The propulsion system in watercraft is a critical element responsible for smooth and efficient movement across water. Understanding the structure of this system helps with maintenance, repairs, and performance improvements, making it essential for both professionals and enthusiasts.

This section delves into the key mechanical components found in the propulsion mechanism, focusing on their arrangement and roles. By gaining insight into how these parts interact, operators can extend the lifespan of the system and ensure optimal function during use.

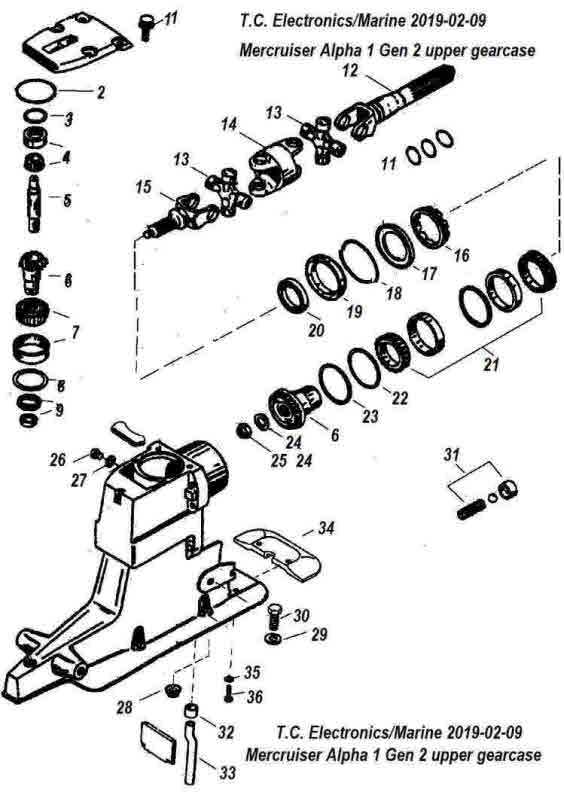

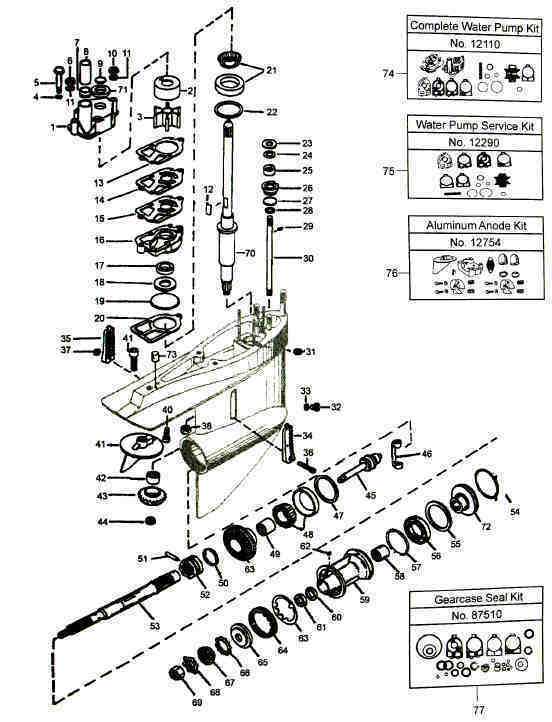

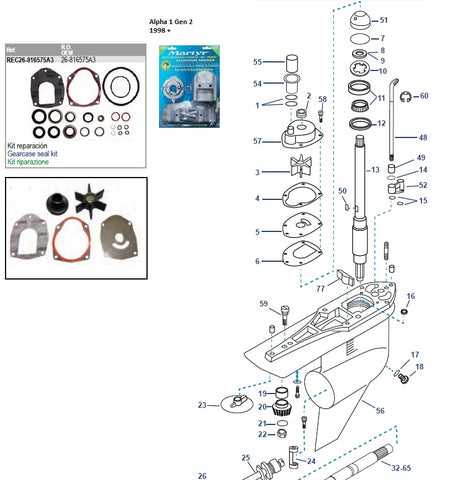

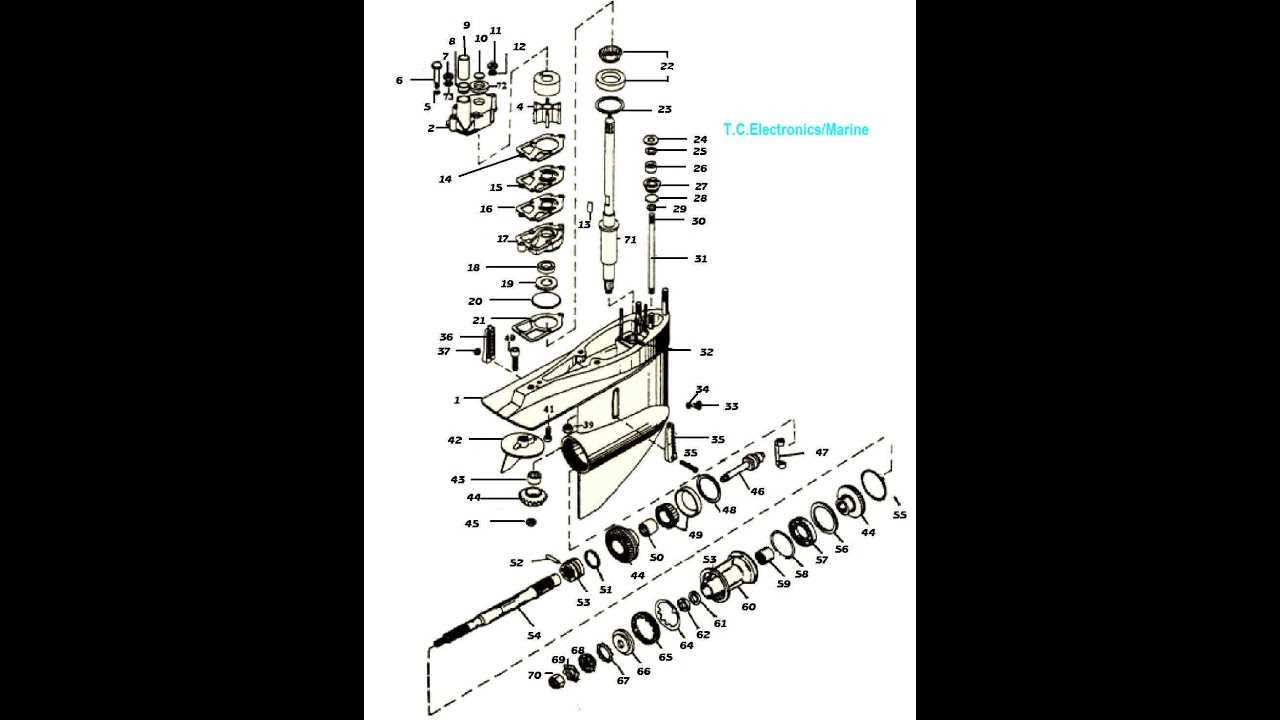

Mercruiser Alpha One Lower Unit Overview

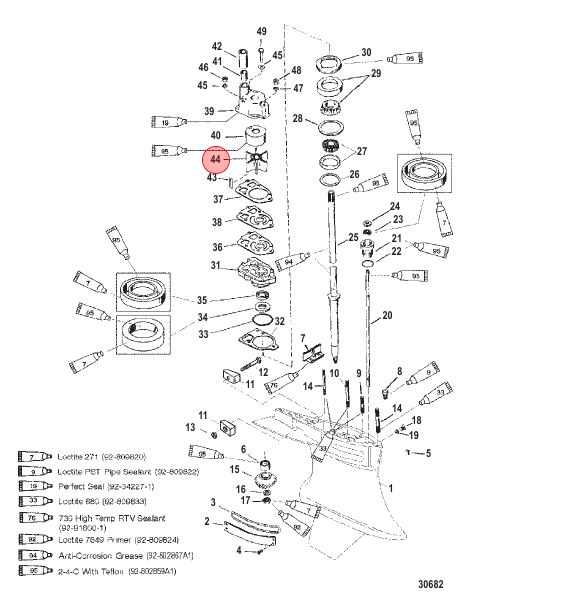

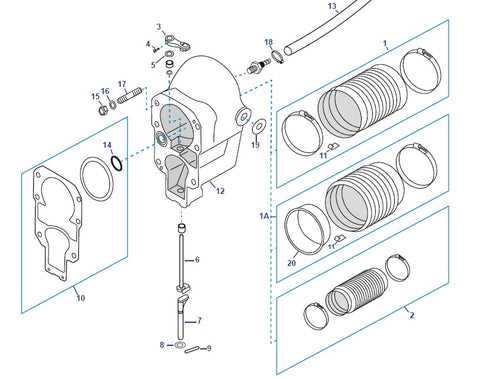

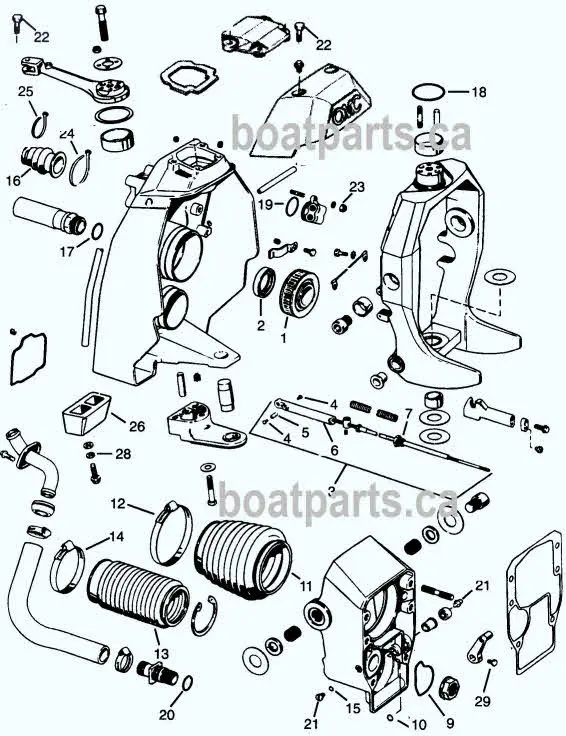

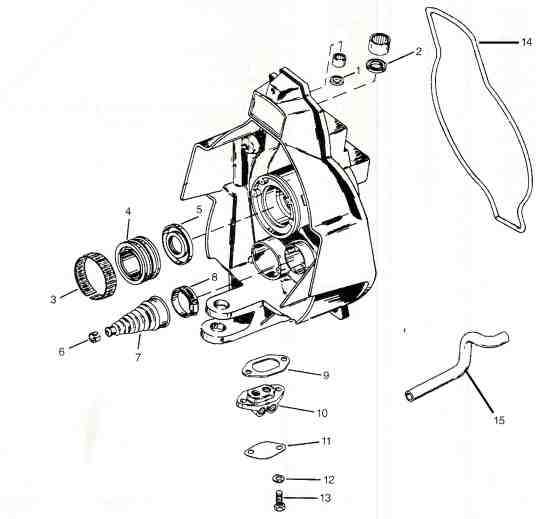

The focus of this section is on a specialized assembly designed to transfer power efficiently and ensure smooth propulsion. This mechanism integrates multiple components to manage watercraft movement and maintain operational stability in various conditions. It plays a critical role in linking the engine’s output with the propeller, ensuring the vessel responds effectively to throttle inputs.

| Component | Function | |||||||

|---|---|---|---|---|---|---|---|---|

| Propeller Shaft |

| Component | Description | ||||

|---|---|---|---|---|---|

| Drive Gear | Responsible for transmitting rotation from the engine to the secondary gears. |

| Component | Function |

|---|---|

| Impeller | Rotates to draw water in and push it through the cooling pathways

Importance of the Shift Mechanism

The shift mechanism plays a crucial role in ensuring smooth transitions between gears, allowing for precise control of movement on the water. Without an effective shifting system, operation would become unpredictable, compromising both performance and safety during navigation. This system ensures that propulsion is adjusted to match varying conditions, whether for slow maneuvers Propeller Shaft Structure and Role

The propeller shaft is a crucial component in the propulsion system of marine vessels, playing a significant role in transferring power from the engine to the propeller. Its design and functionality are essential for optimal performance and efficiency. This shaft consists of several key elements that work together to ensure smooth operation. The primary functions of the propeller shaft include:

In addition to these functions, the materials used in the construction of the propeller shaft are critical for durability and resistance to corrosion, especially in marine environments. Regular maintenance and inspection of this component are essential to ensure longevity and reliability in operation. Understanding Bearings and Seals

Bearings and seals play a crucial role in the smooth operation of mechanical systems. They contribute to the overall efficiency and longevity of machinery by reducing friction and preventing contamination. A solid grasp of these components is essential for anyone involved in maintenance or repair. Bearings are designed to support rotating parts, ensuring they move smoothly while minimizing wear. Seals, on the other hand, protect internal components from dirt, moisture, and other external elements that could cause damage. Together, these elements are vital for optimal performance.

Understanding these components enhances maintenance practices and promotes better machinery performance. By prioritizing the integrity of bearings and seals, operators can ensure their systems run efficiently and effectively. Common Issues with the Lower Unit

The underwater section of a marine propulsion system can encounter various problems over time. Understanding these common challenges can help boat owners take preventive measures and ensure proper maintenance. By recognizing potential issues early, it is possible to extend the lifespan of the entire assembly. Here are some frequent complications that may arise:

Regular inspections and maintenance can significantly reduce the risk of these issues, ensuring smooth operation and reliability on the water. Maintenance Tips for Longevity

Regular upkeep is essential to ensure the extended life of your marine propulsion system. By following a few straightforward practices, you can prevent wear and tear, enhance performance, and ultimately save on costly repairs.

Implementing these practices will contribute significantly to the durability and reliability of your marine propulsion system, ensuring it operates smoothly for years to come. |