In the world of commercial food preparation, there are a variety of tools designed to streamline operations and enhance efficiency. Among these, certain machines stand out due to their versatility and reliability. These devices are composed of numerous intricate elements that work in harmony to ensure smooth performance in a demanding environment.

Each component within such a machine plays a crucial role, from the motor that powers the operation to the blades responsible for precise cutting or blending. Maintaining and replacing these elements when necessary is key to prolonging the lifespan of the equipment and ensuring continuous productivity in the kitchen.

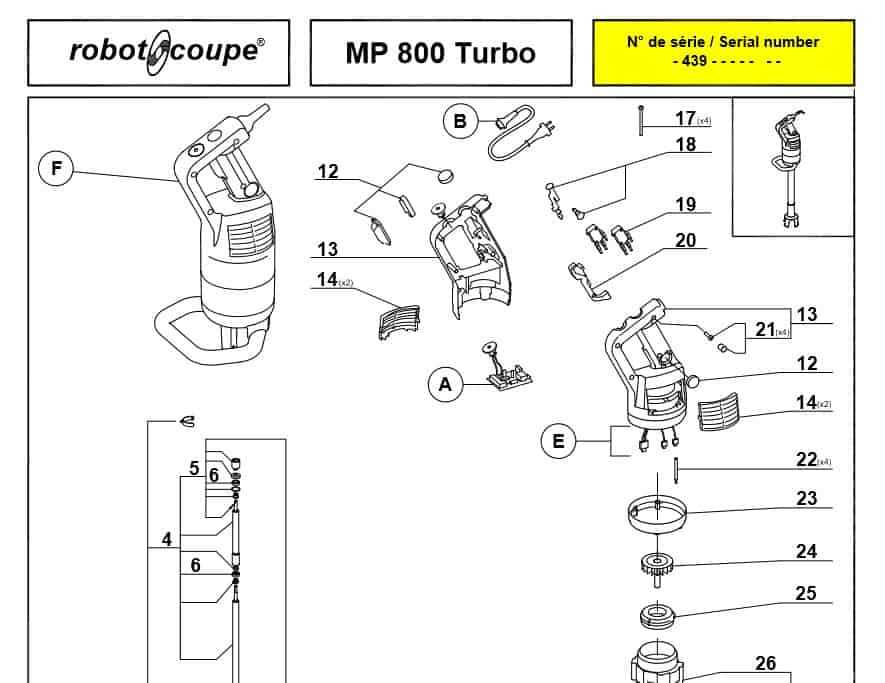

This guide delves into the layout and functions of the key elements that make up this essential kitchen tool. Understanding the arrangement and interconnection of these parts will help users to identify the right elements for replacement and maintain optimal performance over time.

Overview of the Robot Coupe MP 450

The device in question is a high-performance tool designed for professional kitchens, widely known for its powerful performance and versatility. It is ideal for blending, mixing, and pureeing large quantities of ingredients, making it a key asset in food preparation. Its ergonomic design and durable materials ensure long-lasting use even in demanding environments.

Key Features and Specifications

Engineered for efficiency, this tool comes with multiple key features that enhance its performance in various food preparation tasks. It is equipped with a powerful motor, designed to handle heavy-duty tasks, and a long mixing arm to reach deep into containers for thorough blending.

| Feature | Specification |

|---|---|

| Motor Power | 750 Watts |

| Mixing Arm Length | 45 cm |

| Weight | 5 kg |

Practical Applications

This versatile equipment is suitable for a wide range of culinary tasks, including creating soups, sauces, and emulsions. Its user-friendly design allows for easy handling, while the powerful motor ensures that even large batches of ingredients are processed efficiently.

Main Components and Their Functions

This section provides an overview of the key elements that make up the device and their respective roles in ensuring efficient operation. Each part has a distinct purpose, contributing to the overall performance and durability of the equipment.

- Motor Assembly: The powerhouse of the unit, responsible for driving the movement of internal mechanisms. It ensures that the tool operates smoothly and effectively, providing the necessary force to complete tasks.

- Blending Shaft: This long attachment facilitates the direct contact with ingredients. Its design allows for deep immersion, enabling thorough mixing and blending processes.

- Blade System: A sharp, rotating component that handles cutting, chopping, and pureeing functions. It operates at high speeds to break down various materials with precision.

- Grip Handle: A user-friendly handle that ensures comfort and control during operation. Its ergonomic shape is designed to reduce fatigue during prolonged use.

- Speed Control: This feature allows the user to adjust the intensity of the tool’s performance. Different settings cater to various tasks, providing flexibility in operation.

These elements work together seamlessly, making the equipment highly effective for various kitchen tasks, from light blending to heavy-duty mixing.

Understanding the Motor Assembly

The motor assembly is a key component responsible for powering the device, converting electrical energy into mechanical force. This section will explain the inner workings of the motor, focusing on how its components function together to ensure efficient performance. Understanding these elements is essential for proper maintenance and troubleshooting.

Core Components of the Motor

The motor consists of several vital parts, each playing a specific role in the overall operation. These include the housing, which encases the motor, the rotor, which moves in response to electrical input, and the bearings, which reduce friction and allow smooth movement.

| Component | Function |

|---|---|

| Housing | Protects internal elements from external damage and provides structural stability. |

| Rotor | Rotates when electrical energy is applied, driving the mechanical operation. |

| Bearings | Facilitate smooth rotation by reducing friction between moving parts. |

Operational Mechanism

The motor operates by converting electrical current into rotational motion. This process is initiated when an electric charge flows through the windings, creating a magnetic field that interacts with the rotor. As the rotor spins, the mechanical energy is transferred to the working parts of the device.

Blade and Shaft Specifications

The efficiency of blending and mixing tools relies on the precision and durability of the cutting and rotating components. These elements are designed to ensure consistent performance, with particular attention given to their dimensions and materials. The right combination of these features influences the overall operation and longevity of the machine, making them critical factors for achieving desired results in any kitchen environment.

| Component | Material | Dimensions | Key Features |

|---|---|---|---|

| Cutting Blade | Stainless Steel | Diameter: 4.5 inches | Corrosion-resistant, high-precision cutting edge |

| Shaft | Aluminum Alloy | Length: 16 inches | Lightweight, durable, easy to clean |

Handle Design and Material Details

The grip section is a critical aspect of any professional kitchen tool, offering a secure and comfortable hold during prolonged use. A well-thought-out design ensures that the user can maintain control without discomfort, even in demanding environments. This section explores the characteristics of the handle, focusing on its shape, material, and ergonomic features.

| Feature | Description |

|---|---|

| Ergonomics | Shaped to reduce hand fatigue and provide a natural grip, allowing for extended periods of use without strain. |

| Material | Constructed from durable, heat-resistant materials that are easy to clean and maintain, ensuring long-term reliability. |

| Texture | A non-slip surface ensures a firm hold even when hands are wet or greasy, enhancing safety and precision. |

| Weight Distribution | Balanced to minimize effort during operation, providing a lightweight feel without sacrificing control. |

Exploring the Gearbox Mechanism

The gearbox serves as a critical component in numerous machines, facilitating the conversion of energy and motion. Its design is essential for ensuring optimal performance and efficiency, allowing the device to operate smoothly under various conditions.

Understanding the inner workings of this mechanism involves examining several key elements:

- Transmission System: This system plays a vital role in transferring power from the motor to other moving parts, enhancing speed and torque as necessary.

- Gear Arrangement: The configuration of gears affects the overall functionality, influencing the machine’s output and responsiveness.

- Lubrication: Proper lubrication is essential for reducing friction, minimizing wear and tear, and ensuring longevity.

- Housing: The outer casing protects the internal components from external damage, contributing to the durability of the mechanism.

Through a detailed analysis of these components, one can appreciate the complexity and sophistication of the gearbox system. Each part works in harmony, contributing to the efficient operation of the equipment.

Sealing and Gasket Elements

In any mechanical system, the integrity of connections plays a crucial role in maintaining optimal performance. The components responsible for creating tight seals are essential for preventing leaks and ensuring that the machinery operates efficiently. This section delves into the various types of sealing solutions and gasket materials used in these systems.

Types of Sealing Solutions

- O-rings: Commonly used for their versatility and ability to accommodate different pressures.

- Flat gaskets: Effective in creating a seal between flat surfaces, often made from materials such as rubber or fiber.

- Cylindrical seals: Typically found in rotating applications, designed to minimize friction and wear.

- Composite seals: Combine multiple materials to achieve enhanced performance under extreme conditions.

Material Considerations

Choosing the right material for sealing elements is vital for durability and effectiveness. Factors to consider include:

- Temperature resistance: Ensuring the material can withstand operational heat.

- Chemical compatibility: Selecting substances that will not degrade when exposed to various fluids.

- Pressure tolerance: Evaluating how well the material can maintain its integrity under pressure.

Understanding the importance of these sealing components and the materials used can significantly impact the longevity and reliability of mechanical systems.

Power Cord and Electrical Connections

This section delves into the essential components that facilitate electrical supply and connectivity in the appliance. Understanding these elements is crucial for ensuring optimal performance and safety during operation.

Power Cord Specifications

The electrical supply line is a vital component that connects the device to the main power source. It must adhere to specific standards to ensure durability and efficient energy transfer. Using a cord with the appropriate gauge and insulation type is imperative for maintaining safety during usage. Users should also check for any signs of wear or damage regularly, as this could impact the overall functionality.

Connection Points and Safety Features

The points where the electrical line interfaces with the machine are designed for seamless connectivity. These junctions often include protective features that prevent overload and short circuits. It is important to familiarize oneself with these areas, ensuring they are free from debris and functioning correctly. Regular maintenance checks can help in identifying potential issues before they escalate.

Maintenance Tips for Longevity

To ensure the extended lifespan and optimal performance of your kitchen equipment, regular upkeep is essential. Implementing a few simple practices can significantly enhance durability and efficiency, allowing you to maximize your investment.

Regular Cleaning

Maintaining a clean working environment is crucial. After each use, thoroughly cleanse all components to prevent residue buildup. Utilize appropriate cleaning agents and tools to avoid damage to surfaces, ensuring all areas are free from food particles and grease.

Routine Inspections

Conduct periodic checks of the machinery to identify any signs of wear or malfunction. Pay close attention to moving parts and electrical connections. Addressing minor issues promptly can prevent more significant problems down the line. Additionally, consulting the user manual for specific maintenance recommendations can provide valuable guidance.

Common Replacement Parts for the MP 450

In any high-performance kitchen appliance, certain components may require attention over time due to wear and tear from frequent use. Understanding which elements are most commonly replaced can help maintain optimal functionality and prolong the lifespan of the equipment. This section highlights key components that users often need to consider when servicing their machines.

Blades and Cutting Discs

One of the most frequently replaced components in food processing equipment are the blades and cutting discs. These essential elements are responsible for achieving precise cuts and consistent texture in various ingredients. Regular inspection for signs of dullness or damage can ensure that food preparation remains efficient and effective.

Motor and Drive Belts

The motor and associated drive belts play a crucial role in the overall operation of the device. Over time, belts may become worn or stretched, leading to decreased performance. Ensuring that these components are in good condition is vital for reliable operation and to avoid unexpected breakdowns.

Troubleshooting Issues with the Unit

When operating a food preparation appliance, encountering difficulties can disrupt workflow. Understanding common problems and their solutions is essential for maintaining efficiency and ensuring the device functions optimally.

Here are some frequent issues and tips for resolving them:

- Device Won’t Start:

- Check the power source to ensure it’s plugged in and operational.

- Inspect the main switch for proper engagement.

- Verify that safety mechanisms are not engaged.

- Unusual Noises:

- Examine the blades and attachments for any debris or blockages.

- Ensure all components are securely fastened.

- Listen for any abnormal sounds that may indicate a mechanical issue.

- Inconsistent Performance:

- Check the settings to confirm they are properly adjusted for the intended task.

- Inspect the motor for overheating or signs of wear.

- Replace any worn-out or damaged components as necessary.

By following these troubleshooting steps, users can effectively address and resolve issues, ensuring the unit continues to operate efficiently. Regular maintenance and timely attention to problems can extend the lifespan of the appliance and improve overall performance.

Choosing the Right Accessories

Selecting the appropriate add-ons for your kitchen equipment can significantly enhance its functionality and versatility. Understanding the various options available is essential to ensure you make informed decisions that cater to your culinary needs.

Compatibility is a crucial factor to consider when choosing attachments. Ensure that the accessories you select are designed to work seamlessly with your machine. This compatibility will prevent potential operational issues and enhance overall performance.

Additionally, evaluate the specific functions each accessory provides. Whether you need attachments for slicing, shredding, or mixing, identifying your primary cooking tasks will guide you in selecting the most beneficial tools for your culinary endeavors.

Lastly, consider the material quality of the accessories. High-quality materials not only ensure durability but also contribute to the safety and hygiene of food preparation. Investing in reliable attachments will ultimately save you time and money in the long run.