In the world of machinery, comprehending the intricate layout of components is essential for effective maintenance and repair. Every device consists of a multitude of elements that work in harmony to ensure optimal performance. By familiarizing oneself with the configuration of these parts, one can enhance their troubleshooting skills and prolong the life of the equipment.

The analysis of a specific model reveals a structured arrangement that is both logical and functional. Each segment serves a unique purpose, contributing to the overall efficacy of the system. Recognizing how these pieces interconnect can demystify the operation of the machine and empower users to address issues with confidence.

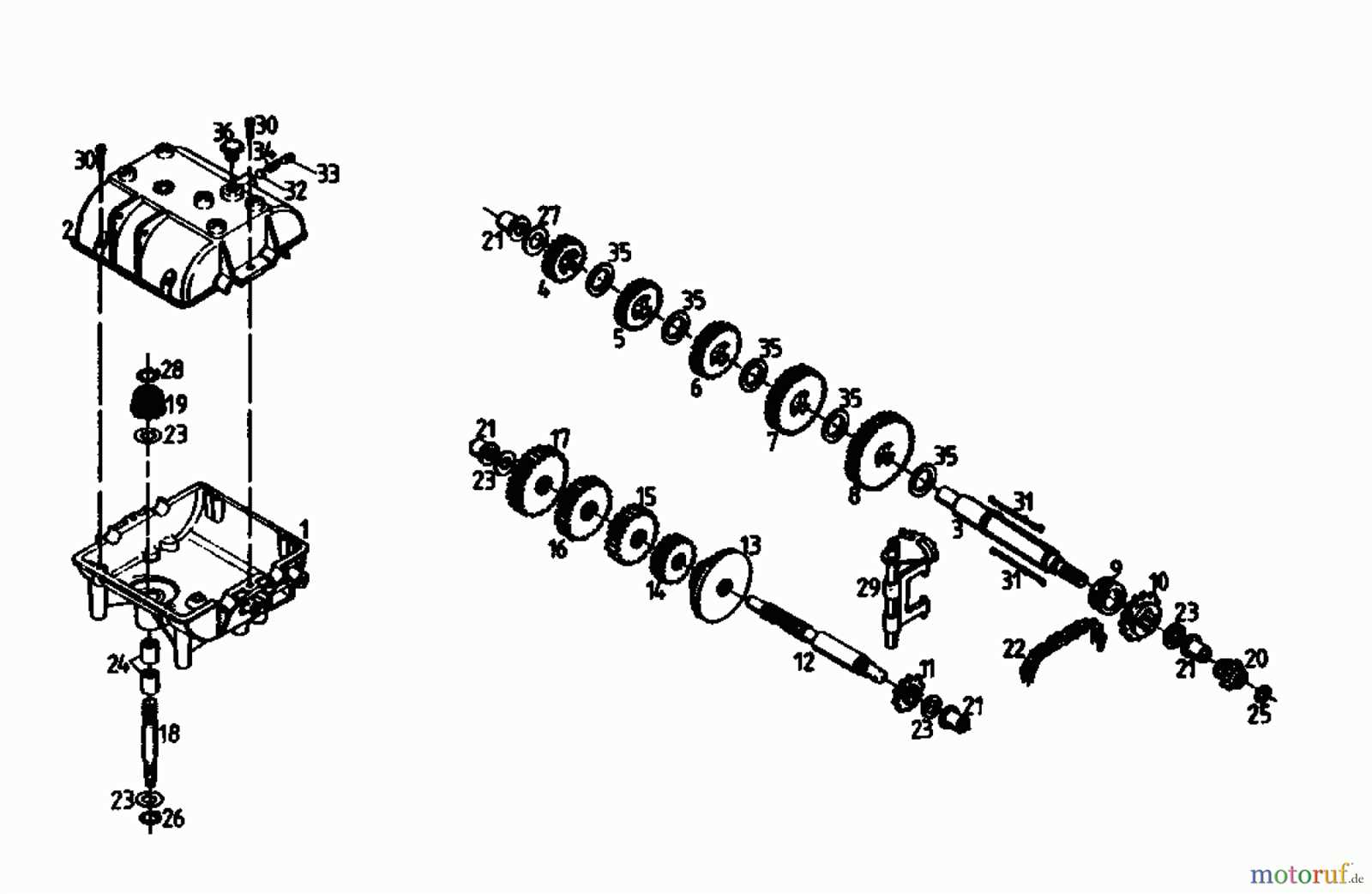

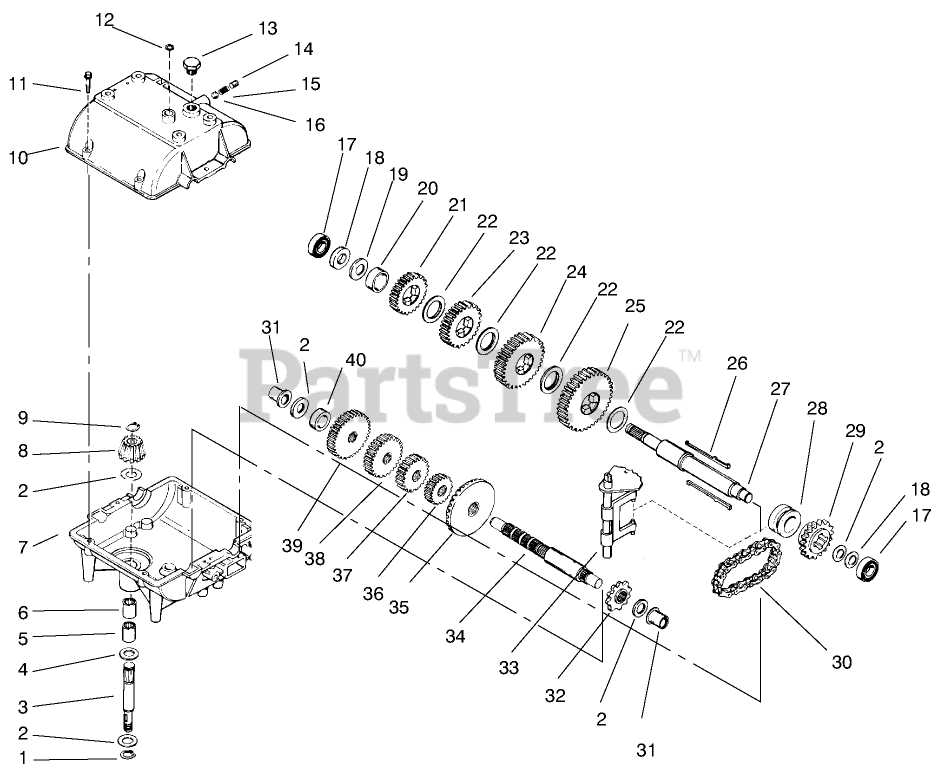

For those engaged in the repair and upkeep of such mechanisms, a visual representation of the layout proves invaluable. It serves not only as a guide for reassembly but also as a reference for understanding the role of each individual component. This knowledge is crucial for ensuring that any maintenance undertaken is precise and effective, ultimately leading to enhanced performance and reliability.

Understanding Peerless 700-070A Components

In any mechanical assembly, comprehending the individual elements and their interactions is crucial for effective maintenance and troubleshooting. Each component plays a specific role, contributing to the overall functionality of the system. By analyzing these parts, one can gain insights into the performance and durability of the machinery, ensuring it operates efficiently.

Key Elements Overview

The structure of the assembly consists of various key elements, each designed for a particular purpose. These components must work in harmony to achieve optimal performance. Understanding their specifications and how they fit together is essential for both repairs and enhancements.

| Component | Description | Function |

|---|---|---|

| Housing | Encases the internal mechanisms | Provides protection and structural integrity |

| Gear Set | Collection of interlocking gears | Transmits power and alters rotational speed |

| Shaft | Cylindrical rod | Transfers torque from one component to another |

| Seals | Rubber or metal rings | Prevents leakage of fluids and contaminants |

Importance of Component Quality

The quality of each individual part significantly impacts the overall reliability and longevity of the machinery. Selecting high-grade materials and adhering to precise manufacturing standards can prevent premature wear and failure, thereby reducing maintenance costs and downtime. Regular inspection and timely replacement of worn elements are key practices for sustaining optimal operation.

Importance of Parts Diagrams

Understanding the assembly and components of a machine is crucial for maintenance and repair. Visual representations serve as essential tools, enabling users to identify individual elements and their functions within a complex system. This clarity not only aids in troubleshooting but also enhances the overall efficiency of repairs.

Facilitating Repairs

When a breakdown occurs, having a visual reference can significantly streamline the repair process. Technicians can quickly pinpoint the necessary components, reducing downtime and ensuring that each piece is correctly reassembled. This efficiency ultimately leads to more reliable performance.

Enhancing Understanding

Detailed visuals contribute to a deeper comprehension of how machinery operates. Users can delve into the relationships between various components, fostering a greater appreciation for engineering principles. This knowledge is invaluable for both novice and experienced operators alike.

Overview of Peerless Transmission Models

The landscape of mechanical drive systems is enriched by a variety of transmission designs, each serving distinct applications and performance requirements. This section delves into the characteristics, functionalities, and applications of various models within this renowned series, highlighting their significance in the realm of machinery and automotive engineering.

Design Features and Specifications

Each model in this series showcases unique design attributes that cater to specific operational needs. These include variations in gear configurations, torque capabilities, and power handling efficiency. Understanding these specifications is essential for selecting the right model for various industrial and automotive uses.

Applications and Usage

The versatility of these transmission units allows for widespread adoption across different sectors. From agricultural machinery to automotive applications, each variant is tailored to enhance performance and reliability. Exploring their practical uses reveals how these models contribute to the efficiency and functionality of complex systems.

Key Features of the 700-070A

This model stands out due to its innovative design and advanced functionalities that cater to a variety of applications. Its construction reflects a blend of durability and efficiency, making it a preferred choice for users seeking reliability and performance.

Durability and Reliability

Engineered with high-quality materials, this device offers exceptional longevity. Its robust design ensures consistent performance even under demanding conditions, making it ideal for heavy use.

Enhanced Performance

Featuring state-of-the-art technology, it maximizes operational efficiency. The intuitive controls and seamless integration with other systems allow for a user-friendly experience, ultimately enhancing productivity.

Common Applications for Peerless 700-070A

This component is widely utilized in various mechanical systems, showcasing its versatility and reliability. Its design allows it to perform efficiently across different applications, making it a preferred choice for many industries.

Automotive Industry

In the automotive sector, this unit is often employed in transmission systems, providing seamless power transfer and enhancing overall vehicle performance. Its durability ensures it can withstand the demands of everyday use.

Industrial Machinery

In industrial settings, this mechanism plays a crucial role in equipment such as conveyors and heavy machinery. Its robust construction allows it to handle significant loads, ensuring operational efficiency and longevity.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective assembly and maintenance. This guide will illuminate the key aspects that enhance your ability to interpret these illustrations, ensuring you can identify each element accurately and navigate through your project with confidence.

1. Familiarize Yourself with Symbols: Each representation often uses specific icons to denote various items. Recognizing these symbols is the first step to grasping the overall structure.

2. Pay Attention to Numbers: Typically, each part is accompanied by a unique identifier. These numerals correlate with a list, making it easier to find replacements or additional information.

3. Observe Relationships: Note how components interact with one another. Arrows or lines can indicate connections, helping you understand how the assembly fits together.

4. Consult the Accompanying Documentation: Often, a detailed explanation accompanies these visuals. Utilize this information to deepen your understanding and clarify any uncertainties.

By mastering these elements, you’ll be equipped to navigate any technical illustration, empowering you to tackle projects with ultimate precision.

Identifying Essential Components

Understanding the key elements of a mechanical system is crucial for efficient operation and maintenance. Recognizing these fundamental parts allows users to troubleshoot issues effectively and optimize performance, ensuring longevity and reliability.

Core Elements

The primary constituents typically include gears, bearings, and drive systems. Each component plays a specific role, contributing to the overall functionality of the assembly. Familiarity with these essentials aids in proper assembly and disassembly processes.

Functional Importance

Each element’s function directly impacts the system’s efficiency. For instance, the interaction between gears determines speed and torque output, while bearings reduce friction and wear. Grasping these relationships is vital for achieving peak performance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires regular upkeep and attention to detail. Adopting a systematic approach to maintenance can prevent unexpected breakdowns and enhance performance efficiency. Here are some essential practices to consider.

- Regular Inspections: Frequently check components for wear and tear. Identify any irregularities early to address them before they escalate.

- Cleanliness: Keep the machinery clean from debris and contaminants. Regularly remove dust and dirt to prevent damage to sensitive parts.

- Lubrication: Apply appropriate lubricants to moving parts. This reduces friction and helps in maintaining optimal performance.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer to ensure all aspects are covered.

- Monitor Performance: Keep track of the machinery’s performance. Noticing any changes can be critical for timely interventions.

By implementing these practices, you can significantly enhance the durability and reliability of your equipment, ensuring it serves you well over the years.

Where to Find Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its performance and longevity. Whether you’re dealing with mechanical issues or simply upgrading, knowing where to look is essential for successful repairs.

| Source | Description |

|---|---|

| Manufacturer’s Website | The first place to check is the official site, which often offers direct purchasing options and detailed specifications. |

| Authorized Dealers | Visiting authorized retailers ensures you receive genuine components, often accompanied by warranties. |

| Online Marketplaces | Websites like eBay and Amazon provide a wide selection, but verify seller ratings for reliability. |

| Local Repair Shops | Neighborhood mechanics or specialized shops may have spare components and can offer professional advice. |

Common Issues and Solutions

When working with mechanical devices, users often encounter a variety of challenges that can impact performance and functionality. Identifying these issues early can save time and prevent further complications. Below are some frequent problems and their respective solutions that can assist in maintaining optimal operation.

Frequent Operational Failures

One common issue is a complete failure to operate. This can stem from electrical malfunctions or mechanical obstructions. Solution: Begin by checking the power source and connections. If everything appears intact, inspect for any blockages or debris that may hinder movement. Regular cleaning and maintenance can prevent this from occurring in the future.

Unusual Noises During Operation

Strange sounds can indicate underlying mechanical issues, such as wear and tear or improper alignment. Solution: If unusual noises are detected, immediately halt operation to prevent damage. Examine the components for signs of deterioration or misalignment. Lubricating moving parts can also help reduce friction and noise, enhancing overall performance.

Comparing with Other Peerless Models

When evaluating various models from the same manufacturer, it is essential to consider their unique features, performance capabilities, and design variations. This analysis not only highlights the strengths and weaknesses of each unit but also helps potential users determine which option best fits their specific needs. A comparative approach allows for a deeper understanding of the offerings available in the market.

Design Variations

Different models often showcase a range of design elements that can significantly impact functionality and user experience. Variations may include size, weight distribution, and overall construction materials. Such differences can affect everything from ease of installation to long-term durability, making it crucial to assess how these factors align with user requirements.

Performance and Usability

In addition to design, performance metrics can vary widely among similar units. Factors such as operational efficiency, speed, and maintenance needs are vital for comparison. By analyzing these aspects, users can gain insights into which model offers superior usability for their intended applications, ultimately leading to more informed purchasing decisions.

Customer Reviews and Feedback

This section aims to highlight the insights and experiences shared by users regarding the product. Feedback from customers plays a crucial role in understanding its effectiveness and reliability, offering valuable perspectives for potential buyers.

Overall Impressions

- Many users appreciate the quality and performance.

- Several reviewers noted ease of use as a key benefit.

- Customer service experiences have received positive remarks.

Common Issues

- Some customers reported minor compatibility challenges.

- A few users mentioned a need for clearer instructions.

- Durability concerns were raised by a small percentage.

Resources for Further Information

This section aims to provide valuable resources for those seeking deeper insights and knowledge about mechanical components and their configurations. Whether you are a hobbyist, a professional technician, or simply curious, these materials can enhance your understanding and support your projects effectively.

Online Tutorials and Guides

Numerous websites offer comprehensive tutorials and guides that cover various aspects of mechanical assemblies. These resources can range from basic introductions to advanced repair techniques, making them suitable for all skill levels.

Technical Manuals and Specifications

Official manuals often contain detailed information regarding components and their functionalities. Accessing these documents can provide clarity on specifications, maintenance procedures, and assembly processes.

| Resource Type | Website |

|---|---|

| Tutorials | example.com/tutorials |

| Technical Manuals | example.com/manuals |

| Forums | example.com/forums |

| Videos | example.com/videos |