In the world of creative expression, the significance of precise application techniques cannot be overstated. Enthusiasts and professionals alike often seek a comprehensive understanding of the various elements that contribute to the effective functioning of their equipment. This section will delve into the intricate details that form the backbone of these specialized devices, providing insight into their construction and functionality.

By gaining familiarity with each individual component, users can enhance their skills and troubleshoot common issues more efficiently. This knowledge empowers artists to make informed decisions about maintenance and upgrades, ultimately improving their overall experience. Whether you’re a seasoned practitioner or a newcomer, understanding these vital features will significantly enrich your artistic journey.

Exploring the intricacies of these mechanisms opens the door to mastering the application process. As we investigate the specific functions of each segment, it becomes evident that even the smallest piece plays a crucial role in achieving the desired results. Awareness of these details not only fosters confidence but also inspires creativity in one’s work.

This section aims to provide a comprehensive overview of the essential elements involved in a specific painting tool designed for detailed artwork. By breaking down these components, users can gain insights into their functions and significance, enhancing their overall experience and proficiency in using this equipment.

Overview of Key Elements

Understanding the primary components is crucial for effective operation. Here are the main elements:

- Body

- Needle

- Nozzle

- Air Cap

- Trigger

- Fluid Cup

- Adjustable Knob

- Hose Connection

- Seal

- Cleaning Tools

Functionality of the Body

The main structure houses all other elements, providing stability and control during use.

Importance of the Needle

This component plays a pivotal role in controlling the flow of paint, affecting both the application technique and the overall finish.

Role of the Nozzle

The nozzle is responsible for shaping the spray pattern, allowing for versatility in artistic expression.

Understanding the Air Cap

The air cap influences the distribution of air and paint, crucial for achieving the desired effect.

Trigger Mechanism

The trigger enables the user to control paint flow and air pressure, facilitating precise adjustments.

Fluid Cup Capacity

This element holds the paint and is available in various sizes, impacting the length of uninterrupted usage.

Adjustable Knob Features

The adjustable knob allows customization of paint flow, enhancing user control over the application process.

Connecting the Hose

Understanding the connection of the hose is essential for ensuring proper airflow and paint delivery.

Maintenance with Cleaning Tools

Utilizing specific cleaning tools is vital for the longevity and performance of the equipment, preventing clogging and buildup.

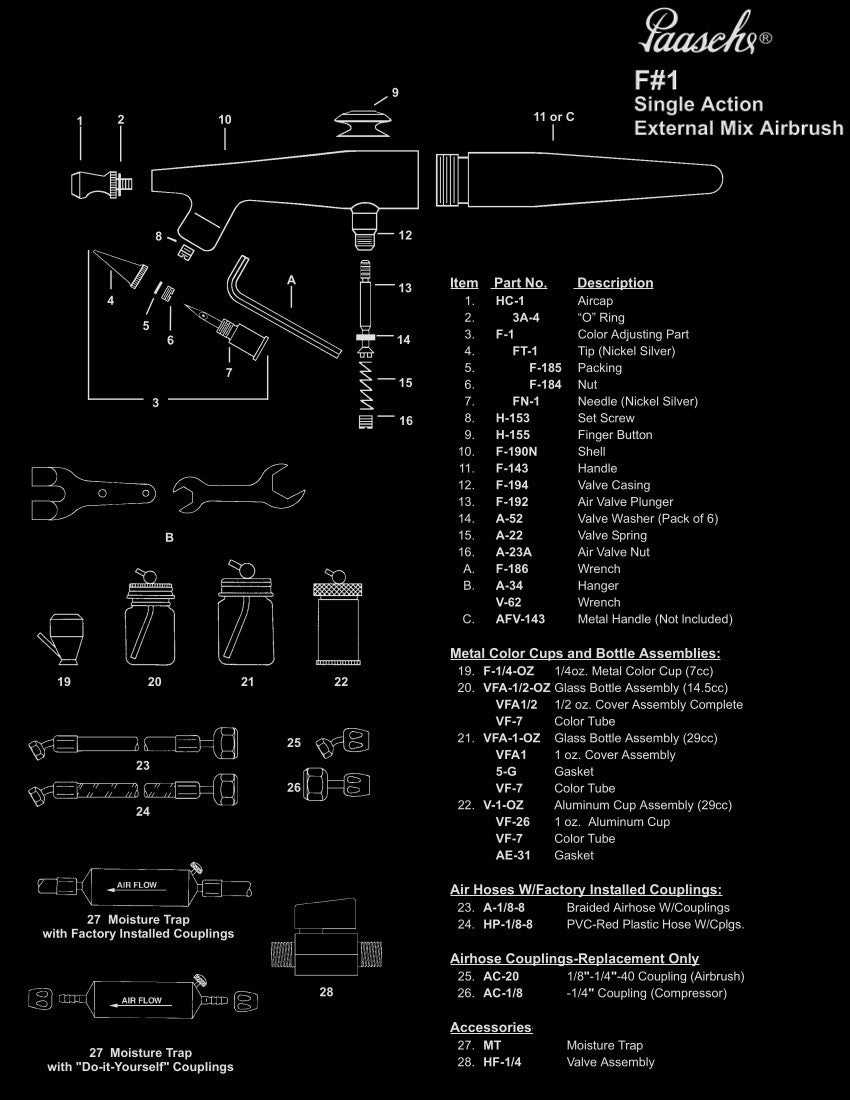

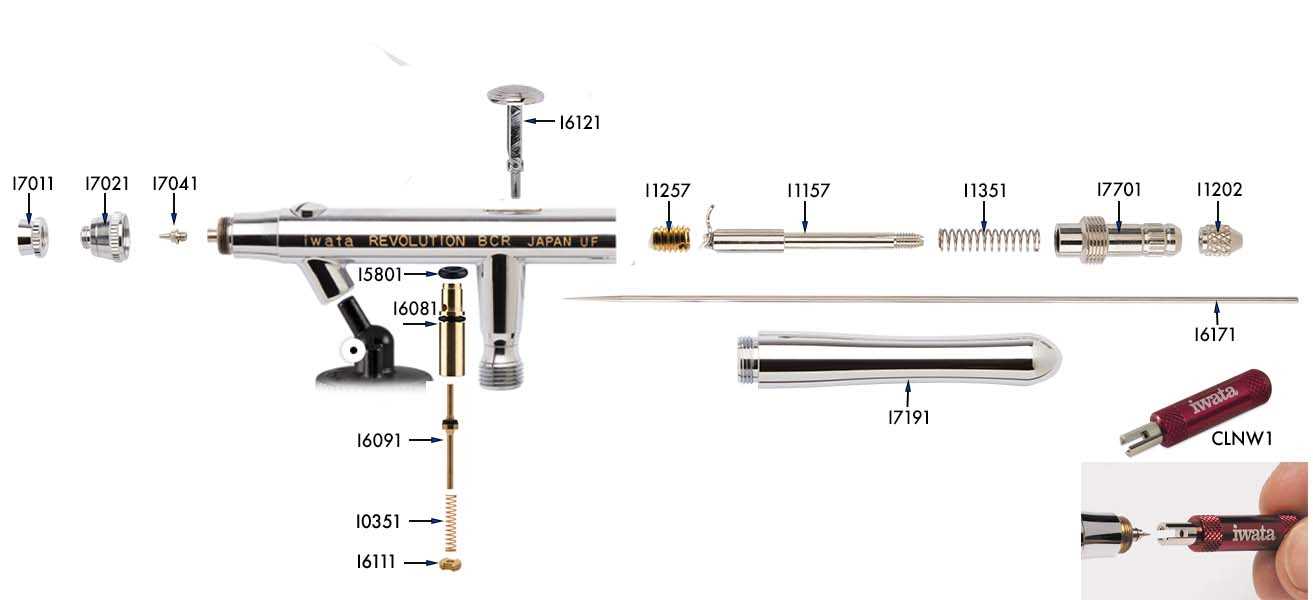

Key Parts of Airbrush Models

Understanding the fundamental components of spray equipment is essential for effective usage and maintenance. Each element plays a crucial role in ensuring optimal functionality and achieving desired results. This section will highlight the significant elements commonly found in various spray tools.

| Component | Description |

|---|---|

| Nozzle | The opening through which the fluid is expelled, crucial for controlling the spray pattern and thickness. |

| Needle | A precision component that regulates the flow of the liquid, allowing for various application techniques. |

| Trigger | The mechanism that activates the spray function, enabling the user to control the output easily. |

| Body | The main structure that houses the internal components, providing stability and support during operation. |

| Fluid Cup | The container that holds the liquid being sprayed, designed for easy refilling and cleaning. |

| Air Source Connector | The fitting that connects the air supply, essential for creating the necessary pressure for operation. |

Identifying Nozzles and Needles

Understanding the various components involved in fine application techniques is essential for achieving optimal results. The elements that direct and control the flow of medium play a crucial role in the performance and versatility of the tool. By familiarizing oneself with the characteristics of these components, users can enhance their crafting experience.

Recognizing Different Types

Components designed for fluid transfer come in various shapes and sizes, each tailored for specific applications. It is important to distinguish between the configurations to ensure compatibility with the device being used. For instance, a larger aperture allows for thicker mediums, while finer openings are ideal for detail work.

Maintenance and Care

Proper maintenance of these essential components is vital for longevity and efficiency. Regular cleaning and inspection can prevent clogs and ensure smooth operation. Users should pay attention to any signs of wear or damage, as these can significantly impact performance.

Function of the Trigger Mechanism

The trigger mechanism serves as a critical component in enabling precise control over the flow of medium during application. Its design facilitates the user’s ability to regulate both the quantity and pressure of the substance being released, ensuring an even and accurate distribution.

Key Responsibilities

- Control of Medium Flow: The mechanism allows users to adjust how much material is dispensed, providing versatility for various techniques.

- Pressure Regulation: It helps maintain consistent pressure, which is vital for achieving smooth finishes.

- Fine Adjustments: Users can make subtle modifications to the output, enhancing the detail in their work.

Impact on Performance

Effective functioning of this mechanism directly influences the overall performance and quality of application. A well-calibrated trigger mechanism enables artists and professionals to achieve desired results with minimal effort.

- Improved Accuracy

- Enhanced Control

- Reduced Waste

Exploring Airbrush Body Design

The design of spray instruments plays a crucial role in achieving precise and consistent application of various mediums. Understanding the structure and function of these tools is essential for artists and hobbyists alike. The body of such devices typically encompasses several key features that enhance usability and performance, contributing to a smooth and controlled experience.

Materials used in the construction of the outer shell often influence the weight and durability of the device. A lightweight yet sturdy framework allows for extended use without causing fatigue. Furthermore, the ergonomic shape ensures a comfortable grip, enabling artists to maintain steady hands while working on intricate details. The incorporation of adjustable components allows for versatility, adapting to different styles and techniques.

Another significant aspect is the internal configuration, which houses essential mechanisms that regulate the flow of mediums. This complex arrangement ensures a uniform distribution and optimal performance, allowing for fine lines or broad strokes depending on the artist’s intention. Additionally, proper maintenance of these internal systems is vital to sustain functionality and longevity.

Maintenance of Paint Cups

Ensuring the longevity and optimal performance of your color reservoirs is essential for achieving high-quality results. Proper upkeep not only enhances the functionality but also prevents contamination and blockages that can disrupt the application process.

Cleaning Techniques

Regular cleaning is vital to maintain the integrity of the color containers. Here are some effective methods:

- Rinse immediately after use to avoid paint residue drying.

- Utilize a soft brush to gently scrub the interior surfaces.

- Use specialized cleaning solutions to dissolve stubborn paint.

Storage Guidelines

Correct storage practices contribute to the longevity of your color cups. Consider the following tips:

- Store in a cool, dry place to prevent warping.

- Keep covered to avoid dust accumulation.

- Avoid exposure to direct sunlight to maintain material integrity.

| Maintenance Task | Frequency | Recommended Tools |

|---|---|---|

| Rinse after use | Every use | Water |

| Deep clean | Weekly | Soft brush, cleaning solution |

| Inspect for damage | Monthly | Visual inspection |

Air Control and Pressure Regulation

Maintaining optimal airflow and pressure is essential for achieving precise and consistent results in painting techniques. Proper management of these elements ensures smooth operation and enhances the quality of the final application. Understanding how to manipulate airflow and adjust pressure settings can significantly impact the overall effectiveness of the process.

Adjusting Airflow

Controlling airflow is crucial for achieving the desired coverage and detail in your work. By utilizing various mechanisms, operators can fine-tune the air supply, allowing for either broad strokes or intricate details. Experimenting with different airflow levels can help identify the ideal settings for specific applications, contributing to a more refined output.

Pressure Settings

Regulating pressure is equally important, as it influences the consistency and spray pattern of the applied medium. Proper pressure adjustments can prevent issues such as spattering or uneven distribution. Utilizing pressure gauges can aid in monitoring levels, ensuring that adjustments are made accurately and promptly for optimal performance.

Assembly and Disassembly Instructions

This section provides essential guidance on the process of putting together and taking apart your device efficiently and safely. Understanding the steps involved is crucial for proper maintenance and optimal performance.

Required Tools

- Precision screwdriver set

- Small pliers

- Cleaning cloth

- Lubricant (if necessary)

Disassembly Steps

- Begin by ensuring the device is disconnected from any power source.

- Use the precision screwdriver to remove any screws holding the components together.

- Carefully detach each piece, taking note of their arrangement.

- Place the removed parts in a safe location to avoid loss.

- If any parts are stuck, gently wiggle them to release without using excessive force.

Assembly Steps

- Start by aligning the components according to the original configuration.

- Secure each part with screws, ensuring they are tight but not over-tightened.

- If lubrication is needed, apply a small amount to the appropriate areas.

- Perform a visual inspection to ensure everything is correctly positioned.

- Reconnect the device to the power source and test for functionality.

Common Issues with Parts Replacement

Replacing components of a spraying device can lead to various challenges that users may encounter. Understanding these difficulties is crucial for achieving optimal performance and extending the lifespan of the equipment. This section highlights the most frequent problems faced during the replacement process and offers guidance for effective resolution.

Compatibility Concerns

One of the primary issues is ensuring that the new elements are compatible with the existing system. Incompatible components can lead to malfunction or suboptimal functionality. Users should consider the following:

- Verify specifications and measurements before purchase.

- Consult manufacturer guidelines or expert recommendations.

- Check for updates on design or model changes that may affect compatibility.

Installation Challenges

Another common difficulty is the installation process itself. Improper installation can result in further complications and may require additional repairs. To avoid such issues, users should:

- Follow detailed instructions meticulously.

- Use appropriate tools to ensure proper fit and alignment.

- Take care when handling delicate components to prevent damage.

Improving Performance with Upgrades

Enhancing the functionality of your painting tool can significantly elevate your creative outcomes. By integrating various enhancements, you can achieve smoother application, finer detail, and increased versatility in your artistic endeavors. Here are some effective modifications to consider:

- Needle and Nozzle Change: Opt for different sizes to achieve various paint flow rates and precision. This can result in better control over line thickness and shading.

- Pressure Regulation: Installing a pressure regulator allows for more consistent airflow, leading to a smoother and more even application.

- Upgraded Trigger Mechanism: A responsive trigger can enhance your ability to control paint flow, making it easier to achieve desired effects.

- Enhanced Paint Cup: Larger or specially designed cups can accommodate various paint types and reduce the need for frequent refills.

By carefully selecting and implementing these enhancements, you can maximize the efficiency and adaptability of your painting tool, resulting in a more enjoyable and productive creative process.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process when utilizing online resources. Various platforms provide access to a wide range of accessories, enabling enthusiasts to maintain or upgrade their tools effectively.

When searching for these necessary items, it is essential to consider a few strategies to ensure a successful experience:

| Strategy | Description |

|---|---|

| Use Specialized Websites | Focus on retailers that specialize in equipment components, as they often have extensive catalogs and knowledgeable staff to assist you. |

| Check Manufacturer’s Website | Visiting the official site of the manufacturer can provide direct access to original items and detailed information regarding compatibility. |

| Join Online Communities | Engaging with forums and social media groups can yield recommendations and tips from experienced users who may have faced similar challenges. |

| Read Reviews | Look for customer feedback on specific items and sellers to gauge reliability and quality before making a purchase. |