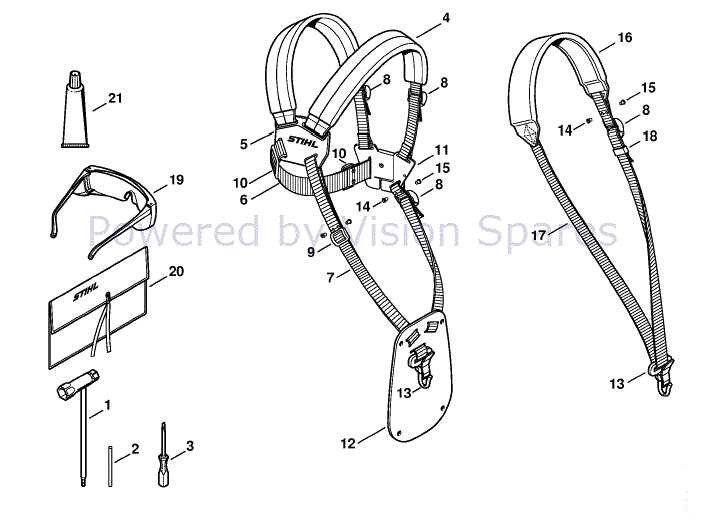

How to Read Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual guide helps users identify and locate various elements within a system, allowing for easier troubleshooting and replacement.

Key Elements to Consider

When analyzing a schematic illustration, pay attention to the labels accompanying each component. These identifiers are crucial for understanding the function and relationship of each part within the assembly. Additionally, familiarize yourself with the symbols used, as they often represent specific functions or characteristics.

Steps for Effective Interpretation

Begin by locating the main components, which are typically highlighted. Next, trace the connections between elements, ensuring to note any special annotations that may indicate variations or specific instructions. Finally, consult any accompanying documentation for further clarification on complex sections, ensuring a comprehensive understanding of the overall structure.

Identifying Each Part in Diagram

Understanding the components represented in a visual schematic is essential for effective maintenance and repair. Each element plays a crucial role in the overall functionality, and recognizing them can greatly aid in troubleshooting and enhancing performance.

To effectively navigate the illustration, it’s helpful to categorize the components based on their functions. Here are the main categories to consider:

- Mechanical Elements: These are the physical parts that contribute to movement and structural integrity.

- Electrical Components: These elements are essential for powering the system and ensuring its operation.

- Control Systems: These parts regulate the functions and maintain desired settings.

Once the categories are established, follow these steps to identify individual components:

- Examine the visual representation closely.

- Refer to any accompanying labels or annotations.

- Cross-check with a comprehensive list or resource for clarification.

- Take note of the relationships between different elements to understand their interactions.

By systematically analyzing each part within its category, you can gain a clearer understanding of the entire assembly and ensure efficient troubleshooting and repairs.

Maintenance Tips for FS110 Components

Regular upkeep of machinery is essential to ensure optimal performance and longevity. Implementing proper maintenance practices can prevent unexpected breakdowns and enhance the efficiency of each individual element.

Here are some key strategies to consider for effective maintenance:

- Regular Inspections: Conduct frequent examinations to identify signs of wear and tear. This proactive approach allows for timely replacements or repairs.

- Cleaning: Keep all components free from dirt and debris. Use appropriate cleaning agents to avoid damaging sensitive parts.

- Lubrication: Apply lubricants to moving parts to reduce friction and wear. Ensure to follow manufacturer guidelines regarding the type and amount of lubricant.

- Storage: When not in use, store machinery in a dry and protected environment to prevent corrosion and damage from external factors.

- Record Keeping: Maintain a log of maintenance activities, including inspections, repairs, and replacements. This helps track performance and facilitates future maintenance planning.

By following these maintenance tips, you can enhance the durability and functionality of your equipment, ultimately leading to better performance and reduced downtime.

Replacing Damaged Parts Effectively

When components of machinery or equipment become worn or broken, timely replacement is crucial to maintain optimal performance and prevent further issues. Understanding the replacement process not only extends the lifespan of your device but also enhances its efficiency. This section explores effective strategies for replacing damaged components, ensuring you can execute this task with confidence and precision.

Assessing Damage and Identifying Components

The first step in the replacement process is to thoroughly assess the extent of the damage. This involves inspecting the affected areas to determine which parts require attention. By identifying the specific components that are compromised, you can make informed decisions on the necessary replacements. Documenting any findings can also facilitate better planning and organization during the repair process.

Choosing the Right Replacement Parts

Selecting appropriate replacements is essential for restoring functionality. Opt for high-quality components that match the specifications of the original parts. Consulting the manufacturer’s guidelines or expert resources can aid in making the right choice. Ensuring compatibility will minimize the risk of future issues and contribute to the overall reliability of the equipment.

Where to Find Genuine FS110 Parts

When it comes to maintaining your equipment, sourcing authentic components is essential for optimal performance and longevity. Ensuring that you obtain the right items can save you time and prevent further complications down the line.

Authorized Dealers: One of the most reliable options is to purchase through authorized distributors. These outlets offer a wide range of certified items that meet the manufacturer’s standards. You can usually find a list of these vendors on the official website.

Online Retailers: Several reputable online platforms specialize in genuine components. Make sure to check customer reviews and seller ratings to ensure that you are purchasing from a trustworthy source.

Local Repair Shops: Many local repair services are equipped to supply authentic items. Establishing a relationship with a nearby technician can also provide valuable insights on installation and maintenance.

Manufacturer’s Website: Always check the manufacturer’s official website for recommendations and direct purchasing options. They often have dedicated sections for components, making it easier to locate what you need.

Community Forums: Online forums and communities dedicated to your equipment can be a helpful resource. Members often share their experiences and may direct you to reliable sources for obtaining genuine components.

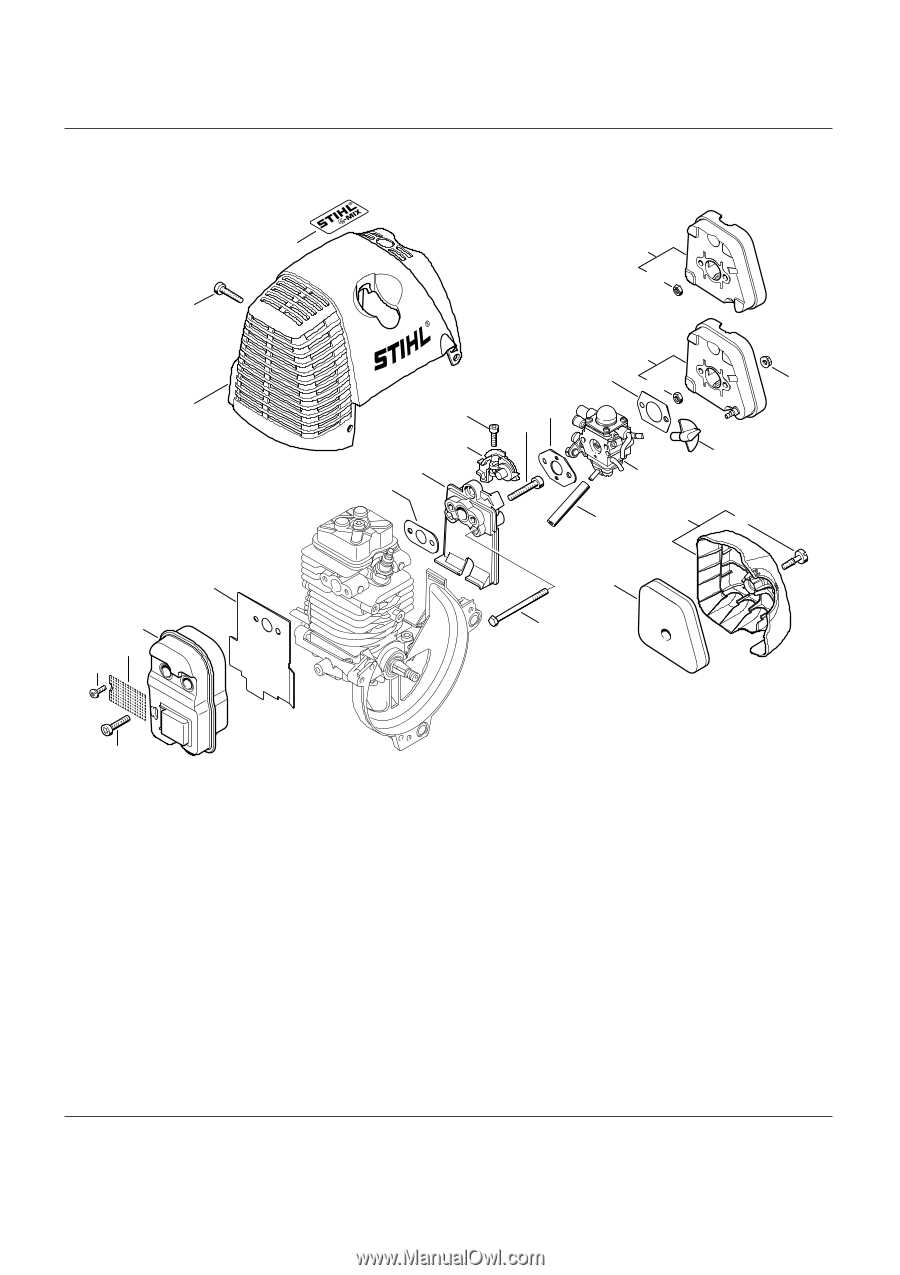

Visual Guide to FS110 Assembly

This section provides an informative overview of the assembly process for a specific model. A well-organized visual guide simplifies the understanding of the components and their respective placements. Each element plays a crucial role in the overall functionality, ensuring that everything fits together seamlessly. Utilizing diagrams can significantly enhance the assembly experience, making it more intuitive and efficient.

Step-by-Step Assembly Process

To begin the assembly, ensure that all necessary components are gathered and easily accessible. Following a systematic approach, each step should be executed carefully, ensuring proper alignment and connection of parts. A clear sequence of assembly helps in avoiding confusion and minimizes the risk of errors. Referencing the provided visuals at each stage aids in confirming correct positioning.

Common Challenges and Solutions

During the assembly, one may encounter common challenges such as misalignment or difficulty in connecting certain components. It is essential to remain patient and double-check the corresponding visuals to identify any discrepancies. Additionally, having a basic understanding of the functions of each piece can assist in troubleshooting issues effectively. If complications persist, consulting the assembly guide can provide further insights and solutions.

Tools Needed for FS110 Repairs

When undertaking maintenance or fixing issues, having the right equipment is essential for ensuring a smooth process. A well-equipped workspace can greatly enhance efficiency and effectiveness during the repair procedure. Various instruments serve specific purposes, allowing for a thorough examination and resolution of any concerns that may arise.

Basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for most tasks. These items enable you to access and manipulate components easily. Additionally, an adjustable wrench can provide the flexibility needed for different sizes of fittings, making it a valuable asset.

For more complex repairs, you may require specialized equipment. A torque wrench, for instance, ensures that all fastenings are secured to the appropriate specifications, preventing damage from over-tightening. Furthermore, utilizing a multimeter can assist in diagnosing electrical issues, providing a clearer understanding of the system’s performance.

Lastly, maintaining a clean and organized workspace is vital. This can be achieved by incorporating storage solutions for your tools, ensuring everything is readily accessible. Keeping your tools in good condition will also prolong their lifespan and enhance your repair capabilities.

Frequently Asked Questions About FS110

This section addresses common inquiries related to the model in question. Users often seek clarification on various aspects, including functionality, maintenance, and compatibility with other equipment. Below are the most frequently posed questions and their corresponding answers.

-

What are the key features of this model?

The unit is designed with several advanced features that enhance performance and efficiency. Users appreciate its ergonomic design and user-friendly interface.

-

How can I ensure optimal performance?

Regular maintenance is crucial for ensuring the device operates at peak efficiency. Users should follow the recommended care instructions and schedule periodic checks.

-

Are there compatible accessories available?

Yes, a variety of compatible accessories can enhance the functionality of this unit. Users can explore options that best suit their needs for improved performance.

-

What should I do if I encounter a problem?

If issues arise, consult the troubleshooting guide provided with the product. For persistent problems, reaching out to customer support is recommended.