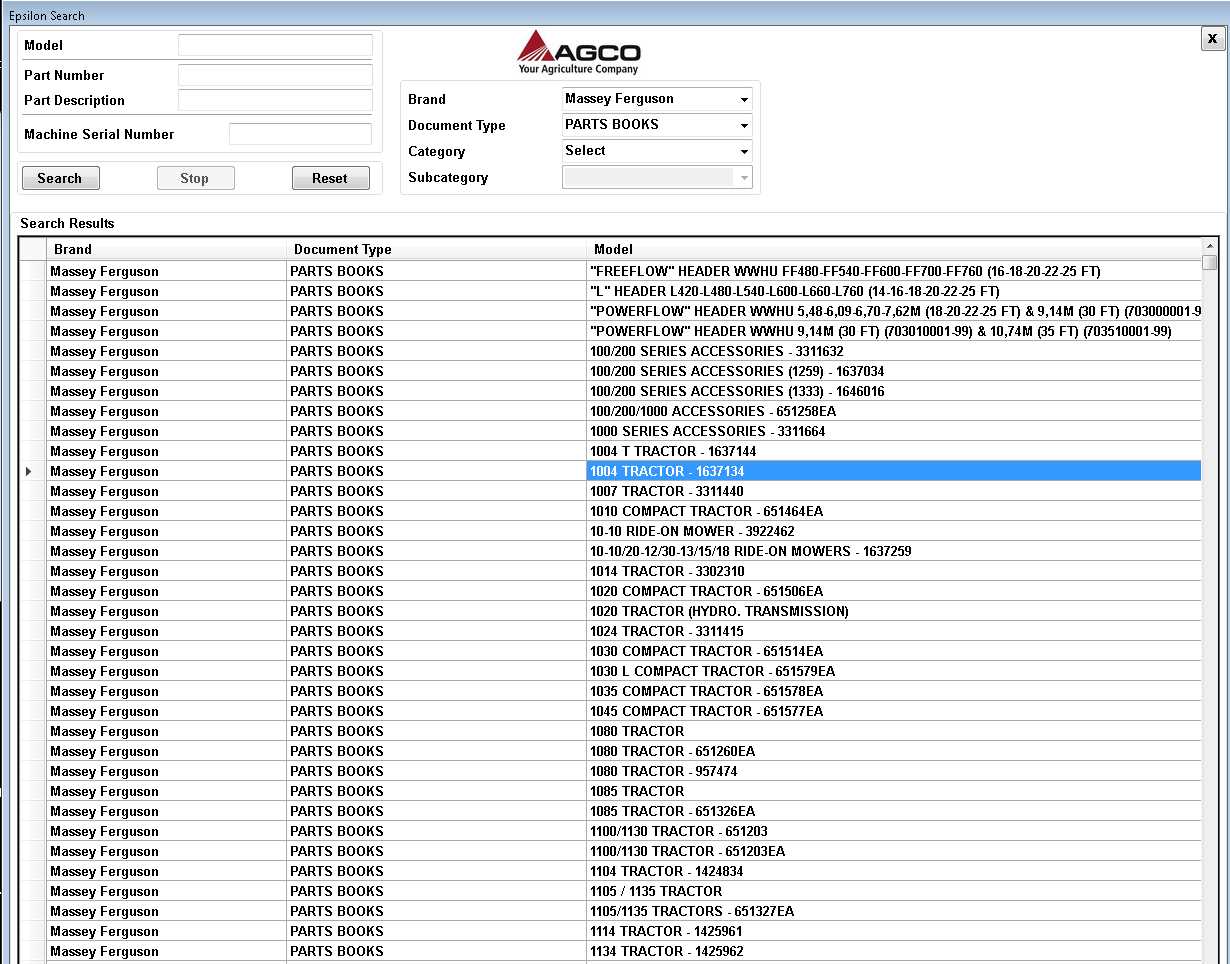

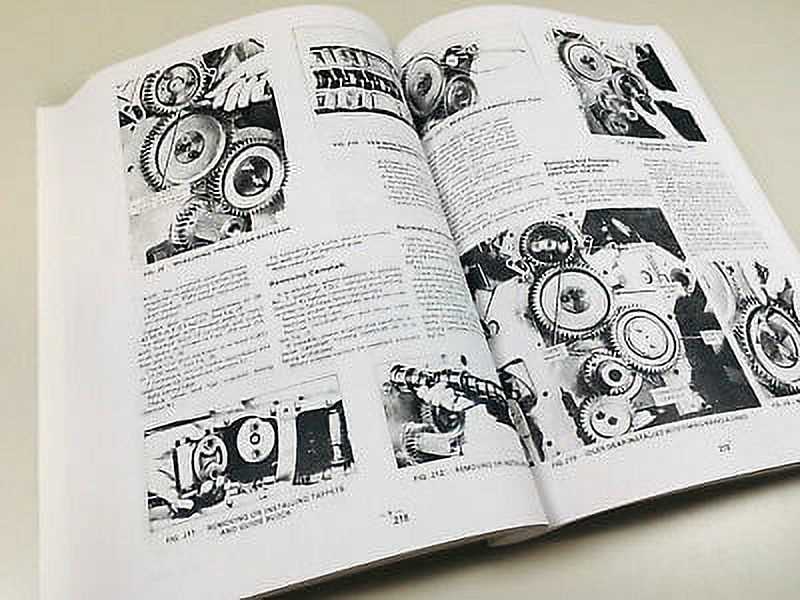

Understanding the structure and arrangement of machinery elements is crucial for maintaining and repairing equipment effectively. By examining the internal mechanisms and how various sections connect, it becomes easier to pinpoint potential issues and address them with precision. This knowledge ensures smoother operation and extends the longevity of the system.

The visual representation of mechanical elements plays a key role in grasping the complexity of these systems. Having a clear map of the entire structure enables efficient troubleshooting and provides insight into which segments need attention. This approach simplifies the maintenance process and enhances overall performance.

Accurate identification of various elements is essential for ensuring proper functioning. By knowing how each component fits into the larger system, it’s possible to optimize performance and prevent potential malfunctions. Comprehensive diagrams serve as indispensable tools in this process, guiding users through the complexities of the machinery.

Engine Components Overview

The engine is a complex system that requires a careful understanding of its individual parts to ensure smooth operation. Each component plays a critical role in maintaining the functionality and efficiency of the machinery. Proper knowledge of these elements is essential for upkeep and troubleshooting.

Cylinder block, pistons, and the crankshaft form the core structure of the power generation unit, converting fuel into mechanical energy. These parts work together to provide the necessary force for other mechanical processes.

Other essential elements like the fuel injection system and cooling mechanisms ensure the engine runs efficiently while preventing overheating. These systems work in unison to optimize performance and longevity.

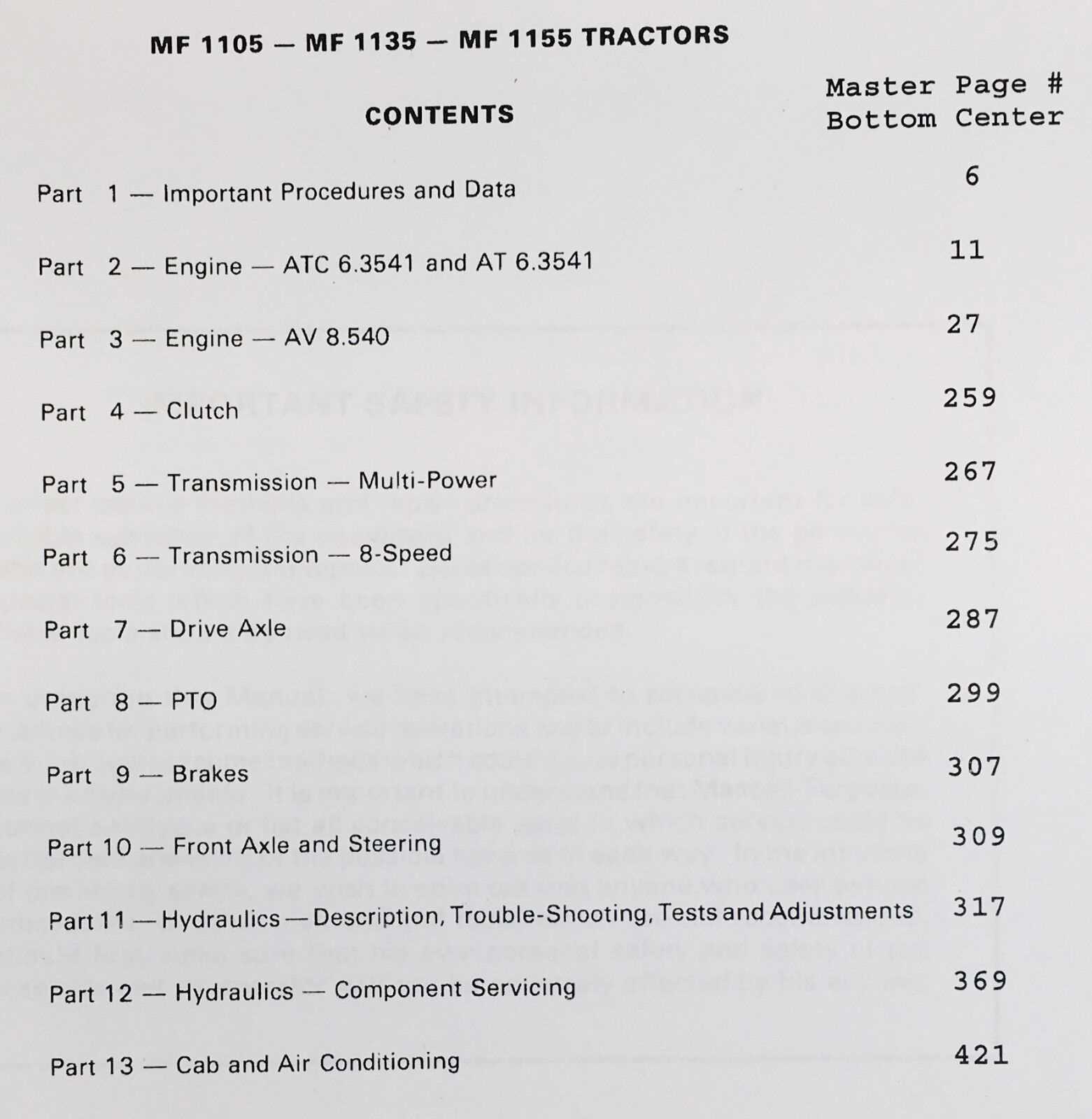

Transmission and Drivetrain Layout

The transmission and drivetrain are integral components that ensure the proper transfer of power from the engine to the wheels. These systems work in tandem to control speed, torque, and overall vehicle movement. Proper maintenance and understanding of these elements can enhance performance and longevity.

Main Components

The drivetrain includes several essential parts such as the gearbox, differential, and axles. Each component has a specific role in ensuring efficient energy distribution and controlling the vehicle’s movement. The gearbox allows for speed adjustments, while the differential ensures the correct rotation of the wheels.

Functionality and Maintenance

Keeping the transmission and drivetrain in optimal condition requires regular checks for wear and lubrication. Ensuring that all elements are functioning correctly can prevent significant issues. Routine maintenance can help identify early signs of potential problems, such as unusual noise or reduced performance.

Hydraulic System Components Breakdown

The hydraulic mechanism is a critical aspect of efficient machinery operation. It relies on several interconnected elements that work together to manage the transfer of fluid power, ensuring precise control and smooth performance.

Pumps are responsible for generating the flow of hydraulic fluid, which powers the entire system. Their reliability and efficiency directly affect the overall functionality.

Valves control the direction and pressure of the fluid, regulating its movement throughout the different parts of the system, thus ensuring optimal operation under varying conditions.

Another essential component, cylinders, converts the fluid power into mechanical

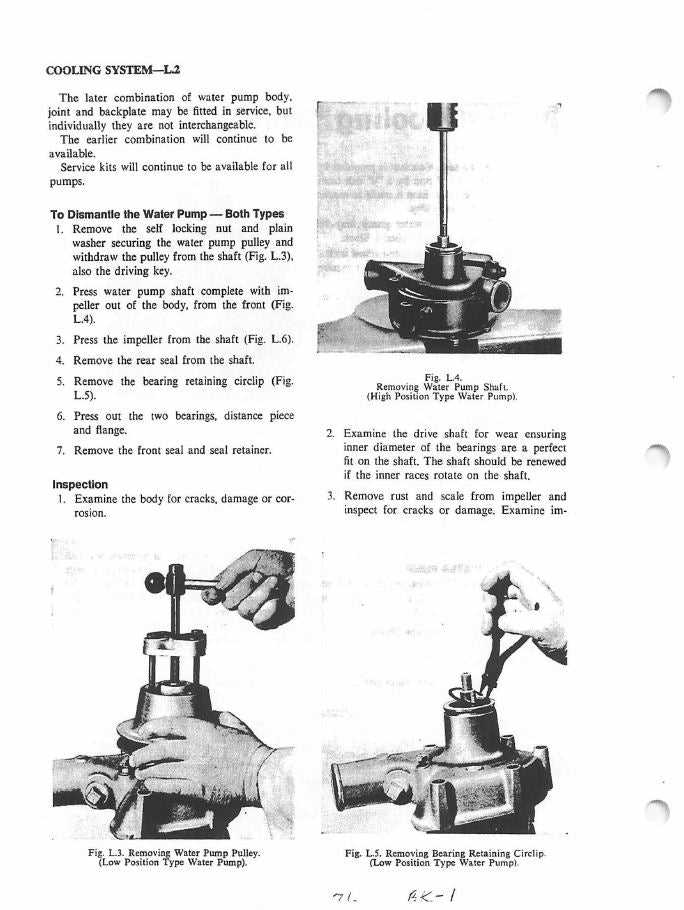

Cooling System Parts and Functions

The cooling mechanism is essential for maintaining optimal temperatures in various equipment, ensuring efficiency and preventing overheating. Each component within this system plays a critical role in regulating temperature and distributing coolant to key areas. Proper understanding of these elements helps in maintaining and troubleshooting the system.

- Radiator: The radiator is responsible for dissipating heat, allowing the coolant to cool before it circulates again.

- Water Pump: This device ensures the continuous flow of coolant throughout the system, keeping engine temperatures under control.

- Thermostat: The thermostat regulates the flow of coolant by opening and closing at specific temperatures, ensuring the system operates within the desired range.

- Cooling Fan: The fan assists in cooling the radiator

Electrical Wiring and Connections

Understanding the electrical system is crucial for the proper operation of any equipment. The wiring and connections ensure that all components receive the necessary power, allowing the machine to function efficiently and safely. Faulty or damaged wiring can lead to operational issues, making it important to regularly inspect and maintain these connections.

- Inspect wiring for wear and tear regularly

- Ensure connections are tight and secure to prevent electrical failures

- Use appropriate insulation materials to protect wires from environmental damage

- Refer to the correct wiring scheme when making repairs or adjustments

Properly connected circuits reduce the risk of short circuits and other electrical malfunctions. It’s important to handle any electrical components with care to avoid hazards. Regular maintenance of connections helps ensure longevity and safe operation.

Fuel System Components Explained

The fuel system is crucial for the efficient operation of any engine. It ensures that the correct amount of fuel is delivered to the engine for combustion, influencing performance, efficiency, and overall functionality. Understanding the various elements of the fuel system can help in diagnosing issues and maintaining optimal operation.

Key Elements of the Fuel System

Several components work together in the fuel system to ensure proper fuel delivery. These elements include the fuel tank, fuel pump, fuel filter, and injectors, each playing a significant role in the process.

Component Function Fuel Tank Stores fuel until needed by the engine. Fuel Pump Transports fuel from the tank to the engine. Fuel Filter Removes impurities from the fuel before it reaches the engine. Injectors Atomize the fuel for efficient combustion. Maintenance Tips

Regular maintenance of the fuel system is essential for prolonging its lifespan and ensuring reliable performance. It is advisable to check the fuel filter periodically, replace worn-out components, and keep the fuel tank clean to prevent sediment buildup.

Steering Mechanism and Key Parts

The steering system of agricultural machinery is crucial for ensuring precise navigation and control during operation. Understanding its components and their functions enhances maintenance and efficiency.

Essential Components

Key elements of the steering mechanism include:

- Steering Wheel: The primary control interface for the operator, allowing direction changes.

- Steering Column: Connects the steering wheel to the gearbox, transmitting movement.

- Gearbox: Converts the rotational movement of the steering wheel into linear motion for the wheels.

- Linkage System: Transfers force from the gearbox to the wheels, facilitating turns.

- Ball Joints: Allow for flexibility in the steering linkage, accommodating terrain variations.

Functionality and Maintenance

Regular inspection and lubrication of these components are vital for optimal performance. Ensuring that each part functions correctly prevents excessive wear and enhances the longevity of the steering system.

Brake Assembly and Its Components

The brake assembly plays a crucial role in ensuring the safe and effective operation of machinery. It consists of various elements that work together to provide reliable stopping power, contributing to overall vehicle performance and operator safety.

Key Components

Understanding the individual parts of the brake assembly is essential for maintenance and troubleshooting. Here are the primary components:

- Brake Pads: These are essential for creating friction against the rotor, enabling the vehicle to slow down or stop.

- Brake Rotor: A disc that the brake pads press against to reduce the wheel’s speed.

- Caliper: Houses the brake pads and pistons, pushing the pads against the rotor when braking.

- Pistons: Hydraulic components that force the brake pads against the rotor, creating the necessary friction.

- Brake Lines: These carry hydraulic fluid from the master cylinder to the caliper, allowing for effective braking action.

Maintenance Tips

Regular inspection and maintenance of the brake assembly are vital for optimal performance. Consider the following tips:

- Check brake fluid levels regularly.

- Inspect brake pads for wear and replace them as needed.

- Examine the rotors for any signs of damage or warping.

- Ensure that the caliper functions smoothly and does not stick.

- Look for any leaks in the brake lines that could affect performance.

Cabin Controls and Instrumentation Layout

The arrangement of control mechanisms and display instruments within the operator’s compartment plays a crucial role in enhancing the usability and efficiency of machinery. An optimal layout ensures that the operator can easily access all necessary functions while maintaining comfort and safety during operation.

Key components typically found within the control area include steering mechanisms, throttle controls, and various gauges that provide real-time data on performance metrics. Understanding the location and purpose of these elements can significantly improve operational effectiveness.

Control Type Function Location Steering Wheel Controls direction Front center Throttle Lever Regulates speed Right side console Brake Pedals Controls stopping Floor, center Display Gauges Shows operational metrics Dashboard Climate Controls Adjusts cabin temperature Center console Axles and Wheel Assembly Details

The axles and wheel assembly are crucial components that contribute significantly to the overall performance and stability of agricultural machinery. These elements are designed to endure substantial loads and provide support for the entire structure, ensuring efficient operation across various terrains.

Structure and Functionality

The axle serves as a central shaft that connects the wheels, allowing for rotational movement while bearing the weight of the vehicle. It is engineered to withstand high torque and stress during operation. Wheel assemblies consist of tires, rims, and hubs, each part meticulously crafted to enhance durability and performance. Regular maintenance of these components is essential for optimal functionality, as wear and tear can lead to reduced efficiency and potential failures.

Maintenance Tips

To ensure longevity and reliable performance, it’s important to regularly inspect the axle and wheel assembly for signs of wear, such as cracks or excessive play. Lubrication of moving parts is crucial to prevent friction and overheating. Additionally, checking tire pressure and tread depth helps maintain traction and stability during operation. Timely replacements of any worn components will enhance safety and efficiency in the field.

Maintenance and Replacement Parts Guide

This section provides essential insights into the upkeep and component substitution for your machinery. Regular maintenance ensures optimal performance and longevity, while timely replacement of worn elements can prevent unexpected breakdowns and costly repairs.

Essential Maintenance Practices

Adhering to a routine maintenance schedule is crucial for preserving the functionality of your equipment. Regular inspections should focus on fluid levels, filter conditions, and the integrity of moving components. Implementing preventative measures, such as lubrication and alignment checks, can enhance operational efficiency and reduce wear.

Identifying and Sourcing Components

When it comes to replacing components, knowing the correct specifications is vital. Consult the manufacturer’s recommendations for suitable replacements, ensuring compatibility with your machinery. Utilizing high-quality substitutes can significantly impact performance. Engage with trusted suppliers for authentic replacements to maintain operational integrity.