In the realm of machinery, having a clear representation of various elements and their arrangements is crucial for effective maintenance and repair. This section delves into the intricate layouts that showcase how each part interacts within the overall system. By comprehending these configurations, users can better navigate the complexities of their devices.

Detailed illustrations serve as a valuable reference, highlighting the functionality of individual segments and their collective roles. Such visual guides empower users to identify components quickly, facilitating smoother troubleshooting processes. This understanding is essential for anyone looking to optimize performance and longevity in their equipment.

Moreover, these visual representations enhance the learning experience for technicians and enthusiasts alike. Familiarity with the structure allows for improved hands-on engagement, ensuring that every element is understood in context. As we explore the various features, keep in mind the importance of recognizing how each part contributes to the seamless operation of the entire assembly.

This section provides insights into the various components and their arrangements within a specific model, which are essential for maintenance and troubleshooting. Understanding how these elements fit together enhances the overall efficiency of the machine, making it crucial for both users and technicians.

| Component Name | Description | Function |

|---|---|---|

| Frame | The structural base that supports all other elements. | Provides stability and alignment. |

| Engine | The power source driving the unit. | Generates the necessary force for operation. |

| Transmission | System that transfers power from the engine to the wheels. | Enables movement and control. |

| Control Panel | User interface for operating the machine. | Allows for adjustments and monitoring of functions. |

| Wheels | Components that facilitate mobility. | Support movement across various terrains. |

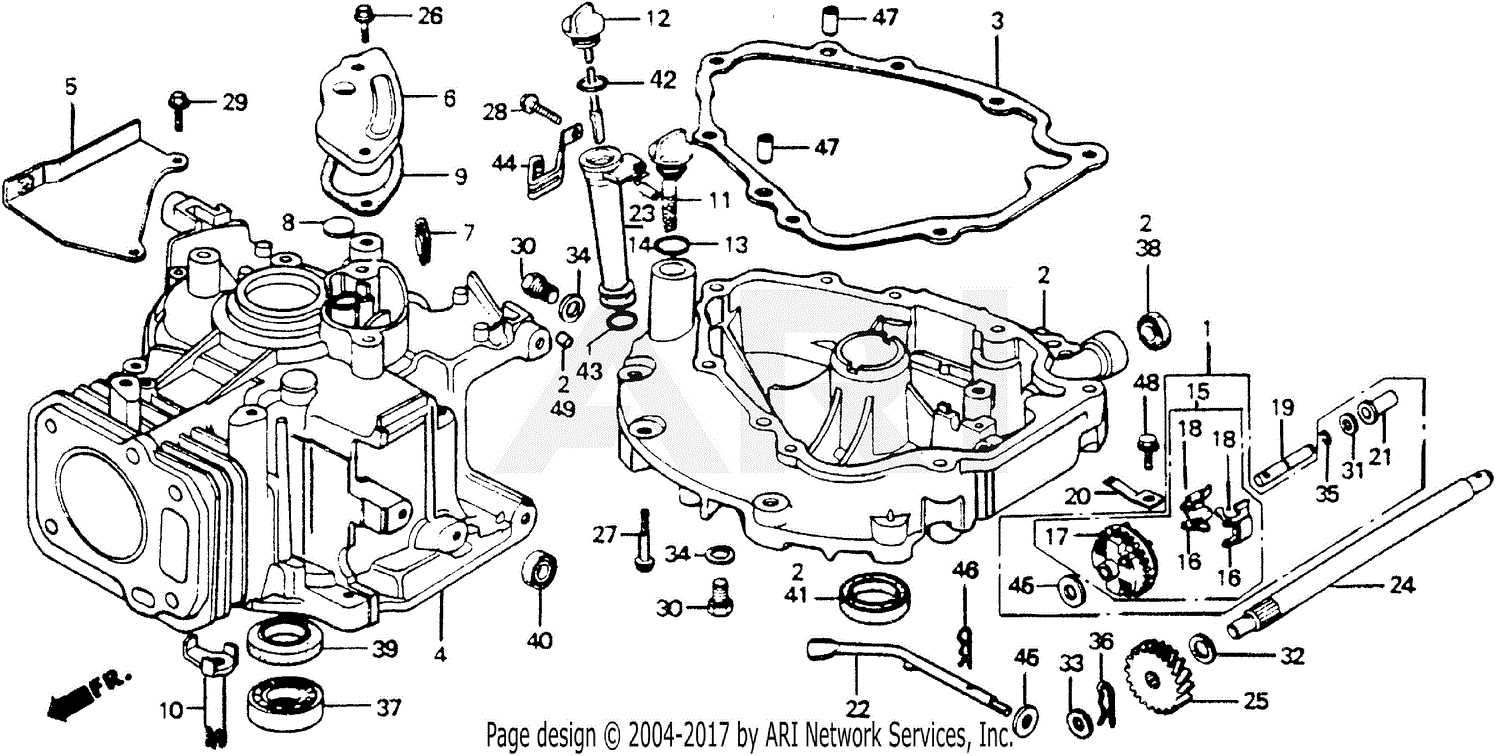

Overview of HR214 Components

This section provides a comprehensive examination of the various elements that make up the machinery in question. Understanding these components is essential for maintenance, troubleshooting, and enhancing performance. Each part plays a critical role in the overall functionality and efficiency of the unit.

Key Elements of the Machinery

The machine consists of several key parts, each designed to fulfill a specific function. These components work in harmony to ensure optimal operation, contributing to the effectiveness of the entire system.

| Component Name | Description |

|---|---|

| Engine | The power source that drives the entire unit, providing the necessary energy for operation. |

| Transmission | Transfers power from the engine to the wheels, allowing for movement and control. |

| Chassis | The frame that supports all other components, ensuring stability and durability. |

| Control System | Includes the interface for the operator to manage various functions and settings. |

| Hydraulic System | Facilitates movement and power through fluid transfer, essential for various operations. |

Importance of Understanding Components

Familiarity with these individual elements is crucial for efficient operation and troubleshooting. Regular inspection and maintenance of these parts can significantly enhance the lifespan and performance of the machine. Knowledge of how each component interacts also allows for better decision-making when it comes to upgrades or repairs.

Importance of Accurate Diagrams

Clear and precise representations are essential in any technical field. They serve as vital tools for understanding complex structures and systems, enabling individuals to visualize components and their relationships effectively. When these illustrations are meticulously crafted, they facilitate smoother communication among team members, ensuring everyone is on the same page.

High-quality visuals not only assist in troubleshooting and maintenance but also play a crucial role in training new personnel. By having reliable references, individuals can quickly grasp the functionality of various elements, enhancing their overall competence. This ultimately leads to increased efficiency and reduced downtime in operations.

Furthermore, accurate renderings can prevent costly errors during assembly or repairs. Misinterpretations stemming from unclear visuals can result in improper installations or replacements, which may compromise the integrity of the entire system. Thus, investing in well-made illustrations is paramount for sustaining long-term reliability and performance.

Key Features of HR214 Model

This model stands out due to its innovative design and exceptional functionality. Its components work together seamlessly to deliver a superior user experience, making it a valuable asset for various applications.

- Robust Construction: Built with high-quality materials that ensure durability and longevity.

- Efficient Performance: Engineered for optimal operation, minimizing energy consumption while maximizing output.

- User-Friendly Interface: Intuitive controls allow for easy navigation and operation, making it accessible for all users.

- Versatile Applications: Suitable for a wide range of tasks, providing flexibility in usage.

- Maintenance-Friendly: Designed for straightforward servicing, reducing downtime and enhancing productivity.

Overall, this model combines cutting-edge features with practical design elements, ensuring reliability and efficiency for users in various settings.

Commonly Used Parts Explained

Understanding the essential components of a machine can greatly enhance your ability to troubleshoot and maintain its functionality. This section delves into the frequently utilized elements that play a critical role in the operation and efficiency of various devices. Familiarity with these components can aid in efficient repairs and ensure optimal performance.

Key Components

- Motor: The powerhouse that drives the entire system, converting electrical energy into mechanical motion.

- Control Unit: This acts as the brain of the equipment, managing functions and operations through programmable settings.

- Chassis: The structural frame that supports all other elements, providing stability and housing internal components.

- Sensor: Instruments that detect changes in conditions, providing real-time data to the control unit for adjustments.

- Drive Mechanism: The system responsible for transmitting motion from the motor to the desired part of the machine.

Additional Elements

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Power Supply: Converts and delivers electrical energy to all components, ensuring reliable operation.

- Connectors: Facilitate communication between different sections, allowing for synchronized operation.

- Filters: Essential for maintaining cleanliness within the system, preventing debris from causing damage.

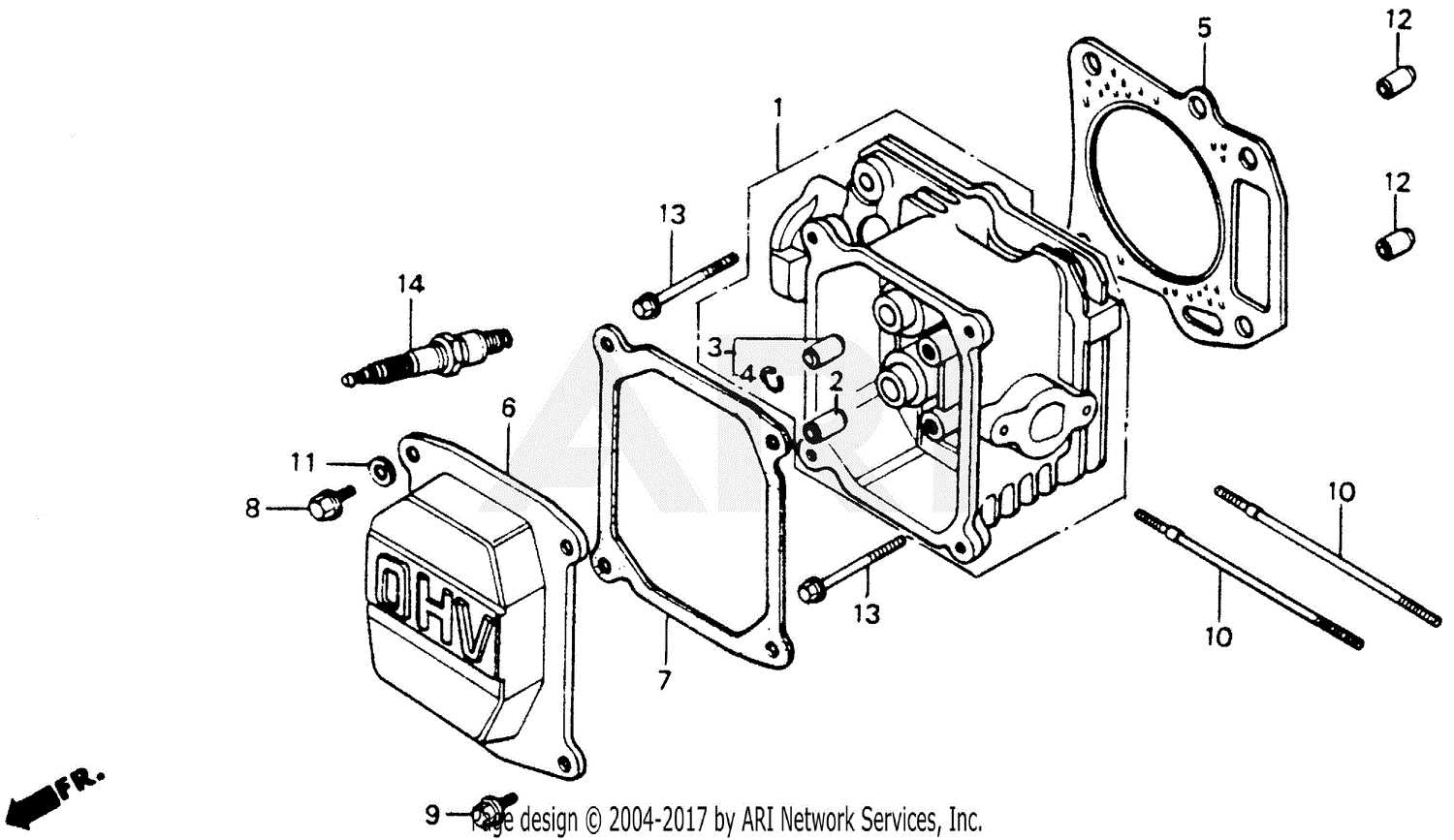

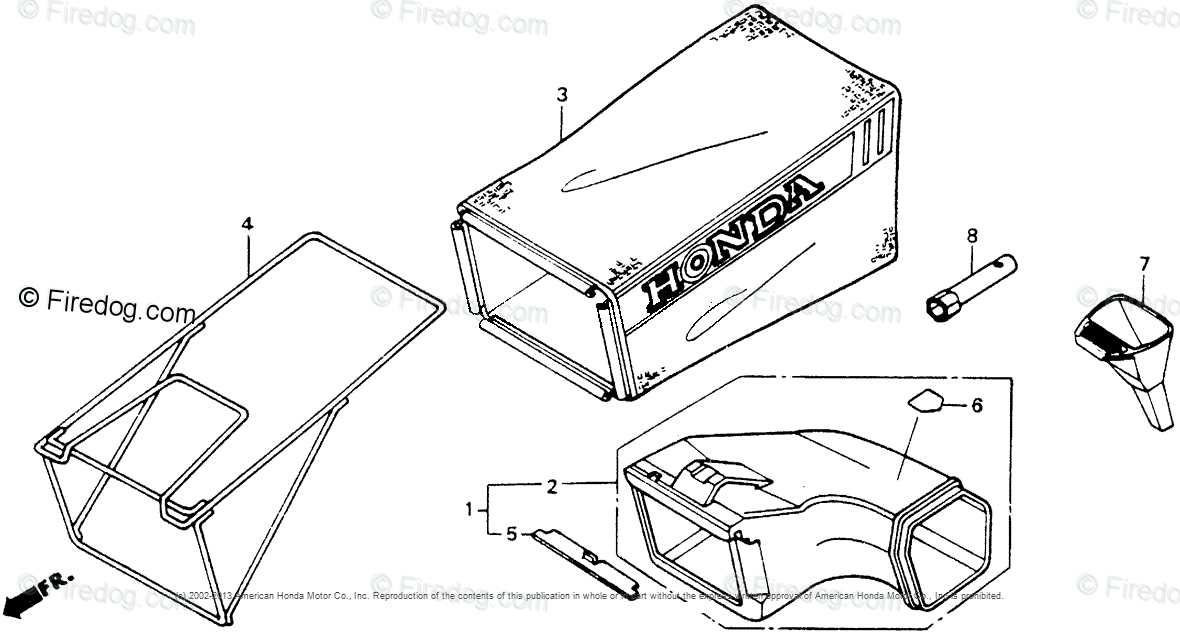

How to Interpret the Diagram

Understanding visual representations of components can significantly enhance your ability to troubleshoot and maintain machinery. These illustrations serve as valuable tools, allowing users to identify parts and comprehend their relationships within the system. By grasping the layout and function of each element, you can ensure efficient operation and address issues more effectively.

To navigate these visual guides, it is essential to familiarize yourself with the common symbols and notations used. Each symbol typically represents a specific part, while connecting lines indicate how components interact. Here are some key aspects to consider:

| Element | Explanation |

|---|---|

| Symbol Shape | Different shapes often denote specific types of parts, such as circles for connectors or rectangles for housings. |

| Lines | Solid lines usually indicate direct connections, while dashed lines might represent optional or auxiliary paths. |

| Labels | Accompanying text can provide additional information, including part numbers or specific functions. |

| Legend | A legend may be included to clarify the meanings of various symbols and notations used in the illustration. |

By following these guidelines, you can effectively decode these representations, enhancing your comprehension of the machinery’s design and functionality. This knowledge ultimately leads to more informed maintenance decisions and improved operational efficiency.

Step-by-Step Assembly Instructions

Assembling a complex unit requires careful attention to detail and a methodical approach. Following a structured process ensures that every component is properly aligned and secured, leading to optimal performance. The instructions below guide you through each phase of the assembly, highlighting critical steps and best practices.

Preparation of Components

Begin by gathering all necessary elements. Verify that you have everything required for the assembly process. Lay out each piece in an organized manner to facilitate easy access during the assembly. This preliminary step will save time and reduce confusion as you progress.

Assembly Process

Start the assembly by connecting the primary sections together. Align the components accurately and ensure that all fasteners are ready for use. Secure each part firmly but avoid over-tightening, which could lead to damage. Once the main structure is complete, proceed with attaching secondary elements. Follow the order of assembly as specified to maintain structural integrity.

Once all pieces are in place, conduct a thorough inspection to confirm that everything is aligned and secured. This final check is crucial to ensure the assembly functions as intended.

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your equipment, regular maintenance is essential. Implementing a consistent care routine can help prevent potential issues and extend the lifespan of your device. Here are some key practices to keep in mind.

Routine Inspection

- Regularly check for wear and tear on moving parts.

- Inspect connections and cables for any signs of damage.

- Ensure that all components are securely attached and functioning properly.

Cleaning and Lubrication

- Keep the exterior clean to prevent dirt accumulation.

- Use appropriate lubricants on moving parts to reduce friction.

- Remove debris from ventilation areas to maintain airflow.

By following these maintenance tips, you can significantly enhance the reliability and lifespan of your equipment, ensuring it remains in top condition for years to come.

Identifying Replacement Parts Easily

Understanding how to recognize essential components for machinery can greatly simplify the repair process. By familiarizing yourself with various elements and their functions, you can swiftly identify what needs to be replaced when issues arise. This knowledge not only saves time but also enhances the overall efficiency of maintenance tasks.

To effectively pinpoint the required elements, it’s beneficial to consult comprehensive resources that provide clear visuals and detailed descriptions. These materials can help you connect the visible symptoms of a malfunction with the specific components that may be causing the issue. Furthermore, taking note of serial numbers or specific identifiers can streamline the search for suitable replacements.

Another useful strategy is to keep an organized inventory of commonly needed items. By having these readily accessible, you can minimize downtime during repairs. Additionally, maintaining a relationship with reliable suppliers can facilitate quick procurement of necessary components, ensuring that your operations remain uninterrupted.

Ultimately, enhancing your ability to identify critical components allows for more effective maintenance and repair processes, contributing to the longevity and performance of your equipment.

Common Issues and Solutions

When dealing with machinery, various challenges can arise that may hinder performance or efficiency. Understanding these common problems and their respective solutions can significantly enhance the operational lifespan of the equipment. Here are some frequent issues encountered, along with practical remedies.

Frequent Challenges

- Unusual noises during operation

- Inconsistent performance levels

- Overheating components

- Difficulty in starting the machine

- Frequent breakdowns or malfunctions

Recommended Solutions

- Regular Maintenance: Schedule routine check-ups to identify wear and tear.

- Lubrication: Ensure all moving parts are adequately lubricated to reduce friction.

- Inspect Electrical Connections: Check all wiring and connections for signs of damage or wear.

- Replace Worn Parts: Identify and replace any components that show significant signs of degradation.

- Monitor Operating Conditions: Keep an eye on the environmental conditions and adjust settings as needed.

By addressing these common issues proactively, users can maintain optimal functionality and extend the life of their machinery.

Resources for Further Reference

This section provides essential materials and sources to enhance your understanding of the topic. Accessing reliable information is crucial for effective learning and troubleshooting, ensuring you have the right tools at your disposal.

Consider exploring online manuals and technical publications that offer detailed insights and guidelines. These resources often include illustrations and comprehensive explanations that can aid in your comprehension.

Additionally, community forums and discussion boards can be invaluable for sharing experiences and tips with others who have encountered similar issues. Engaging with knowledgeable individuals in these spaces can provide practical advice and solutions.

For further exploration, seek out video tutorials available on platforms like YouTube, which can provide visual demonstrations and step-by-step instructions. These can be particularly helpful for visual learners who benefit from seeing processes in action.

FAQs About HR214 Parts

This section addresses common inquiries regarding components and their functionalities within a specific model. Understanding these elements is essential for effective maintenance and troubleshooting.

Common Questions

- What should I consider when selecting replacements?

- How can I ensure compatibility with existing components?

- Where can I find reliable information about specifications?

- What are the signs of wear and tear in critical elements?

Maintenance Tips

- Regularly inspect each part for any signs of damage or deterioration.

- Keep a record of maintenance history to track replacements.

- Consult the manufacturer’s guidelines for recommended practices.

- Use only high-quality components to ensure optimal performance.