The intricate world of antique sound reproduction devices offers a fascinating glimpse into the history of audio technology. These remarkable machines rely on various essential elements that work in harmony to create the rich, warm tones cherished by enthusiasts. Delving into the specifics of these elements allows us to appreciate the craftsmanship and engineering behind the art of sound.

Each component plays a crucial role in the overall function and performance of these devices, contributing to the unique auditory experience they provide. From mechanisms that transform physical vibrations into audible sound waves to systems designed for precise rotation and tracking, understanding these elements enhances our appreciation for vintage audio equipment.

Exploring the configuration and relationships between these integral components reveals insights into the design philosophy and technological advancements of their time. This knowledge not only enriches our understanding of audio history but also inspires a deeper respect for the artistry involved in their creation.

The tonearm plays a crucial role in the overall functionality and sound quality of a turntable system. It serves as the bridge between the stylus and the record, ensuring accurate tracking and sound reproduction. A well-designed tonearm contributes significantly to the listening experience by affecting the dynamics and clarity of the music.

Key functions of the tonearm include:

- Stylus Tracking: The tonearm’s primary task is to guide the stylus across the grooves of a record, allowing it to follow the undulations precisely.

- Weight Distribution: Proper weight and balance ensure that the stylus maintains contact with the record without excessive pressure, which can cause wear or distortion.

- Vibration Isolation: A well-constructed tonearm minimizes unwanted vibrations that could interfere with sound quality, providing a cleaner audio signal.

- Adjustment Features: Many tonearms offer various adjustments, such as azimuth and anti-skating, allowing users to optimize performance based on their setup.

Overall, the tonearm is integral to achieving high-fidelity sound, making its design and functionality vital components in any audio playback system.

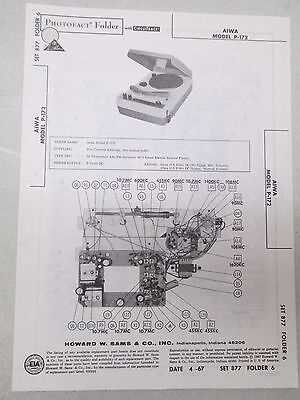

Exploring the Cartridge Mechanics

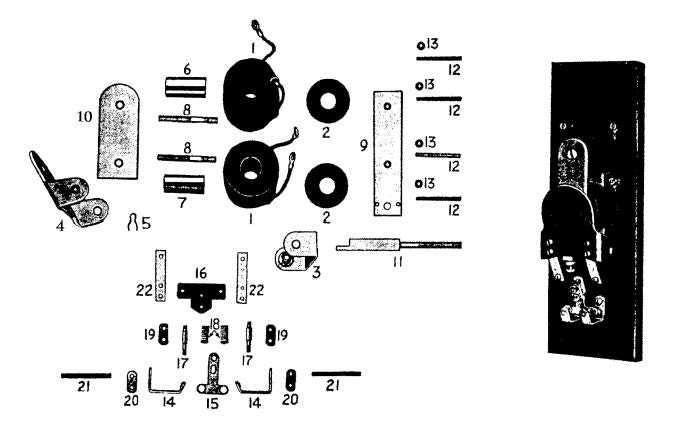

The cartridge serves as a vital component in the sound reproduction process, playing a crucial role in converting physical vibrations into electrical signals. Understanding its mechanics can enhance the listening experience and provide insights into the intricacies of audio technology.

Functionality of the Cartridge

This device operates by utilizing a stylus that tracks the grooves of a rotating disc. As the needle moves through these grooves, it generates vibrations that are transformed into an electrical signal. The efficiency of this conversion process directly influences sound quality and fidelity.

Types of Cartridges

There are two main types of cartridges: moving magnet (MM) and moving coil (MC). Moving magnet cartridges are characterized by a magnet attached to the stylus, while moving coil cartridges feature coils attached to the stylus, offering distinct sound signatures and performance levels. Each type presents unique advantages, making them suitable for different audio preferences.

How the Stylus Operates

The stylus plays a crucial role in the process of sound reproduction, serving as the point of contact between the rotating medium and the playback mechanism. This component translates the physical grooves of the medium into audible signals, enabling listeners to enjoy recorded music and sounds.

As the medium spins, the stylus moves along the grooves, which vary in depth and shape. The minute vibrations caused by these variations are picked up by the stylus and transferred to a cartridge. Within the cartridge, these vibrations are converted into electrical signals, which are then amplified and sent to the speakers, producing sound.

Maintaining the stylus is essential for optimal performance. Regular cleaning and replacement, when necessary, ensure that sound quality remains high and distortion is minimized. The angle at which the stylus contacts the grooves also impacts sound reproduction; an improper alignment can lead to reduced fidelity and increased wear on both the stylus and the medium.

In summary, the stylus is a vital element in sound playback systems, with its proper function directly influencing the overall listening experience. Understanding its operation helps in maintaining equipment and ensuring the best possible audio output.

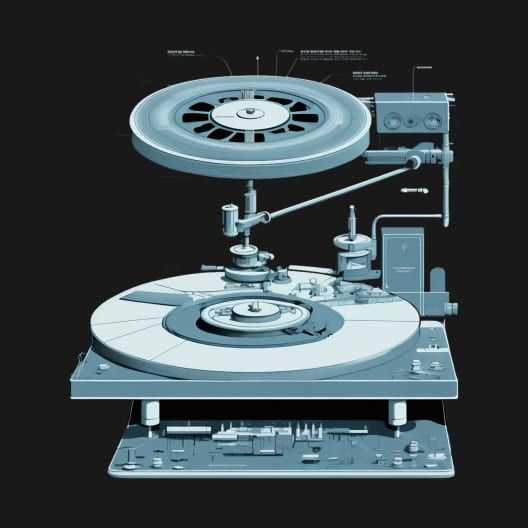

Importance of the Platter

The platter serves a crucial role in the overall functionality of an audio playback device, contributing significantly to sound quality and performance. It acts as the foundation where the record rests, facilitating smooth rotation and optimal interaction with the stylus.

Stability is essential for high-fidelity audio reproduction. A well-designed platter ensures that the record remains level and minimizes vibrations, which can distort sound. Moreover, the material and weight of the platter can greatly influence the system’s ability to maintain consistent speed during playback.

Proper alignment between the platter and other components is vital for accurate tracking. Any misalignment can lead to increased wear on the record and the stylus, adversely affecting longevity and sound clarity. Thus, attention to the platter’s construction and integration within the device is paramount for achieving an immersive listening experience.

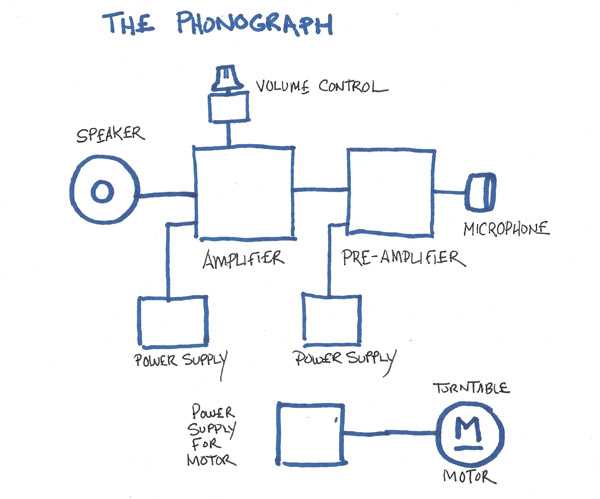

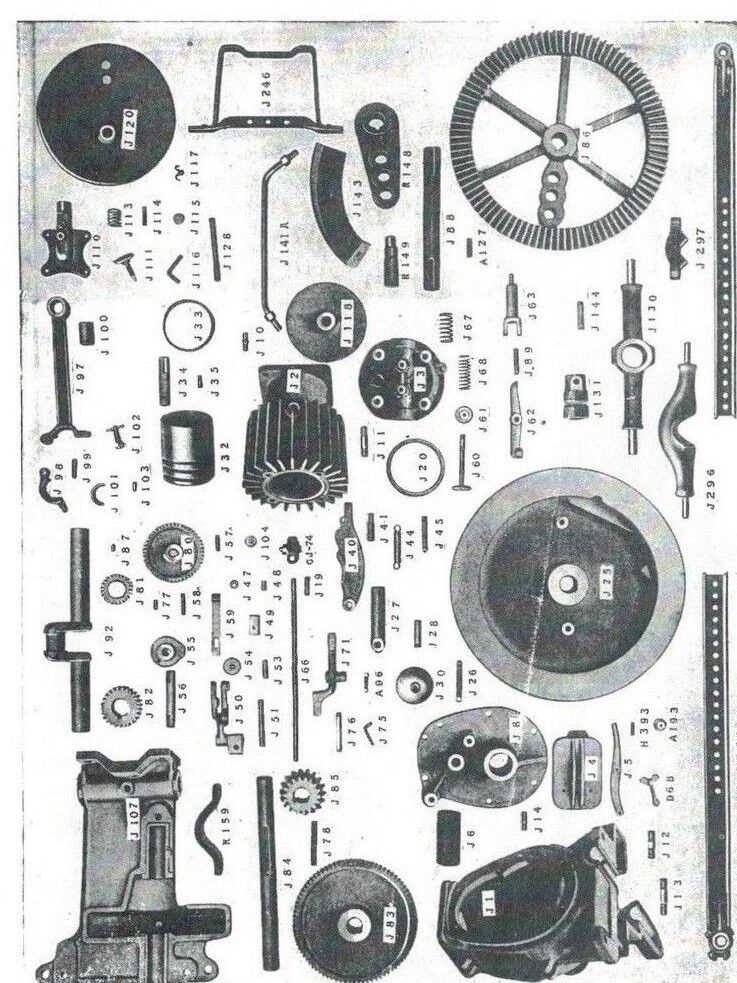

Understanding the Drive System

The drive mechanism plays a crucial role in the overall functionality of a sound reproduction device. It is responsible for transferring energy from the motor to the various components that facilitate sound playback. By grasping the intricacies of this system, users can appreciate how it contributes to the quality and consistency of audio output.

Key Elements

At its core, the drive system consists of several key elements, including the motor, belts, and gears. Each component interacts with others to create a seamless flow of motion. The motor generates rotational energy, which is then transmitted through belts or gears to drive the sound-producing mechanisms.

Importance of Maintenance

Regular maintenance of the drive mechanism is essential for optimal performance. Over time, components may wear out or require adjustment, impacting the overall sound quality. Ensuring that all elements are functioning properly helps to maintain clarity and fidelity in audio playback.

Overview of the Motor Types

This section explores the various mechanisms responsible for driving sound reproduction devices. Different motor configurations are essential for ensuring consistent performance and sound quality in audio playback equipment.

Types of Motors

There are several common types of motors used in sound reproduction devices:

- DC Motors: Known for their simplicity and ease of control, these motors utilize direct current to provide steady rotation.

- AC Motors: Typically offering greater reliability, AC motors operate using alternating current and are favored for their robust performance.

- Stepper Motors: These are designed for precise movement, allowing for accurate positioning and control over playback speed.

Advantages of Each Type

Each motor type presents unique benefits:

- DC Motors: Easy to control and often less expensive, making them ideal for entry-level devices.

- AC Motors: Provide better torque and can sustain longer periods of operation without overheating.

- Stepper Motors: Excellent for applications requiring high precision, suitable for advanced playback systems.

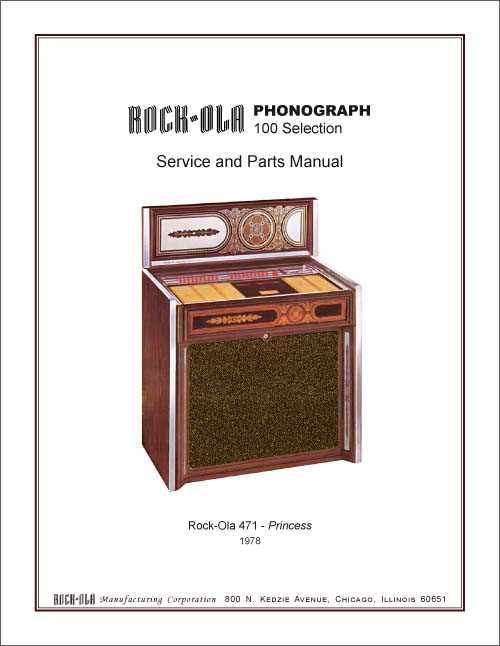

Significance of the Cabinet Design

The design of the housing plays a crucial role in the overall functionality and aesthetic appeal of audio playback devices. It not only serves as a protective enclosure but also contributes to the acoustic properties, ensuring optimal sound quality. A well-crafted cabinet can enhance the listening experience by minimizing vibrations and resonances that may distort audio output.

Additionally, the visual aspects of the enclosure can greatly influence consumer attraction and market value. Aesthetically pleasing designs can draw attention and foster a sense of nostalgia, often appealing to collectors and enthusiasts alike. The materials used and the craftsmanship involved in the construction of the cabinet can also reflect the quality and longevity of the device, making it a significant factor for users when selecting audio equipment.

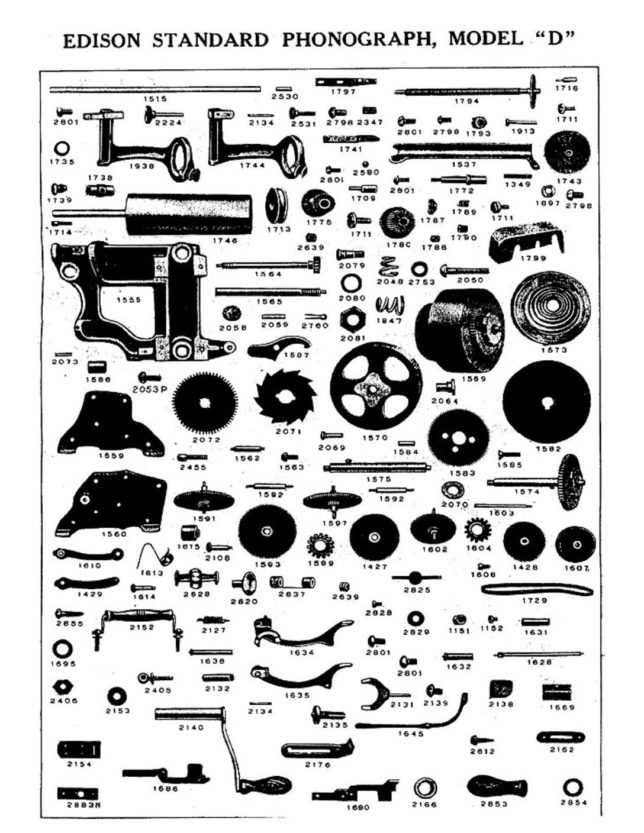

Maintaining Phonograph Parts

Regular upkeep of audio equipment is essential for ensuring optimal performance and longevity. Attention to various components not only enhances sound quality but also prevents potential issues that may arise over time.

General Care Tips

- Keep the device in a dust-free environment to prevent debris buildup.

- Regularly inspect all components for signs of wear or damage.

- Use a soft cloth to gently clean surfaces, avoiding harsh chemicals.

- Ensure that all connections are secure to maintain sound integrity.

Specific Component Maintenance

- Needle: Replace it periodically based on usage frequency to ensure clear sound reproduction.

- Drive Belt: Check for elasticity and replace if frayed or stretched to maintain proper speed.

- Motor: Lubricate as recommended to ensure smooth operation and reduce noise.