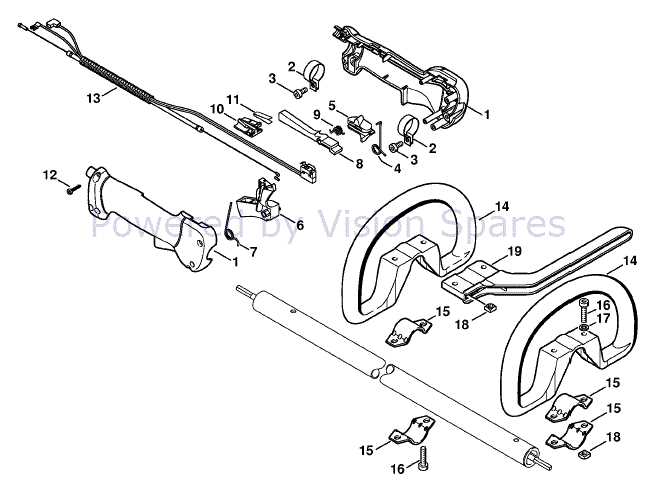

The following section provides an in-depth look at the arrangement and structure of key mechanical elements. This guide will help you understand how various components are organized and connected within the system.

Each element plays a crucial role in ensuring proper functionality, and understanding their positions can greatly assist in maintenance or repair tasks. By gaining insight into this layout, you’ll be better prepared to identify potential issues or carry out replacements efficiently.

Efficient organization and clear labeling make it easier to navigate the assembly, ensuring that every element is properly accounted for. This approach ensures the system operates smoothly and remains in good working condition over time.

Fs130 Parts Diagram Overview

Understanding the arrangement and structure of components is essential for maintaining the performance of your equipment. A visual representation that outlines each element, its placement, and how they connect can significantly aid in repairs or replacements. By examining the layout, you gain insight into how the various elements function together to ensure proper operation.

Main Components and Their Positions

The following table highlights key elements and their relative positions. This breakdown helps in quickly identifying the necessary piece when performing maintenance or troubleshooting.

| Component | Location | Function |

|---|---|---|

| Engine | Central Body | Provides power for operation |

| Handle Assembly | Upper Section | Controls and directs the equipment |

| Cutting Mechanism | Lower Section | Performs the main cutting action |

Main Components and Their Functions

The structure of this machine is made up of several key elements that work together to ensure its efficiency and performance. Each of these elements plays a critical role in the overall functionality, supporting various tasks and operations. Understanding these components helps in maintaining and optimizing the device’s performance.

Core Elements

- Engine Unit: This is the powerhouse of the machine, providing the energy needed to drive its various functions.

- Drive Shaft: Responsible for transmitting the engine’s power to the working parts, ensuring smooth and efficient operation.

- Control Handles: These allow the user to manage speed and direction, offering full control during use.

Supporting Parts

- Fuel System: Supplies the engine with the necessary fuel mix, ensuring consistent energy flow.

- Cooling Mechanism: Prevents overheating by dissipating excess heat during operation.

- Protective Guard: Shields the operator from debris, enhancing safety during use.

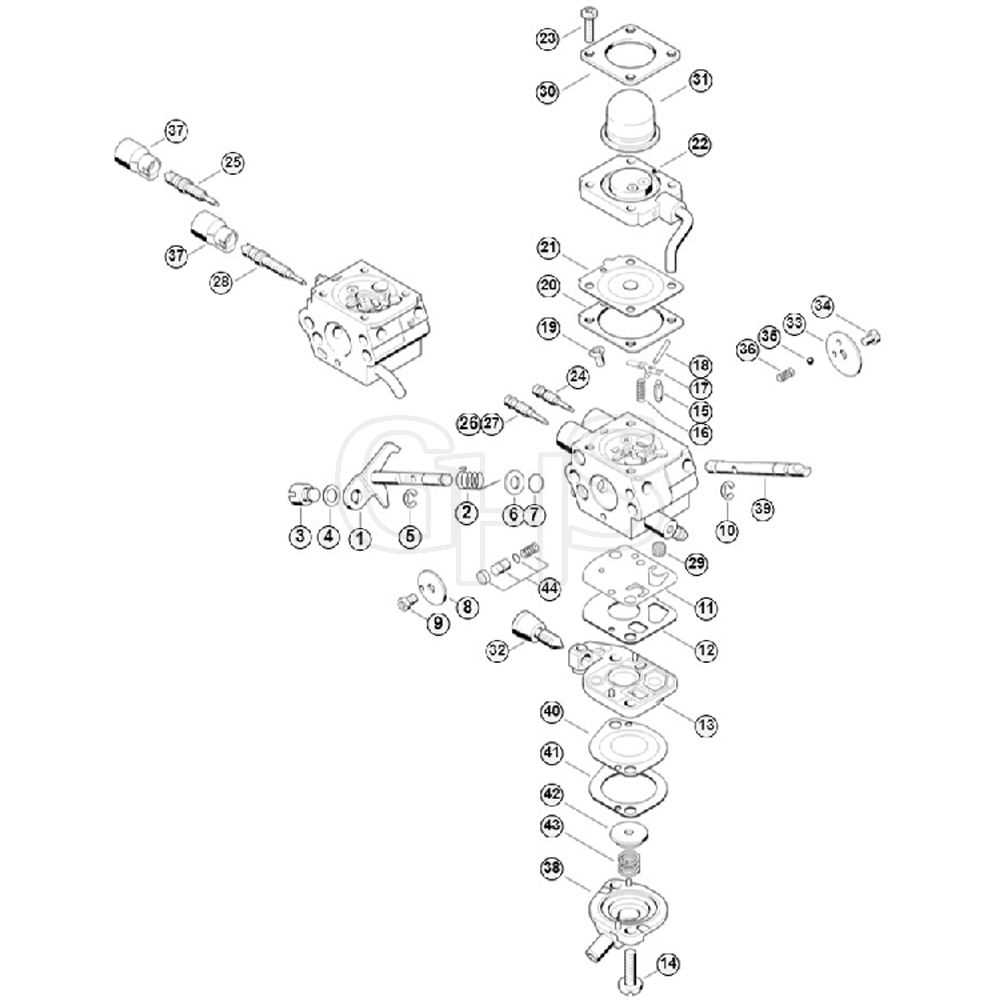

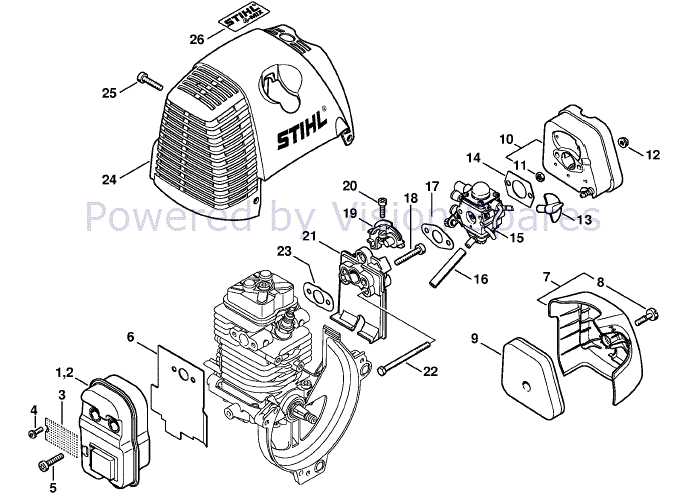

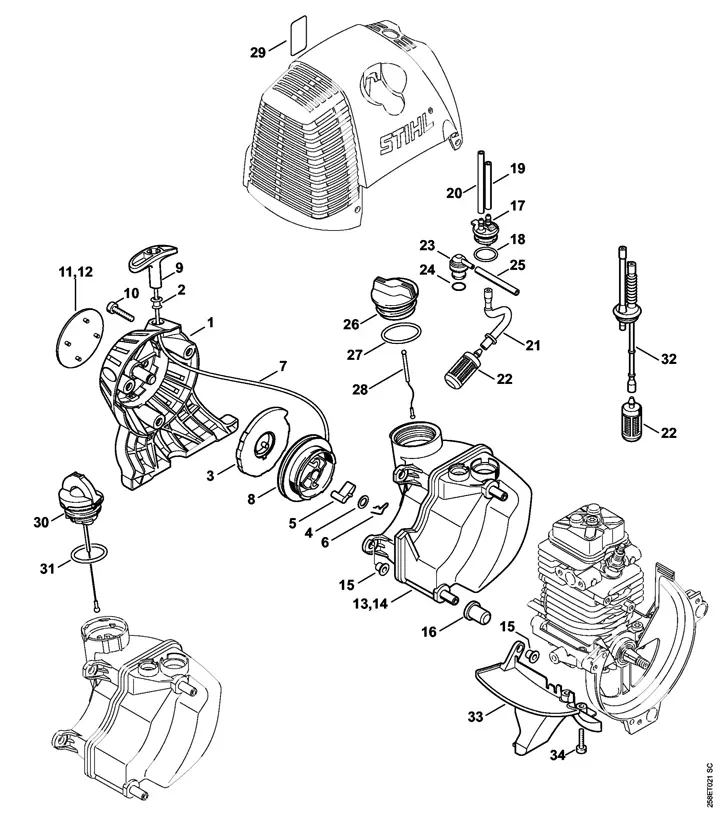

Exploded View of Fs130 Engine

The internal structure of this powerful machine reveals a detailed arrangement of components, each playing a crucial role in its operation. Understanding the breakdown of these elements allows for easier identification and replacement during maintenance or repairs.

Below is a comprehensive look at the key elements of the engine’s assembly:

- Cylinder Block: The core component that houses the moving parts and manages combustion.

- Piston Assembly: A crucial element that converts energy from combustion into mechanical motion.

- Crankshaft: This part converts linear motion into rotational movement, driving the machinery forward.

- Fuel System: Delivers the necessary fuel mix to ensure optimal performance and combustion.

- Exhaust System: Responsible for expelling combustion byproducts and managing airflow.

Each part in this configuration is meticulously aligned to ensure efficient operation, with careful attention to how all components interact within the system.

How to Identify Key Parts

Understanding the main elements of your equipment is essential for proper maintenance and operation. By recognizing specific components, you can ensure smooth performance and address any issues that arise during usage. This section will guide you through identifying the most important elements, focusing on their function and placement.

Main Components Overview

- Engine section: Located at the core, this is responsible for powering the entire machine. Look for a large, central unit connected to fuel systems.

- Control handles: These allow the operator to manage the device. Look for ergonomically designed handles positioned near the user interface.

- Cutting assembly: Usually found at the bottom or front, this is where cutting or trimming occurs. It’s vital for performance and requires regular checks.

Steps to Locate Critical Elements

- Examine the outer body to spot any controls or access points for maintenance.

- Identify moving parts that engage when the equipment is in use.

- Check for safety features like guards or shields that protect important areas.

Maintenance Tips for Fs130 Parts

Regular upkeep is essential to ensure your equipment operates efficiently and lasts longer. Proper care helps prevent issues and keeps everything in optimal working condition. Paying attention to routine checks and small adjustments can make a big difference in performance and reliability.

Lubrication: Ensure all moving components are well-oiled to avoid friction that could lead to damage. Check lubricant levels regularly and top them up when necessary to keep everything running smoothly.

Cleaning: Dirt and debris can accumulate in various areas, affecting functionality. Make it a habit to clean the key areas after each use to prevent build-up that could lead to operational issues or long-term wear.

Tightening: Over time, some connections may loosen due to vibration and use. Inspect all critical fastenings regularly, ensuring they are tight and secure to avoid malfunctions during operation.

Assembly Guide for Fs130 Components

This section provides a comprehensive overview of the assembly process for various elements of the equipment. Understanding how to effectively combine these components is crucial for achieving optimal performance and ensuring longevity. The following guide outlines essential steps and tips for a successful assembly experience.

Essential Steps for Assembly

- Gather all necessary tools and components before starting.

- Begin by examining each part to ensure they are free from damage.

- Follow the sequential order of assembly as outlined in your manual.

- Secure each piece firmly to avoid any looseness during operation.

Tips for Successful Assembly

- Refer to instructional materials for detailed images and descriptions.

- Work in a well-lit area to clearly see all components.

- Take your time to ensure each part is properly aligned.

- Consider having a second person assist for larger or heavier components.

By following this guide, you can ensure that all elements are assembled correctly, enhancing functionality and efficiency.

Where to Find Fs130 Spare Parts

Locating components for your equipment can enhance its performance and longevity. Various sources offer essential elements for your machinery, ensuring you can maintain its efficiency and functionality.

Here are some effective options for sourcing the required components:

| Source | Description |

|---|---|

| Manufacturer’s Website | The official website often provides a dedicated section for ordering replacement items directly from the source, ensuring authenticity. |

| Authorized Dealers | Certified retailers typically carry a wide selection of essential items and can assist with special orders for hard-to-find components. |

| Online Marketplaces | Platforms such as eBay or Amazon allow you to browse various listings, where you can often find new or gently used components at competitive prices. |

| Local Repair Shops | Neighborhood repair facilities may have spare elements in stock or can help in ordering them for your equipment. |

| Community Forums | Online groups and discussion boards dedicated to your machinery can offer advice on where to locate components and share their experiences with suppliers. |

Common Issues with Fs130 Parts

When working with machinery, certain components may present challenges that can affect overall performance. Understanding these frequent concerns can lead to better maintenance practices and enhanced functionality. Recognizing the symptoms of potential problems is crucial for timely intervention and repair.

Wear and Tear on Components

Over time, certain elements may show signs of deterioration due to continuous usage. This natural degradation can lead to reduced efficiency and, in some cases, complete failure. Regular inspections can help identify worn parts before they impact the overall operation.

Improper Installation and Adjustment

Another common issue arises from incorrect setup or alignment of various components. When parts are not properly installed, it can lead to misalignment, causing unnecessary strain and potential damage. Ensuring that each element is correctly positioned is vital for optimal performance and longevity.

Fs130 Parts Compatibility Guide

This section aims to provide essential insights into the interchangeability of components for specific equipment. Understanding which elements can be swapped or replaced is crucial for maintaining efficiency and ensuring optimal performance. Here, we will explore various considerations to help users identify suitable substitutes.

When evaluating compatibility, several factors come into play:

- Manufacturer Specifications: Always refer to the guidelines provided by the original manufacturer. This ensures that replacements meet necessary standards.

- Model Variations: Different versions of the same equipment may have unique requirements. Verify model numbers to avoid mismatches.

- Material Compatibility: Ensure that materials used in replacements can withstand similar operational conditions.

- Size and Dimensions: Components must fit properly within designated spaces. Measure carefully before making a selection.

Here is a simple checklist to follow when assessing replacement options:

- Identify the original component’s specifications.

- Consult compatibility charts or guides provided by trusted sources.

- Cross-reference with alternative models that have similar designs.

- Consider user reviews and experiences regarding substitutions.

By adhering to these guidelines, users can confidently navigate the process of finding appropriate replacements, ensuring their equipment operates smoothly and effectively.

Cleaning and Caring for Fs130 Parts

Maintaining equipment requires attention to detail and a consistent cleaning routine to ensure optimal performance. Proper care not only extends the lifespan of components but also enhances functionality and efficiency. Regular maintenance can prevent wear and tear, ultimately saving time and money.

Essential Cleaning Steps

To effectively clean your equipment, follow these key steps:

| Step | Description |

|---|---|

| 1 | Disconnect power source to ensure safety. |

| 2 | Remove any debris or residue with a soft brush. |

| 3 | Use a damp cloth to wipe down surfaces. |

| 4 | Inspect components for any signs of damage or wear. |

| 5 | Reassemble and test the equipment before use. |

Best Practices for Longevity

To ensure durability, consider these best practices: store equipment in a dry place, avoid exposing it to harsh chemicals, and perform regular inspections. Keeping everything in optimal condition will lead to a more reliable performance and minimize unexpected issues.

Fs130 Parts Replacement Process

Maintaining and replacing components in machinery is essential for optimal performance and longevity. This process ensures that each element functions effectively, minimizing downtime and enhancing efficiency. Understanding the replacement procedure can significantly streamline the task and reduce the likelihood of errors.

To effectively replace components, follow these steps:

- Preparation:

- Gather necessary tools and equipment.

- Review the user manual for specific instructions.

- Ensure the machinery is powered off and secured.

- Identification:

- Locate the component needing replacement.

- Check for any specific markings or codes to verify compatibility.

- Removal:

- Carefully detach the component using appropriate tools.

- Take note of the assembly process for reinstallation.

- Installation:

- Position the new component correctly.

- Secure it in place following the assembly notes.

- Double-check connections and fittings.

- Testing:

- Power on the machinery to ensure proper functionality.

- Monitor for any unusual sounds or performance issues.

By adhering to these steps, you can ensure a smooth and effective replacement process, enhancing the overall functionality of your equipment.

Detailed View of Internal Parts

This section provides an in-depth examination of the essential components that contribute to the overall functionality of the system. Understanding the intricate elements helps in appreciating how each piece plays a vital role in achieving optimal performance.

Key Components Overview

Among the crucial elements, the main assembly stands out, serving as the backbone of operation. Additionally, the transmission mechanism ensures smooth interaction between various parts, enhancing efficiency and reliability.

Functionality and Interaction

Each component works synergistically, with the engine unit providing power, while the control systems facilitate precise management of operations. Analyzing these interactions reveals the ultimate purpose behind their design.

Troubleshooting Fs130 Component Failures

Identifying and addressing component issues can significantly enhance the efficiency of machinery. Recognizing symptoms early on allows for timely interventions, preventing further damage and costly repairs.

Here are some common signs of malfunction:

- Unusual noises during operation

- Decreased performance or power loss

- Visible wear or damage on critical components

- Unexpected leaks or fluid loss

To effectively troubleshoot, follow these steps:

- Conduct a visual inspection of all accessible parts.

- Check fluid levels and look for contamination.

- Test electrical connections and components for continuity.

- Refer to manufacturer specifications for performance standards.

Regular maintenance and prompt action can lead to improved longevity and reliability of equipment.