The intricate world of painting tools is essential for achieving high-quality finishes in various applications. This section aims to illuminate the essential elements that make up these specialized instruments, emphasizing their roles and interconnections. By exploring these components, users can gain valuable insights into their operation and maintenance.

Familiarity with these elements not only enhances performance but also extends the lifespan of the equipment. Each component serves a unique function, contributing to the overall efficiency of the tool. Understanding how these elements interact is crucial for optimizing usage and ensuring satisfactory results in every project.

Whether you are a seasoned professional or a novice, knowledge of these critical elements equips you with the expertise to make informed decisions regarding your equipment. This understanding is the first step towards mastering the art of painting, enabling you to achieve superior outcomes with confidence.

This section will provide a comprehensive overview of high-quality painting equipment, emphasizing their components and functionality. Understanding these tools is essential for achieving optimal results in various painting tasks, whether in professional settings or DIY projects.

Key Components of Painting Equipment

- Fluid Nozzle

- Air Cap

- Trigger Mechanism

- Paint Cup

- Adjustment Controls

Importance of Each Component

Each element plays a critical role in the performance and efficiency of the equipment. The fluid nozzle is responsible for delivering the paint evenly, while the air cap regulates the airflow, ensuring a fine mist for an impeccable finish. The trigger mechanism provides user control over the paint flow, making it essential for precision work.

Maintenance Tips for Longevity

- Regular cleaning after use

- Inspecting for wear and tear

- Proper storage to avoid damage

Common Issues and Troubleshooting

- Clogs in the nozzle

- Inconsistent spray patterns

- Leaking from the cup

Choosing the Right Equipment for Your Needs

Different tasks require specific types of painting tools. Factors such as the viscosity of the paint and the desired finish will influence the choice of equipment.

Understanding Compatibility with Paint Types

- Acrylics

- Enamels

- Water-based coatings

Safety Precautions While Operating

It is crucial to adhere to safety protocols, including wearing protective gear and ensuring proper ventilation during use to minimize health risks.

Advanced Features in Modern Equipment

- Electronic controls for precise adjustments

- Ergonomic designs for enhanced comfort

- Lightweight materials for easy handling

Training and Skill Development

Gaining proficiency in using these tools often requires practice and training. Workshops and online tutorials can provide valuable guidance.

Conclusion

In summary, understanding the various components and functionalities of these sophisticated tools can significantly enhance the quality of work produced, making it essential for both enthusiasts and professionals alike.

Key Components of Spray Guns

Understanding the essential elements of a fluid application tool is crucial for optimal performance and efficiency. These devices comprise various components that work together to ensure a smooth and even application of liquids, whether for coatings, paints, or other substances. This section delves into the fundamental elements that constitute such instruments.

1. Fluid Delivery System

The fluid delivery system is integral to the function of the tool, as it facilitates the transfer of the liquid from the container to the nozzle. This system typically includes a reservoir, tubing, and a mechanism to regulate flow. Proper maintenance of this component is essential for achieving consistent results.

2. Atomization Mechanism

Another critical aspect is the atomization mechanism, which breaks down the liquid into fine particles, allowing for a uniform distribution. This feature is influenced by factors such as air pressure and nozzle design. A well-designed atomization system contributes significantly to the quality of the finish.

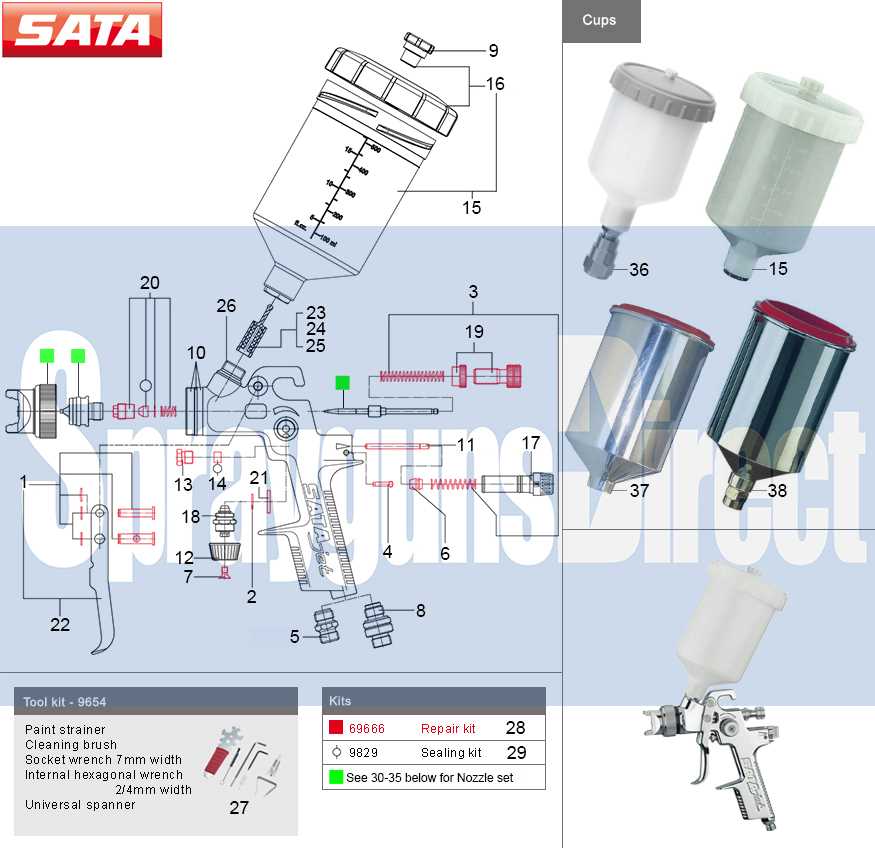

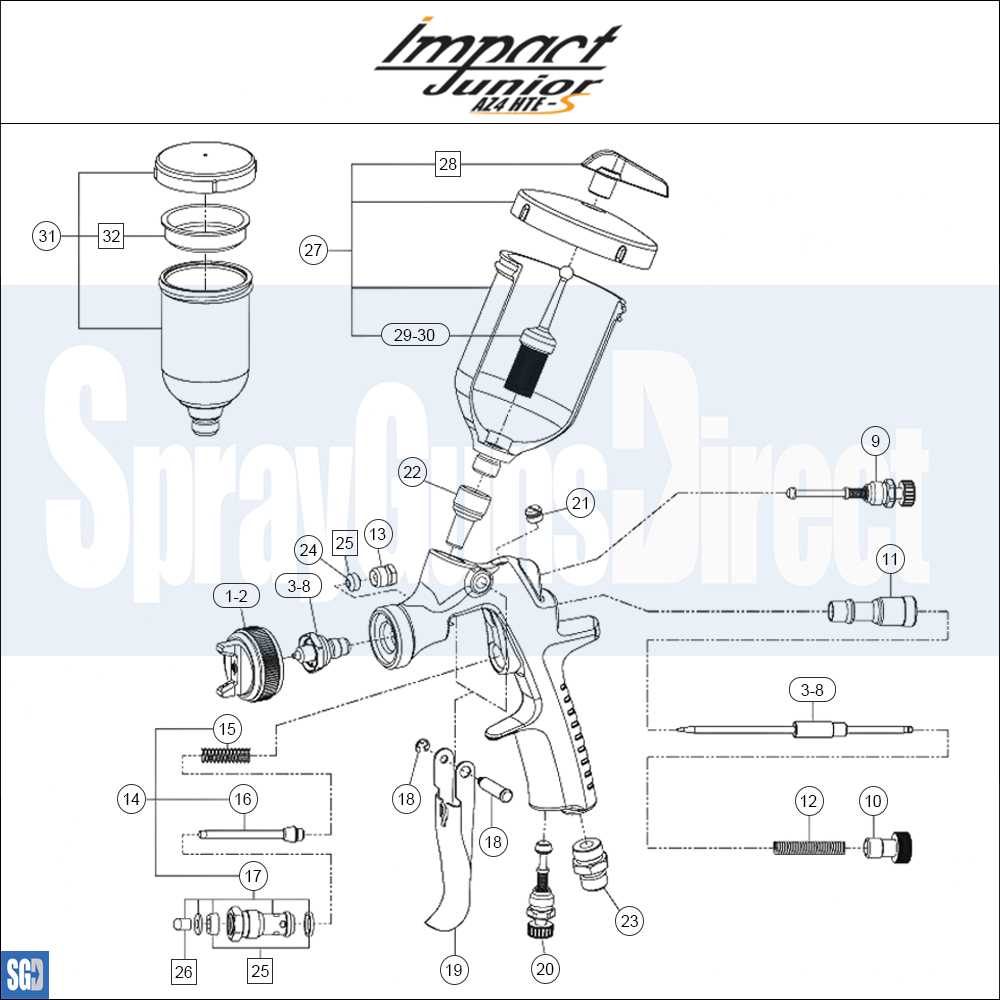

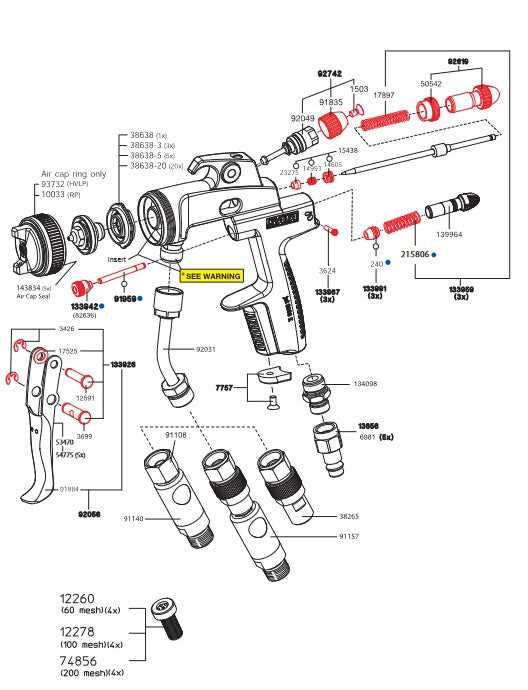

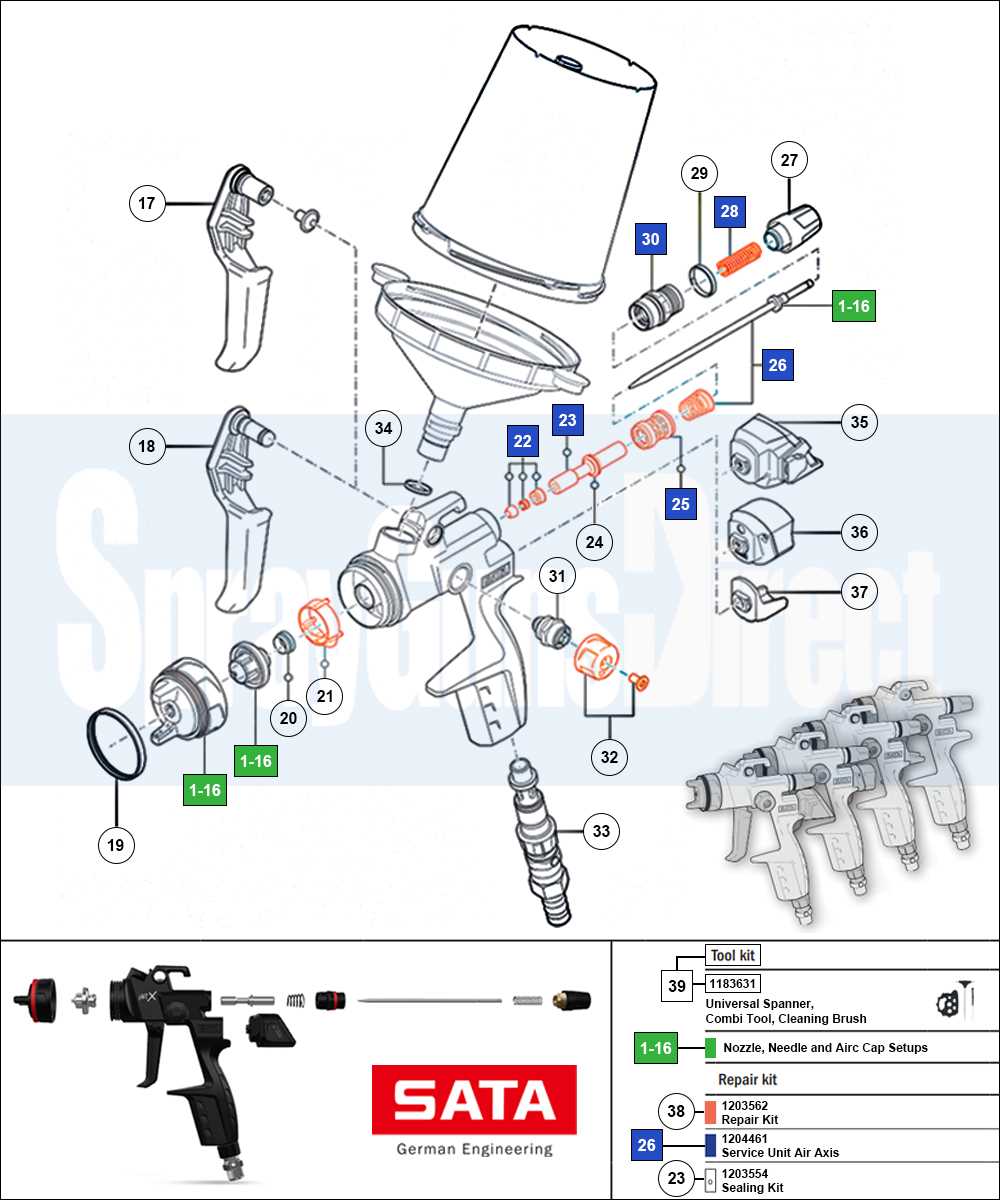

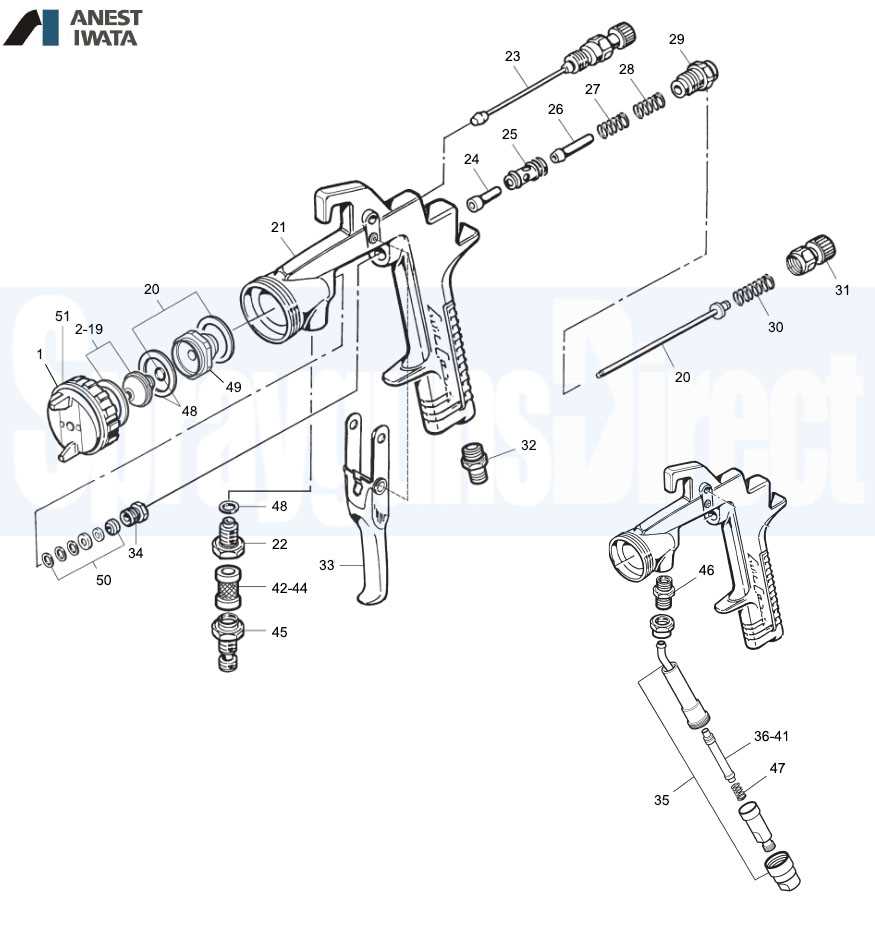

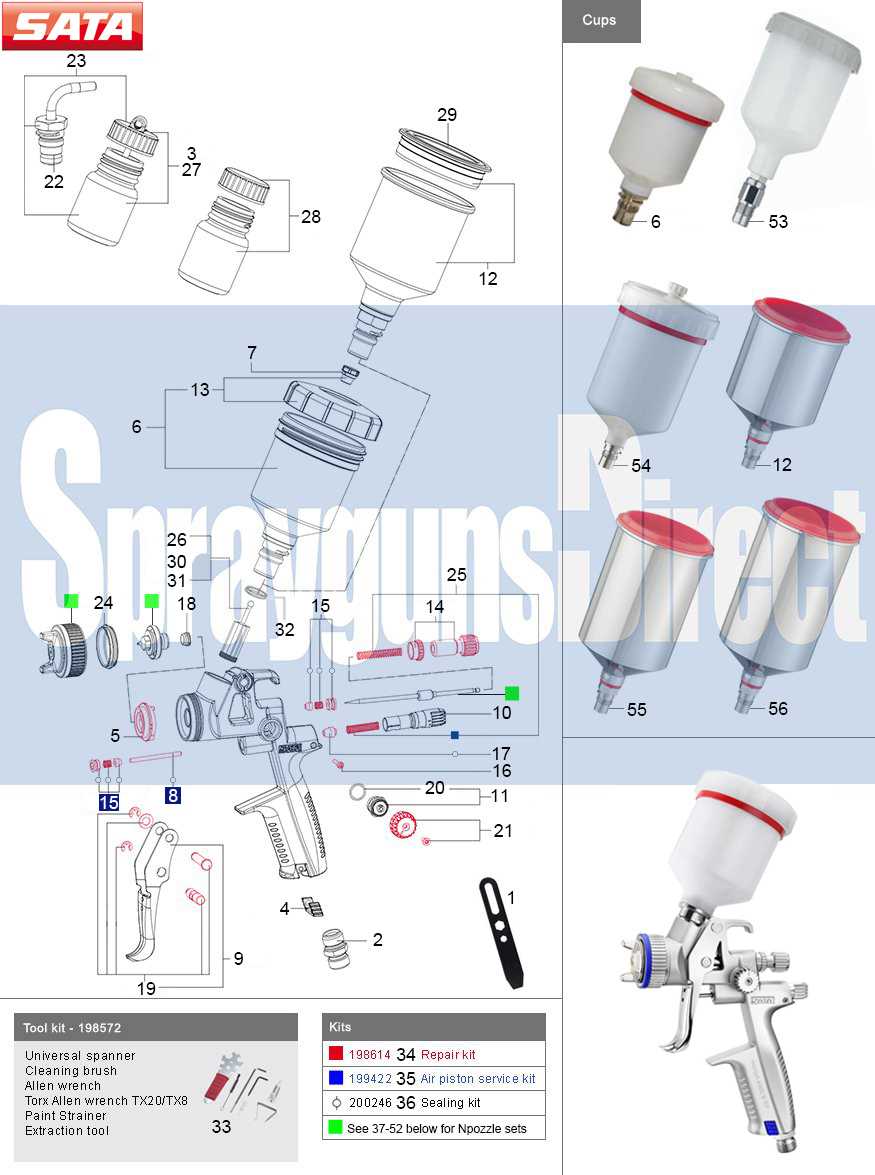

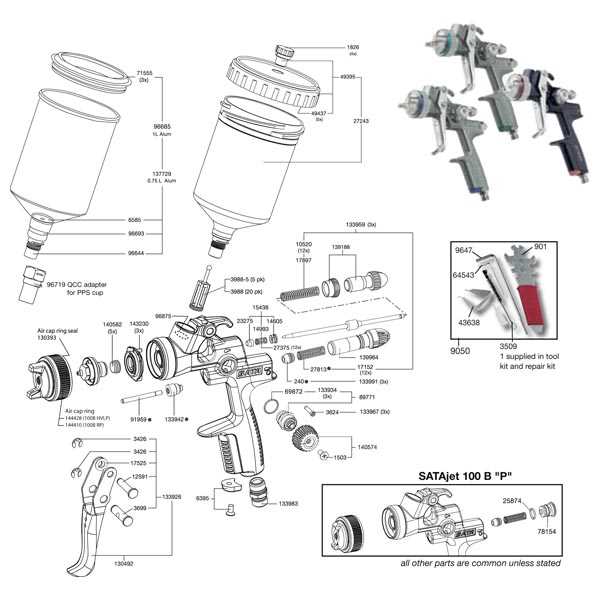

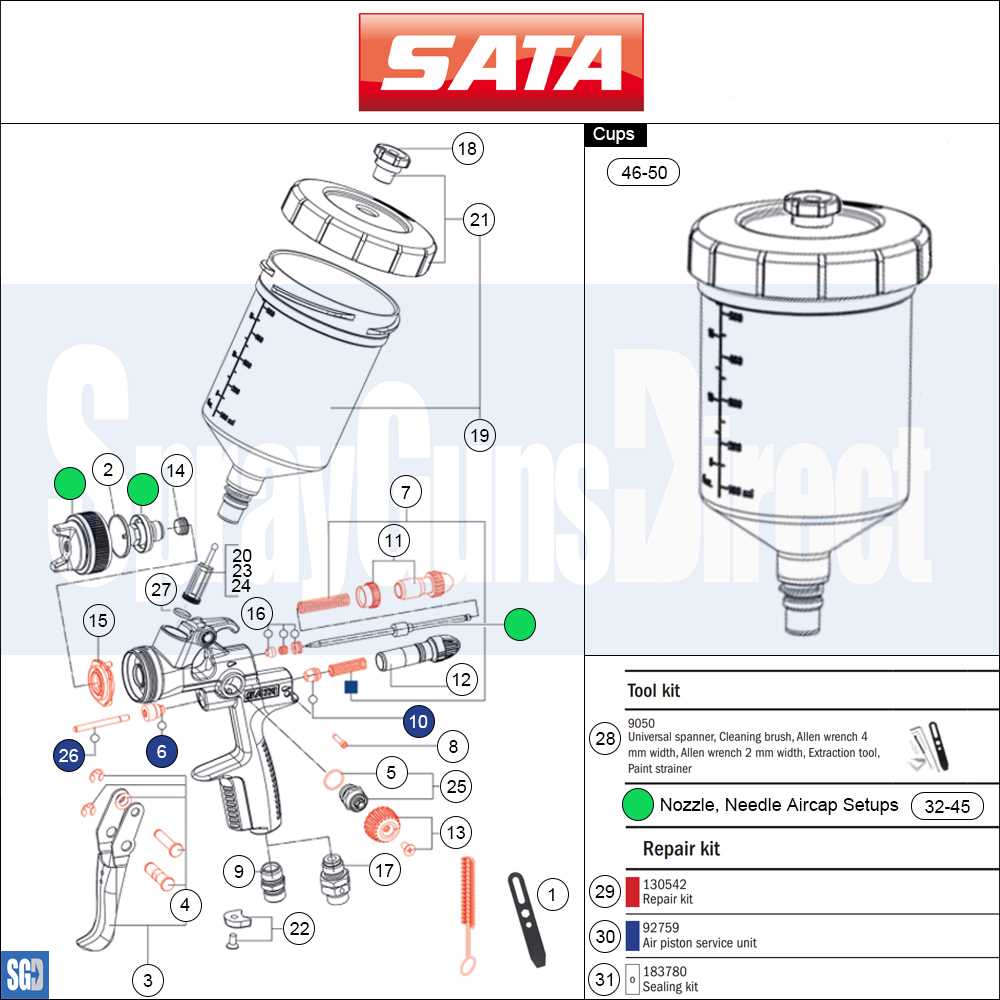

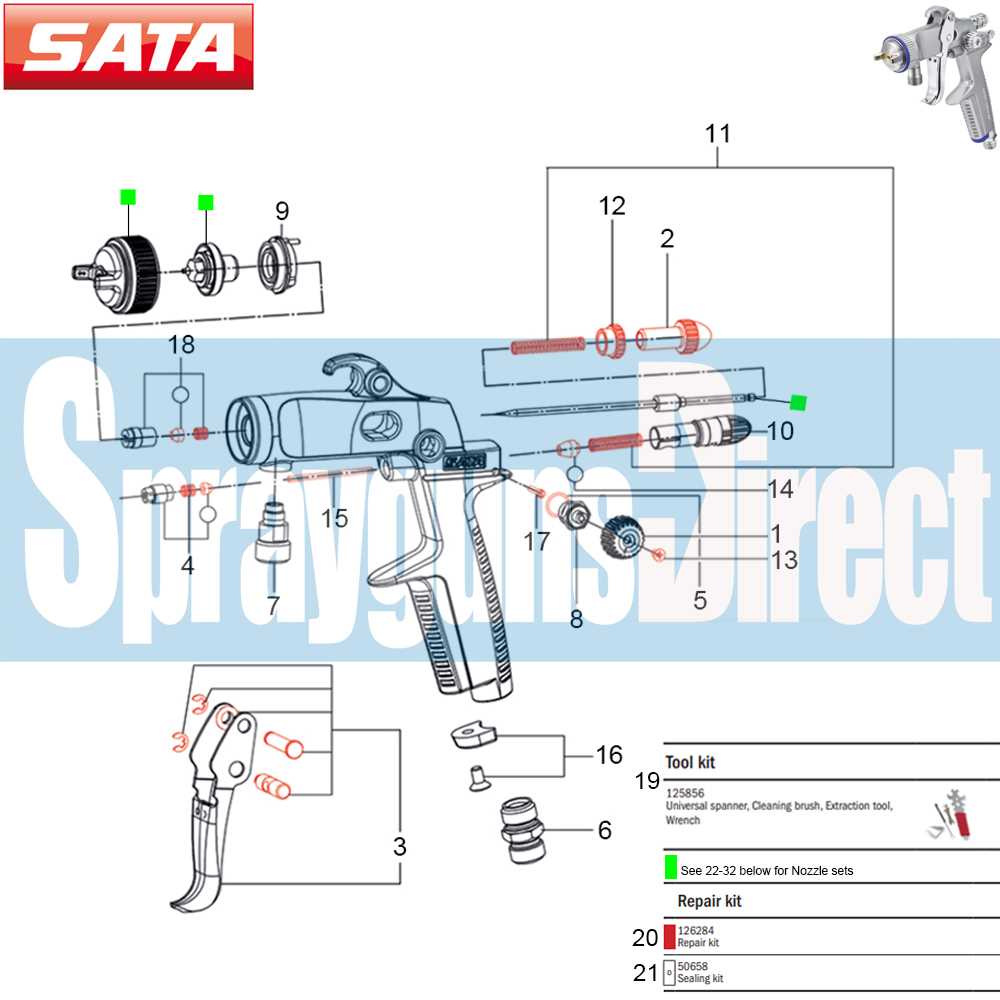

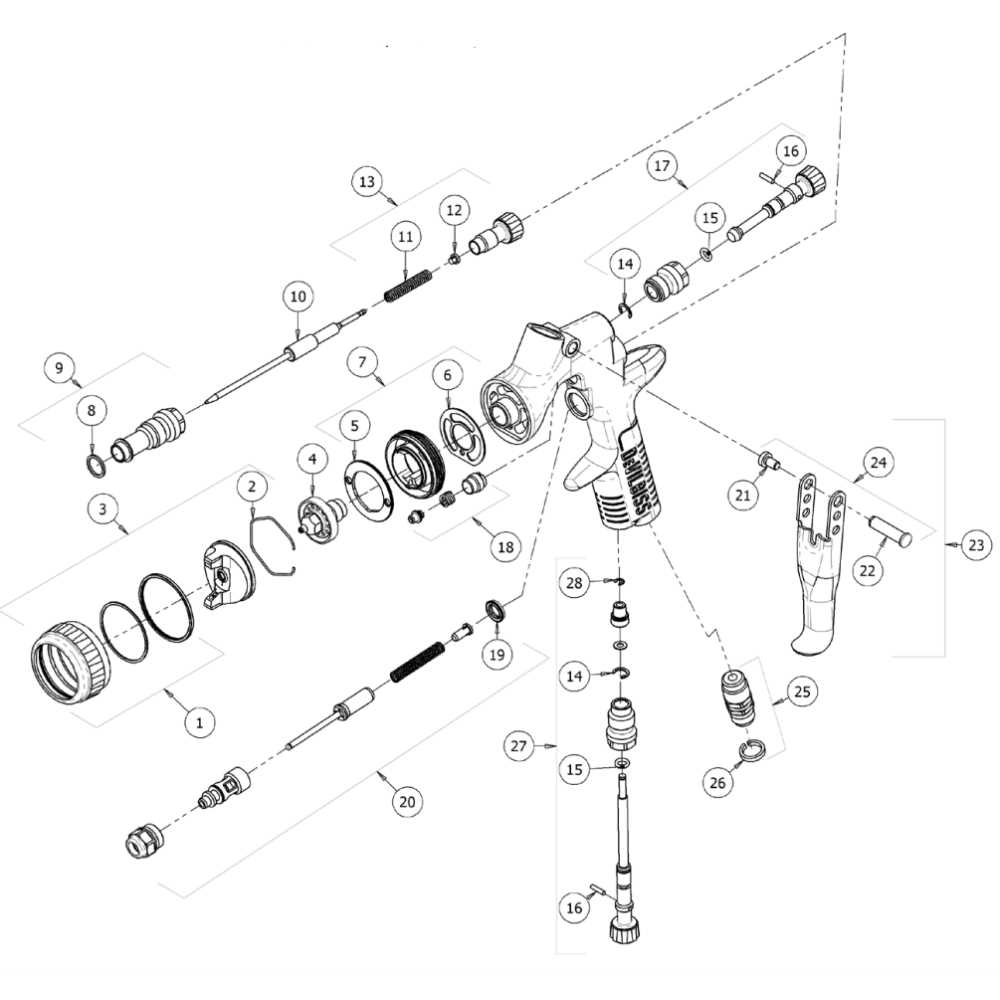

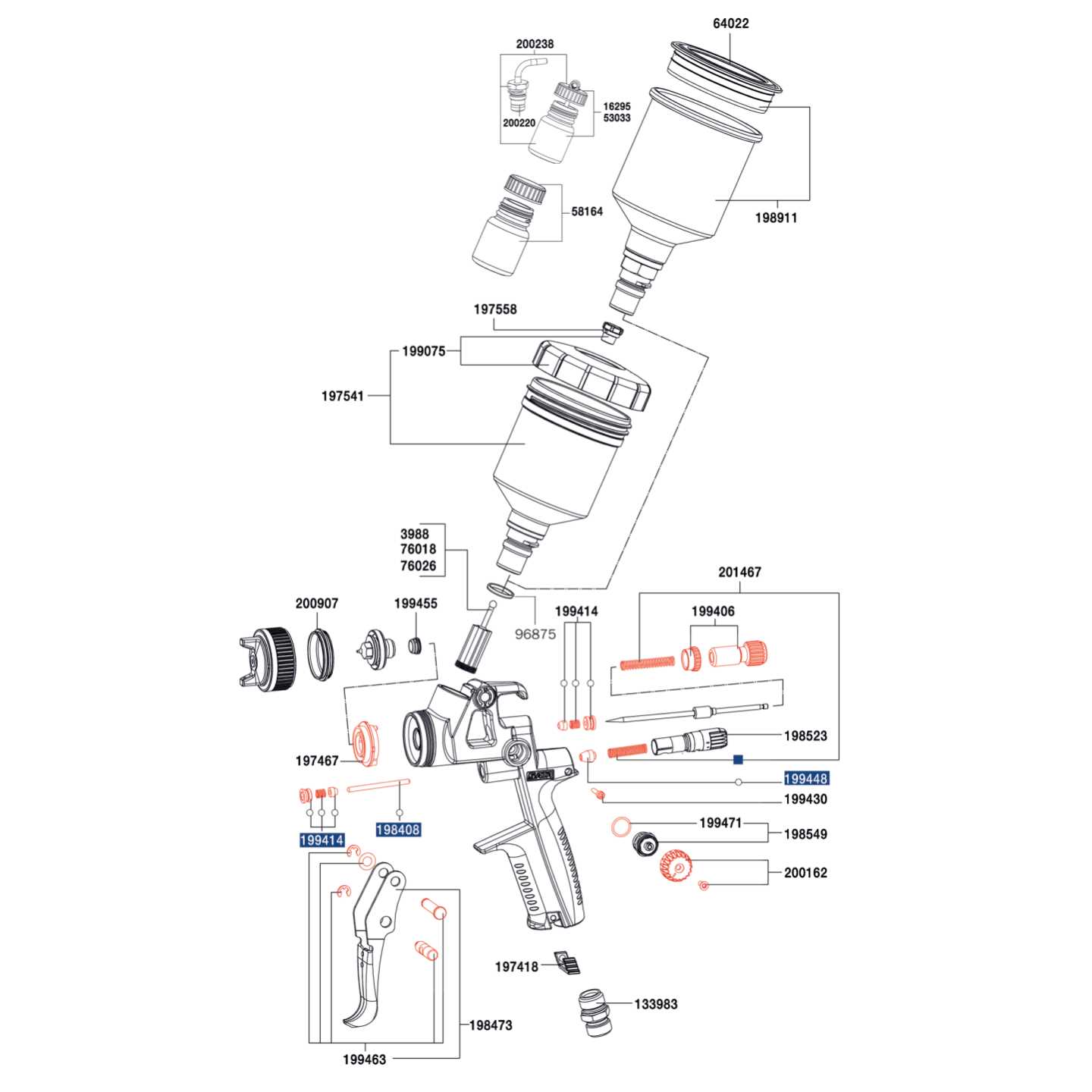

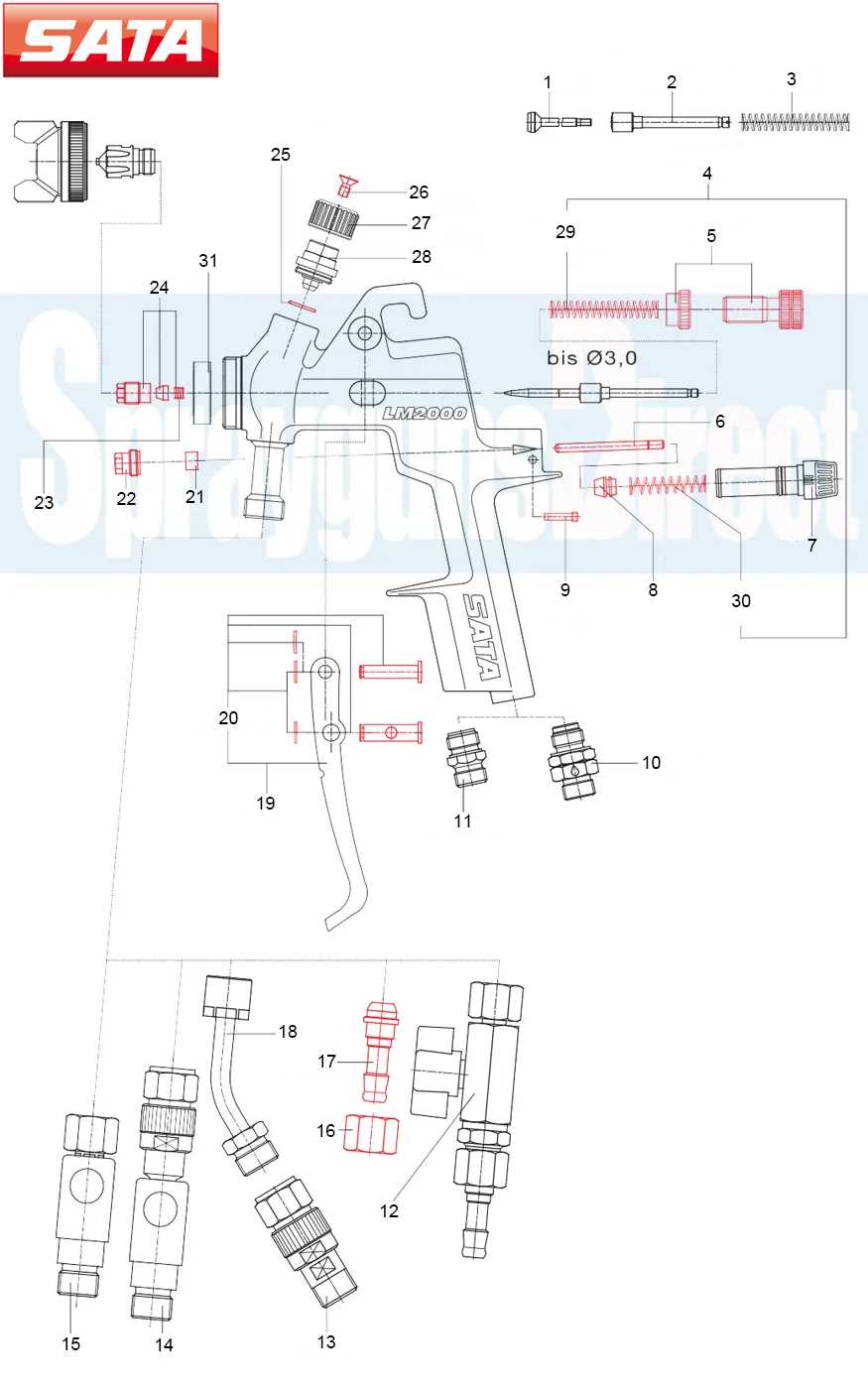

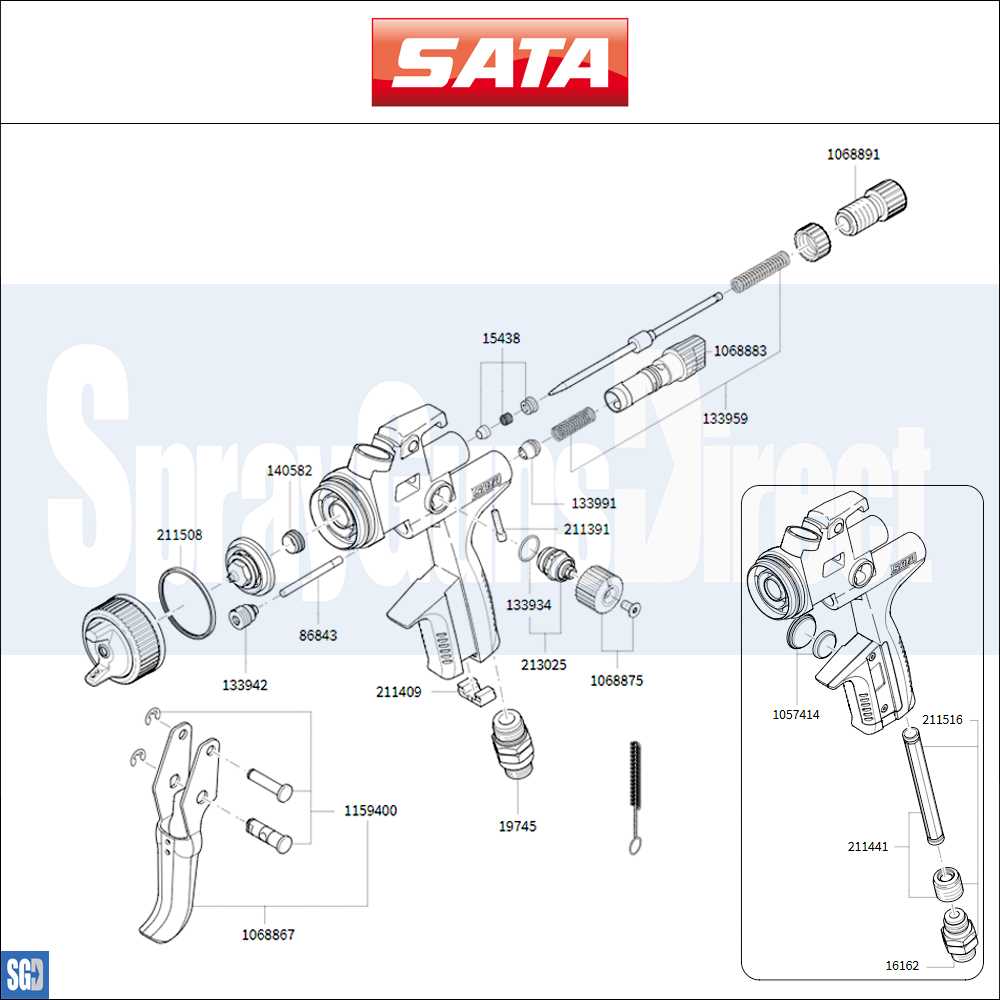

Understanding the Parts Diagram

This section aims to provide a clear overview of the various components involved in the functioning of a particular equipment model. A well-structured representation allows users to identify and comprehend each element’s role within the assembly, facilitating maintenance and troubleshooting tasks. By examining the configuration of individual components, one can gain insights into the operational efficiency of the entire mechanism.

Key Components Overview

Each component plays a vital role in ensuring optimal performance. The following table highlights the main elements along with their respective functions:

| Component Name | Function |

|---|---|

| Nozzle | Controls the flow and pattern of the output. |

| Trigger | Regulates the release of the material. |

| Body | Houses internal components and provides structure. |

| Air Cap | Mixes air with the material for optimal atomization. |

| Fluid Control Knob | Adjusts the material flow rate for desired output. |

Importance of Understanding Components

Familiarity with each element not only aids in effective operation but also enhances the user’s ability to troubleshoot potential issues. A comprehensive grasp of the internal workings empowers users to make informed decisions regarding maintenance and repairs, ultimately extending the lifespan of the equipment.

Functionality of Each Component

Understanding the role of each element in a fluid application tool is crucial for optimal performance and maintenance. Each component contributes to the overall functionality, ensuring a smooth operation and effective application of materials. Below, we explore the main elements and their specific functions.

Essential Elements and Their Roles

- Trigger: This mechanism activates the flow of liquid, allowing the user to control the application precisely.

- Nozzle: The nozzle is responsible for shaping and directing the fluid stream, affecting the width and pattern of application.

- Fluid Cup: This container holds the liquid, facilitating easy refilling and monitoring of material levels.

- Air Cap: The air cap regulates the airflow, which influences the atomization of the material being applied.

- Needle: The needle controls the amount of liquid dispensed, enabling fine adjustments for different applications.

Supporting Components

- Air Hose: This component delivers compressed air from the source to the tool, necessary for proper operation.

- Pressure Regulator: It maintains consistent air pressure, crucial for uniform application results.

- Cleaning Kit: Essential for maintenance, ensuring that components remain free from blockages and function effectively.

Common Issues and Solutions

When using a high-performance application tool, users may encounter various challenges that can affect the quality of their work. Understanding these common problems and their solutions is essential for maintaining efficiency and achieving optimal results.

One frequent issue is uneven application, which can result from improper settings or blockages in the flow mechanism. To resolve this, it is advisable to check and adjust the pressure settings according to the manufacturer’s recommendations. Additionally, inspecting for any obstructions in the nozzle or hose can help restore a consistent flow.

Another concern is the buildup of residue, which can lead to reduced performance over time. Regular cleaning and maintenance are crucial in preventing this issue. Users should ensure that all components are thoroughly cleaned after each use, focusing on areas prone to accumulation, such as the nozzle and cup.

Lastly, inconsistencies in finish may arise from incorrect material viscosity or unsuitable spray techniques. It is important to test materials beforehand and adjust dilution as necessary. Practicing different application methods can also enhance proficiency and ensure a flawless finish.

Maintenance Tips for Spray Guns

Regular upkeep of your painting equipment is essential to ensure optimal performance and longevity. Implementing proper care practices can enhance efficiency and reduce the likelihood of issues during operation. Here are some key suggestions to maintain your equipment effectively.

- Clean After Use: Always clean your equipment immediately after each use to prevent buildup and clogs. Use appropriate solvents to remove any residual material.

- Inspect Regularly: Check for signs of wear or damage periodically. Pay attention to seals and O-rings, as these components are critical for maintaining pressure and preventing leaks.

- Lubricate Moving Parts: Apply lubricant to all moving components to ensure smooth operation. This will also help reduce friction and wear over time.

- Store Properly: Keep your equipment in a clean, dry place. Use protective covers to shield against dust and debris when not in use.

- Follow Manufacturer Guidelines: Refer to the user manual for specific maintenance instructions and recommendations tailored to your equipment.

By following these maintenance practices, you can extend the lifespan of your painting equipment and ensure consistent performance for all your projects.

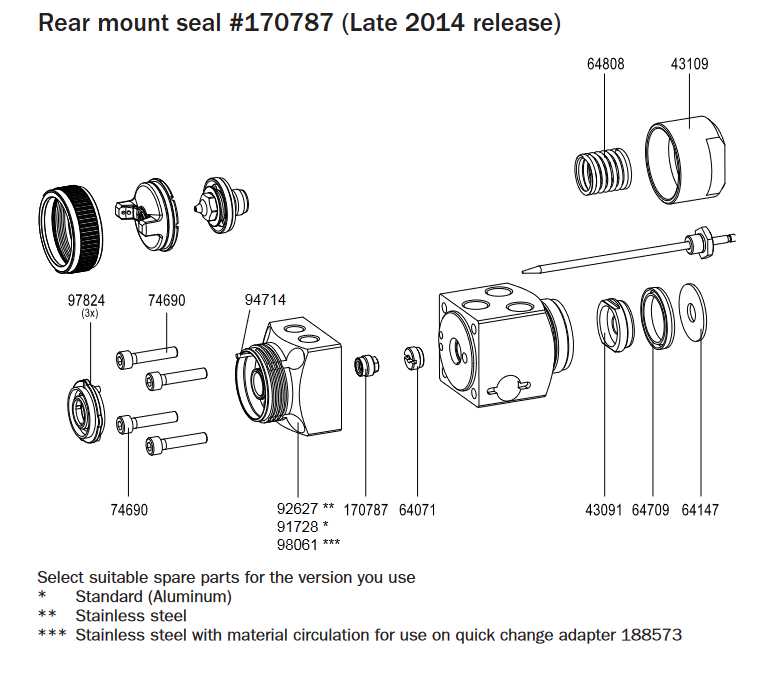

Choosing the Right Replacement Parts

When it comes to maintaining your equipment, selecting the appropriate components is crucial for optimal performance. Ensuring compatibility and quality can enhance efficiency and extend the lifespan of your tools. This section will guide you through essential considerations when replacing specific elements of your apparatus.

Factors to Consider

- Compatibility: Always check that the new components are compatible with your existing setup. Mismatched parts can lead to malfunctions.

- Quality: Opt for high-quality materials that withstand wear and tear. Investing in superior components pays off in the long run.

- Manufacturer Recommendations: Follow the guidelines provided by the manufacturer to ensure that you select the right components for your needs.

- Reviews and Ratings: Research customer feedback and expert reviews to gauge the performance of specific components.

Where to Find Replacement Components

- Authorized Distributors: Purchase from trusted distributors who specialize in equipment supplies.

- Online Retailers: Explore reputable online platforms that offer a variety of options.

- Local Hardware Stores: Visit nearby stores that carry a selection of necessary items for equipment maintenance.

How to Assemble Spray Gun Parts

Assembling a high-quality application tool requires careful attention to detail and a methodical approach. This section provides a comprehensive guide to effectively bringing together various components, ensuring optimal functionality and performance.

Preparation Steps

- Gather all necessary components before starting the assembly process.

- Ensure that each element is clean and free from debris to avoid contamination.

- Familiarize yourself with the function of each individual element for a smoother assembly experience.

Assembly Process

- Begin by securing the base and attaching it to the main body, ensuring a snug fit.

- Install the nozzle by aligning it properly and tightening it to avoid leaks.

- Connect the air inlet, ensuring that it is securely fastened to maintain proper airflow.

- Attach the trigger mechanism, ensuring it operates smoothly without obstruction.

- Finally, perform a thorough inspection to confirm all connections are secure and that there are no loose components.

Safety Precautions When Using Guns

Ensuring safety during the operation of spraying devices is essential for protecting both the user and the surrounding environment. Adhering to proper guidelines minimizes risks and enhances efficiency. It is crucial to be aware of potential hazards and implement effective measures to prevent accidents.

Protective Gear

Wearing appropriate protective equipment is vital. This includes safety goggles, gloves, and masks to shield against harmful substances and particles. Ensuring that all gear fits properly will provide the best defense against exposure.

Work Environment

Maintaining a clean and organized workspace can significantly reduce the likelihood of accidents. Ensure proper ventilation to disperse fumes and use barriers to protect others in the vicinity. Always follow the manufacturer’s instructions regarding the setup and operation of the equipment.

Comparative Analysis of Different Models

This section provides a detailed comparison of various models available in the market, focusing on their unique features, performance, and suitability for different applications. By examining multiple options, users can make informed decisions that align with their specific needs and preferences.

The analysis encompasses several critical aspects:

- Design and Ergonomics: The physical structure and user comfort play a vital role in the overall experience.

- Performance Metrics: Evaluating flow rate, pressure settings, and overall efficiency helps determine effectiveness.

- Maintenance Requirements: Understanding the upkeep and ease of cleaning is essential for long-term use.

- Compatibility: Assessing compatibility with various materials and finishes is crucial for diverse applications.

Below is a brief overview of key models:

-

Model A:

Known for its lightweight construction and ease of handling, this option excels in precision tasks.

-

Model B:

This variant is appreciated for its robust build and high durability, making it ideal for industrial settings.

-

Model C:

Features advanced technology that enhances performance and efficiency, suitable for professionals seeking high-quality results.

In conclusion, understanding the distinctions among these models allows users to select the most suitable option tailored to their requirements.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components used in various equipment. Understanding the essential elements can significantly enhance the functionality and longevity of your tools. Below are some frequently encountered questions that users often have regarding these crucial items.

What is the purpose of each component?

Each element plays a specific role in ensuring optimal performance. From controlling the flow to maintaining pressure, knowing their functions helps in troubleshooting and repairs.

How do I identify the right component for my needs?

Identifying the correct item involves understanding your equipment’s specifications and compatibility. Refer to manuals or consult with professionals for guidance.

What are the signs of wear and tear?

Common indicators include leaks, inconsistent output, or unusual noises during operation. Regular inspections can help in early detection and replacement of worn items.

Can I replace components myself?

Many users can perform replacements with basic tools and instructions. However, for complex replacements, it may be advisable to seek professional assistance to avoid damage.

Where can I purchase high-quality components?

Quality items can be sourced from specialized retailers or manufacturers. Always ensure that you are buying from reputable sources to guarantee authenticity and durability.