Understanding the structure and functionality of professional equipment is crucial for both maintenance and effective use. This guide delves into the essential components of a specific piece of industrial machinery, offering detailed insights into its assembly and key elements. Familiarizing yourself with these parts will help improve both longevity and performance during operation.

In this section, we will explore the major elements of the equipment, their roles, and how they interact within the system. Each component plays a vital role, ensuring that the machinery operates smoothly and efficiently under demanding conditions. This breakdown will help you navigate through each element more easily.

As we move forward, expect a clear and thorough explanation of the different components, making it easier to identify and understand their individual functions. Whether you’re performing routine maintenance or troubleshooting issues, this guide will serve as a valuable reference.

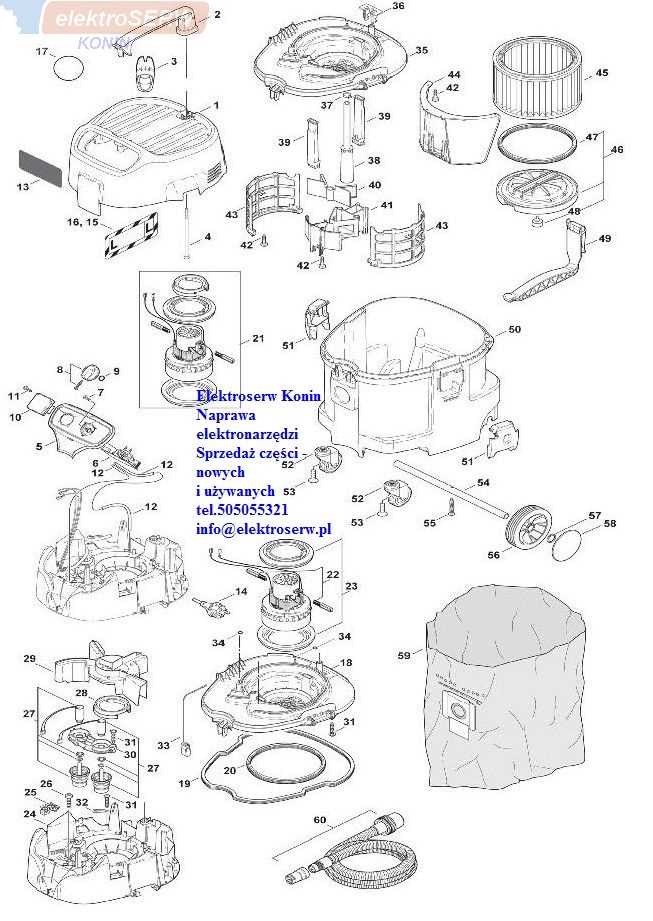

Understanding the Hilti VC 40-U Components

The structure of advanced industrial equipment consists of numerous essential elements that work together to ensure efficient operation. Each piece plays a crucial role in maintaining functionality, from the smallest connectors to larger internal systems. To fully grasp the construction of such a device, it’s important to recognize how these elements interrelate, ensuring optimal performance and durability.

Key Internal Elements

The internal mechanisms of this equipment consist of various functional units. These components, designed for different purposes, contribute to suction, filtration, and motor control. Each element has been specifically crafted to support smooth and reliable operation in demanding conditions.

External and Supportive Features

On the exterior, various controls, handles, and additional support elements enhance usability and maintenance. These external features allow operators to handle the device effectively while ensuring that it remains robust and easy to transport across worksites. Understanding these external features is crucial for seamless operation and upkeep.

Exploring the Internal Structure of the Vacuum

Understanding the internal configuration of a vacuum device can offer insight into its functionality and efficiency. By examining the arrangement and interaction of various components, we can grasp how these elements work together to ensure optimal performance. The following sections break down the key areas that contribute to the overall mechanism of the vacuum system.

- Motor Assembly: The core power source that drives the suction, converting electrical energy into mechanical motion.

- Filtration Unit: Responsible for trapping dust and debris, ensuring that the exhaust air is clean and the interior remains unobstructed.

- Hose and Nozzle System: Directs the airflow and ensures precise suction across surfaces, allowing for effective cleaning.

- Collection Container: A compartment where debris is stored until disposal, typically easy to remove and clean.

- Wiri

Key Features of the Hilti VC 40-U

This high-performance tool offers a range of standout characteristics designed to meet the demands of both professional and industrial applications. With a focus on efficiency, reliability, and user-friendly operation, it excels in various environments and ensures a high standard of productivity.

Powerful Suction and Durability

The equipment is equipped with a robust motor that delivers strong suction power, making it ideal for handling challenging tasks. Its sturdy construction ensures long-lasting durability, allowing it to withstand heavy use and harsh conditions without compromising performance.

Advanced Filtration System

Another key aspect is its advanced filtration system, which efficiently captures dust and debris, maintaining clean air quality in the workspace. This system not only extends the life of the machine but also improves overall working conditions, particularly in dust-intensive environments.

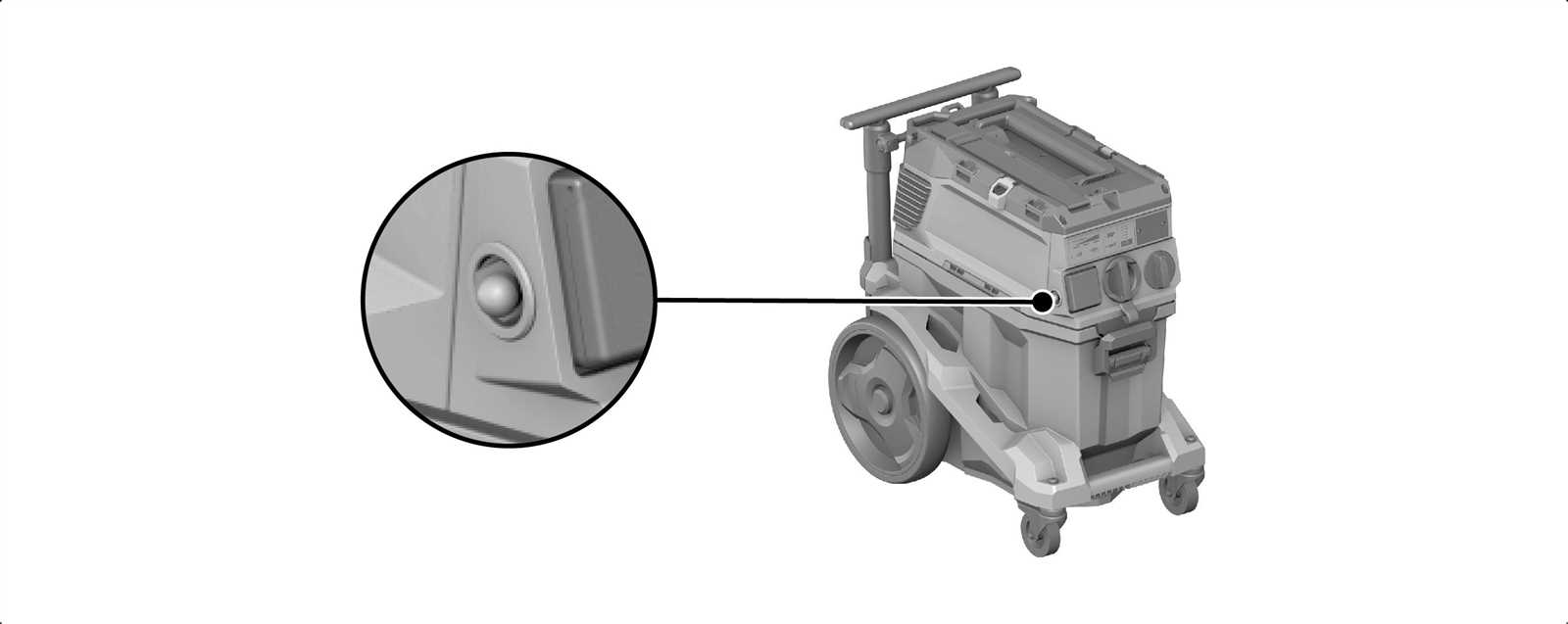

How to Identify Essential Replacement Parts

Maintaining equipment in proper working condition often requires recognizing when certain components need to be replaced. Knowing how to detect critical elements that may wear out over time can help prevent larger issues and prolong the lifespan of the device.

To effectively identify key elements for replacement, follow these steps:

- Understand the device’s construction: Familiarize yourself with the general structure and the function of various components to see which ones are vital for its performance.

- Look for common wear points: Pay close attention to parts that typically experience the most friction, heat, or pressure, as these tend to degrade faster than others.

- Check for physical signs of damage: Inspect components for cracks, corrosion, or other visible issues that may signal a need for replacement.

- Consult the manual or manufacturer guidelines: Review any documentation that provides details about the expected lifespan of individual elements and recommended replacement intervals.

By following these guidelines, you can ensure that the most important parts are replaced in time, avoiding disruptions and maintaining peak performance.

Maintenance Tips for Longevity of the Device

To ensure the optimal functioning and extended lifespan of your equipment, regular upkeep is crucial. Proper care not only enhances performance but also prevents potential breakdowns, reducing the need for frequent repairs or replacements. By following a few essential guidelines, you can keep the device in top condition for years to come.

Keep it clean: After every use, ensure the device is thoroughly cleaned. Dust, debris, and other particles can accumulate, leading to wear and reduced efficiency. Wipe down surfaces and remove any build-up from filters or vents.

Regular inspections: Periodically check for any signs of wear, such as cracks, loose connections, or frayed wiring. Addressing these early can prevent further damage and ensure the equipment continues to function smoothly.

Lubricate moving parts: To prevent friction and extend the life of mechanical components, apply the appropriate lubricants where necessary. This will ensure smooth operation and reduce the strain on the device.

Store properly: When not in use, store the device in a cool, dry place, away from moisture and extreme temperatures. This will help protect it from environmental damage and ensure it’s ready for future use.

By adhering to these maintenance tips, you can significantly extend the service life of your device, ensuring it remains a reliable tool in your work.

Breaking Down the Filtration System

The filtration system plays a vital role in ensuring the efficiency and longevity of any equipment by effectively separating dust and debris from the air. Understanding how it works can help in maintaining optimal performance and preventing potential issues that may arise from clogging or wear. Below, we’ll explore the components that make up the filtration unit and how they function together to provide clean airflow.

Component Function Primary Filter Captures large particles and prevents them from reaching the motor. Secondary Filter Traps smaller particles that pass through the primary filter, ensuring fine filtration. HEPA Filter Provides advanced filtration, removing up to 99.97% of dust, allergens, and pollutants. Automatic Cleaning Mechanism Keeps the filters clear by regularly shaking off accumulated dust, maintaining airflow. Steps for Proper Assembly of the Unit

Assembling the unit correctly ensures optimal performance and longevity. Following an organized approach is key to avoiding common issues during setup. It is essential to pay attention to the positioning and alignment of each component, ensuring a seamless and efficient assembly process.

Step 1: Preparation of Tools and Workspace

Before starting, make sure you have all the necessary tools at hand. A well-organized workspace can significantly simplify the task, allowing you to focus on each assembly step with precision.

Step 2: Base Assembly

Begin by assembling the foundation, ensuring that all base components fit together snugly. Tighten the fasteners, but avoid over-tightening, as this could affect stability or damage parts.

Step 3: Attaching Functional Components

Once the base is secure, attach the operational elements in their designated spots. It’s important to double-check that every piece is aligned according to the design, as this will influence the overall operation of the unit.

Step

Common Issues and How to Fix Them

In any equipment, regular use can lead to various problems that require prompt attention to ensure smooth operation. Some malfunctions can occur over time due to wear or external factors. Identifying these issues early and knowing the steps to resolve them can significantly extend the lifespan of the device and enhance its performance.

Issue Possible Cause Solution Reduced suction power Clogged filter or hose Clean or replace the filter and inspect the hose for blockages Unusual noise during operation Debris in motor or worn-out components Check for debris, and clean or replace affected parts Overheating Blocked airflow or prolonged use Ensure proper ventilation and allow the equipment to cool Cleaning and Care for Maximum Efficiency

To ensure optimal performance and longevity of your equipment, regular maintenance and proper cleaning techniques are essential. Keeping your device in excellent condition not only enhances its efficiency but also minimizes potential issues during operation.

Implementing a systematic approach to cleaning can significantly impact functionality. Here are some essential practices to follow:

- Daily Cleaning: Remove debris and dust after each use to prevent buildup.

- Deep Cleaning: Schedule thorough cleaning sessions regularly to reach hard-to-access areas.

- Inspect Components: Regularly check filters and hoses for wear and tear.

- Use Appropriate Tools: Utilize the right cleaning tools to avoid damage to sensitive parts.

By adhering to these guidelines, you can maintain peak performance and extend the lifespan of your machinery.

Choosing the Right Accessories for the Job

Selecting the appropriate tools and attachments is crucial for achieving optimal performance and efficiency in various tasks. Whether you are working on construction, renovation, or maintenance projects, the right accessories can significantly enhance your productivity and ensure high-quality results.

Understanding Your Requirements

Before purchasing any additional tools, it is essential to assess the specific needs of your project. Consider the materials you will be working with, the environment, and the type of tasks to be performed. This understanding will guide you in selecting the most suitable accessories that align with your goals.

Types of Accessories to Consider

Various attachments are available, each designed to perform specific functions. Familiarizing yourself with these options can help streamline your workflow. Here are some common accessory types:

Accessory Type Function Vacuum Attachments Enhance dust control and maintain a clean workspace. Drilling Bits Allow for precise drilling in various materials. Cutting Blades Facilitate efficient cutting through different surfaces. Sanding Discs Provide smooth finishes on surfaces. Troubleshooting the Power and Suction Problems

Addressing issues related to energy supply and airflow efficiency is crucial for maintaining optimal performance in any equipment. Identifying the root causes of these problems can significantly enhance functionality and prolong the lifespan of the machine.

Common Issues with Power Supply

Frequent power interruptions may stem from various factors, including faulty connections, worn-out cables, or a malfunctioning switch. Inspecting the electrical components for damage or loose connections is essential. Additionally, ensuring the correct voltage supply can help prevent performance issues.

Improving Airflow Efficiency

Reduced suction power can result from clogged filters or blocked hoses. Regularly cleaning and replacing filters is vital to ensure unobstructed airflow. Examining the hoses for any kinks or damage can also aid in restoring suction capabilities. Furthermore, maintaining proper seals will enhance the overall efficiency of the device.