When it comes to understanding the internal workings of a firearm, it’s essential to dive deep into how every component functions together. Each element plays a vital role in ensuring precision, reliability, and performance. By breaking down these individual elements, enthusiasts and professionals alike can gain insights into the assembly, operation, and maintenance of the weapon.

This section provides a detailed exploration of the key components that make up a classic rifle model, highlighting their purpose and interaction within the overall mechanism. Whether you are looking to perform routine upkeep or simply enhance your knowledge, understanding the internal structure is crucial for ensuring long-term functionality and safety.

Through this guide, we will explore how various elements come together to creat

Overview of Key Components in Remington 7600

The design of this model revolves around a well-structured set of mechanical elements that work together to ensure reliable performance. These individual elements are integral to the functionality, allowing seamless operation. Understanding the arrangement of these elements helps in maintaining and improving overall functionality.

Barrel Assembly

The barrel is a crucial piece that directs the movement and speed of the projectile. It’s engineered to handle the pressure generated, guiding the shot with precision. Its length and bore quality impact the overall accuracy.

Trigger Mechanism

The trigger mechanism is another vital feature, designed for precise control. It regulates the release of the shot, providing a smooth and consistent action. This system is built to offer both reliability and safety during use, ensuring every shot is deliberate.

Internal Mechanisms and Their Functions

Understanding the inner workings of a complex device is essential for effective operation and maintenance. Each component inside contributes to the overall functionality, working together in harmony to ensure reliability and precision. In this section, we will explore the primary systems that drive the internal processes and how each mechanism plays a role in its operation.

Main Structural Components

The internal structure consists of multiple interconnected elements designed to handle specific tasks. These include various assemblies responsible for movement control, energy transfer, and overall system coordination. Each part is meticulously engineered to provide strength, durability, and smooth operation under varying conditions.

Operational System Overview

The internal mechanisms are designed to manage several essential functions, from initial activation to consistent operation. Key systems work in tandem, ensuring that energy is properly harnessed, distributed, and applied. Below is a table outlining

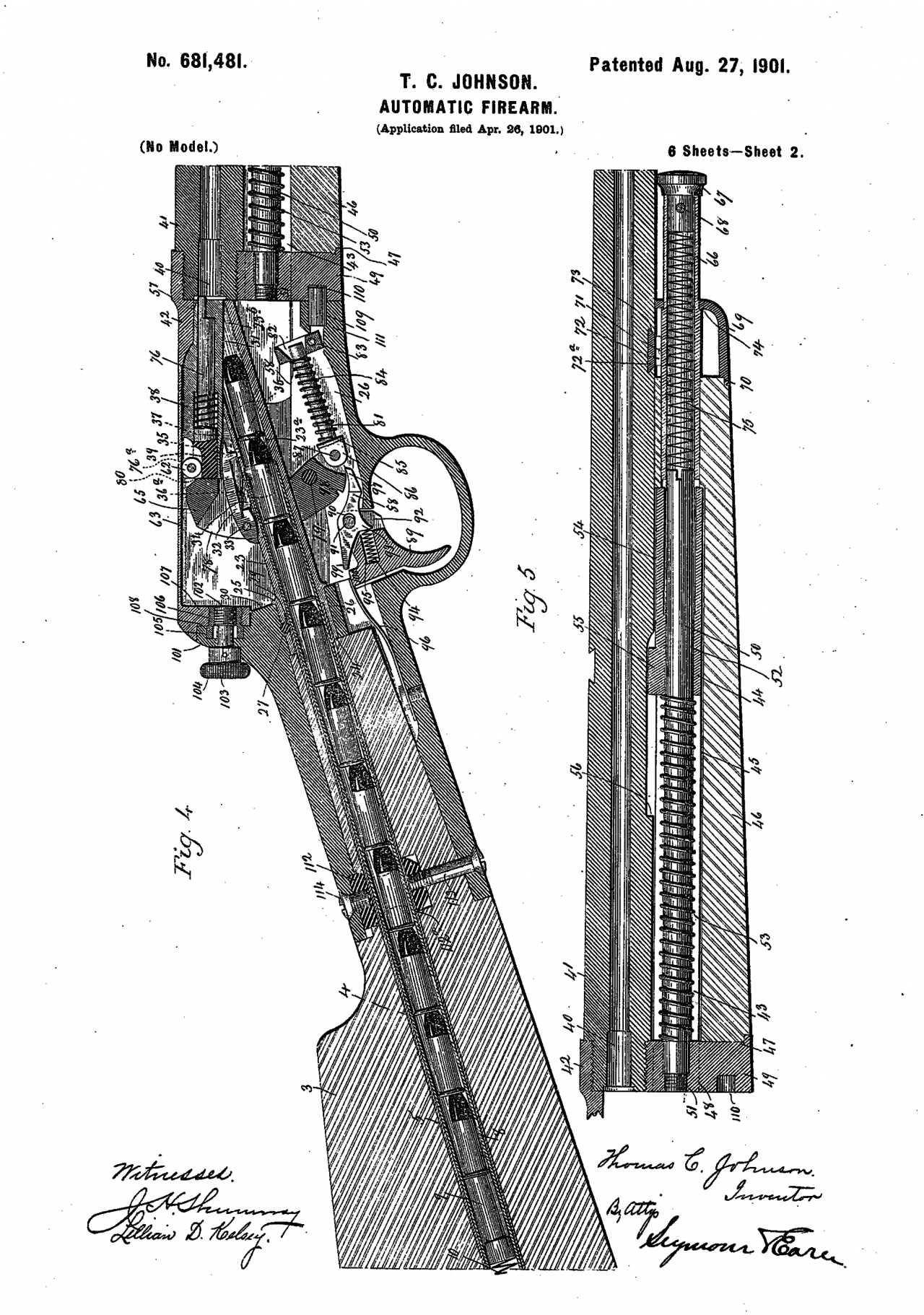

Barrel and Receiver Construction Details

The overall structure of the barrel and the receiver plays a crucial role in ensuring both accuracy and durability. These two components work together to provide a stable foundation for the firearm’s operation, contributing to its performance under various conditions. Proper alignment, machining precision, and material choice are essential aspects that define the functionality of these parts.

Barrel Design Features

The barrel is engineered for optimal performance, combining strength and heat resistance. Its inner profile ensures smooth projectile travel, while the external design supports attachments and enhances overall handling. The rifling inside the barrel is a critical feature that affects the projectile’s trajectory, providing both spin and stability.

Receiver Engineering

The receiver is the central hub, housing esse

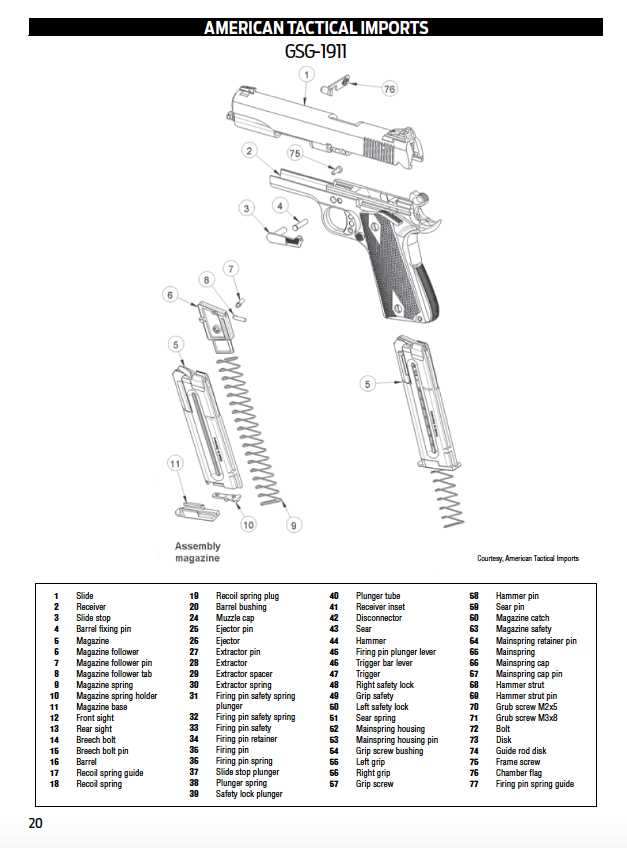

Trigger Assembly and Safety Mechanism

The operation of the firing system and the protective device is critical for ensuring both functionality and user security. This section explores the inner workings of the trigger system, detailing how various components interact to enable precise control over the release mechanism. Additionally, attention is given to the safety system, which is designed to prevent accidental firing by locking the trigger mechanism in place when engaged.

The trigger mechanism operates through a series of interconnected parts that work together to initiate the firing process. When pressure is applied to the trigger, it activates a series of controlled movements that release the firing component. This mechanism must be well-maintained and free of obstructions to function correctly, as even slight wear can affect performance.

On the other hand, the safety device plays an essential role in blocking the trigger mechanism. It prevents unintended firing

Stock Variations and Customization Options

When considering modifications to the structure of your rifle, stock variations offer a range of possibilities for improved comfort, control, and aesthetic appeal. Tailoring the stock to fit individual needs can enhance the shooting experience, allowing for both practical and visual adjustments.

- Material Choices: Stocks are available in different materials, each providing unique benefits. Options include wood for a traditional look, synthetic materials for durability, and composite variants for lightweight handling.

- Adjustable Features: Many models feature adjustable length, comb height, and recoil pads. These adjustments help shooters fine-tune their setup for better ergonomics and recoil management.

- Color and Finish Options: Customization doesn’t stop at functionality. A variety of finishes, from matte black to camo patterns, allow owners to match their preferences and environment.

- Aftermarket Upgrades:

Magazine System: Loading and Operation

The magazine mechanism plays a crucial role in the functionality of firearms, ensuring a seamless feeding process for cartridges. Understanding the principles behind this system is essential for proper maintenance and effective use. This section delves into the procedures involved in loading and operating the ammunition feeding system.

Loading the Magazine: The loading process begins with the careful insertion of cartridges into the magazine, following the designated orientation. It is important to ensure that each round is positioned correctly to facilitate smooth feeding into the chamber. Users should avoid overloading, as this can lead to malfunctions or jamming.

Operation Mechanics: Once the magazine is loaded, it is inserted into the firearm until it locks securely into place. The action of the firearm, activated by pulling the trigger, initiates the feeding process. As the mechanism cycles, the next cartridge is lifted from the magazine and aligned with the chamber, ready for firing. This efficient operation allows for quick follow-up shots, enhancing the overall shooting experience.

Maintenance Tips: Regular cleaning and inspection of the magazine system are vital to ensure optimal performance. Users should remove any debris or buildup that may hinder the feeding process. Additionally, checking the spring tension can help prevent feeding issues, maintaining reliability during use.

Maintenance and Lubrication Points

Proper upkeep is essential for ensuring optimal functionality and longevity of firearms. Regular maintenance helps to prevent wear and tear, enhance performance, and ensure safety during use. This section outlines key areas that require attention and lubrication to maintain the integrity of the mechanism.

Key Areas for Maintenance

It is crucial to identify specific components that benefit from routine care. Regularly inspecting and applying appropriate lubricants can greatly enhance the overall efficiency of the firearm. Below is a table highlighting the main components that require maintenance, along with recommended lubricants and frequencies.

Component Recommended Lubricant Maintenance Frequency Action Mechanism Synthetic Oil Every 100 rounds Barrel Cleaning Solvent After each use Trigger Assembly Light Grease Every 300 rounds Stock Wood Conditioner Every 6 months Lubrication Techniques

Applying lubricant correctly is vital for effective maintenance. Use a clean cloth to wipe off excess oil and prevent buildup that can attract dirt and debris. Focus on moving parts, ensuring they operate smoothly without obstruction. Additionally, store the firearm in a dry place to further enhance its longevity.

Sight Mounting and Adjustment Tips

Accurate aiming is essential for effective shooting, and the way sights are mounted and adjusted plays a crucial role in this process. Proper alignment and calibration ensure that your shots hit the intended target, enhancing overall performance. This section will provide valuable insights into optimizing sight installation and fine-tuning adjustments for improved accuracy.

Before proceeding with the installation, it’s important to gather all necessary tools and components. Ensure that the mounting system is compatible with your firearm and that you understand the specific requirements for achieving optimal sight placement.

Step Description 1 Choose the appropriate mounting hardware based on the type of sight and firearm. 2 Carefully position the sight on the mounting base, ensuring it is level and aligned with the bore. 3 Tighten the screws securely, but avoid overtightening to prevent damage. 4 Conduct a preliminary zeroing process at a suitable distance, typically 25 to 50 yards. 5 Make necessary adjustments to windage and elevation to refine accuracy. Regular maintenance and periodic checks on sight alignment will help maintain precision over time. When making adjustments, it is advisable to take test shots to verify accuracy after each change, ensuring that you achieve the best performance possible.

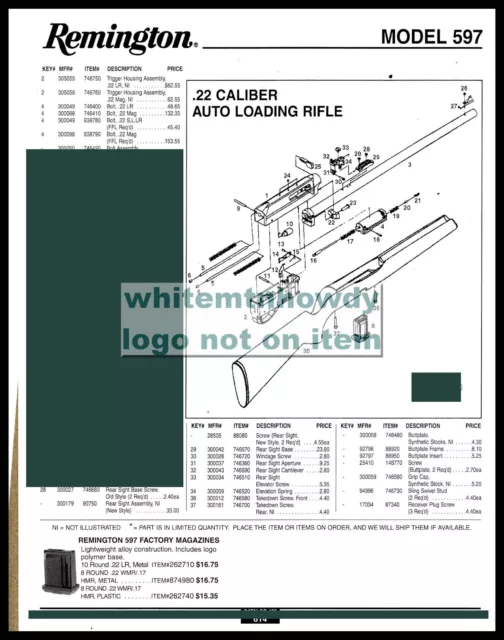

Common Replacement Parts and Their Availability

When maintaining or repairing firearms, understanding the various components that may need to be replaced is essential. This section highlights frequently sought-after elements that are often subject to wear and tear, ensuring optimal performance and longevity of the weapon. The availability of these items can significantly affect maintenance schedules and overall functionality.

Component Description Availability Barrel The primary tube through which the projectile is fired. Readily available through specialized retailers and online stores. Trigger Assembly The mechanism that releases the firing pin when engaged. Commonly found at gunsmith shops and major firearm retailers. Stock The part that provides support and stability for the shooter. Available in various styles and materials from numerous suppliers. Magazine A container that holds ammunition and feeds it into the chamber. Easily accessible through manufacturers and firearm accessory stores. Recoil Spring Absorbs the impact during firing, aiding in cycling the action. Often stocked by firearm maintenance shops and online platforms. Inspecting Wear and Tear on Moving Parts

Regular examination of the dynamic components in any mechanism is essential for ensuring optimal functionality and longevity. By identifying signs of degradation, users can prevent potential malfunctions and maintain the overall performance of the device. This section focuses on effective methods for evaluating these critical elements.

Identifying Signs of Degradation

When assessing the moving components, look for visible indicators such as scratches, dents, or unusual wear patterns. Noise during operation can also signal issues, as can excessive friction or binding. Lubrication points should be monitored for dryness, which can accelerate deterioration. Addressing these factors promptly can prolong the lifespan of the assembly.

Best Practices for Maintenance

To maintain the functionality of the moving parts, establish a routine inspection schedule. Regularly clean the components to remove debris and residue that could impede performance. Additionally, applying the appropriate lubricants can help minimize friction and reduce wear. Documenting each inspection can also aid in tracking changes over time, making it easier to spot developing issues early.

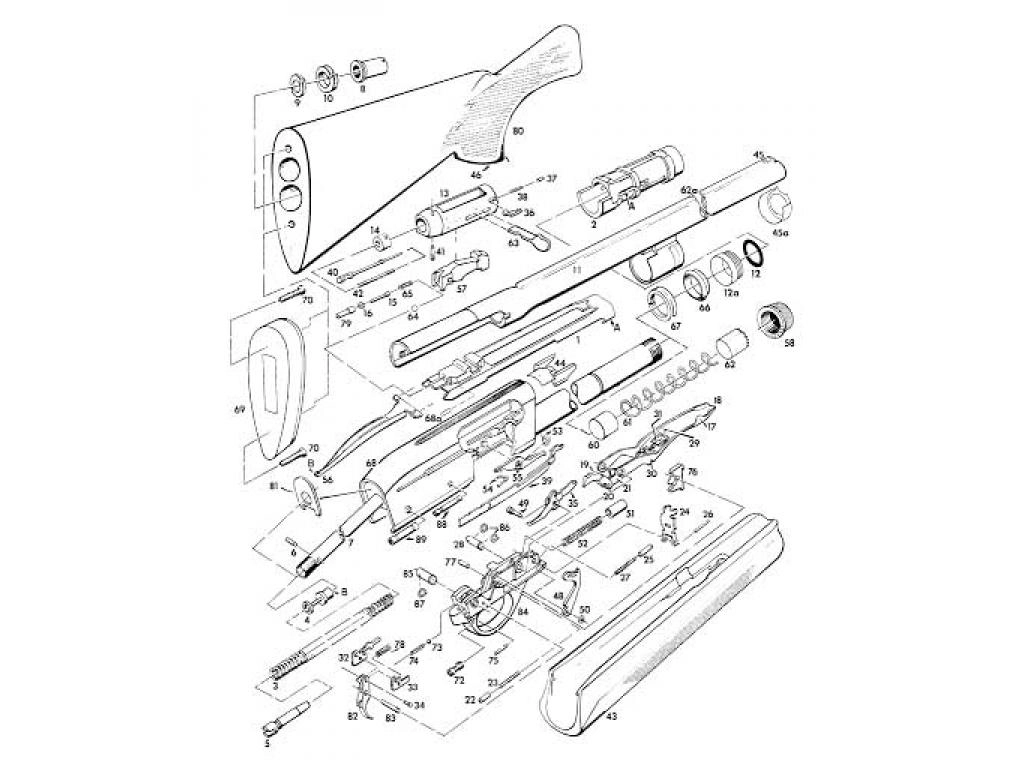

Assembly and Disassembly Procedures

This section provides a comprehensive overview of the methods used to assemble and disassemble firearm components effectively and safely. Understanding these procedures is crucial for maintenance, repair, and customization of the mechanism.

General Guidelines

Before starting the process, consider the following recommendations to ensure safety and efficiency:

- Always work in a well-lit and clean environment.

- Wear appropriate safety gear, including gloves and eye protection.

- Ensure the firearm is unloaded and free of ammunition before beginning any work.

- Have all necessary tools readily available to avoid interruptions.

Steps for Disassembly

- Remove the magazine and verify that the chamber is empty.

- Begin by loosening any screws or fasteners that secure the exterior components.

- Carefully detach the stock and any attached parts, following the manufacturer’s instructions.

- Proceed to disassemble internal mechanisms, noting the order of removal for reassembly.

- Store removed parts in an organized manner to facilitate the reassembly process.

Steps for Assembly

- Start by placing the main components on a clean, flat surface.

- Refer to the documentation to ensure correct orientation and alignment of parts.

- Reattach internal mechanisms, securing each piece in the order of disassembly.

- Carefully attach the stock and any other external components, ensuring all screws are tightened appropriately.

- Conduct a thorough inspection to confirm that all parts are correctly installed and functioning as intended.

Following these procedures will help maintain the longevity and reliability of your firearm while ensuring a safe and efficient process for both assembly and disassembly.

Upgrading Accessories for Performance Improvement

Enhancing the functionality of your firearm can lead to a more enjoyable and effective shooting experience. By carefully selecting and upgrading various components, enthusiasts can optimize accuracy, control, and overall handling. Whether you are looking to improve stability or increase precision, the right accessories can make a significant difference.

Choosing the Right Optics

Investing in high-quality optics can greatly enhance your shooting experience. A reliable sighting system not only improves accuracy but also allows for quicker target acquisition. When selecting optics, consider factors such as magnification, reticle type, and durability. This will ensure you have a setup that complements your shooting style and needs.

Enhanced Grips and Stocks

Upgrading to ergonomic grips and adjustable stocks can dramatically improve comfort and control. An enhanced grip allows for a more secure hold, reducing fatigue during extended use. Additionally, adjustable stocks enable shooters to customize length and positioning for better alignment and comfort. These improvements lead to increased stability and better overall performance.