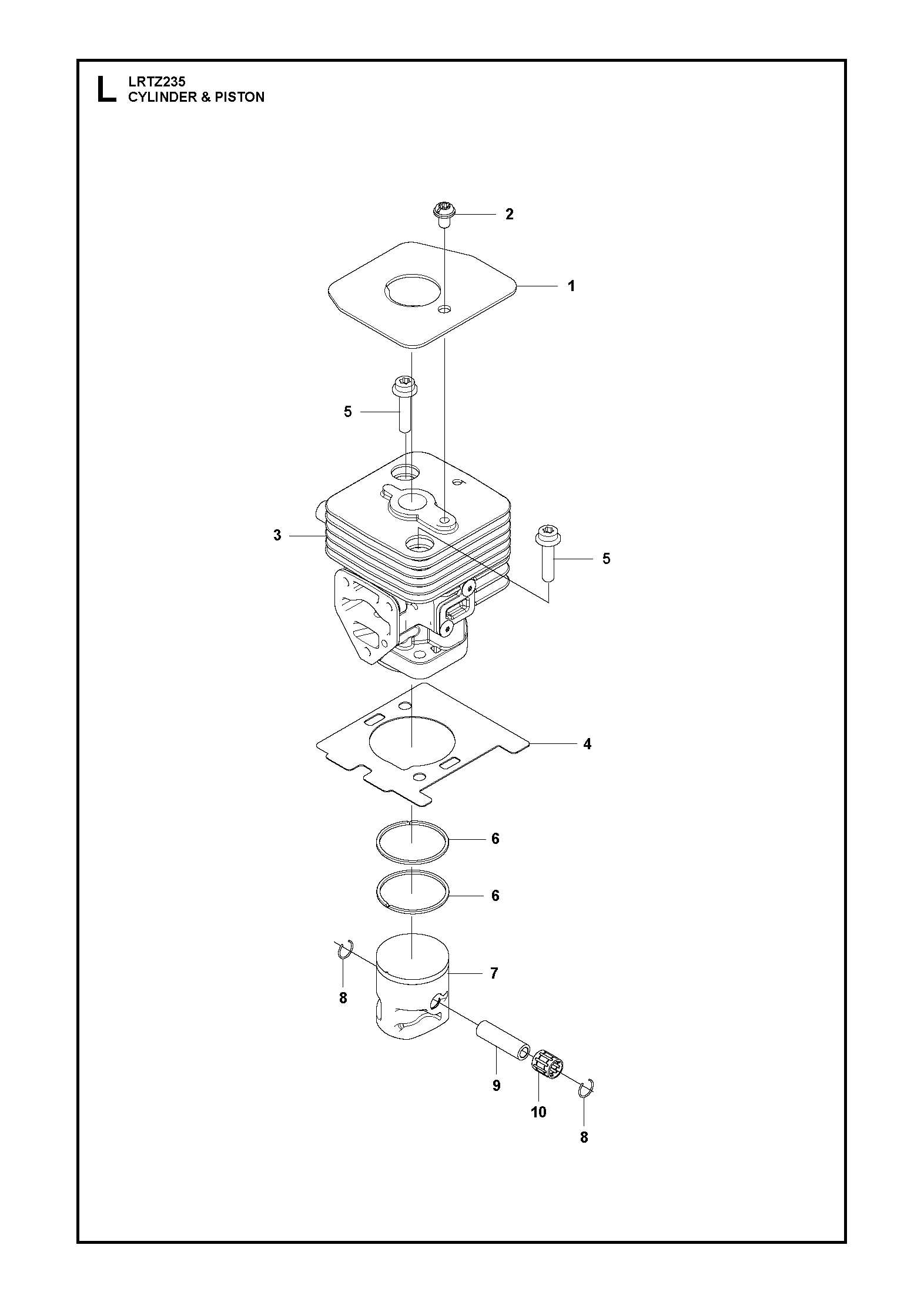

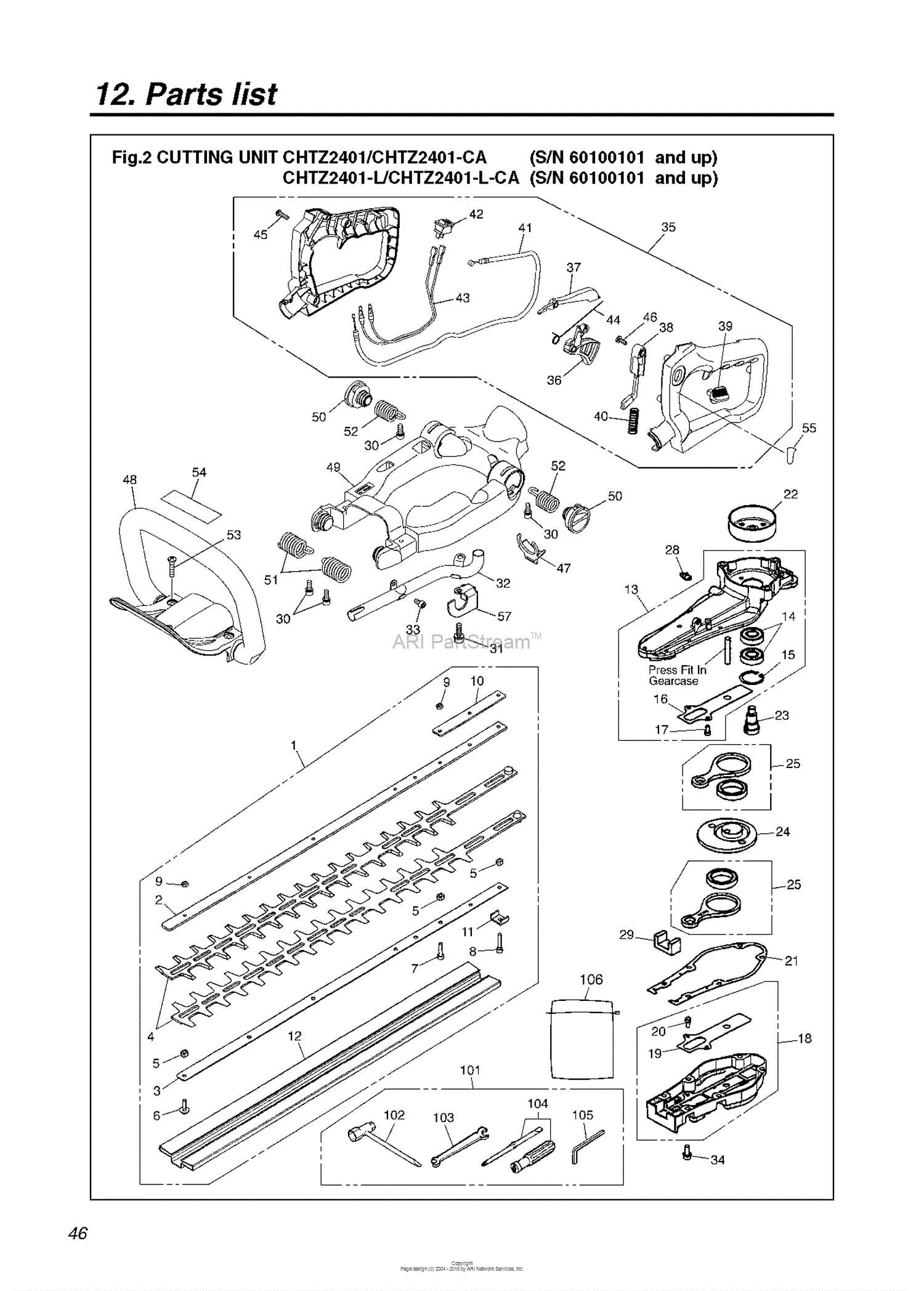

When it comes to maintaining outdoor equipment, having a clear visual reference for the individual components can be invaluable. This guide serves as an essential resource for enthusiasts and professionals alike, providing a comprehensive look at the various elements that make up these powerful machines. By breaking down the assembly into manageable sections, users can better understand the relationships and functions of each part.

In exploring the intricacies of the assembly, one can delve into the details of how each component contributes to overall performance and efficiency. Understanding the layout not only aids in troubleshooting issues but also enhances the ability to perform repairs or upgrades. With the right knowledge, maintaining these tools becomes an ultimate goal, ensuring longevity and optimal functionality.

Whether you are a seasoned user or a newcomer, grasping the structure and assembly of these vital parts is essential. This guide aims to illuminate the connections and roles of each segment, empowering you to tackle any challenge with confidence. Embrace the opportunity to deepen your understanding and keep your equipment running smoothly.

Understanding Redmax GZ23N Components

Grasping the essential elements of outdoor equipment can significantly enhance its performance and maintenance. Each component plays a vital role in ensuring optimal functionality and longevity, making it crucial for users to familiarize themselves with these integral parts.

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operation.

- Fuel System: Responsible for delivering energy, it includes the tank, filter, and lines.

- Ignition System: This component initiates combustion, ensuring the engine starts smoothly.

- Cooling System: Keeps the engine at a stable temperature, preventing overheating during use.

- Drive Shaft: Connects the engine to the working attachments, transferring power efficiently.

Understanding these components allows users to troubleshoot issues effectively and maintain equipment properly, ultimately prolonging its lifespan and enhancing performance.

Importance of Parts Diagrams

Visual representations of component assemblies play a crucial role in the maintenance and repair of equipment. They provide users with a clear understanding of how individual elements interact and fit together, facilitating more efficient troubleshooting and restoration processes.

Such illustrations enhance the ability to identify specific elements, making it easier to locate replacements or carry out repairs. When users can visually comprehend the arrangement and function of various pieces, they are better equipped to address issues effectively.

Moreover, these schematics serve as valuable educational tools, helping both novices and experienced technicians deepen their understanding of machinery. By studying these visuals, users can grasp the operational principles behind complex systems, ultimately leading to improved proficiency in handling equipment.

In addition, detailed visuals can streamline the ordering process for replacements. Users can quickly pinpoint the required components, minimizing errors and reducing downtime. This clarity ultimately supports overall efficiency and productivity in maintenance efforts.

Common Issues with GZ23N Models

Understanding the frequent challenges that users encounter with specific equipment can significantly enhance maintenance and usability. Addressing these issues proactively can lead to improved performance and longevity. Here are some of the most prevalent problems faced by operators.

Performance Problems

- Difficulty starting the engine, often caused by fuel system issues or spark plug failures.

- Inconsistent power output, which may result from a clogged air filter or carburetor blockages.

- Excessive vibration during operation, often linked to worn-out components or improper assembly.

Maintenance Concerns

- Frequent need for cleaning or replacement of the air filter due to dust and debris accumulation.

- Oil leaks, typically arising from worn gaskets or seals that require timely attention.

- Inadequate lubrication, which can lead to overheating and accelerated wear on moving parts.

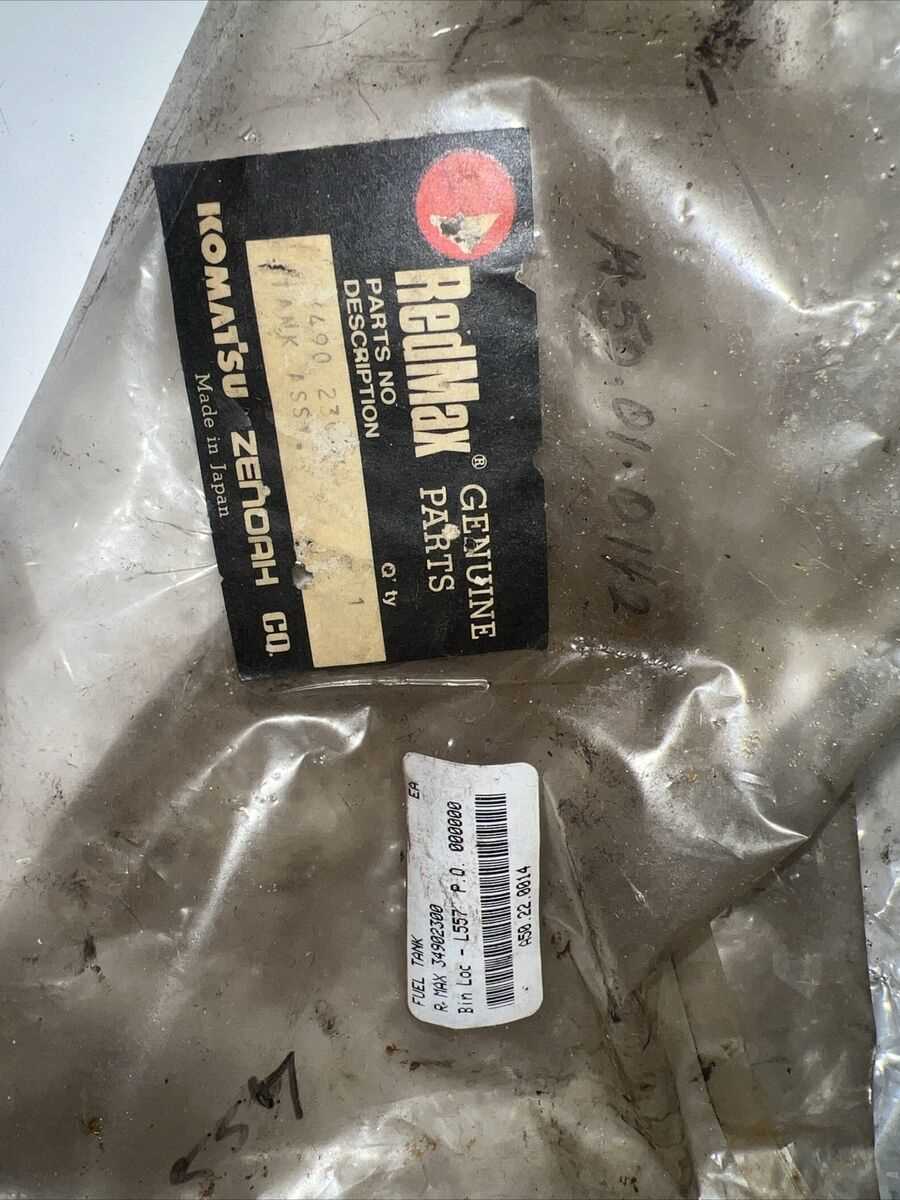

How to Identify Genuine Parts

Ensuring the authenticity of components is crucial for maintaining the efficiency and longevity of your equipment. Genuine items not only provide optimal performance but also help prevent potential issues that can arise from using substandard alternatives. Understanding how to distinguish between original and counterfeit parts can save you time and money in the long run.

Visual Inspection

Start with a thorough visual check. Authentic components often have precise finishes and clear markings. Look for any inconsistencies, such as uneven surfaces or poor labeling, which may indicate a replica. Additionally, examine the packaging; reputable manufacturers usually present their products with high-quality branding.

Check Compatibility

Ensure that the component matches the specifications required for your equipment. Genuine items are designed to fit seamlessly, whereas imitation parts might be poorly sized or incompatible, leading to operational failures. Refer to the manufacturer’s documentation for exact details.

Maintenance Tips for GZ23N Users

Proper upkeep of your equipment ensures optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns. Following a few essential guidelines can keep your machine running smoothly.

Regular Inspections

Frequent checks of the main components are crucial. Look for signs of wear and tear, and address any issues promptly. Pay special attention to filters, spark plugs, and fuel lines to maintain peak functionality.

Cleaning and Lubrication

Keeping your device clean is vital for its operation. Regularly remove dirt and debris from surfaces, and ensure that all moving parts are well-lubricated. This practice reduces friction and minimizes the risk of damage over time.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues with outdoor power equipment. By following each step carefully, you can ensure effective repairs and maintain optimal performance.

Begin by gathering all necessary tools and replacement components. This preparation will streamline the process and minimize downtime.

Next, consult the user manual to identify specific symptoms and corresponding solutions. Understanding the root cause is crucial for a successful fix.

Proceed by disassembling the equipment, taking care to document each step. Use containers to keep small parts organized and avoid misplacement.

Once disassembled, inspect all components for wear or damage. Replace any defective parts with high-quality alternatives to ensure longevity.

After replacements, carefully reassemble the unit in reverse order. Double-check all connections and tighten fasteners securely.

Finally, conduct a thorough test to confirm that the repairs have resolved the issues. Regular maintenance will prolong the lifespan of your equipment.

Where to Find Replacement Parts

Locating suitable components for outdoor power equipment can enhance performance and longevity. Understanding where to source these items is crucial for effective maintenance and repairs.

Online Retailers

- Major e-commerce platforms

- Specialized tool and equipment websites

- Manufacturer’s official website

Local Suppliers

- Authorized dealerships

- Hardware stores

- Repair shops specializing in outdoor equipment

Compatibility with Other Redmax Models

This section explores the interchangeability of components across various models from the same manufacturer, highlighting the advantages of using compatible units. Understanding these relationships can enhance maintenance efficiency and expand the range of available options for repairs and upgrades.

Common Compatible Units

Many products share similarities in their construction, allowing users to substitute parts without sacrificing performance. This compatibility not only streamlines repairs but also provides flexibility in choosing components based on availability and cost.

| Model | Compatible Components | Notes |

|---|---|---|

| Model A | Engine, Fuel System | Direct fit; check specifications. |

| Model B | Ignition System, Carburetor | Similar designs; slight adjustments may be needed. |

| Model C | Starter, Exhaust | Excellent match; ensures optimal performance. |

Benefits of Interchangeability

Utilizing interchangeable components can result in significant cost savings and reduced downtime. It allows users to maintain their equipment more effectively while also promoting sustainability through the extended life of various parts.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools at your disposal is essential. Proper tools not only make the job easier but also ensure that repairs are done efficiently and safely. Below is a list of essential instruments you should consider when preparing for any repair task.

Essential Hand Tools

- Wrenches: A variety of sizes to fit different nuts and bolts.

- Screwdrivers: Both flathead and Phillips for various fasteners.

- Pliers: Needle-nose and standard for gripping and twisting.

- Socket set: For more efficient tightening and loosening of fasteners.

- Cutters: For trimming wires and small components.

Specialized Equipment

- Torque wrench: To ensure bolts are tightened to manufacturer specifications.

- Feeler gauges: For checking gaps and settings in precision tasks.

- Multimeter: Essential for diagnosing electrical issues.

- Fuel canister: For easy transport and storage of fuel when needed.

- Safety gear: Goggles, gloves, and masks to protect yourself during repairs.

Equipping yourself with these tools will significantly enhance your ability to perform repairs and keep your equipment in optimal condition.

Tips for Efficient Troubleshooting

Effective problem-solving is essential when dealing with equipment malfunctions. By adopting a systematic approach, you can identify issues more quickly and accurately, minimizing downtime and enhancing overall performance. Here are some strategies to help you streamline the troubleshooting process.

- Gather Information: Start by collecting relevant data about the issue. This includes any unusual sounds, performance drops, or error messages.

- Refer to Manuals: Consult the operation manuals or technical guides to understand the design and function of the equipment.

- Visual Inspection: Conduct a thorough visual check for signs of wear, loose connections, or damaged components.

Once you have gathered initial insights, follow these additional steps:

- Systematic Testing: Isolate and test individual components to identify the source of the problem.

- Utilize Diagnostic Tools: Employ diagnostic equipment to pinpoint issues that may not be visible during a manual inspection.

- Document Findings: Keep a record of any anomalies and the steps taken for future reference, which can be invaluable for recurring problems.

By implementing these practices, you can enhance your troubleshooting efficiency and ensure a more reliable operation of your equipment.

Frequently Asked Questions About GZ23N

This section addresses common inquiries related to a specific model of outdoor power equipment. By providing clear answers, we aim to enhance user understanding and assist with maintenance and operation.

General Inquiries

Users often seek information about the functionality and maintenance requirements of this machine. Regular upkeep ensures longevity and optimal performance.

Technical Support

Many questions arise regarding troubleshooting and parts replacement. It is essential to consult appropriate resources for accurate guidance.

| Question | Answer |

|---|---|

| What type of fuel should I use? | Use a high-quality fuel with the appropriate octane rating recommended by the manufacturer. |

| How often should I perform maintenance? | Regular maintenance should be conducted after every 25 hours of operation. |

| Where can I find replacement components? | Replacement parts can be sourced from authorized dealers or online retailers specializing in outdoor equipment. |