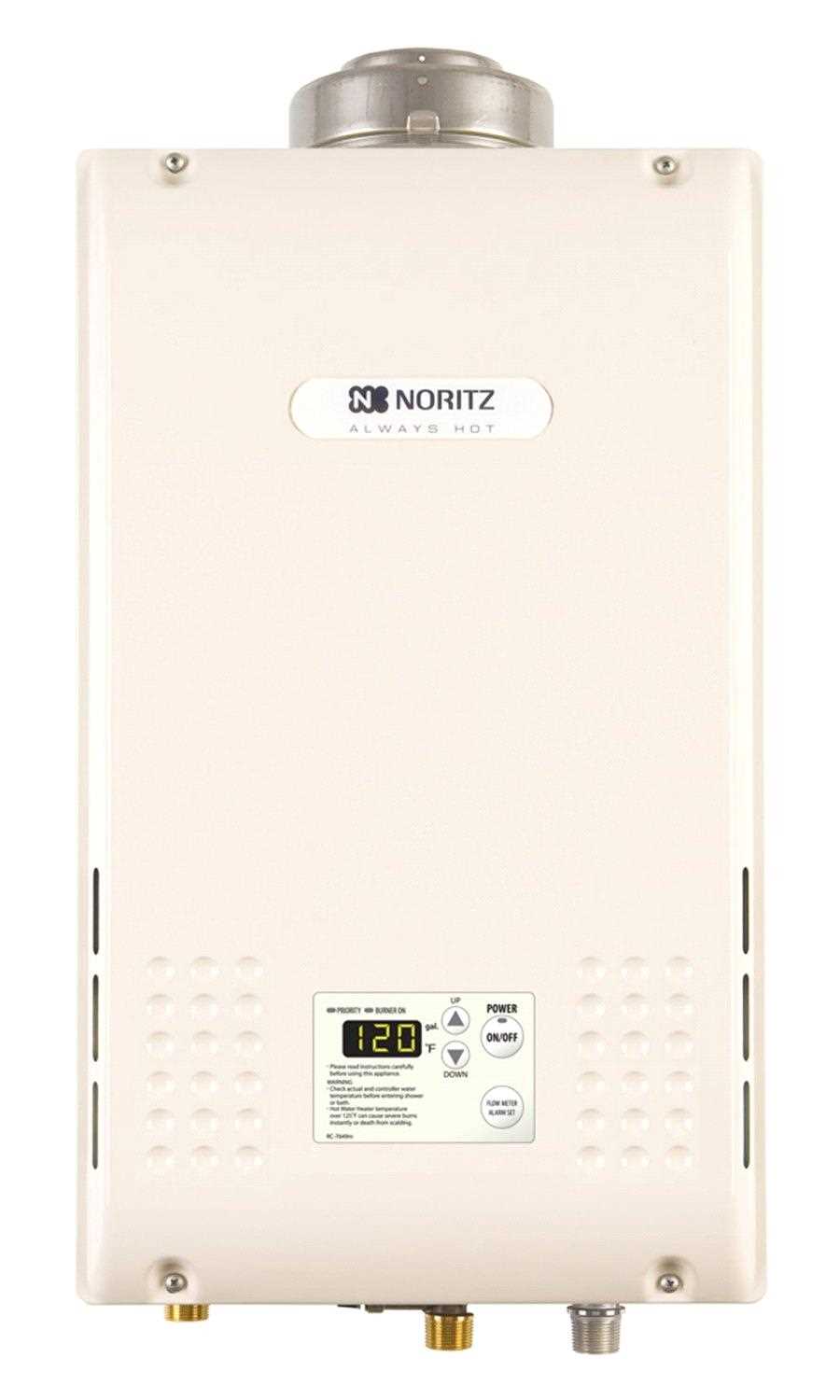

When dealing with the maintenance and repair of water heating systems, it is crucial to have a clear understanding of how the various elements are connected and function together. Proper knowledge of the internal structure and operational layout can significantly improve troubleshooting efficiency, ensuring that any potential issues are swiftly identified and resolved.

Each water heater is composed of multiple key elements, each serving a specific purpose in the heating process. These components are arranged systematically to ensure optimal performance, from heating mechanisms to safety controls. Having a clear overview of the system’s structure can help homeowners and technicians alike maintain the unit and keep it running efficiently over time.

By familiarizing yourself with the arrangement and functionality of each element within the water heating unit, you can not only address common issues but also prevent future malfunctions.

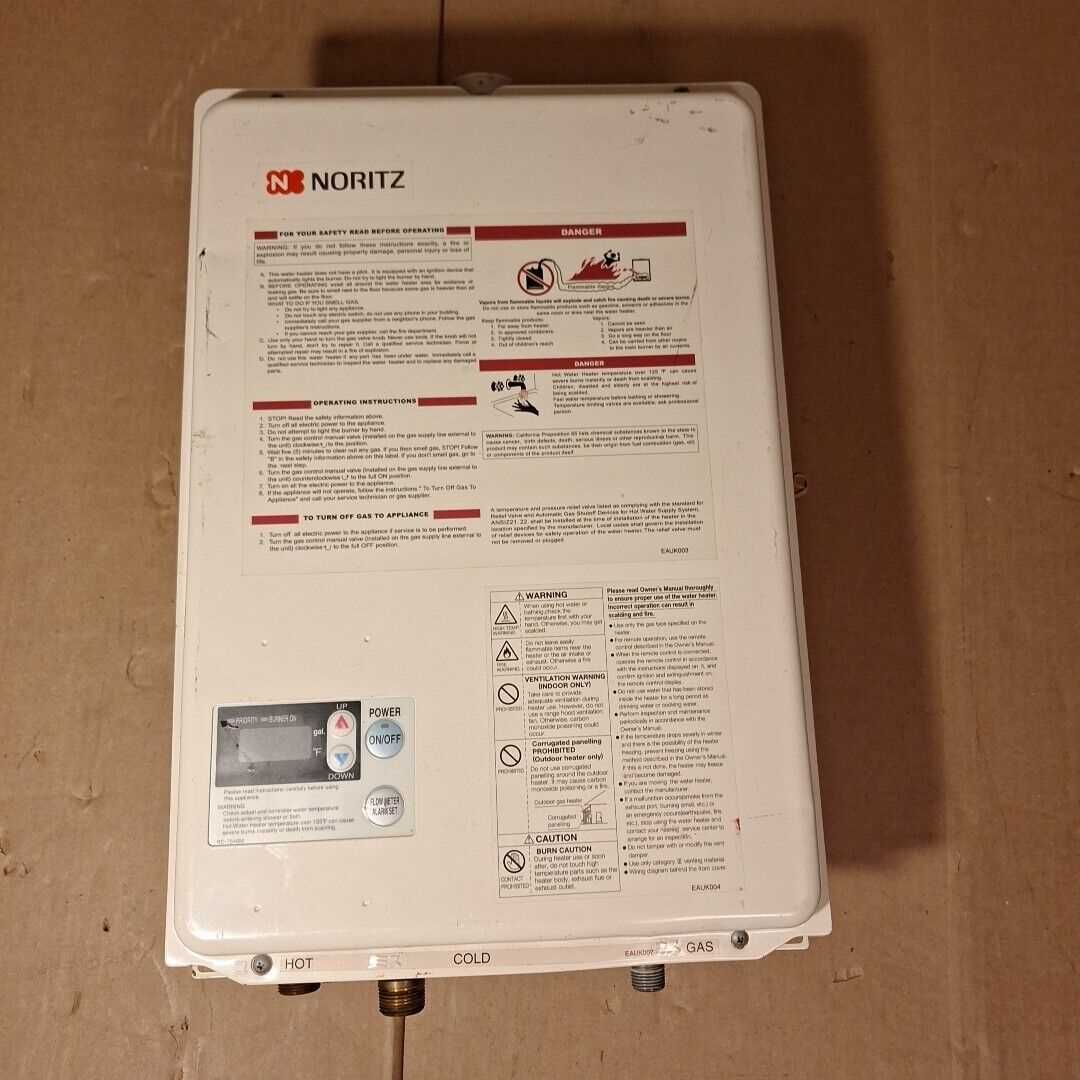

Noritz N-0751M: Key Components Overview

The efficient performance of this unit relies on several crucial elements that work together to ensure smooth operation. Each part plays a vital role in maintaining functionality, from controlling water temperature to regulating gas flow. Understanding these elements can help users appreciate the intricacies behind the system’s dependable service.

One of the central elements is the burner assembly, which generates the necessary heat for water heating. In addition, the heat exchanger is responsible for transferring thermal energy efficiently, ensuring minimal heat loss. Another important part is the flow sensor, which detects water movement and initiates the heating process as needed. Gas and water valves also contribute significantly by controlling the precise amounts of each resource entering the system.

Maintenance and troubleshooting can be greatly simplified by familiarizing oneself with these essential components. With a clear understanding of how these elements interact, it becomes easier to ensure optimal performance and longevity of the unit.

Understanding the Heat Exchanger in Model N-0751M

The heat exchanger is a critical component in any efficient heating system, playing a pivotal role in transferring thermal energy to the water. This process is what enables consistent and effective heating, ensuring optimal performance and energy savings. Recognizing how this element works will help you better appreciate the overall functionality of the device and identify any potential issues early on.

How the Heat Exchanger Works

At its core, the heat exchanger functions by utilizing combustion gases to warm the water flowing through its pipes. These gases are produced by burning fuel, which generates heat. The water flows through narrow channels, allowing maximum contact with the heated surfaces, ensuring quick and efficient temperature transfer.

Materials and Durability

Made from durable materials, such as stainless steel or copper, the heat exchanger is designed to withstand extreme temperatures and constant exposure to water. These materials are chosen for their high thermal conductivity and resistance to corrosion,

Exploring the Water Flow Sensor Functionality

The water flow sensor plays a crucial role in monitoring and regulating the movement of water within heating and plumbing systems. This component is designed to detect changes in flow rate and ensure optimal performance by adjusting the system’s behavior accordingly. Understanding how it works is essential for both maintaining efficiency and preventing potential malfunctions.

Key Features of the Water Flow Sensor include its ability to measure water velocity and provide real-time data, which can be used to fine-tune system settings. The sensor typically consists of a rotor and a magnetic sensor, which collaborate to detect flow rates as water passes through the device.

By converting mechanical energy from flowing water into electrical signals, the flow sensor ensures precise control over water distribution. This functionality is crucial for ensuring consistent operation and reducing unnecessary water consumption. Regular maintenance and occasional sensor cleaning help maintain accuracy and system reliability.

How the Ignition System Works in Noritz N-0751M

The ignition process in modern water heaters is a critical function that ensures the unit operates efficiently and safely. This system is responsible for initiating the flame that heats the water, and it does so with precise timing and coordination between several components. Understanding how this ignition system operates can help in troubleshooting and maintaining optimal performance.

Electronic Ignition Control

The ignition system is managed by an electronic control module, which monitors various sensors to determine when to activate the ignition sequence. This module receives input from the thermostat, which detects when the water temperature has fallen below the desired level. Once triggered, the control sends a signal to open the gas valve and begin the ignition process. The electronic spark is then generated to ignite the gas, creating the flame necessary

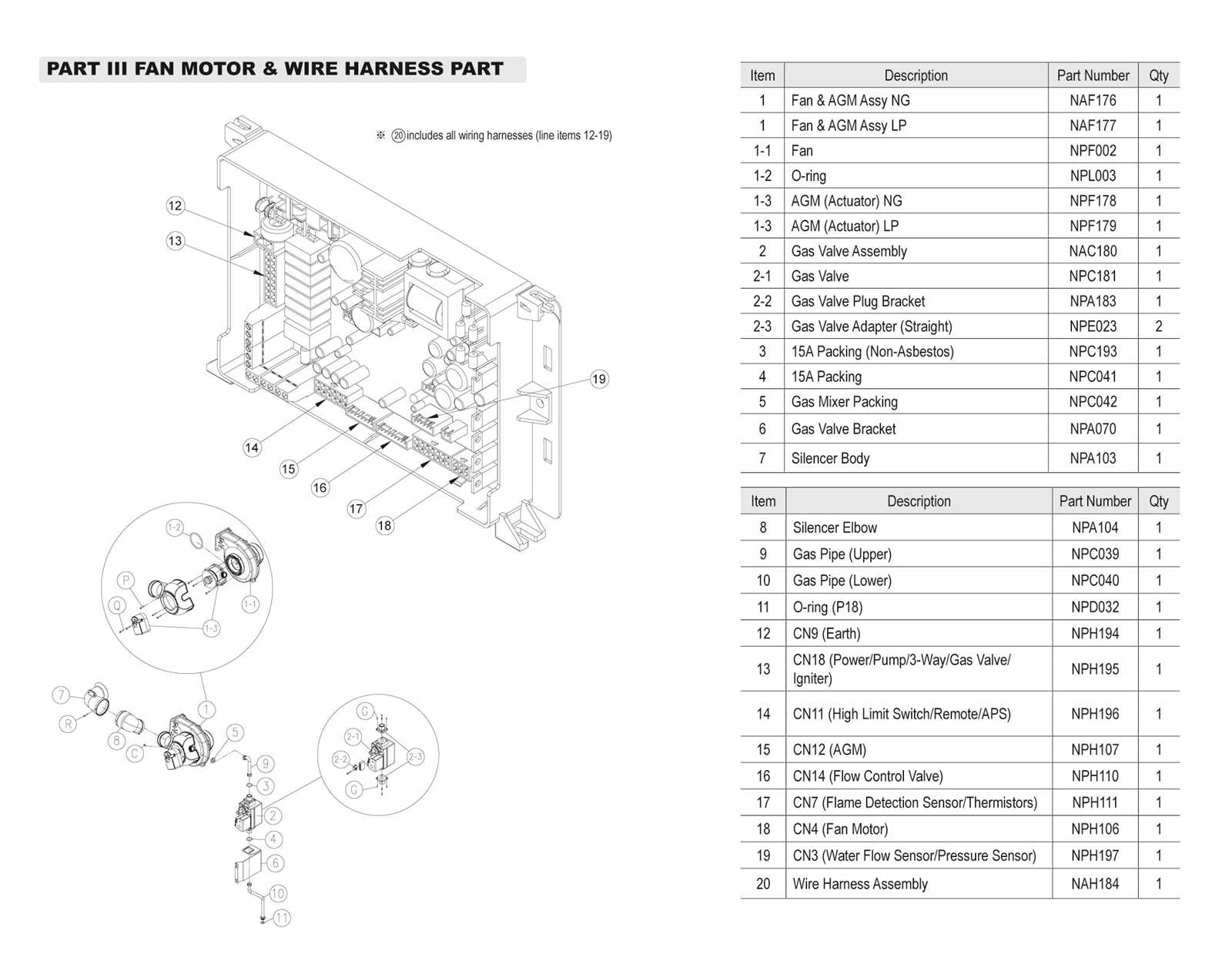

Common Issues with Gas Valve Assembly

The gas valve assembly plays a critical role in controlling the flow of fuel in a heating system. Over time, various problems can arise that may affect its performance. Recognizing these issues early can help avoid system malfunctions and ensure the efficient operation of your heating equipment.

- Sticking or Stiff Valve: One common problem is the gas valve becoming stuck or difficult to turn. This can occur due to debris build-up or internal wear, leading to inconsistent gas flow and potential heating failures.

- Gas Leaks: A faulty valve can develop leaks, which may pose a significant safety hazard. Regular inspections are essential to detect and fix any minor leaks before they become dangerous.

- Electrical Control Failure: Some gas valves rely on electrical signals to function. If there is an issue with the wiring or electronic components, the valve may fail to open or close as needed, affecting system performance.

- Pressure Regulation Issues:

Role of the PCB Board in Noritz N-0751M

The printed circuit board (PCB) serves as the central hub for electronic components, facilitating communication and power distribution among various parts of the system. This essential component plays a critical role in ensuring the efficient operation of the unit, contributing to its overall functionality and reliability.

In this context, the PCB is responsible for integrating key functionalities such as temperature control, ignition sequence management, and safety monitoring. Its design incorporates various traces and pads that connect to other components, enabling seamless interaction and operation. A well-structured PCB is vital for maintaining the performance and longevity of the system.

The following table outlines the primary functions of the PCB within this system:

Function Description Power Distribution Directs power to various components ensuring stable operation. Signal Processing Handles incoming and outgoing signals for effective communication. Temperature Regulation Monitors and adjusts temperatures for optimal performance. Safety Monitoring Detects anomalies and triggers safety protocols to prevent malfunction. Ultimately, the printed circuit board is integral to the efficient and safe functioning of the system, ensuring that all components work harmoniously to deliver reliable performance.

Importance of Temperature Sensors in Performance

Temperature sensors play a crucial role in the efficiency and reliability of various systems. Their primary function is to monitor heat levels, ensuring that equipment operates within optimal ranges. By providing real-time data, these devices help maintain safety, enhance performance, and prevent potential failures, ultimately contributing to the longevity of the system.

Enhancing Operational Efficiency

Accurate temperature readings enable systems to adjust their operations dynamically. When temperatures exceed predefined limits, the control mechanisms can react swiftly to mitigate risks, such as overheating. This proactive approach not only enhances operational efficiency but also reduces energy consumption, leading to cost savings for users.

Ensuring Safety and Reliability

The integration of temperature sensors is vital for safety protocols. In many applications, excessive heat can lead to hazardous conditions. By constantly monitoring thermal conditions, these sensors can trigger alarms or shutdown procedures, safeguarding both the equipment and its surroundings. This reliability is essential for maintaining trust in the performance of any system.

Maintaining the Burner Assembly for Efficiency

Regular upkeep of the combustion unit is essential for optimal performance and energy conservation. Proper maintenance not only enhances efficiency but also extends the lifespan of the entire heating system. A well-maintained burner ensures that fuel is utilized effectively, minimizing waste and reducing operating costs.

Regular Cleaning and Inspection

Routine cleaning is crucial for the burner to function efficiently. Over time, dust, debris, and soot can accumulate, obstructing airflow and impacting combustion quality. Inspect the unit periodically to identify any signs of wear or damage. Ensure that all components, including the ignition electrode and flame sensor, are clean and free from obstructions.

Adjusting Air-to-Fuel Ratio

The air-to-fuel ratio plays a significant role in the efficiency of the combustion process. Regular adjustments may be necessary to ensure the right balance between air and fuel. Too much fuel can lead to incomplete combustion, while too much air can cause the burner to run inefficiently. Consult the manufacturer’s guidelines for recommended settings and make adjustments as needed to maintain optimal performance.

Pressure Relief Valve: Safety and Maintenance

The pressure relief valve is a crucial safety device that protects systems from excessive pressure buildup. It serves as a fail-safe mechanism, allowing fluid to escape when the pressure exceeds safe operating levels. Regular maintenance and understanding its function are essential for ensuring the longevity and reliability of the equipment it protects.

Importance of Proper Functionality

A properly functioning relief valve is vital for maintaining system integrity. If the valve fails to open during overpressure conditions, it can lead to catastrophic failures, equipment damage, or even personal injury. Regular inspection can help identify any wear or corrosion that may impede its operation. Always check the manufacturer’s specifications to ensure compatibility with your system.

Maintenance Practices

Routine maintenance of the relief valve includes visual inspections and functional tests. It is advisable to clean the valve regularly to prevent debris from obstructing its operation. Additionally, testing the valve’s opening pressure can confirm it is functioning correctly. If any issues arise, such as leaks or difficulty in opening, replacing the valve is recommended to maintain safety standards.

Replacing the Fan Motor in Noritz N-0751M

When your heating unit exhibits signs of inefficiency or unusual noise, it may indicate that the fan motor needs replacement. This component is essential for maintaining optimal airflow and ensuring the system operates smoothly. In this section, we will discuss the steps necessary to successfully replace the fan motor, enhancing the performance of your equipment.

Step 1: Gather Necessary Tools

Before starting the replacement process, ensure you have the right tools on hand. Common tools required include a screwdriver, socket wrench, and pliers. Having these items ready will streamline the procedure and minimize downtime.

Step 2: Disconnect Power Supply

Safety should always be the top priority. Begin by disconnecting the power supply to your heating appliance. This precaution will prevent any electrical hazards while you work on the fan motor.

Step 3: Access the Fan Assembly

Carefully remove any panels or covers to access the fan assembly. Make sure to keep track of screws and components, as they will be needed during reassembly. Note the orientation and connections of the existing motor to ensure correct installation of the new one.

Step 4: Remove the Old Motor

Once you have access to the fan assembly, disconnect the wiring from the old motor. Loosen any mounting bolts or screws holding the motor in place and carefully remove it from the assembly.

Step 5: Install the New Motor

Position the new motor in the same orientation as the previous one. Secure it using the mounting bolts or screws. Reconnect the wiring, ensuring all connections are secure and properly insulated to prevent electrical issues.

Step 6: Reassemble and Test

Replace any panels or covers removed earlier, securing them in place. Reconnect the power supply and test the unit to ensure the new motor operates correctly and efficiently. Listen for any unusual noises and monitor performance closely to confirm successful installation.

By following these steps, you can effectively replace the fan motor, restoring the functionality and efficiency of your heating system.

Guide to Finding Genuine Replacement Parts

When it comes to maintaining your heating system, ensuring you have access to authentic components is crucial for optimal performance and longevity. Selecting high-quality replacements not only guarantees compatibility but also enhances efficiency and safety. This guide aims to assist you in navigating the process of sourcing legitimate parts for your equipment.

1. Authorized Dealers: One of the most reliable ways to find authentic components is to purchase from authorized distributors. These vendors have direct relationships with the manufacturers, ensuring that the items they sell meet quality standards.

2. Online Resources: Various websites specialize in offering genuine components. Make sure to visit the official website of the manufacturer for a list of trusted online retailers. Look for customer reviews and ratings to verify the credibility of the seller.

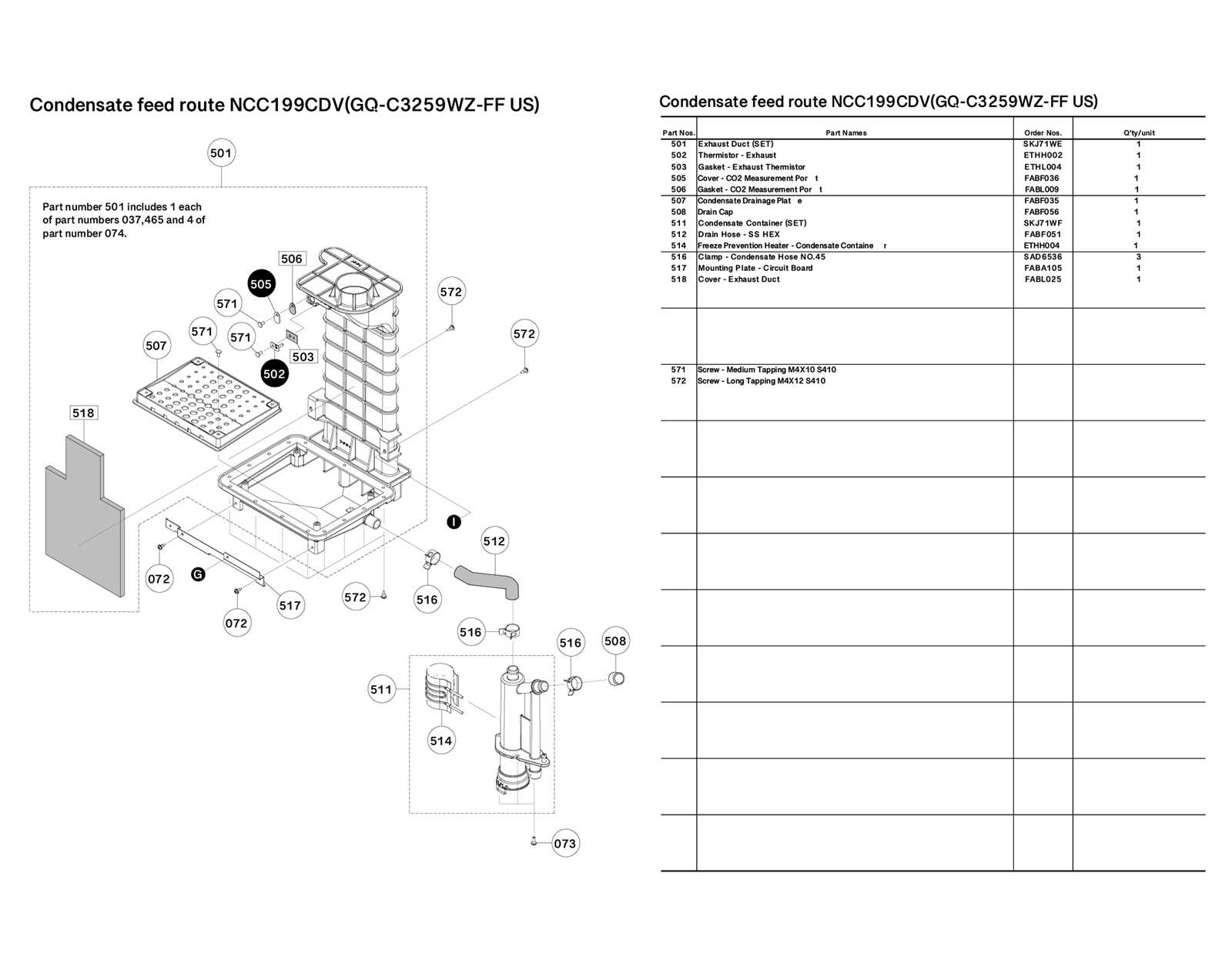

3. Part Number Identification: Knowing the specific identification numbers of the required components is vital. This information can usually be found in the original manual or documentation that came with your heating unit. Using the correct numbers will help avoid the confusion of similar-looking items.

4. Local Supply Stores: Visit local suppliers that specialize in heating and plumbing equipment. Often, these stores carry genuine items or can order them for you. It’s advisable to inquire about the authenticity of the products they offer.

5. Avoiding Counterfeits: Be cautious of unusually low prices or vendors that do not provide adequate information about their products. Counterfeit components may look similar but often lack the durability and reliability of genuine items, potentially leading to system failures.

By following these tips, you can ensure that you find the right replacements, thus maintaining the efficiency and safety of your heating system.