In the world of coffee preparation, the functionality of each element plays a crucial role in delivering the perfect brew. This section delves into the intricate details of a specific model, shedding light on how various components interact and contribute to the overall performance. Grasping the arrangement and role of each piece is essential for enthusiasts and professionals alike, ensuring a seamless experience in crafting exquisite beverages.

As we explore the various sections of this sophisticated apparatus, you will gain insights into the essential elements that facilitate its operation. Each part is designed with precision, and understanding their relationships helps in maintaining and optimizing the equipment. Whether you are a novice or a seasoned barista, comprehending the configuration of these elements will enhance your appreciation for the art of coffee making.

Moreover, familiarity with the layout can assist in troubleshooting common issues, enabling users to diagnose and rectify problems efficiently. This knowledge empowers coffee lovers to take charge of their brewing experience, ensuring consistency and quality in every cup. Embracing the complexity of these mechanisms not only enhances your skills but also enriches your passion for coffee.

This section aims to provide a comprehensive overview of the various elements that make up a specific coffee preparation appliance. By understanding these components, users can enhance their knowledge and maintenance skills, ensuring optimal performance and longevity of the device. The following content outlines key features and functions of each element, helping enthusiasts and professionals alike.

Key Components and Their Functions

- Hopper: The container that holds the coffee beans before they are processed.

- Burrs: The grinding mechanism responsible for producing coffee grounds of desired consistency.

- Chamber: The area where ground coffee collects after passing through the grinding mechanism.

- Adjustable Settings: Controls that allow users to customize the grind size based on brewing preferences.

- Motor: The component that powers the grinding mechanism, influencing speed and efficiency.

Maintenance and Care Tips

- Regularly clean the hopper and chamber to prevent residue buildup.

- Check burrs for wear and replace them as needed to maintain grinding quality.

- Adjust settings carefully to avoid unnecessary strain on the motor.

- Keep the device dry and stored in a suitable environment to prolong its lifespan.

Overview of Grinder Functionality

This section delves into the essential operations of a coffee preparation tool, emphasizing its role in achieving the desired texture and consistency of coffee beans. Understanding how these mechanisms interact is crucial for optimizing the overall brewing experience.

Key Components and Their Roles

Every coffee preparation device is composed of several critical elements that work in harmony. Each component contributes uniquely to the grinding process, influencing both the efficiency and the quality of the resulting product.

| Component | Function |

|---|---|

| Burrs | These elements crush the beans uniformly, ensuring a consistent size. |

| Motor | Powers the mechanism, providing the necessary force for operation. |

| Hopper | Holds the beans before they enter the grinding mechanism. |

| Chamber | Collects the ground coffee, facilitating easy access for brewing. |

Importance of Consistency

The uniformity of the ground material is pivotal for achieving a balanced flavor profile in brewed beverages. Variations in texture can lead to uneven extraction, impacting the overall taste and quality.

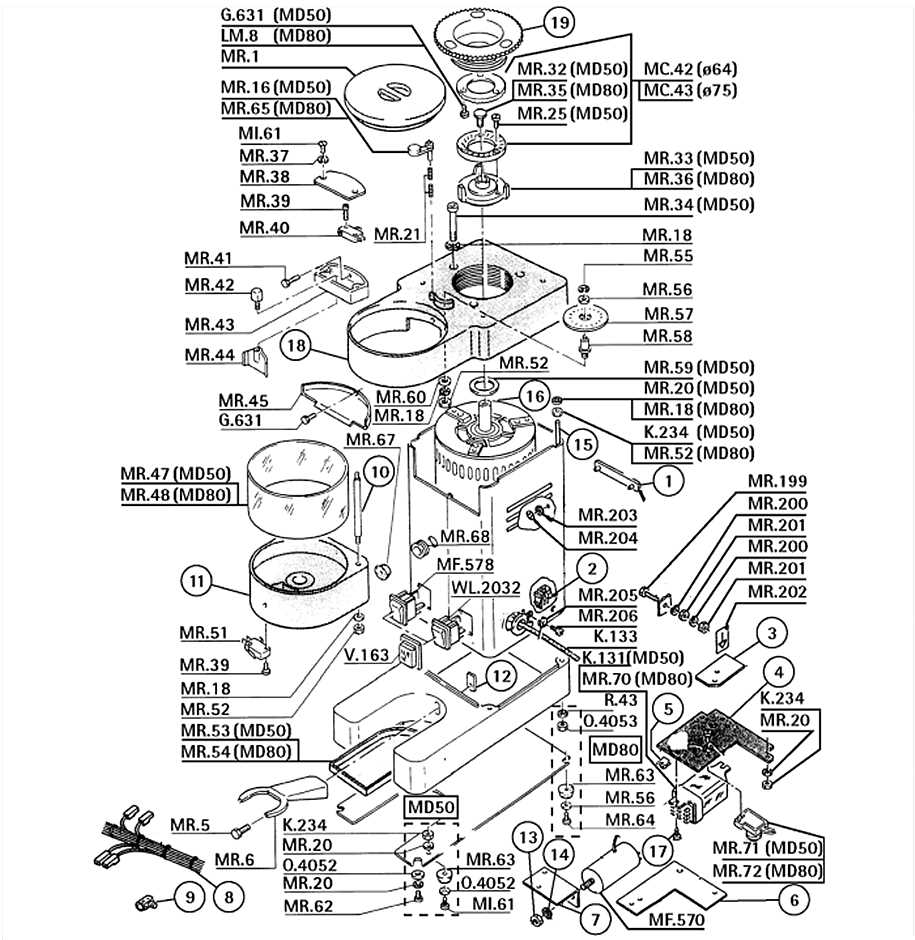

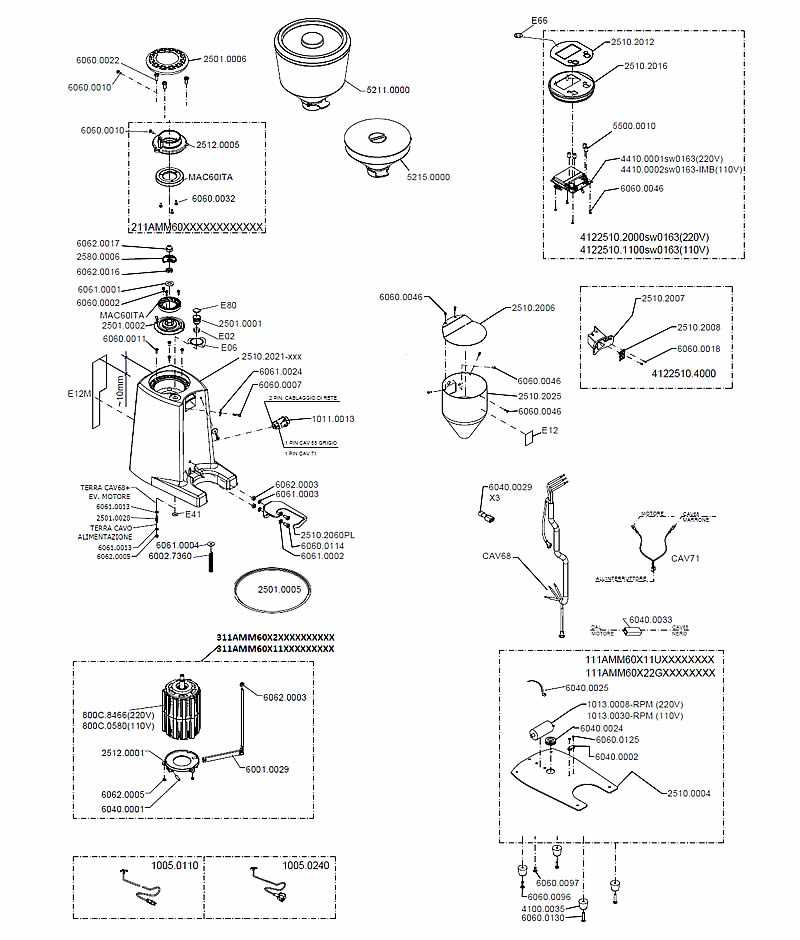

Key Parts of the Mythos Grinder

Understanding the essential components of this coffee preparation device is crucial for optimizing performance and ensuring longevity. Each section plays a significant role in the overall function, contributing to the efficiency and quality of the brewing process. Familiarity with these elements helps in troubleshooting and maintenance, allowing users to achieve the best results from their equipment.

Main Components

The primary elements include the motor, which drives the grinding mechanism, and the hopper that holds the coffee beans. The burrs are critical, as they determine the consistency of the grind, impacting the flavor extraction during brewing. Additionally, the dosing chamber helps in measuring the precise amount of coffee for each use, ensuring consistency in preparation.

Other important features include the adjustment mechanisms that allow for fine-tuning the grind size, catering to different brewing methods. The housing not only provides protection but also contributes to the overall aesthetic and ergonomics of the equipment. Furthermore, various sensors and controls enhance usability, making the process more intuitive for the user.

Exploring Grinding Mechanisms

Understanding the various techniques employed in the process of material reduction is essential for anyone interested in the nuances of coffee preparation. The efficiency of these mechanisms plays a crucial role in determining the flavor profile and consistency of the final product. By delving into the intricacies of these systems, one can appreciate the significance of design and engineering in achieving optimal results.

Types of Grinding Systems

Different approaches to material pulverization serve distinct purposes. Cone-shaped systems utilize a rotating element that effectively crushes the beans against a fixed surface, promoting uniformity in texture. In contrast, flat burr setups feature two parallel plates that work together to grind the contents into a consistent particle size. Each method has its advantages, impacting extraction rates and overall beverage quality.

Factors Influencing Performance

Several elements can influence the effectiveness of these mechanisms. Grinding speed, for example, affects the thermal dynamics during the process, which can lead to flavor degradation if not properly managed. Additionally, the choice of materials used in construction can determine durability and maintenance requirements, making it essential for users to consider these factors when selecting a system.

Importance of Proper Maintenance

Maintaining equipment in optimal condition is crucial for ensuring its longevity and efficient performance. Regular care not only enhances functionality but also prevents potential malfunctions that could disrupt operations. By investing time in upkeep, users can enjoy consistent results and avoid costly repairs, ultimately maximizing the lifespan of their machinery.

Benefits of Routine Care

Engaging in routine maintenance brings several advantages. Firstly, it helps in identifying wear and tear early, allowing for timely replacements or repairs. Secondly, consistent upkeep promotes safety by reducing the risk of unexpected failures. Lastly, well-maintained equipment operates more efficiently, leading to improved productivity and energy savings.

Key Maintenance Practices

Implementing a few simple practices can significantly enhance the performance of any machinery. Consider the following table for a quick reference to essential maintenance tasks:

| Task | Frequency | Description |

|---|---|---|

| Cleaning | Daily | Remove debris and residues to ensure smooth operation. |

| Inspection | Weekly | Check for any signs of wear or damage. |

| Calibration | Monthly | Ensure settings are accurate for optimal performance. |

| Parts Replacement | As Needed | Replace worn components to maintain efficiency. |

Identifying Common Wear Parts

In the realm of coffee preparation, understanding the components that experience frequent use is essential for maintaining optimal performance. Certain elements within these machines tend to degrade over time due to their regular exposure to various forces and conditions.

Blades are among the most critical components to monitor, as they directly influence the consistency of the grind. With continual operation, these cutting elements can become dull, necessitating periodic replacement to ensure quality results.

Hoppers, where the beans are stored prior to grinding, can also be prone to wear. Cracks or damage in this area can compromise the storage integrity and lead to potential contamination.

Seals play a vital role in maintaining the machine’s efficiency. As these components age, they may lose their ability to prevent leaks, which can affect the overall functionality.

Finally, screens that filter the ground material can become clogged or damaged, impacting the flow and quality of the output. Regular inspection of these elements will aid in preserving the device’s effectiveness and longevity.

Replacement Guidelines for Components

When maintaining and updating your equipment, understanding the replacement of individual elements is crucial for optimal performance. Proper attention to detail ensures longevity and efficiency, allowing for smooth operation and minimizing downtime.

Before proceeding with any substitutions, consider the following guidelines:

- Identify the Component: Thoroughly examine the part in question. Make sure you know its function and importance within the system.

- Compatibility: Ensure that the replacement item matches the specifications required for your device. Mismatched components can lead to ineffective performance or damage.

- Quality: Opt for high-quality replacements to ensure reliability. Cheaper alternatives may save money initially but could lead to more significant issues down the line.

- Installation: Follow the manufacturer’s guidelines carefully during the installation process. Proper technique is vital to avoid complications.

- Regular Checks: After replacing any component, monitor the performance. Regular inspections will help identify any further issues early.

By adhering to these recommendations, you can effectively manage the replacement of critical elements, ensuring your equipment remains in peak condition.

How to Assemble the Grinder

Bringing together the components of your coffee preparation device requires careful attention to detail and a methodical approach. This section outlines the steps needed to ensure a successful assembly, promoting both functionality and efficiency.

Preparation Steps

- Gather all necessary components and tools.

- Ensure you have a clean workspace to avoid any contamination.

- Review the instruction manual for specific guidance on your model.

Assembly Process

- Begin by connecting the base to the main body. Align the components and secure them using the designated screws.

- Attach the grinding chamber, ensuring that all seals are properly fitted to prevent any leaks.

- Install the adjustment mechanism, which allows for control over the fineness of the ground product.

- Finally, secure the top lid and check that all connections are tight and stable.

- Perform a brief test to confirm that the assembly is functioning as intended.

Following these steps will help you effectively bring together the device, ensuring optimal performance during use.

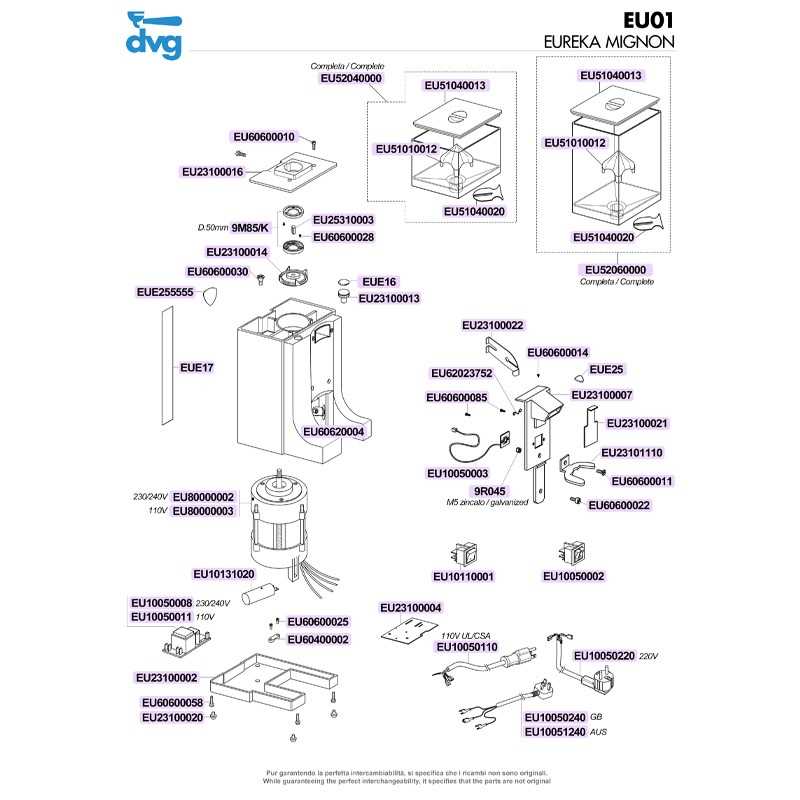

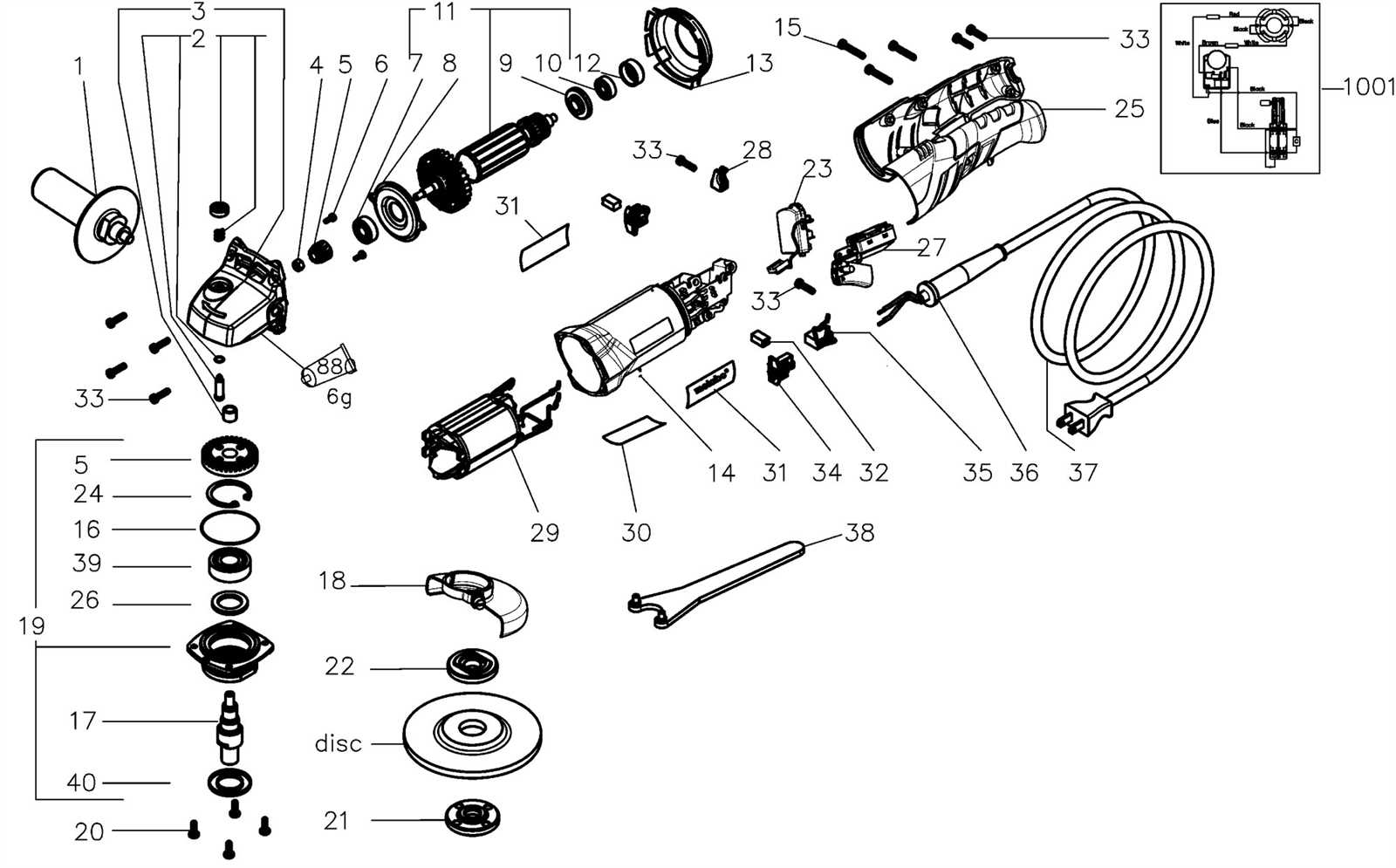

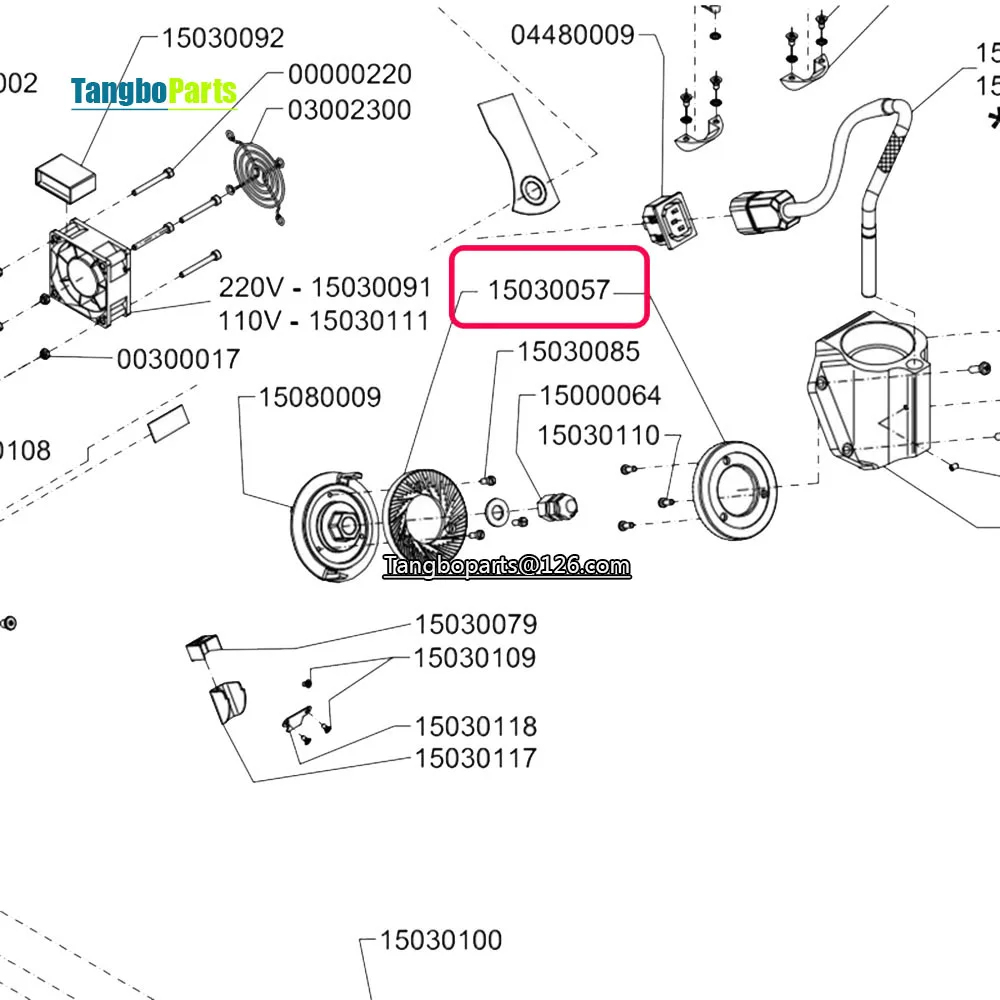

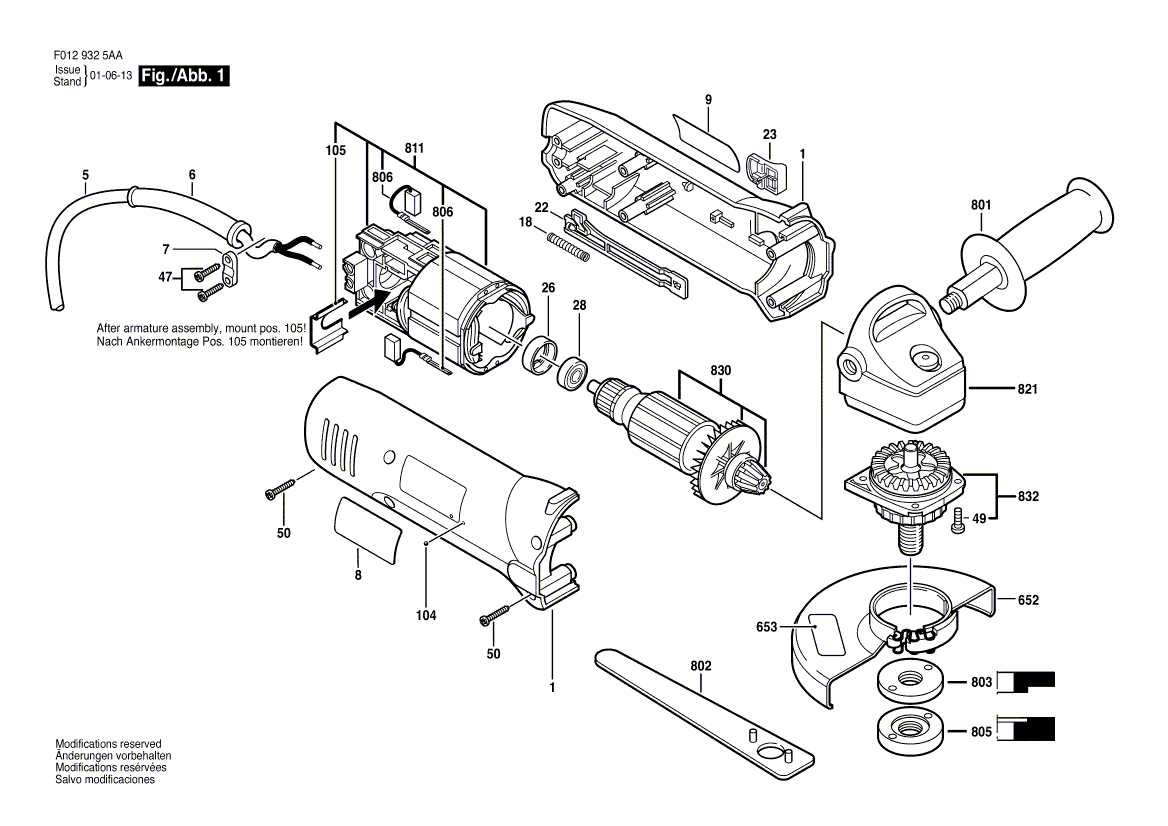

Visualizing the Parts Diagram

Understanding the intricate layout of components within a machine is essential for effective operation and maintenance. This section provides a comprehensive overview of how to interpret the various elements involved in the assembly, facilitating a clearer comprehension of their functions and relationships.

Familiarizing oneself with the configuration of these elements allows users to identify key functionalities and enhance their overall efficiency. By breaking down the structure into manageable sections, one can easily navigate through the complexity and gain valuable insights into the workings of the equipment.

Utilizing detailed illustrations not only aids in recognizing each component but also underscores the importance of proper alignment and integration. This visual representation serves as a vital resource for both novice users and seasoned professionals, enabling them to troubleshoot issues and optimize performance effectively.

Common Issues and Solutions

In the realm of coffee preparation, various challenges may arise during the operation of equipment, impacting performance and consistency. Addressing these issues promptly can enhance efficiency and prolong the lifespan of the machinery. Below are some frequent complications along with effective solutions to ensure optimal functionality.

| Issue | Solution |

|---|---|

| Inconsistent grind size | Adjust the settings to achieve a more uniform texture, ensuring that the mechanism is clean and free from residue. |

| Overheating during use | Allow the unit to cool down between cycles and check for any blockages that may hinder airflow. |

| Excessive noise | Inspect the assembly for loose components and tighten any screws or fittings as needed. |

| Stalling or stopping | Ensure that the power source is stable and check for any jams or foreign objects that may disrupt the operation. |

| Difficulty in adjusting settings | Clean the adjustment mechanism to remove any debris that may interfere with the functionality. |

Upgrading Your Mythos Grinder

Enhancing your coffee equipment can significantly impact the quality of your brews. Whether you are looking to improve consistency, efficiency, or flavor extraction, there are various modifications and enhancements available. These upgrades can help you achieve your desired taste profile and elevate your coffee-making experience.

Improving Grinding Performance

To optimize the grinding process, consider upgrading the burrs. High-quality burrs can ensure a more uniform particle size, which is crucial for extracting the best flavors from your coffee beans. Additionally, exploring different materials, such as titanium-coated or ceramic burrs, can provide distinct benefits in durability and consistency.

Enhancing User Experience

Investing in advanced technology, such as programmable settings or improved digital displays, can enhance usability. These features allow for precise adjustments to grind size and time, catering to individual preferences. Moreover, adding a sound-dampening kit can significantly reduce noise, creating a more pleasant environment during preparation.