Exploring the intricate elements that make up a circular support structure is essential for anyone interested in vehicle functionality. This section aims to unveil the different sections and features that contribute to overall performance and safety. A comprehensive understanding of these components enhances knowledge about how they work together to ensure a smooth and efficient ride.

Each segment of this round structure plays a pivotal role in its operation, influencing aspects such as grip, durability, and stability. By delving into these individual features, readers can gain insights into their significance and how they affect the overall driving experience. Knowledge of these aspects empowers users to make informed decisions regarding maintenance and selection.

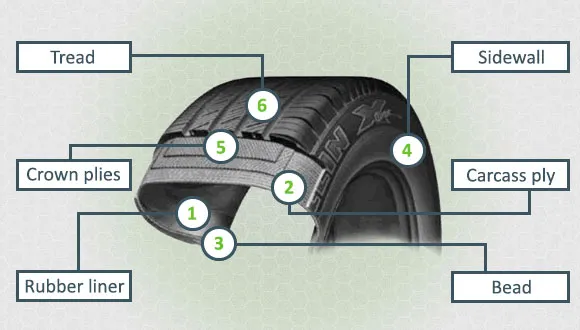

Parts of a Car Tire Diagram

This section explores the various components that contribute to the overall functionality of a wheel covering. Understanding these elements is essential for maintaining optimal performance and safety. Each section plays a significant role in providing stability, traction, and comfort during travel.

Outer Layer

The external layer serves as the first line of defense against road conditions. It is designed to withstand various elements and provide grip. This layer is crucial for ensuring a secure connection with the driving surface.

Inner Structure

The internal composition supports the entire assembly and helps maintain the correct shape under pressure. This framework is vital for absorbing shocks and enhancing the overall driving experience. A well-constructed inner structure promotes longevity and reliability.

Understanding Tire Construction Elements

Comprehending the various components that contribute to the functionality and performance of a wheel’s outer covering is essential for effective maintenance and usage. Each element plays a significant role in determining how well the covering performs under different conditions.

Key aspects of these constructions include:

- Outer Layer: The visible surface that interacts with the road, designed for durability and traction.

- Reinforcement: Materials used to enhance strength and stability, preventing deformation during use.

- Inner Layer: This section maintains air pressure and prevents leaks, ensuring optimal performance.

- Bead: A critical element that secures the outer covering to the rim, providing a tight fit for safety.

- Tread Pattern: The design of the surface that affects grip, handling, and performance in various weather conditions.

Understanding these components helps individuals make informed decisions regarding selection, maintenance, and replacement, ultimately enhancing safety and performance on the road.

Key Components of Tire Anatomy

The structure of a rubber wheel is intricate, comprising various elements that work in unison to ensure optimal performance. Each component plays a significant role in supporting the vehicle’s weight, providing traction, and enhancing safety on the road.

Main Features

- Tread: The outer layer that interacts with the road surface, designed for grip and control.

- Sidewall: The section that connects the tread to the rim, providing flexibility and protection against impacts.

- Bead: The inner edge that secures the wheel to the rim, ensuring stability during movement.

- Casing: The body of the structure that maintains its shape and supports the overall load.

Additional Elements

- Inner Liner: A layer that retains air and enhances durability.

- Steel Belts: Reinforcements that improve strength and resist punctures.

- Shoulder: The transition area between the tread and sidewall, influencing handling characteristics.

Understanding these essential components is vital for maintaining optimal functionality and ensuring a safe driving experience.

The Role of Tread Patterns

The design of surface grooves and patterns plays a crucial role in the performance of vehicles. These intricate designs not only influence traction but also affect handling and stability under various conditions. Understanding their significance can enhance safety and driving experience.

Importance of Groove Design

The arrangement and depth of these grooves contribute to effective water displacement, reducing the risk of hydroplaning. A well-designed surface pattern enables better grip on wet and slippery surfaces, ensuring optimal contact with the ground.

Impact on Performance

The specific configuration of grooves can enhance traction, especially during acceleration and braking. Various patterns are tailored to meet different driving needs, whether on highways, off-road, or in inclement weather.

| Pattern Type | Benefits | Driving Conditions |

|---|---|---|

| Symmetrical | Balanced performance | All conditions |

| Asymmetrical | Improved cornering | Wet and dry |

| Directional | Enhanced grip | Wet conditions |

Types of Tire Sidewalls Explained

The sidewall is an essential component that influences the overall performance and durability of a wheel’s outer covering. Various styles and designs exist, each tailored to meet specific needs and preferences. Understanding the differences can enhance driving experience and safety.

Standard Sidewalls offer a balance between comfort and performance. They are commonly found on everyday vehicles and provide a smooth ride while maintaining adequate handling characteristics.

Low-Profile Sidewalls feature a shorter height, enhancing the vehicle’s aesthetic appeal and handling. These are often preferred for sporty models, as they offer improved cornering stability but may sacrifice some comfort.

Raised White Lettering adds a distinctive look to the outer covering. This design is popular among enthusiasts and can complement a vehicle’s sporty appearance while maintaining performance attributes.

All-Terrain Sidewalls are designed for off-road use. They typically have reinforced construction to withstand rough conditions, providing extra protection against punctures and damage.

Choosing the right type of sidewall is crucial for achieving desired performance and comfort. Each design brings unique benefits that cater to different driving styles and environmental conditions.

Functionality of Tire Beads

The role of beads in a wheel assembly is crucial for maintaining a secure fit between the outer covering and the rim. These components ensure that the outer layer remains properly seated, providing stability and safety during operation.

Importance of Proper Seating

Correct placement of these elements is essential to prevent air loss and maintain optimal pressure. A snug connection minimizes the risk of detachment, enhancing overall performance and longevity.

Impact on Performance

These features also contribute to the dynamic handling characteristics of the vehicle. By allowing for precise alignment and stability, they play a significant role in the driving experience, particularly during cornering and braking.

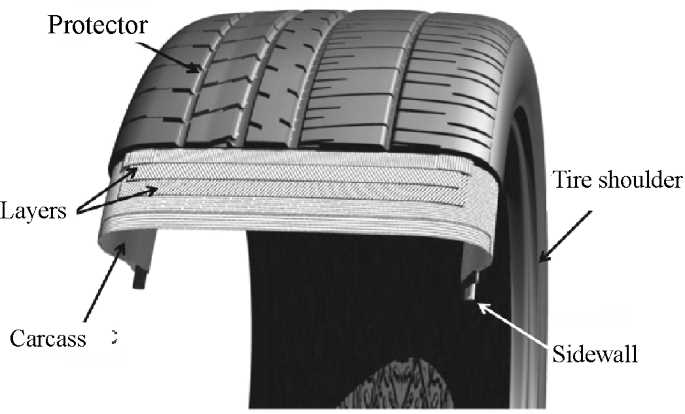

Exploring Tire Belts and Layers

The construction of modern wheels incorporates various components that enhance performance and safety. Understanding the materials and structures involved is essential for appreciating how they contribute to overall functionality. Each layer plays a specific role, working in harmony to provide stability and durability.

Key Components

Among the crucial elements are belts and layers that form the outer shell. These components are designed to withstand stress and provide traction on different surfaces. Their arrangement and composition significantly influence the overall efficiency and longevity of the product.

Importance of Construction

The design and layering techniques are vital for ensuring optimal performance. A well-constructed outer covering can enhance grip, reduce wear, and improve handling. The interaction between various materials allows for better heat dissipation and resistance to punctures.

| Component | Function |

|---|---|

| Outer Layer | Provides protection and grip. |

| Belts | Enhance strength and stability. |

| Inner Layer | Maintains air pressure and shape. |

Importance of Tire Casing Design

The structure that envelops the inner components of a wheel plays a crucial role in determining its overall performance and longevity. A well-crafted outer layer not only supports the internal pressure but also significantly influences traction, handling, and stability while in motion.

Additionally, the design of this protective layer can enhance durability, enabling it to withstand various road conditions and temperature fluctuations. By utilizing advanced materials and innovative manufacturing techniques, the outer shell can effectively absorb shocks and resist wear, thus prolonging its lifespan. Ultimately, a thoughtfully designed casing contributes to a safer and more efficient driving experience.

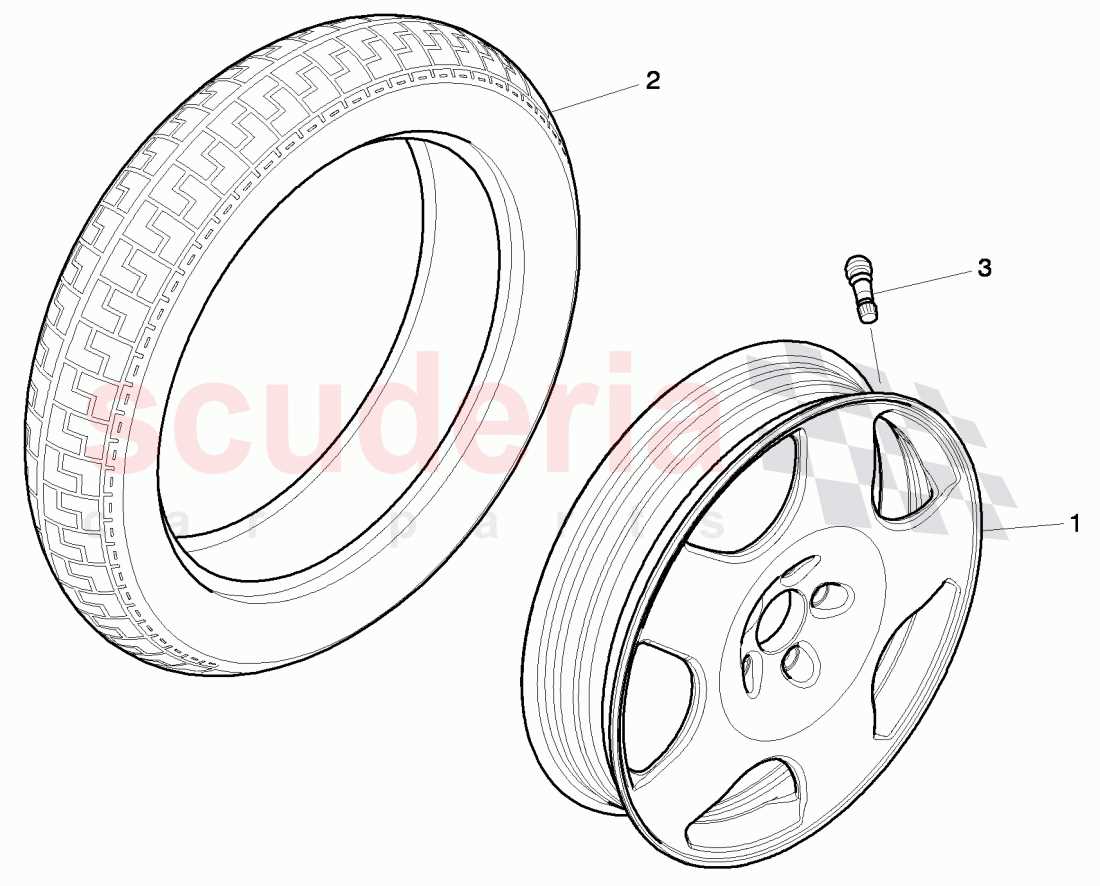

Inflation and Valve Assembly Overview

The process of maintaining optimal pressure within a circular support structure is crucial for overall performance and safety. This section explores the essential components involved in ensuring proper inflation and functionality of the assembly responsible for air retention.

The inflation mechanism is vital for achieving the desired rigidity and performance characteristics. It enables the adjustment of air levels to meet specific requirements. The assembly typically incorporates a specialized inlet designed to facilitate the introduction of air while preventing any unintended release. This feature is fundamental to maintaining the necessary pressure for effective operation.

Moreover, the assembly includes various components that work together seamlessly to ensure reliability. These elements are engineered to withstand varying conditions, contributing to the overall durability of the system. Proper attention to the inflation and valve assembly can enhance performance and prolong the lifespan of the entire structure.

Evaluating Tire Wear Indicators

Understanding the signs of degradation on wheel coverings is essential for ensuring safety and performance. Recognizing when these protective elements require attention can significantly influence driving experience and vehicle maintenance.

Various indicators can reveal the condition of these coverings. Visual inspections play a crucial role; observing for irregularities or significant reductions in tread depth can provide immediate insights. Additionally, wear bars embedded within the material serve as reliable markers. When the surface level aligns with these bars, it signals a need for replacement.

Another vital aspect involves assessing uniformity in wear patterns. Uneven degradation may indicate underlying mechanical issues, necessitating further evaluation. Keeping an eye on these indicators can enhance both safety and longevity of the wheel coverings.

How Tire Markings Convey Information

Understanding the symbols and numbers on the outer surface of a wheel cover is essential for making informed choices regarding vehicle maintenance and performance. These markings provide critical insights about various aspects, including dimensions, load capacity, and speed ratings. Analyzing this information ensures that drivers can select appropriate options for their vehicles, enhancing safety and efficiency.

Decoding the Symbols

The sequence of letters and numbers found on the surface communicates specific details. Each character has a unique significance, ranging from width measurements to aspect ratios. Recognizing these symbols allows individuals to comprehend the compatibility of their selection with the vehicle’s requirements.

Importance of Load and Speed Ratings

Another vital aspect of these inscriptions involves the load and speed ratings. These figures indicate the maximum weight the wheel cover can support and the highest speed it can safely maintain. Understanding this data is crucial for ensuring optimal performance and avoiding potential hazards on the road.