The functionality of various instruments hinges on a clear comprehension of their inner workings. By exploring the intricate relationships between each element, users can enhance their proficiency and ensure optimal performance. This section aims to shed light on the essential components that contribute to the efficient operation of these devices.

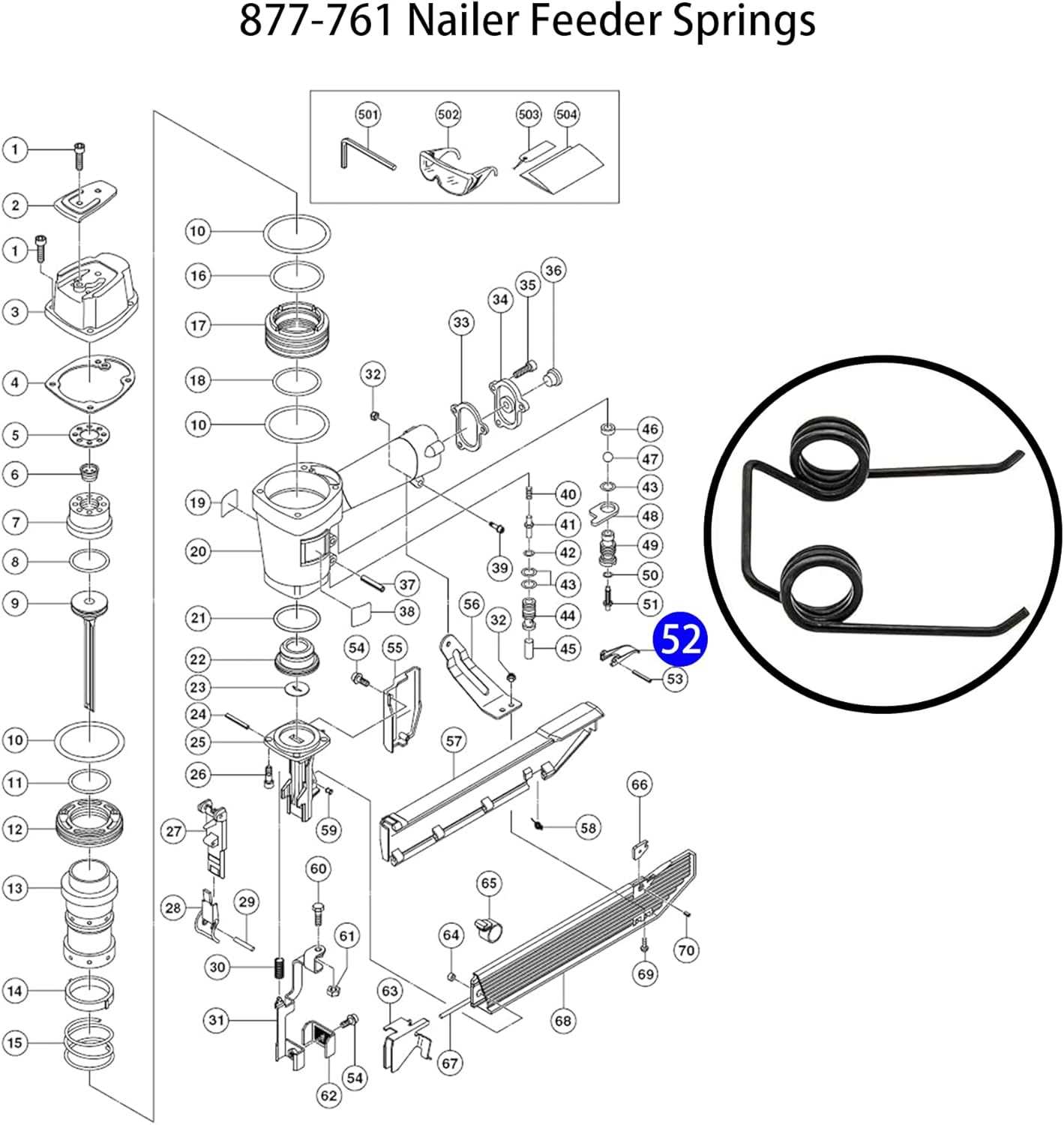

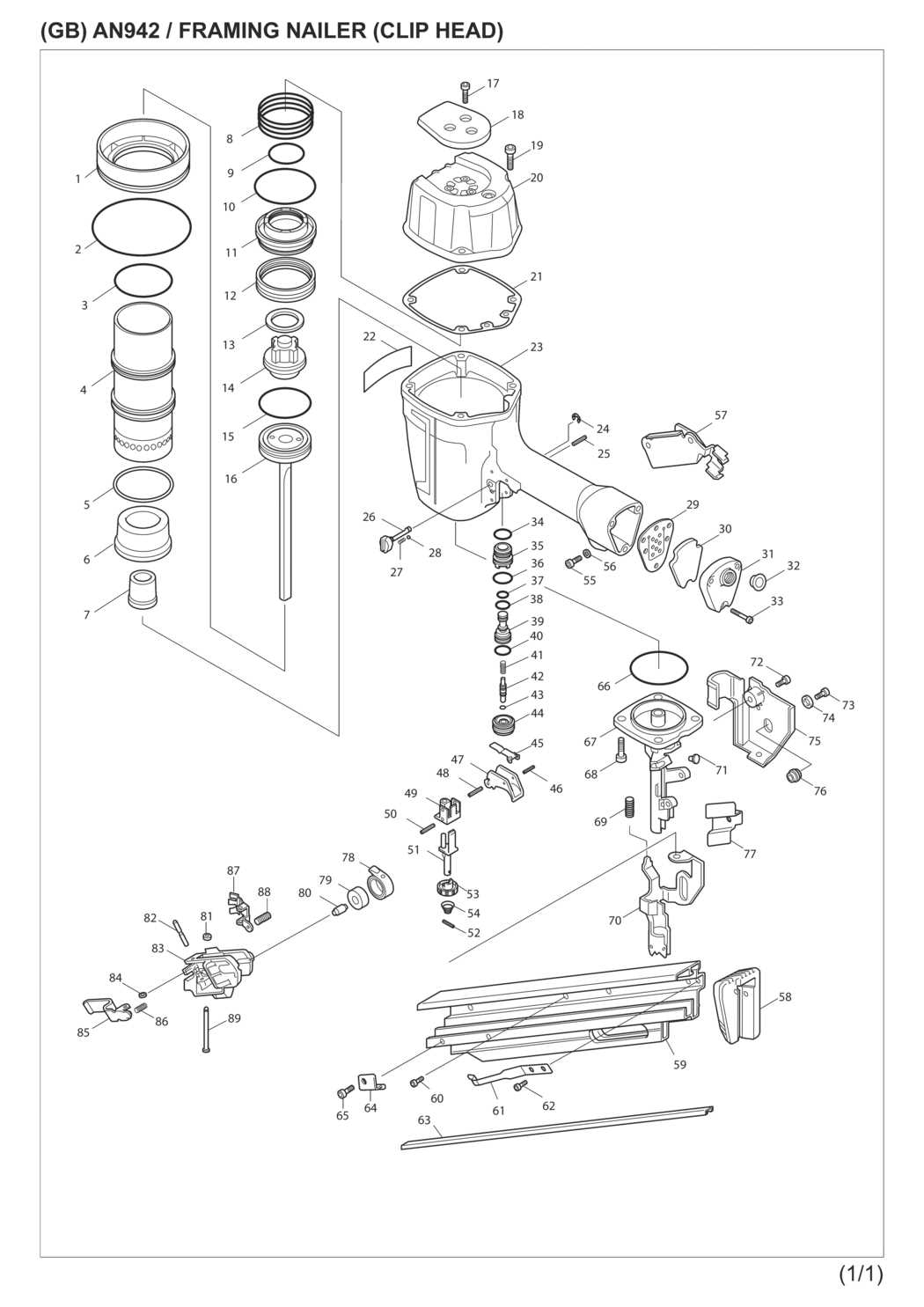

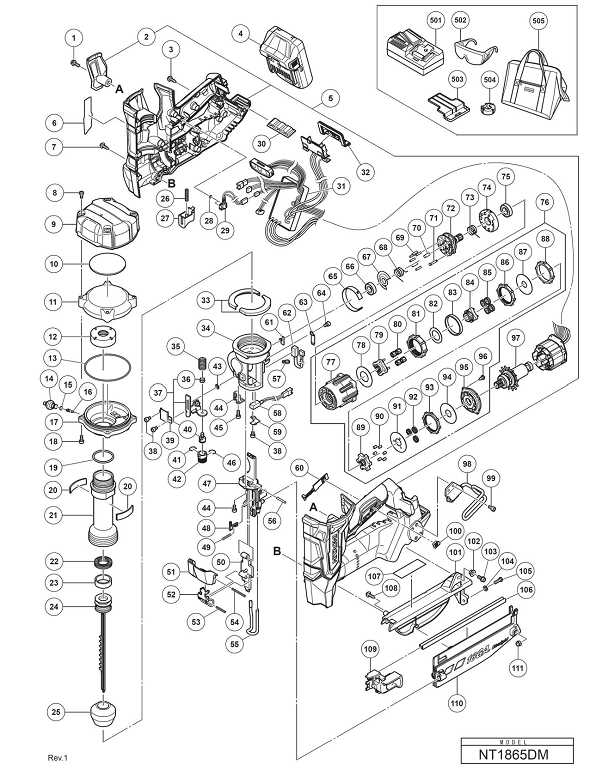

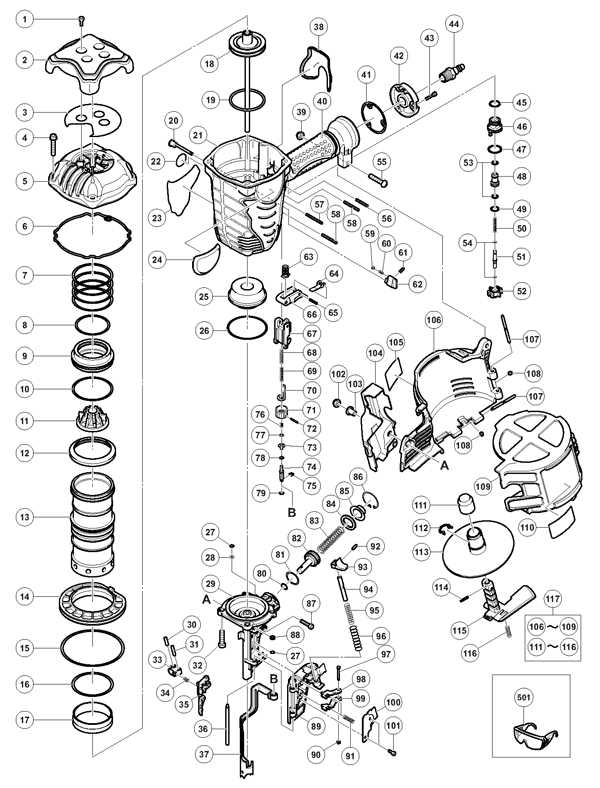

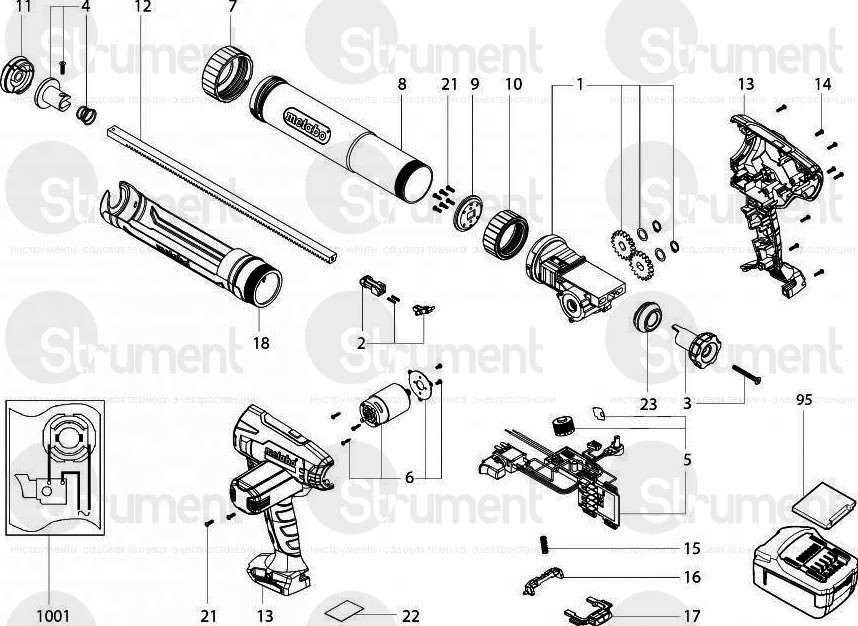

Every mechanism consists of a multitude of segments, each playing a crucial role in the overall system. Recognizing how these elements interact can ultimately lead to improved maintenance practices and extended longevity. In this context, a detailed visual representation can serve as an invaluable resource for both novices and experienced users alike.

As we delve deeper into the anatomy of these tools, we will uncover the significance of each section and its impact on functionality. This knowledge empowers users to troubleshoot issues effectively, making informed decisions during repairs or upgrades. Ultimately, a thorough understanding of the components not only fosters skill development but also enhances the user’s confidence in handling equipment.

Understanding Metabo Nail Guns

The tools designed for fastening materials together have revolutionized the construction and woodworking industries. Their efficiency and precision have made them essential for both professionals and DIY enthusiasts. Grasping the fundamentals of these devices can enhance productivity and ensure effective results in various projects.

Components play a critical role in the overall functionality of these fastening tools. Each element contributes to the device’s performance, influencing factors such as power, speed, and durability. Familiarizing oneself with the inner workings and arrangement of these components can aid in troubleshooting and maintenance, extending the lifespan of the equipment.

Understanding how to operate and care for these devices is vital. Regular maintenance and proper handling not only ensure safety but also maximize efficiency. By learning about the specific features and mechanisms, users can make informed decisions when selecting the right tool for their tasks.

Key Components of Nail Guns

Understanding the essential elements of fastening tools is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the tool functions smoothly and efficiently. A well-designed fastening device consists of several critical features that contribute to its overall performance and reliability.

Power Source

The power source is a fundamental aspect that dictates the operation of the fastening device. Options typically include pneumatic, electric, or battery-powered systems. Each type offers distinct advantages in terms of portability, power, and ease of use, allowing users to select the most suitable option for their specific needs.

Drive Mechanism

The drive mechanism is responsible for the propulsion of fasteners into the material. Different mechanisms, such as sequential or contact firing, provide varying levels of control and speed. Understanding how these mechanisms operate can help users achieve optimal results in their projects while maintaining safety standards.

Importance of Nail Gun Diagrams

Understanding the inner workings of any fastening tool is crucial for effective operation and maintenance. Visual representations not only provide clarity on assembly and functionality but also enhance the user’s ability to troubleshoot issues quickly and efficiently.

Enhanced Maintenance

Detailed visuals serve as an essential reference for performing routine upkeep. By following the illustrations, users can ensure that each component is correctly aligned and functioning optimally, thus prolonging the lifespan of the equipment.

Improved Safety

Using accurate schematics aids in identifying potential hazards associated with improper usage. Awareness of each component’s role helps prevent accidents, ensuring that the tool is used safely and effectively.

How to Read Diagrams Effectively

Understanding visual representations is crucial for anyone working with complex machinery. Mastering the art of interpreting these illustrations can enhance your ability to identify components, understand their functions, and troubleshoot issues efficiently. This section will guide you through essential techniques for effective comprehension.

Key Techniques for Interpretation

Start by familiarizing yourself with the symbols and notation commonly used in these visuals. Each element typically has a specific meaning that conveys information about its function and placement.

Organizing Information

To streamline your understanding, organize the information by breaking it down into manageable sections. This can involve creating a table to highlight key elements:

| Component | Function | Notes |

|---|---|---|

| Element A | Describes primary function | Ensure proper alignment |

| Element B | Supports overall mechanism | Check for wear |

| Element C | Facilitates movement | Lubricate regularly |

Common Parts in Metabo Nail Guns

This section explores the essential components found in these versatile tools, highlighting their functionality and importance in achieving optimal performance. Understanding these elements can enhance your maintenance practices and improve efficiency in your projects.

Key Components

- Trigger: Initiates the action and allows for precise control.

- Magazine: Holds fasteners, ensuring a steady supply during operation.

- Motor: Powers the mechanism, crucial for driving the fasteners.

- Safety Mechanism: Prevents accidental firing for user safety.

Additional Features

- Depth Adjustment: Allows customization of fastener depth for different materials.

- Exhaust Port: Directs air away from the user for comfort during use.

- Rubber Grip: Enhances handling and reduces fatigue.

Maintenance Tips for Nail Gun Parts

Proper upkeep of your fastening tool can significantly enhance its performance and longevity. Regular attention to its components ensures smooth operation and reduces the likelihood of malfunctions.

First, routinely inspect the internal mechanisms for signs of wear or damage. Clean these areas to prevent debris buildup that can hinder functionality. Lubrication of moving elements is crucial; use a suitable oil to maintain optimal performance.

Check the seals and O-rings for any deterioration. Replacing worn seals can prevent air leaks, ensuring efficient operation. Additionally, examine the safety features to ensure they are fully operational before each use.

Store the tool in a dry, clean environment to protect it from moisture and dust. Following these practices will help maintain the reliability of your fastening device over time.

Identifying Replacement Components

Understanding the intricacies of your tool is essential for effective maintenance and repairs. This section aims to guide users through the process of recognizing essential elements that may require substitution, ensuring optimal functionality and longevity of the equipment.

Common Indicators of Wear

Regular usage can lead to wear and tear on various components. Look for signs such as decreased performance, unusual noises, or visible damage, which can indicate the need for replacement parts.

Resources for Identification

Utilizing manuals and online resources can greatly aid in identifying the specific components needed. Diagrams and part lists often provide clarity on what to look for when selecting replacements.

Safety Features of Metabo Nail Guns

Ensuring user protection is paramount in the design of modern fastening tools. These devices incorporate various innovative mechanisms to minimize risks during operation, promoting a secure working environment.

Key Safety Mechanisms

- Contact Control: Prevents unintentional activation by requiring deliberate pressure on the trigger.

- Depth Adjustment: Allows precise control over penetration depth, reducing the chance of damage or injury.

- Sequential Firing Mode: Limits the rate of firing, encouraging deliberate and careful use.

Additional Protective Features

- Integrated safety guards to shield the operator from projectiles.

- Overload protection mechanisms to prevent tool malfunction.

- Ergonomic design that enhances stability and control during use.

Typical Problems and Solutions

This section addresses common challenges encountered with fastening devices and offers practical solutions to enhance performance and reliability.

- Device Fails to Fire:

- Check power source or air supply.

- Inspect for jammed fasteners.

- Ensure correct loading of fasteners.

- Inconsistent Fastening:

- Verify adjustment settings for depth control.

- Clean the tool to remove debris.

- Examine the condition of the fasteners used.

- Leakage Issues:

- Check for damaged hoses or connections.

- Tighten loose fittings and seals.

- Replace worn or cracked components.

- Excessive Noise:

- Lubricate moving parts regularly.

- Inspect for loose screws or components.

- Evaluate the condition of the motor or pump.

Best Practices for Usage

To achieve optimal results with your equipment, it’s essential to follow certain guidelines that enhance both performance and safety. Understanding the proper techniques and maintenance can significantly extend the lifespan of your tools while ensuring efficient operation. Here are key recommendations to consider during use.

Preparation and Safety

Before starting any task, make sure to read the manufacturer’s instructions thoroughly. Always wear appropriate personal protective equipment, such as goggles and gloves, to safeguard against potential hazards. Additionally, inspect the device for any signs of wear or damage before each use; this can prevent accidents and ensure smooth functionality.

Proper Handling Techniques

When operating the device, maintain a firm grip and position yourself comfortably to enhance control. Ensure that your workspace is clear and well-lit, reducing the risk of mishaps. Always keep your hands and body away from the action area. Practicing steady and controlled movements will lead to cleaner results and minimize the chances of jamming or misfires.

Where to Find Parts Diagrams

Locating visual guides for tool components can significantly streamline the repair and maintenance process. These resources provide detailed illustrations that help users identify individual pieces, ensuring proper assembly and disassembly. Understanding where to access these valuable references is essential for efficient troubleshooting.

Online Resources: Numerous websites specialize in tool manuals and schematics. Manufacturer websites often provide downloadable files directly related to their products. Additionally, third-party sites may host extensive libraries of documents, enabling quick searches by model number or category.

Retail and Service Centers: Local hardware stores or authorized service centers can be excellent sources for component illustrations. Many establishments keep hard copies of technical guides that customers can consult in person, offering expert assistance when needed.

User Forums and Communities: Engaging with online forums dedicated to tools can yield helpful insights. Members often share links to diagrams or personal experiences, creating a collaborative environment for troubleshooting and repairs.

Instructional Videos: Video platforms frequently feature tutorials that include breakdowns of various tools. These visual aids not only demonstrate the usage of components but may also show schematic views, enhancing the viewer’s understanding of the assembly.

Upgrading Your Nail Gun Components

Enhancing the functionality of your tool can significantly improve efficiency and precision in your projects. By replacing outdated or worn elements with high-quality alternatives, you can elevate performance, extend lifespan, and ensure reliable operation. Understanding which components to upgrade can lead to more successful outcomes and a more enjoyable experience in your work.

Key Components to Consider

Focusing on crucial elements such as the firing mechanism and air delivery system can make a noticeable difference. Upgrading to a more responsive firing assembly can improve accuracy and reduce misfires. Additionally, enhancing the air intake and exhaust can lead to smoother operation and less downtime due to maintenance.

Benefits of Upgrading

Investing in superior components not only boosts the efficiency of your tool but also contributes to overall safety and ease of use. With improved reliability, you’ll experience fewer interruptions, allowing you to maintain momentum on your projects. Furthermore, enhanced durability means reduced need for frequent replacements, ultimately saving you time and resources.