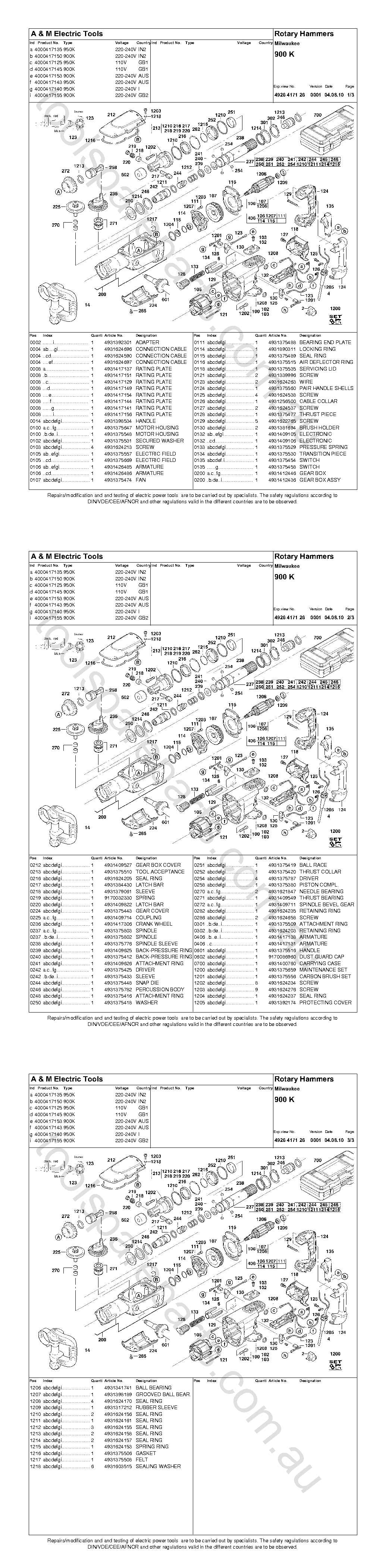

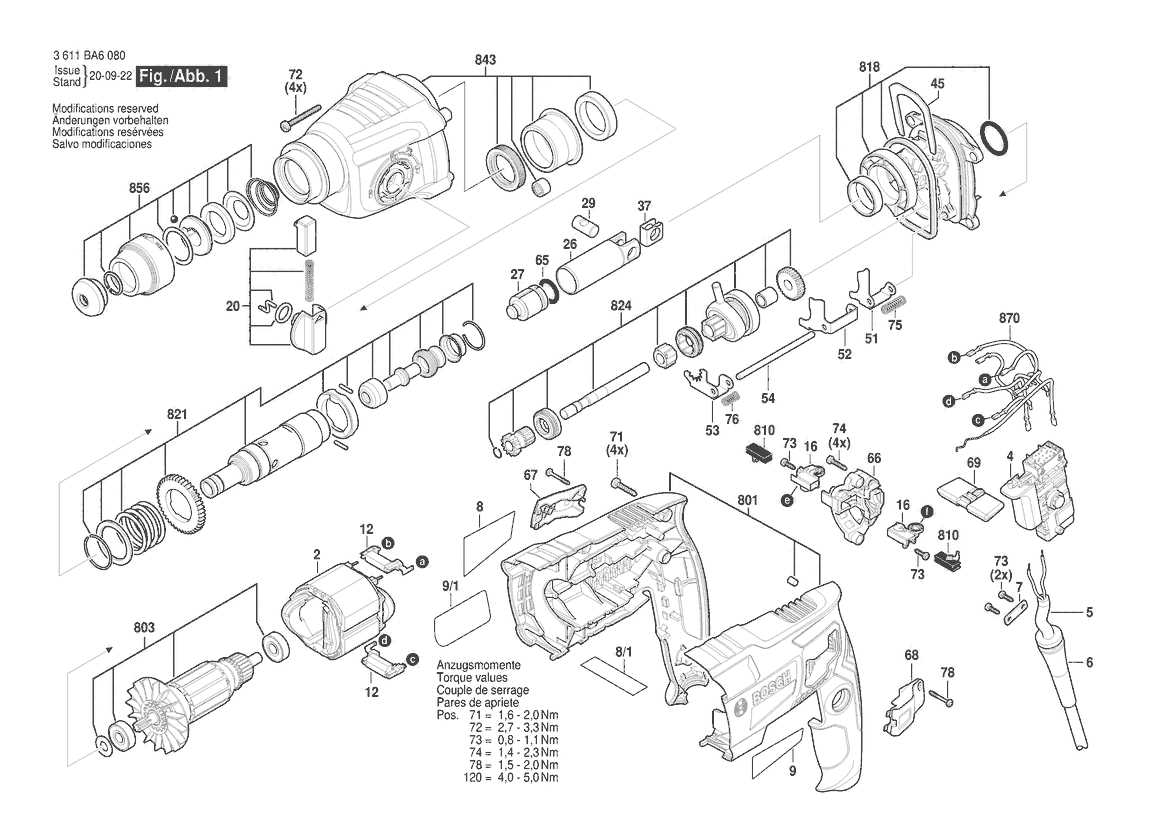

This section provides a comprehensive examination of the various elements that constitute a specific power tool. Understanding the organization and functionality of these components is crucial for effective maintenance and repair. Each part plays a vital role in the overall performance and efficiency of the device.

Identifying individual elements is essential for both troubleshooting issues and facilitating replacements. A well-structured layout allows users to navigate through the intricacies of the machine, ensuring that all components are easily accessible for inspection and repair.

By familiarizing yourself with the layout and roles of the various sections, you can enhance your capability to manage and maintain the tool effectively. This knowledge not only extends the lifespan of the equipment but also improves its performance, making it a valuable asset in any workshop.

Essential Components of Kango 950

This section highlights the fundamental elements that contribute to the effective operation of a powerful tool designed for various construction and renovation tasks. Understanding these key components is crucial for ensuring optimal performance, longevity, and ease of maintenance. Each element plays a significant role in enhancing the functionality and reliability of the equipment.

Main Functional Parts

The primary functional components of the tool include the motor, hammer mechanism, and housing. The motor serves as the driving force, while the hammer mechanism facilitates efficient impact action, crucial for tasks such as breaking concrete or driving heavy materials. The housing protects internal mechanisms and ensures durability in rugged environments.

In addition to the main components, various accessories enhance versatility. Attachments for different applications, safety features, and ergonomic designs improve usability and user comfort during extended use. Regular inspection and maintenance of these parts contribute to the overall efficiency of the tool.

| Component | Description |

|---|---|

| Motor | Provides power for operation and drives the hammer mechanism. |

| Hammer Mechanism | Generates impact force for breaking and driving tasks. |

| Housing | Encloses internal components and protects them from damage. |

| Attachments | Enhance functionality for specific applications. |

| Safety Features | Ensure safe operation and protect the user. |

| Ergonomic Design | Improves user comfort and reduces fatigue during use. |

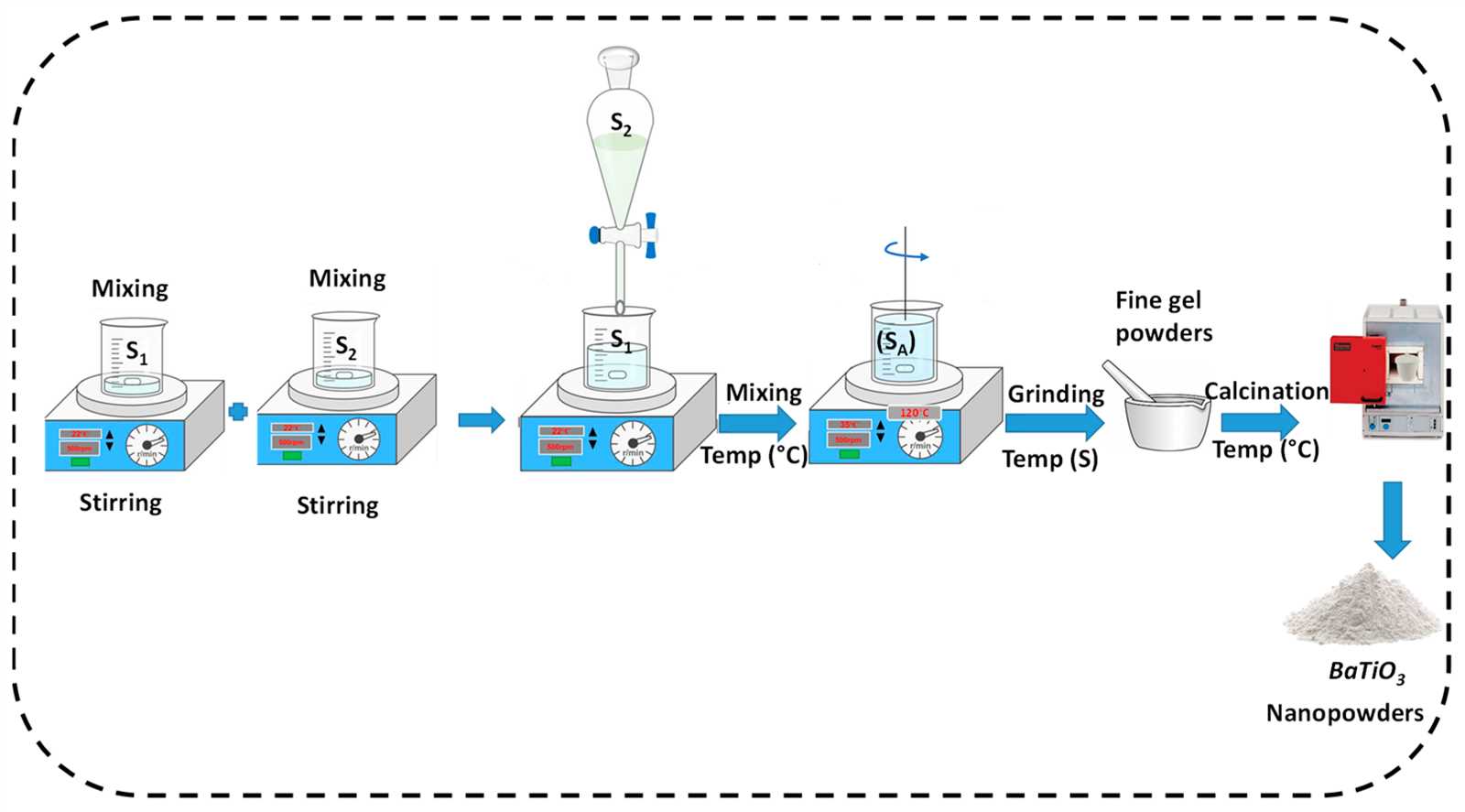

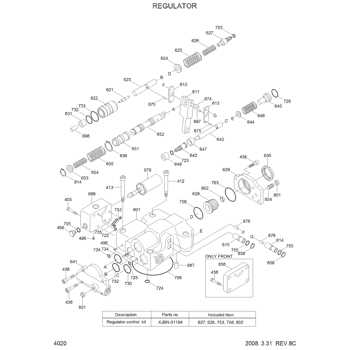

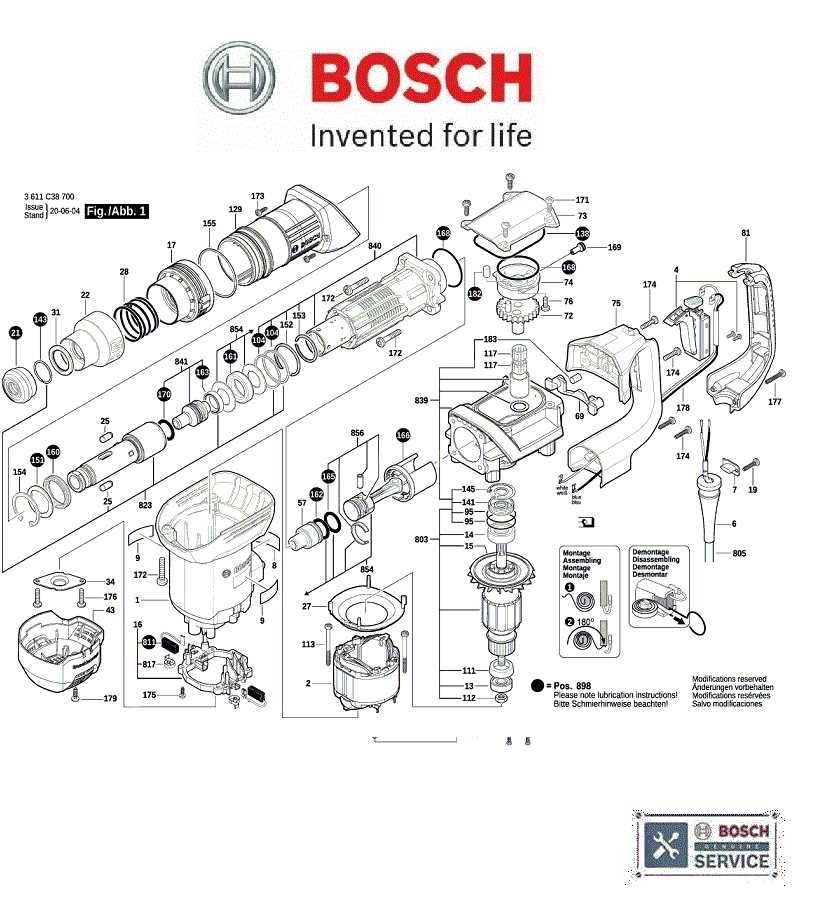

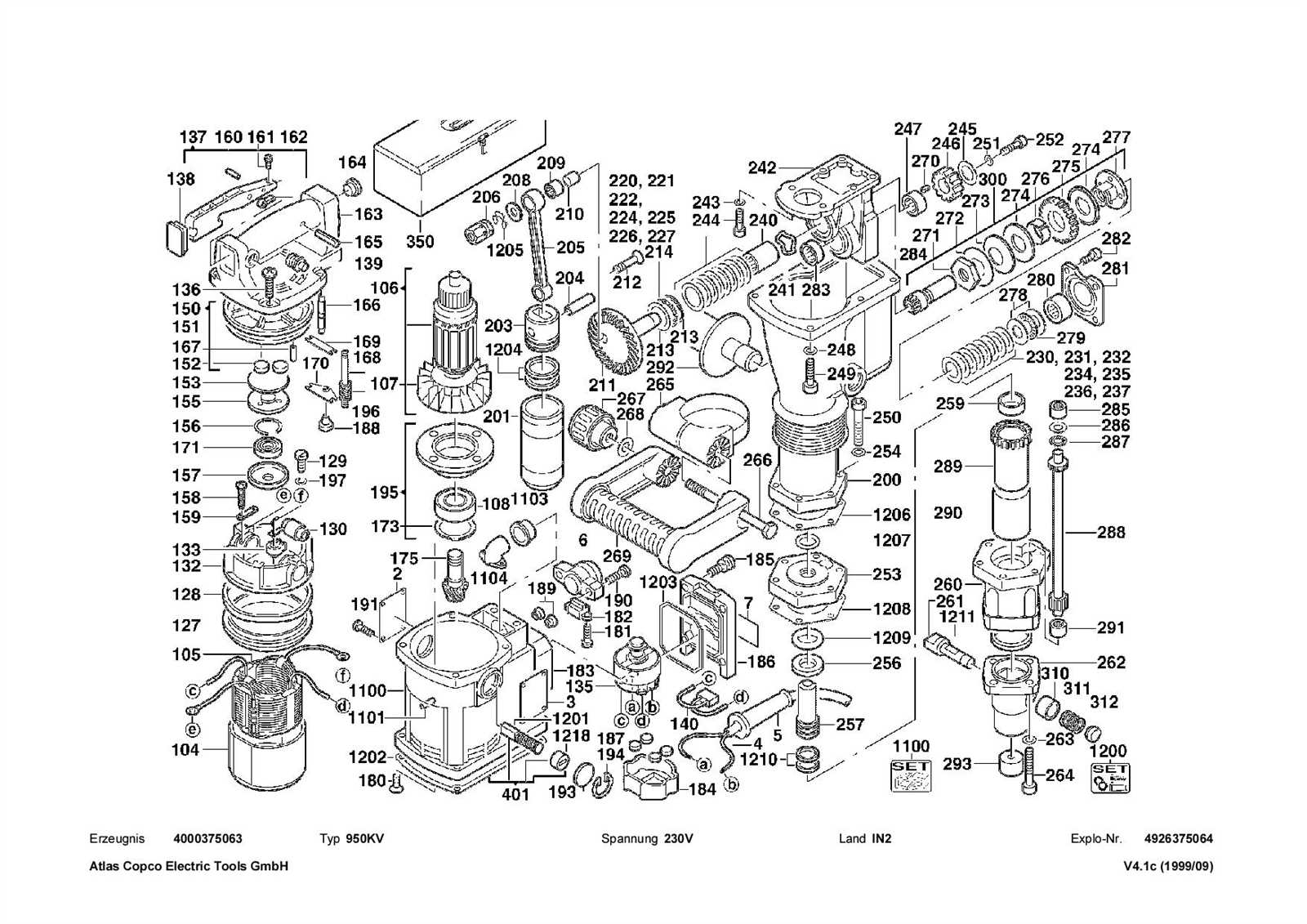

Exploring the Parts Diagram

Understanding the assembly components of machinery is essential for effective maintenance and repair. By visualizing the intricate layout of individual elements, one can gain insights into their function and interrelation. This section delves into the schematic representation of various sections, highlighting their significance in the overall system.

Each section includes specific elements that contribute to the machine’s operation. Familiarity with these components allows users to identify potential issues and streamline the troubleshooting process.

| Component Name | Description | Functionality |

|---|---|---|

| Unit A | Main housing unit | Holds all internal components securely |

| Unit B | Power supply module | Provides energy to operational elements |

| Unit C | Control interface | Allows user interaction and monitoring |

| Unit D | Connecting cables | Facilitates communication between units |

| Unit E | Cooling mechanism | Maintains optimal temperature during operation |

Functionality of Key Parts

This section explores the essential components of a vehicle and their specific roles in ensuring optimal performance and safety. Understanding these elements is crucial for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy, powering the vehicle. |

| Transmission | Transmits power from the engine to the wheels, allowing for speed changes and control. |

| Suspension | Absorbs shocks from the road, ensuring a smooth ride and stability. |

| Braking System | Slows down or stops the vehicle by applying friction to the wheels. |

| Electrical System | Powers lights, entertainment, and other electronic components while supporting the ignition system. |

Maintenance Tips for Each Component

Proper upkeep of various elements is crucial for optimal performance and longevity of your equipment. Each component requires specific attention to ensure reliability and efficiency. Following systematic maintenance practices can prevent malfunctions and extend the life of your machinery.

Regular Inspections

Conduct frequent inspections to identify any signs of wear or damage. Key aspects to check include:

- Wear on moving parts

- Corrosion or rust on metal surfaces

- Cracks or splits in housing

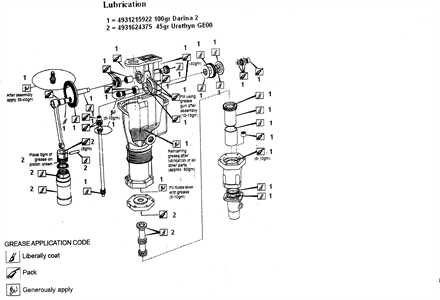

Lubrication and Cleaning

Keeping components clean and well-lubricated is essential. Follow these tips:

- Use appropriate lubricants for different materials.

- Remove dust and debris from surfaces regularly.

- Pay special attention to joints and pivot points.

By adhering to these maintenance practices, you can significantly enhance the functionality and lifespan of your equipment.

Common Issues with Kango 950 Parts

Various components of heavy-duty machinery can encounter frequent challenges that impact their performance and reliability. Understanding these typical problems can help users maintain equipment more effectively and avoid downtime.

One of the most common issues relates to the wear and tear of crucial elements due to prolonged use. This degradation often manifests in decreased efficiency, leading to potential malfunctions. Regular inspections can help identify signs of wear early, allowing for timely replacements.

Another prevalent concern is related to the improper assembly of components. When parts are not fitted correctly, it can lead to alignment issues, causing unnecessary strain and damage. Ensuring that all components are installed according to the manufacturer’s specifications is vital for optimal operation.

Additionally, environmental factors such as dust and moisture can significantly affect the longevity of machinery elements. These elements can cause corrosion or blockages, hindering functionality. Implementing regular cleaning and protective measures can mitigate these effects.

Lastly, the use of incompatible materials during repairs can lead to further complications. It is essential to use components that meet the original specifications to ensure compatibility and performance, as mismatched materials can lead to premature failure.

Replacement Parts Availability

Access to suitable components is essential for maintaining and repairing machinery effectively. Having reliable sources for these items ensures that users can keep their equipment in optimal working condition.

Various suppliers offer a wide range of replacement components, ensuring compatibility and quality. It’s crucial to explore both online platforms and local distributors for the best options available.

Many manufacturers provide detailed specifications, making it easier to identify necessary components. Additionally, aftermarket alternatives often present a cost-effective solution without compromising performance.

When sourcing components, consider checking reviews and ratings for suppliers to ensure a reliable purchasing experience. Timely acquisition of these items can significantly reduce downtime and enhance overall productivity.

Tools Required for Assembly

When embarking on the assembly process of machinery, having the right tools at hand is essential for ensuring a smooth and efficient workflow. This section outlines the necessary equipment that will aid in putting together components accurately and effectively.

Essential Tools

Utilizing appropriate instruments can significantly enhance the assembly experience. Below is a list of fundamental tools that are commonly required:

| Tool Name | Purpose |

|---|---|

| Screwdriver Set | For tightening and loosening screws of various sizes. |

| Wrench Set | To secure nuts and bolts firmly. |

| Pliers | Useful for gripping and manipulating small parts. |

| Hex Key Set | For assembling components with hexagonal sockets. |

| Measuring Tape | To ensure accurate dimensions during the setup process. |

Additional Equipment

In addition to the essential tools, certain items can further facilitate the assembly process:

| Tool Name | Purpose |

|---|---|

| Level | To check the alignment and stability of assembled parts. |

| Torque Wrench | For applying a specific torque to fasteners. |

| Workbench | A sturdy surface to support the assembly process. |

| Safety Goggles | To protect eyes during assembly operations. |

| Gloves | To ensure hand safety while handling tools and components. |

Understanding Wiring in the Diagram

When examining an electrical schematic, grasping the intricacies of the connections is essential for effective troubleshooting and repair. This section will delve into the various elements of wiring represented in the schematic, offering insights into their functions and relationships.

Components and Connections play a vital role in the schematic. Each element, whether it be a switch, resistor, or relay, is represented with specific symbols that convey their purpose. Understanding these symbols is crucial for interpreting how the different parts interact within the system.

Color Codes are often used to indicate the type of wiring and its intended function. Familiarity with these codes can aid in quickly identifying the wiring layout and ensuring that connections are made correctly during assembly or repair.

Flow of Current is another critical aspect to consider. The path that electricity takes through the system determines how components work together. By analyzing the flow, one can diagnose potential issues and understand how to optimize performance.

In summary, mastering the wiring represented in an electrical schematic enhances one’s ability to navigate the complexities of the system, ultimately leading to more efficient maintenance and repairs.

Assembly Instructions for Kango 950

This section provides a comprehensive guide to the assembly process for a specific power tool model. Following these instructions carefully will ensure optimal performance and longevity of the equipment.

Before beginning the assembly, ensure you have all the necessary components at hand. Review the following steps to streamline the process:

- Gather all required tools and components.

- Start by identifying the main body of the device.

- Attach the handle securely, ensuring it aligns properly with the main unit.

- Install any additional attachments or accessories as needed.

- Check all connections to confirm they are tight and secure.

After completing the assembly, perform a final inspection to verify that all parts are in place and functioning correctly. Testing the device before regular use is highly recommended.

Frequently Asked Questions

This section aims to address common inquiries regarding the equipment and its components. Users often seek clarity on various aspects, ranging from operational functionalities to maintenance tips. Below are some of the most frequently asked questions that can enhance your understanding and experience.

Common Issues and Solutions

Many users encounter similar challenges during the usage of their tools. Here are some prevalent concerns and suggested resolutions:

| Issue | Solution |

|---|---|

| Device not starting | Check power supply and ensure connections are secure. |

| Unusual noises during operation | Inspect for loose components or foreign objects obstructing the mechanism. |

| Overheating | Allow the equipment to cool down and check for blockages in ventilation. |

Maintenance Recommendations

To ensure longevity and optimal performance, regular upkeep is essential. Here are some tips to consider:

- Clean the exterior and interior components frequently.

- Lubricate moving parts as indicated in the user manual.

- Store the device in a dry and secure location when not in use.