Understanding the internal structure of various tools is essential for maintaining their longevity and ensuring efficient performance. Each device consists of multiple key elements that work together, and recognizing their placement and function can aid in troubleshooting and repairs.

The focus here will be on the detailed breakdown of one such tool, revealing how its various components fit together. By examining this assembly, you can gain deeper insight into the engineering behind it, as well as the steps required for potential part replacements or servicing.

Whether you’re looking to repair or simply better understand the inner workings of your equipment, this guide offers a detailed map of its essential components, ensuring clarity for any maintenance task you might face.

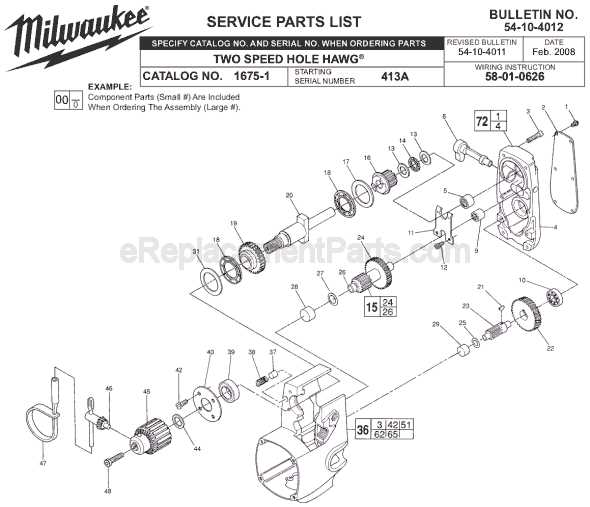

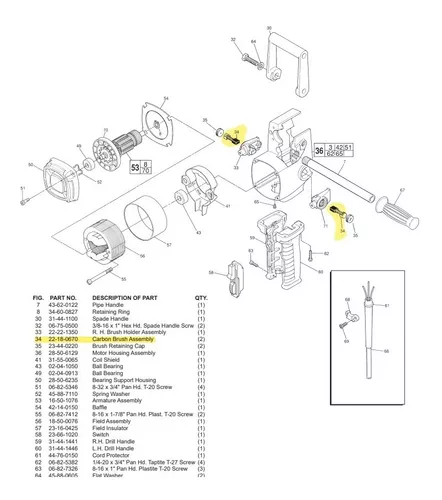

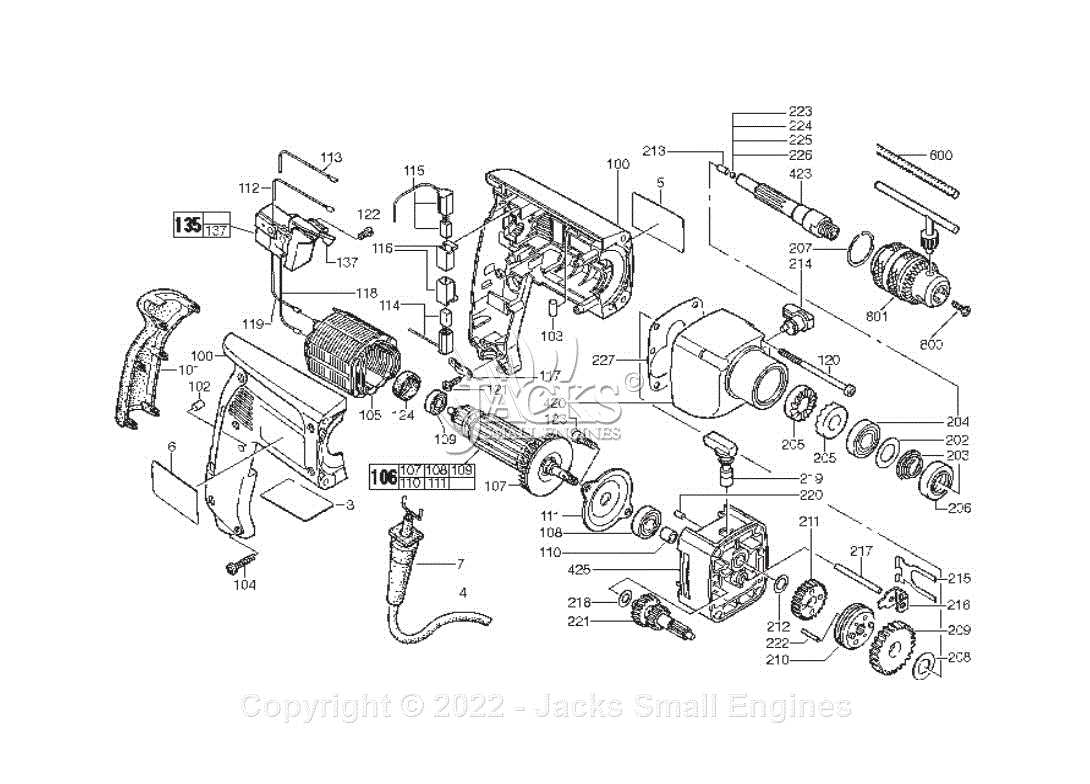

Understanding the Milwaukee 1675-1 Diagram

Grasping the layout and structure of technical illustrations is essential for proper maintenance and troubleshooting. These visual aids offer a detailed breakdown of how different components are arranged and interconnected, enabling users to quickly identify issues and replace necessary elements.

Below are some key points to consider when analyzing such diagrams:

- Focus on the organization of each section, as it will help you understand the overall system more effectively.

- Pay attention to the labeling, as it typically provides clues about the function and compatibility of the elements shown.

- Use the diagram to locate specific parts for easy identification during assembly or repair.

By carefully examining each part of the diagram, users can ensure smoother maintenance and avoid unnecessary issues during repairs.

Exploring Key Components in Detail

Understanding the essential elements of this tool can greatly improve its performance and longevity. By breaking down each component, we can grasp how the different parts work together to deliver optimal results.

Main Functional Units

Each major part plays a crucial role in the overall operation. These units are designed to withstand demanding tasks and ensure smooth functionality over time.

- Motor Assembly – The core of the device, providing the necessary power for operation.

- Gear System – Transfers and adjusts the force generated, allowing precise control.

- Handle and Grips – Ensure stability and comfort during use, reducing strain.

Smaller Components with Big Impact

Beyond the larger units, several smaller elements contribute significantly to the efficiency and safety of the tool.

- Sw

How to Identify Wear and Tear

Recognizing the signs of aging in mechanical equipment is essential for maintaining optimal performance. Regular inspection can help detect deterioration before it leads to more significant problems. Monitoring various components for visible damage, unusual noises, or reduced efficiency can prevent further complications.

Key areas to assess include any moving mechanisms, such as gears or belts, which are prone to friction-based degradation. Surface scratches, rust, and cracks are also indicators that parts may need replacement or maintenance. Early detection of these issues ensures that equipment remains reliable and safe for use.

Common Issues with Drill Parts

Over time, various components of a power drill may experience wear and tear, leading to performance problems. Identifying these common issues can help prevent more significant damage and extend the tool’s lifespan.

Worn Out Bearings

One of the most frequent concerns is related to the bearings. If they start to wear out, the drill may begin to wobble or generate excessive heat. Regular maintenance can help in early detection of this problem.

Electrical Malfunctions

Electrical failures, such as a malfunctioning switch or wiring, are another common issue. These problems can prevent the drill from powering on or result in inconsistent operation.

- Difficulty starting or stopping the tool

- Inconsistent power output

- Sparks or burning smells during use

Recognizing these issues early and addressing them promptly can help avoid costly repairs or the need for replacement.

Proper Maintenance of Milwaukee 1675-1

Regular upkeep is essential for ensuring the long-lasting performance of any heavy-duty drilling equipment. By following a consistent care routine, the tool will remain reliable and efficient for a wide range of tasks. Proper maintenance not only extends the lifespan of the device but also ensures safety during operation.

Cleaning and Lubrication

One of the key aspects of maintaining any drilling tool is keeping it clean. After every use, it’s important to remove dust and debris from all surfaces, especially the moving parts. Periodic lubrication of the mechanical components will help reduce wear and tear, allowing for smoother operation.

Inspection and Replacement of Worn Components

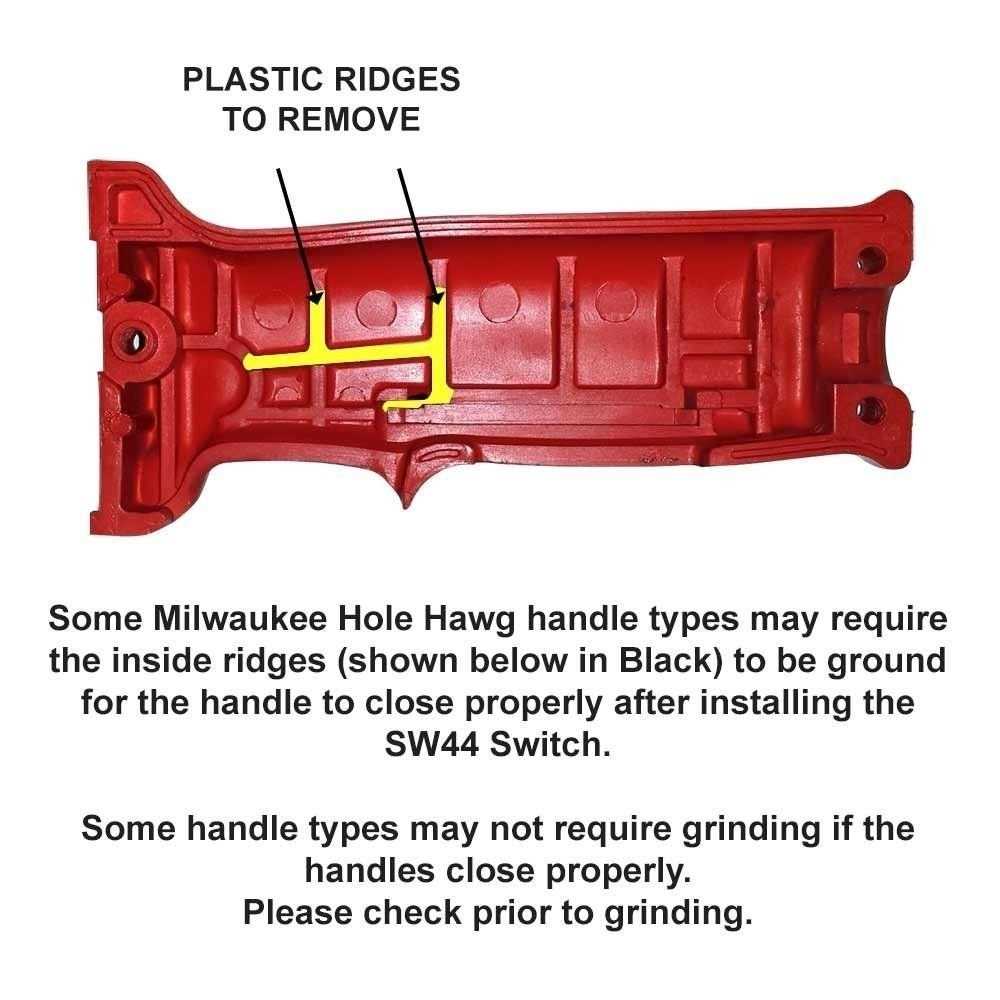

Regularly inspect critical components for signs of wear. If any parts appear to be damaged or excessively worn, replace them immediately to prevent

Replacing Parts for Better Performance

Maintaining optimal functionality of equipment often requires the timely replacement of worn or outdated components. Upgrading specific elements can lead to enhanced efficiency, improved safety, and a longer lifespan for your tools. Understanding which parts to replace and when is crucial for ensuring that your devices perform at their best.

Identifying Components to Upgrade

Before undertaking any replacement, it is essential to assess the condition of various components. Regular inspections can reveal signs of wear, such as cracks, fraying, or diminished performance. Key elements to evaluate include:

Component Signs of Wear Recommended Action Motor Overheating, unusual noises Replace with a high-efficiency model Switch Inconsistent operation Install a new, durable switch Housing Cracks, damage Consider replacing for structural integrity Power Cord Frayed, exposed wiring Replace immediately for safety Benefits of Upgrading Components

Investing in new elements can significantly enhance the overall performance of your tools. Upgraded components often lead to better energy efficiency, reduced operational noise, and improved safety standards. Furthermore, regular updates can prevent costly repairs and downtime, ensuring that your equipment remains reliable and effective.

Essential Tools for Repair and Maintenance

Effective repair and maintenance tasks require a set of fundamental tools that enhance efficiency and precision. Whether you’re a professional technician or a DIY enthusiast, having the right equipment can significantly impact the quality of your work. This section outlines the indispensable tools that every individual should consider for routine upkeep and repairs.

Hand Tools for Versatile Tasks

Hand tools are crucial for various applications, offering flexibility and ease of use. A quality set of screwdrivers is essential for tackling different types of fasteners, while a multi-tool provides multiple functionalities in a single device. Additionally, wrenches and pliers are vital for gripping and turning components, making them indispensable in any toolkit.

Power Tools for Efficiency

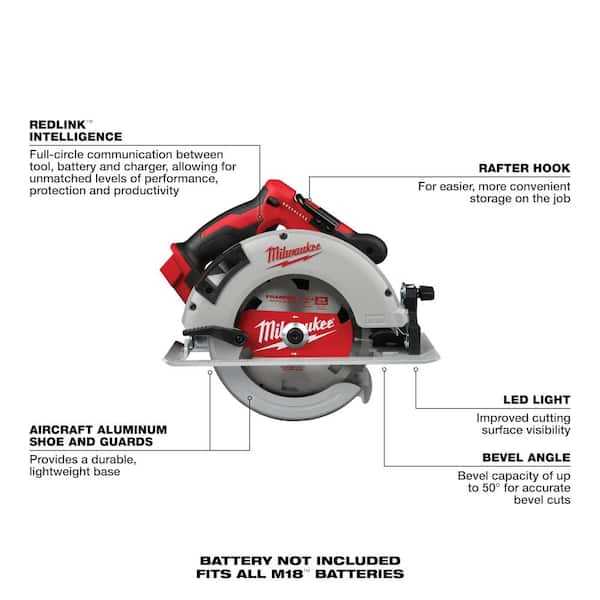

Power tools can elevate repair tasks by saving time and effort. An efficient drill is necessary for creating holes or driving screws, while a saw is essential for cutting materials with precision. For those working on heavy-duty projects, angle grinders and impact drivers offer the power needed to handle tougher jobs, ensuring effective and reliable results.

Troubleshooting Guide for Component Failures

This section provides essential strategies for diagnosing and resolving issues related to equipment components. Effective troubleshooting can minimize downtime and enhance performance by systematically identifying faults and implementing corrective measures.

To assist in the troubleshooting process, the following table outlines common component failures, their potential causes, and recommended solutions:

Component Possible Causes Recommended Solutions Motor Overheating, unusual noises, lack of power Check for obstructions, inspect electrical connections, ensure proper lubrication Switch Failure to engage, intermittent operation Examine wiring, replace faulty switch Gearbox Excessive wear, grinding sounds Inspect for proper lubrication, replace worn gears Power Supply Fluctuating voltage, total loss of power Test with a multimeter, check circuit breakers, ensure proper outlet function Blade/Drill Bit Loss of cutting efficiency, unusual vibration Sharpen or replace as needed, ensure proper alignment Understanding the Motor Assembly Structure

The motor assembly plays a crucial role in the overall functionality of power tools, serving as the heart that drives various operations. Analyzing the components and their interactions within this assembly is essential for effective maintenance and performance optimization. This section delves into the intricate structure, highlighting the significance of each element and how they contribute to the tool’s efficiency.

Components of the Motor Assembly

The motor assembly comprises several key components, including the rotor, stator, and various electrical connections. Each part has a specific function, and their coordination ensures seamless operation. The rotor, typically situated at the center, spins within the stator’s magnetic field, generating the necessary torque to power the tool. Understanding these components is vital for troubleshooting and repairs.

Importance of Maintenance

Regular maintenance of the motor assembly is imperative for prolonging the lifespan of the equipment. Lubrication, cleaning, and inspection of electrical connections can prevent potential failures and enhance performance. By ensuring that each component is in optimal condition, users can achieve better results and minimize downtime during tasks.

Efficient Use of the Parts Diagram

Understanding a component illustration is essential for optimal operation and maintenance. This resource allows users to identify various elements, ensuring effective troubleshooting and repairs. Familiarity with the schematic enhances the user’s ability to locate and address issues swiftly.

To maximize the benefits of the illustration, consider the following strategies:

- Familiarize Yourself: Spend time reviewing the illustration to understand the layout and components involved.

- Identify Key Components: Focus on crucial elements that frequently require maintenance or replacement.

- Organize Your Workspace: Keep tools and parts accessible based on the illustration for efficient repairs.

- Cross-Reference with Manuals: Use the illustration in conjunction with user guides for comprehensive insights.

- Document Changes: Note any modifications made during maintenance for future reference.

By implementing these practices, users can enhance their efficiency and ensure the longevity of their equipment.

Where to Source Authentic Replacement Parts

Finding reliable sources for genuine components is crucial for maintaining the functionality and longevity of your equipment. Authentic replacements ensure that your tools operate efficiently and safely, reducing the risk of malfunctions or damage.

Consider purchasing from authorized retailers or manufacturer websites. These outlets typically offer verified products and often provide warranties, giving you peace of mind regarding quality. Additionally, reputable online marketplaces can be a good option, but it is essential to check seller ratings and reviews to ensure you are buying legitimate items.

Another effective strategy is to join forums or communities dedicated to tool enthusiasts. These platforms often share valuable insights about trusted suppliers and even offer recommendations based on personal experiences. Networking with fellow users can lead to discovering hidden gems in the market.

Finally, local repair shops can be a great resource. Many of these establishments stock genuine components or can order them directly from manufacturers. Establishing a relationship with a local shop can also provide you with expert advice on installation and maintenance.