When exploring the inner workings of any complex machinery, it’s essential to have a clear visualization of its individual elements and their interconnections. A comprehensive overview can greatly enhance your ability to troubleshoot issues and perform maintenance tasks effectively. Grasping how each segment functions within the larger system allows for better comprehension and management of performance.

In this section, we will delve into the intricate details of the various components that make up your equipment. By examining these elements closely, you can gain insights into their roles and how they contribute to the overall functionality. Whether you are a seasoned technician or a novice user, understanding these parts is crucial for optimizing your experience.

Moreover, having a detailed representation of the assembly can assist in identifying potential wear and tear, thereby facilitating timely interventions. This knowledge is invaluable, not only for repairs but also for ensuring that your device operates at its peak efficiency. With the right information at your fingertips, you’ll be empowered to take control of your machinery and enhance its longevity.

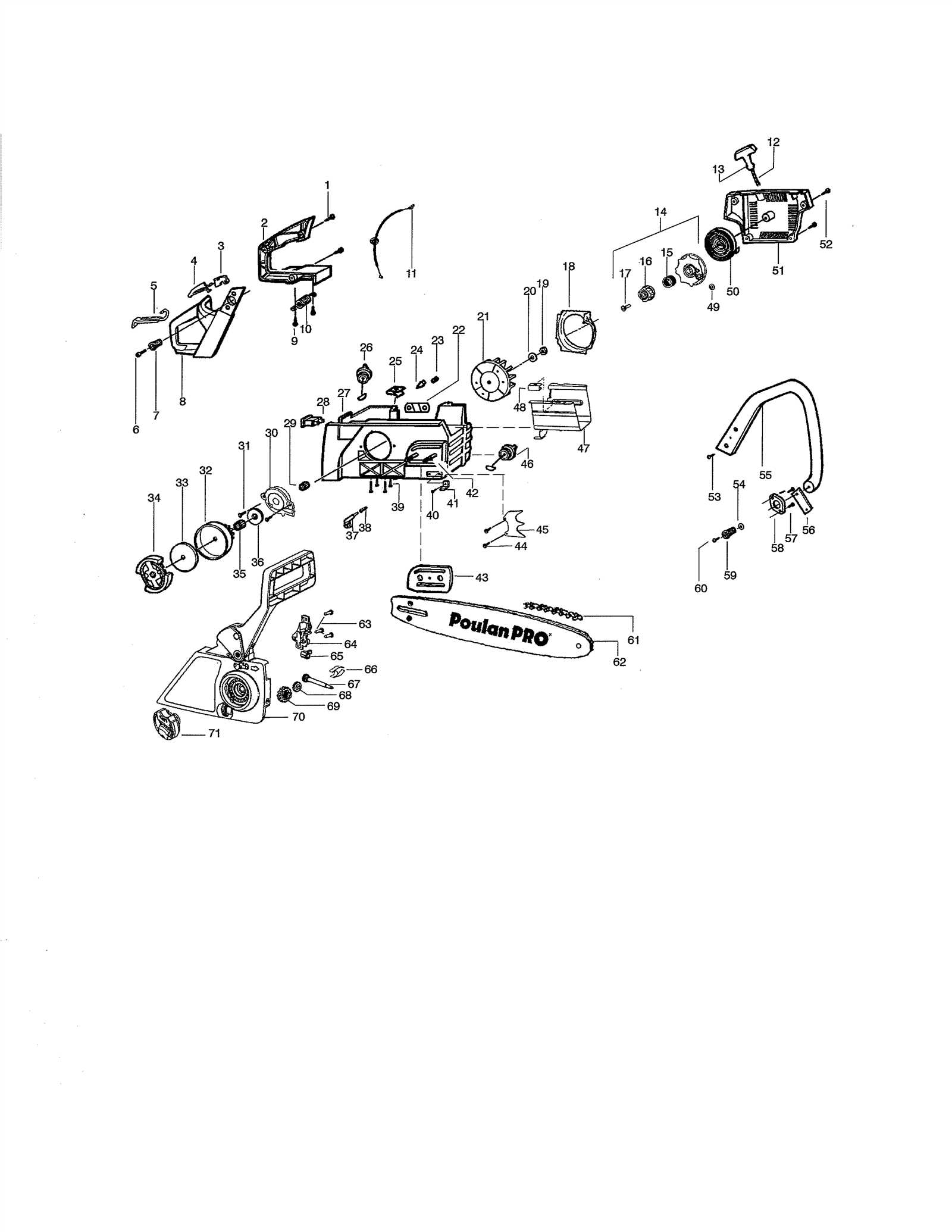

Pp4620avx Parts Overview

This section provides a comprehensive look at the components associated with the Pp4620avx model, highlighting their significance and interrelationships. Understanding these elements is crucial for optimal functionality and maintenance.

Each individual component plays a vital role in the overall operation of the system. For instance, the core unit is essential for performance, while ancillary components support its efficiency and reliability. Proper familiarity with these elements ensures informed decision-making during repairs or upgrades.

Key components include the main assembly, which is responsible for the primary functions, and supplementary units that enhance performance. Attention to detail in these areas can prevent potential issues and extend the lifespan of the equipment.

Overall, a thorough understanding of the different elements and their functions aids users in effectively navigating maintenance tasks and achieving optimal performance.

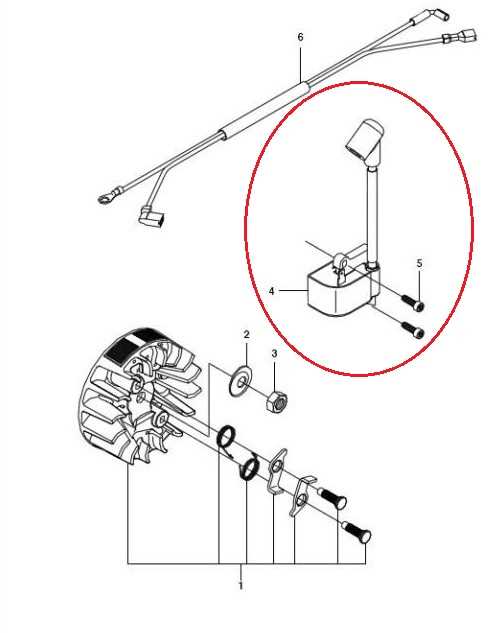

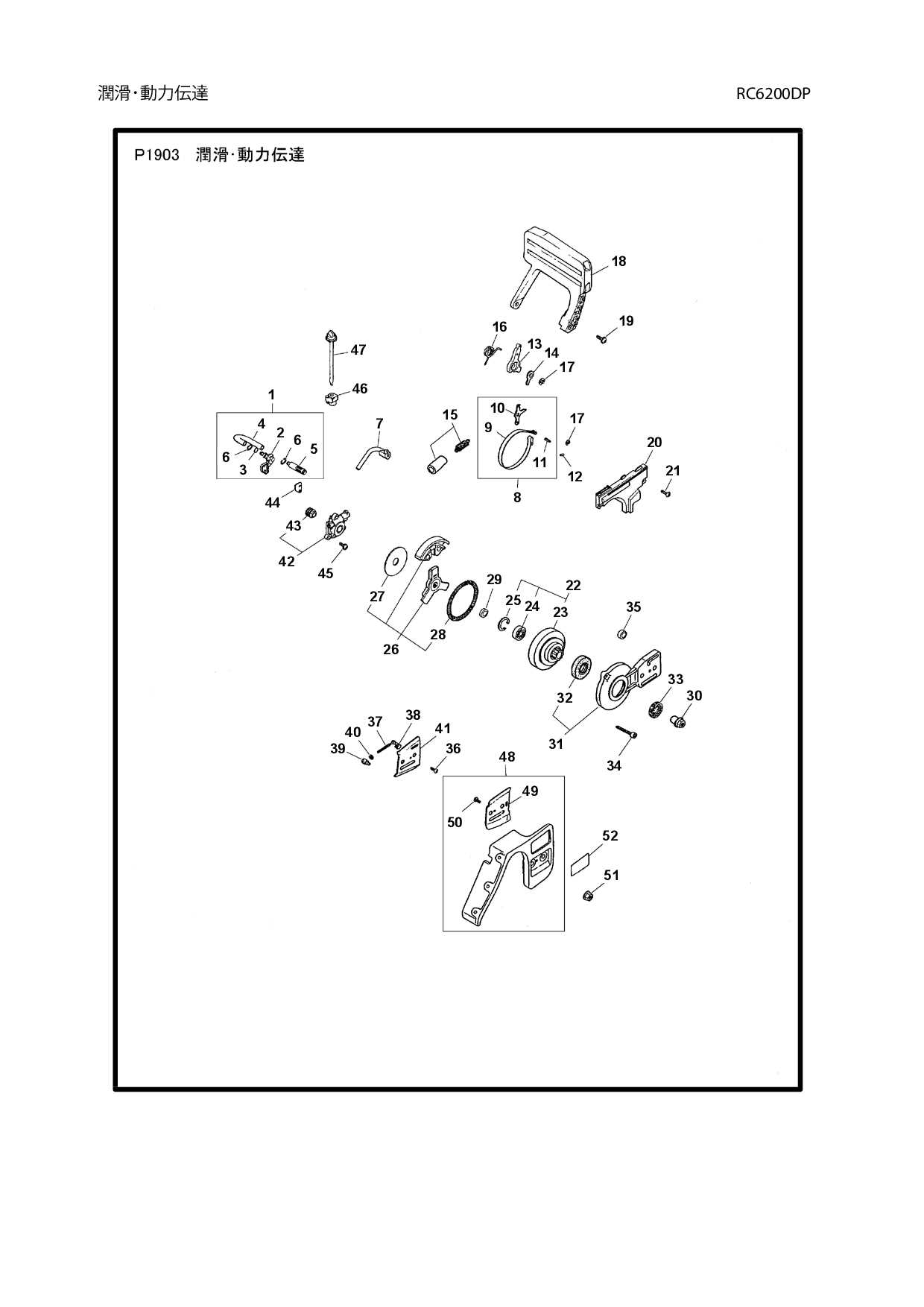

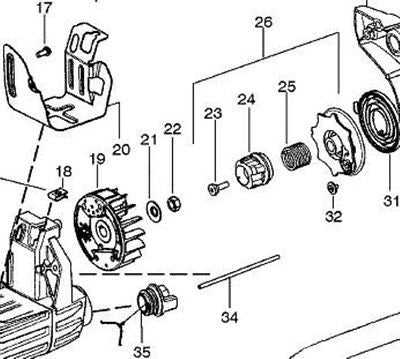

Understanding the Parts Diagram

Grasping the visual representation of components within a mechanical system is essential for effective maintenance and repair. This illustration serves as a blueprint, detailing how each element interacts with others, facilitating a deeper comprehension of the overall structure.

Analyzing this visual guide allows users to identify specific pieces, their functions, and their locations within the assembly. Familiarity with this layout can significantly enhance troubleshooting efforts, enabling technicians to quickly locate and address issues.

Moreover, such representations are invaluable when it comes to ordering replacements or upgrades. A clear understanding of the configuration assists in ensuring that the correct items are procured, ultimately streamlining the repair process and minimizing downtime.

In conclusion, mastering this visual tool is a vital skill for anyone working with complex machinery, fostering efficiency and proficiency in handling repairs and maintenance tasks.

Key Components of Pp4620avx

The intricacies of any sophisticated system often hinge on its essential elements. Understanding these critical parts not only enhances operational efficiency but also aids in troubleshooting and maintenance. This section delves into the primary components that contribute to the overall functionality and performance of the device.

Core Elements

At the heart of this technology are the core elements that ensure reliable performance. These components work in unison to facilitate seamless operation, providing the necessary support for various functions. Key elements typically include processors, power supplies, and control units, all designed to optimize performance and longevity.

Supporting Features

In addition to the core elements, supporting features play a crucial role in enhancing the overall system. These may encompass communication interfaces, sensors, and auxiliary modules that expand functionality. By integrating these features, the system becomes more versatile, accommodating a wide range of applications and user needs.

How to Read the Diagram

Understanding a visual representation of components is crucial for effective troubleshooting and maintenance. Familiarizing yourself with the layout and symbols used can significantly enhance your ability to identify parts and their functions. This guide will help you interpret the information presented in these visual aids.

Familiarize with Symbols

Each illustration utilizes specific icons to represent various elements. These symbols often follow industry standards, so recognizing them will streamline your comprehension. Look for keys or legends that explain the meaning behind each icon, as they provide essential insights into the component functionalities.

Follow the Flow

Pay attention to the connections and pathways depicted in the visual. Understanding how different elements interact with one another is vital for grasping the overall operation. Trace the lines and arrows that indicate movement or relationships, which will help clarify the system’s functioning and guide you in diagnosing potential issues.

Importance of Accurate Diagrams

Precision in visual representations is crucial across various fields, as they serve as essential tools for understanding complex systems. Accurate illustrations facilitate clear communication, enabling individuals to grasp intricate details quickly and effectively. When these visual aids are reliable, they enhance the overall efficiency of projects, reduce misunderstandings, and streamline collaboration among team members.

Moreover, well-crafted representations play a vital role in troubleshooting and maintenance processes. They guide technicians and engineers through procedures, ensuring that every component is handled appropriately. This minimizes errors, saving both time and resources while boosting the quality of outcomes. In educational contexts, accurate visuals can significantly improve learning experiences, allowing students to engage with material in a more meaningful way.

In summary, the reliability of these visual tools cannot be overstated. They are indispensable for effective communication, education, and practical applications, underscoring the need for meticulous attention to detail in their creation.

Common Issues with Parts Breakdown

Understanding the various components of a mechanical system can be challenging. Users often encounter difficulties when trying to navigate the complexities of individual elements and their functions. These challenges can lead to confusion and hinder effective maintenance or repair processes.

- Inaccurate Representations: Sometimes, the visual representation of components does not match the actual parts, leading to misidentification.

- Missing Information: Essential details about specific components, such as dimensions or material specifications, may be omitted, complicating repairs.

- Outdated Diagrams: Relying on outdated information can result in the use of obsolete parts, causing compatibility issues.

- Complexity of Assemblies: Some assemblies may be overly complicated, making it difficult to understand how parts interact with one another.

- Language Barriers: Technical terminology may vary across regions, leading to misunderstandings when translating component names.

Addressing these common challenges requires diligence and attention to detail. By being aware of potential pitfalls, users can better prepare themselves for troubleshooting and repairs.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often be a daunting task. However, with the right approach and resources, this process can become much more straightforward. Understanding how to effectively navigate available options is key to ensuring a smooth replacement experience.

Start by consulting the manufacturer’s website or authorized dealers, as they typically provide comprehensive resources, including catalogs and support. Online platforms can also be invaluable; dedicated forums and communities often share insights about sourcing and compatibility. Utilizing these resources can save you time and effort in finding exactly what you need.

Another effective strategy is to take inventory of the specifications of the original items. Knowing the exact measurements and characteristics will help narrow down your search significantly. Additionally, consider reaching out to customer service representatives who can provide personalized assistance based on your requirements.

Lastly, do not underestimate the power of reviews and recommendations. Engaging with fellow users can lead you to reliable vendors and products that have been tested in real-world applications. By leveraging these strategies, you can simplify the quest for the right components, ensuring your equipment runs smoothly once again.

Maintenance Tips for Pp4620avx

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Proper care not only enhances performance but also minimizes the risk of breakdowns and costly repairs. Here are some vital suggestions to keep in mind.

- Regular Cleaning: Dust and debris can accumulate and hinder functionality. Ensure that all surfaces are cleaned periodically.

- Lubrication: Apply appropriate lubricants to moving components to reduce friction and wear. Follow manufacturer guidelines for specific types.

- Inspect Connections: Routinely check all connections and fittings for wear or damage. Tighten any loose components to maintain optimal performance.

Adhering to a consistent maintenance schedule will help prolong the life of your machinery. Consider implementing the following practices:

- Scheduled Maintenance: Create a timetable for regular inspections and servicing.

- Record Keeping: Document all maintenance activities and repairs to track performance and identify recurring issues.

- Professional Servicing: When in doubt, consult with professionals for thorough evaluations and repairs.

By following these guidelines, you can ensure that your equipment remains in top condition, ready to perform efficiently for years to come.

Tools Needed for Repairs

Effective repairs require a selection of essential implements that facilitate the process. Having the right equipment at hand not only improves efficiency but also ensures a more successful outcome. Below are some common tools that can be invaluable when tackling maintenance tasks.

Essential Tools

The following tools are recommended for most repair jobs:

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for tightening or loosening screws. |

| Wrench Set | Necessary for gripping and turning nuts and bolts. |

| Pliers | Useful for gripping, twisting, or cutting materials. |

| Utility Knife | Ideal for cutting through various materials with precision. |

| Measuring Tape | Essential for taking accurate measurements. |

Safety Equipment

In addition to tools, safety gear is crucial for protection during repair activities:

| Safety Gear | Function |

|---|---|

| Safety Goggles | Protects eyes from debris and harmful substances. |

| Gloves | Prevents cuts and injuries to hands. |

| Ear Protection | Reduces exposure to loud noises. |

Installation Guidelines for Components

Proper assembly of various elements is crucial for ensuring optimal performance and longevity. Adhering to systematic procedures during installation can significantly reduce the risk of malfunction and enhance overall efficiency. This section outlines essential recommendations to follow when integrating individual components into the larger system.

Preparation Steps

Before beginning the installation process, it is vital to gather all necessary tools and components. Ensuring that the workspace is organized and free of distractions will facilitate a smoother assembly experience. Additionally, reviewing the specifications and compatibility of each part is essential to avoid errors during installation.

Installation Process

Follow these step-by-step instructions for effective integration of components:

| Step | Description |

|---|---|

| 1 | Verify that all elements are clean and undamaged prior to installation. |

| 2 | Carefully align each part according to the provided guidelines. |

| 3 | Secure components using appropriate fasteners, ensuring they are tightened to the recommended torque specifications. |

| 4 | Double-check connections and placements to ensure everything is properly positioned. |

| 5 | Conduct a preliminary test to confirm that all integrated components function as intended. |

By following these guidelines, the installation process can be executed with precision, leading to enhanced functionality and reliability of the system as a whole.

Where to Source Quality Parts

Finding high-quality components is essential for maintaining the performance and longevity of your machinery. Various sources can provide reliable options, ensuring you get the best materials for your needs.

Here are some recommended avenues to explore:

- Authorized Dealers: Purchasing from certified distributors guarantees authenticity and reliability. These vendors often provide warranties and support services.

- Manufacturer Websites: Directly visiting the official sites can lead you to genuine offerings. Many manufacturers list their products and provide resources for locating local suppliers.

- Online Marketplaces: Platforms such as eBay or Amazon feature numerous sellers. Look for those with positive reviews and a proven track record.

- Specialty Stores: Local shops that focus on specific industries often carry quality goods. Their expertise can help in selecting the right components.

Additionally, consider joining online forums and communities related to your field. Members frequently share recommendations and experiences that can guide you to reputable sources.

Finally, always verify the specifications and return policies before making a purchase to ensure satisfaction and quality assurance.

Comparing Different Parts Models

When evaluating various components, it is essential to understand the differences and similarities among them. Each model may serve distinct functions, be constructed from unique materials, and offer varying levels of performance. A thorough comparison can reveal which options align best with specific requirements and applications.

One key aspect to consider is compatibility. Certain models may be designed to work seamlessly with specific systems, while others might offer versatility across multiple platforms. Analyzing how each component interacts with its environment can help determine suitability for a given task.

Performance metrics, such as durability, efficiency, and ease of installation, also play a critical role in the decision-making process. Different configurations may excel in certain areas, making it crucial to identify the priorities of the intended use. Understanding these attributes can lead to more informed choices.

Cost-effectiveness is another vital factor. While some options may have a higher initial price, they might provide better long-term value through enhanced reliability or reduced maintenance needs. Conversely, lower-cost alternatives might offer sufficient performance for less demanding situations.

Finally, user feedback and expert reviews can provide valuable insights into real-world performance and reliability. Gathering information from multiple sources can aid in forming a comprehensive view of the options available, guiding users towards the most appropriate selections for their needs.

Understanding Manufacturer Specifications

When dealing with complex machinery or electronic devices, grasping the manufacturer’s guidelines is crucial for optimal performance and longevity. These specifications serve as a comprehensive framework, detailing the essential components and their functionalities. By adhering to these parameters, users can ensure that their equipment operates smoothly and efficiently.

Manufacturer specifications encompass a variety of information, including material quality, operational limits, and compatibility requirements. This data is not merely a suggestion; it is the foundation upon which safe and effective usage is built. Ignoring these specifications can lead to malfunctions or even safety hazards.

Understanding these details also aids in troubleshooting issues that may arise over time. Knowing the exact requirements helps users identify potential problems early, allowing for timely maintenance or replacement. By prioritizing adherence to manufacturer guidelines, individuals can significantly enhance the reliability and functionality of their equipment.