When it comes to maintaining a well-kept lawn, having a comprehensive understanding of the essential elements of your machinery is crucial. Each component plays a significant role in ensuring the equipment operates efficiently, making familiarity with these elements beneficial for any user.

In this section, we will explore the intricate relationships between various components of your machine. By examining how each part contributes to the overall functionality, you will gain valuable insights into proper maintenance and troubleshooting techniques.

Knowledge of these essential elements empowers you to make informed decisions, whether it’s for repairs or enhancements. Recognizing the interplay of these mechanisms can lead to improved performance and longevity of your equipment, ultimately resulting in a healthier and more vibrant lawn.

This section aims to provide a comprehensive understanding of a specific model’s features and components. By exploring the essential elements, readers can gain insights into the functionality and design of the machine.

Key Features of the Model

Highlighting the main characteristics, including:

- Engine specifications

- Size and weight considerations

- Cutting mechanisms

- Control features

Importance of Understanding Components

Grasping the individual elements of the machine allows users to:

- Identify replacement needs

- Enhance maintenance practices

- Improve operational efficiency

Overall, this plan serves as a foundation for deeper exploration into the specifics and intricacies of the machine.

Key Features of the Scotts 1642H

This model is designed with several standout attributes that enhance its functionality and user experience. From its innovative design to its advanced features, this equipment is tailored to meet the diverse needs of its users, making it a reliable choice for various tasks.

Innovative Design

- Ergonomic controls for comfortable operation

- Streamlined structure for improved maneuverability

- Durable materials ensure longevity and resilience

Enhanced Performance

- Efficient engine providing optimal power

- Adjustable settings to cater to different requirements

- Advanced technology for superior performance in various conditions

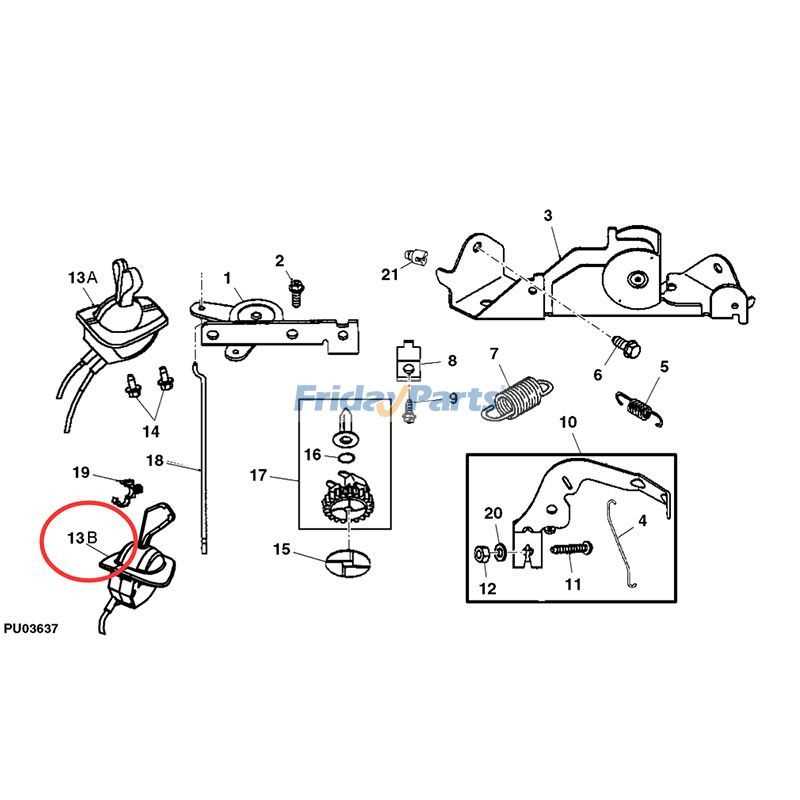

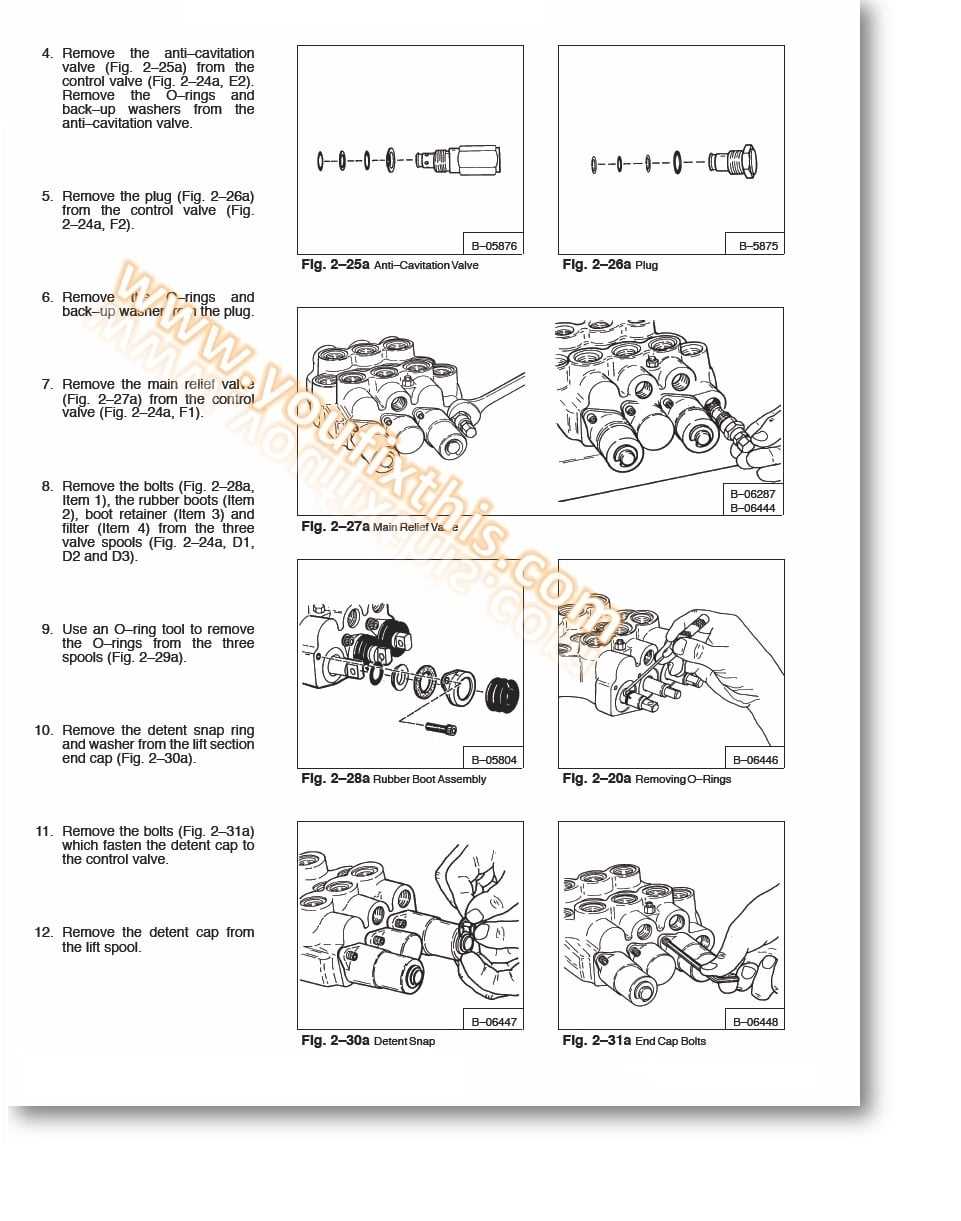

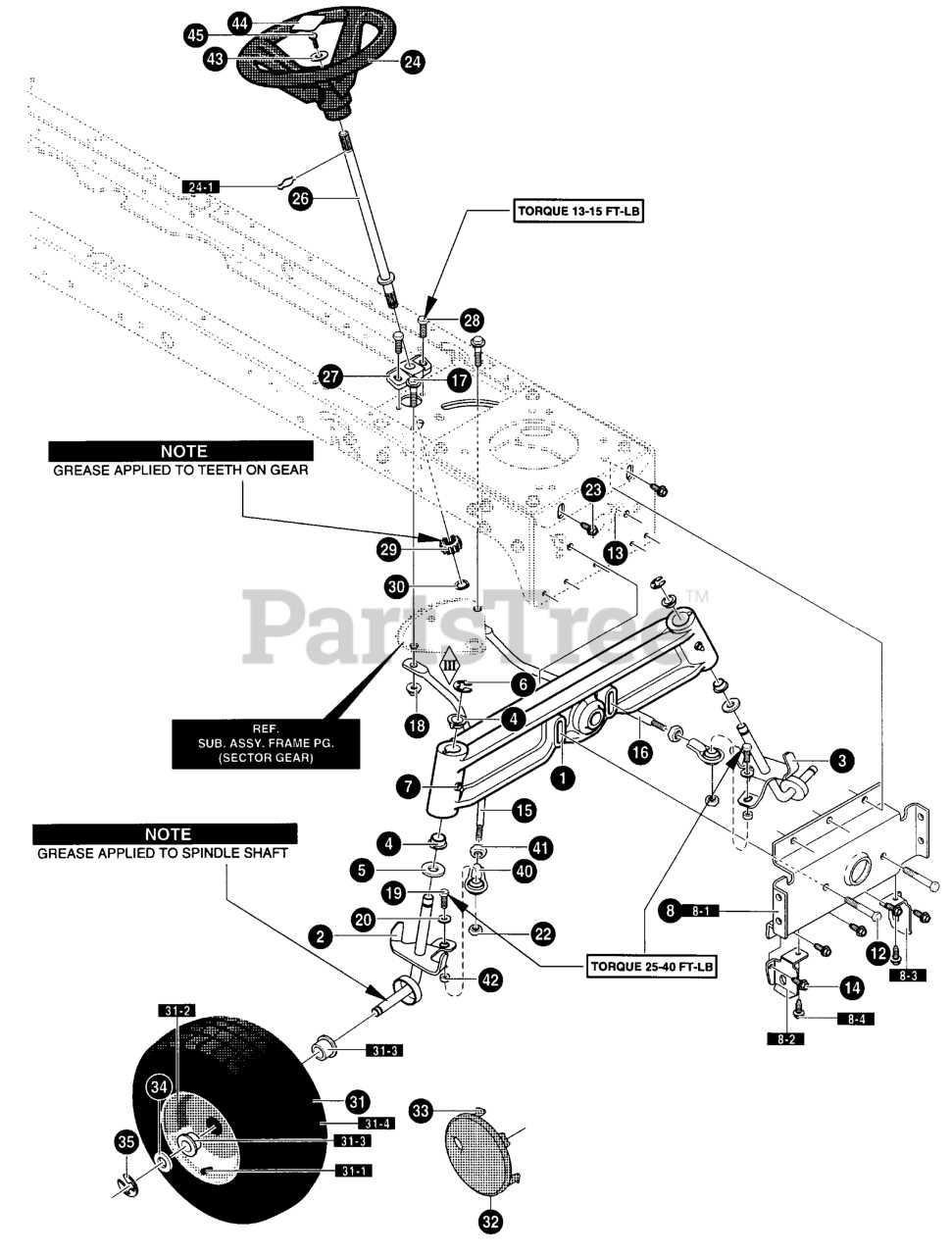

Understanding the Parts Diagram

This section aims to clarify the visual representation of various components within a particular model. By analyzing this schematic, one can gain insights into the arrangement and relationships between different elements, facilitating better maintenance and repairs.

Key Features of the Representation

- Visual Clarity: Each component is distinctly labeled, ensuring easy identification.

- Color Coding: Different hues may indicate specific categories or functions, enhancing understanding.

- Grouping: Related parts are often clustered together, demonstrating their interconnections.

Benefits of Utilizing the Visual Guide

- Enhanced Repair Efficiency: Quickly locate and assess components needing attention.

- Improved Understanding: Gain a deeper knowledge of how different parts interact.

- Accurate Maintenance: Follow the visual guide to ensure all elements are properly managed during upkeep.

Essential Components of the Lawn Mower

The effectiveness of a grass-cutting machine relies on its key elements, each playing a significant role in ensuring optimal performance. Understanding these crucial components can aid in maintenance and enhance the overall lifespan of the device.

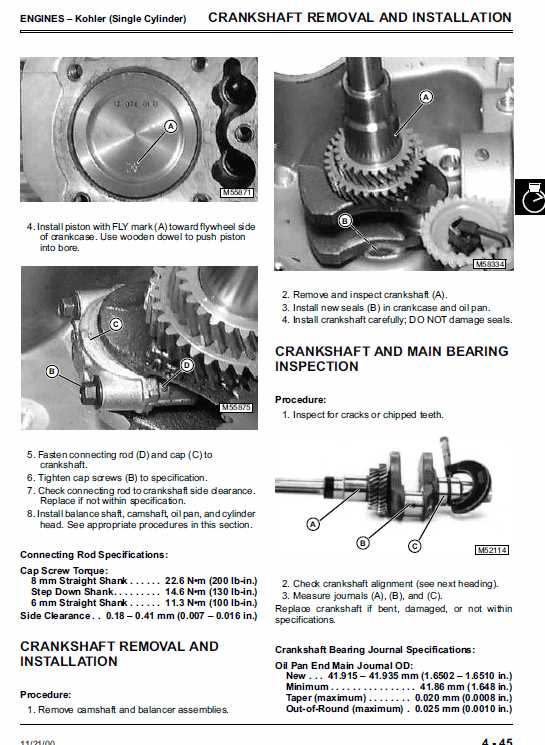

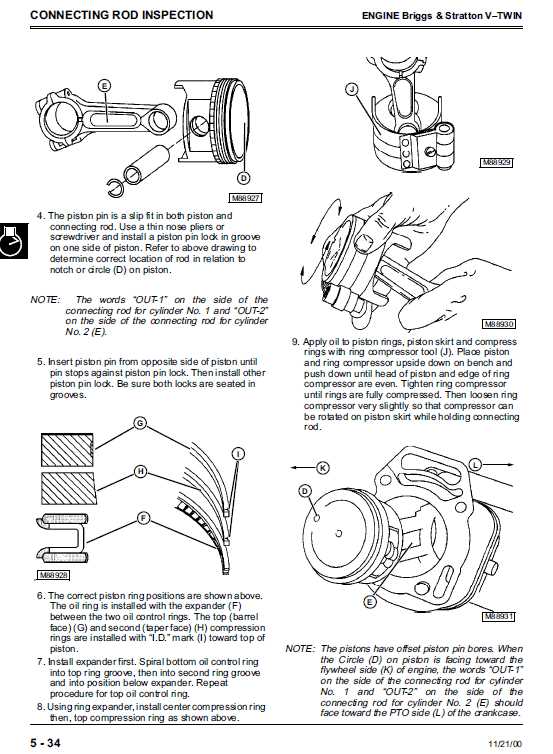

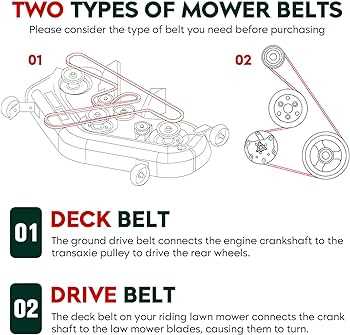

Motor and Drive System

The motor serves as the powerhouse, providing the necessary energy to drive the blades. The drive system, which includes belts and gears, transmits this power efficiently, allowing for smooth operation. Regular checks on these parts are vital to prevent any performance issues.

Cutting Mechanism

The cutting mechanism is fundamental to achieving a neat lawn. This includes the blades, which should be sharp and well-aligned for effective cutting. Routine sharpening and replacement of worn-out blades are essential for maintaining cutting efficiency and ensuring a clean finish.

How to Interpret the Diagram

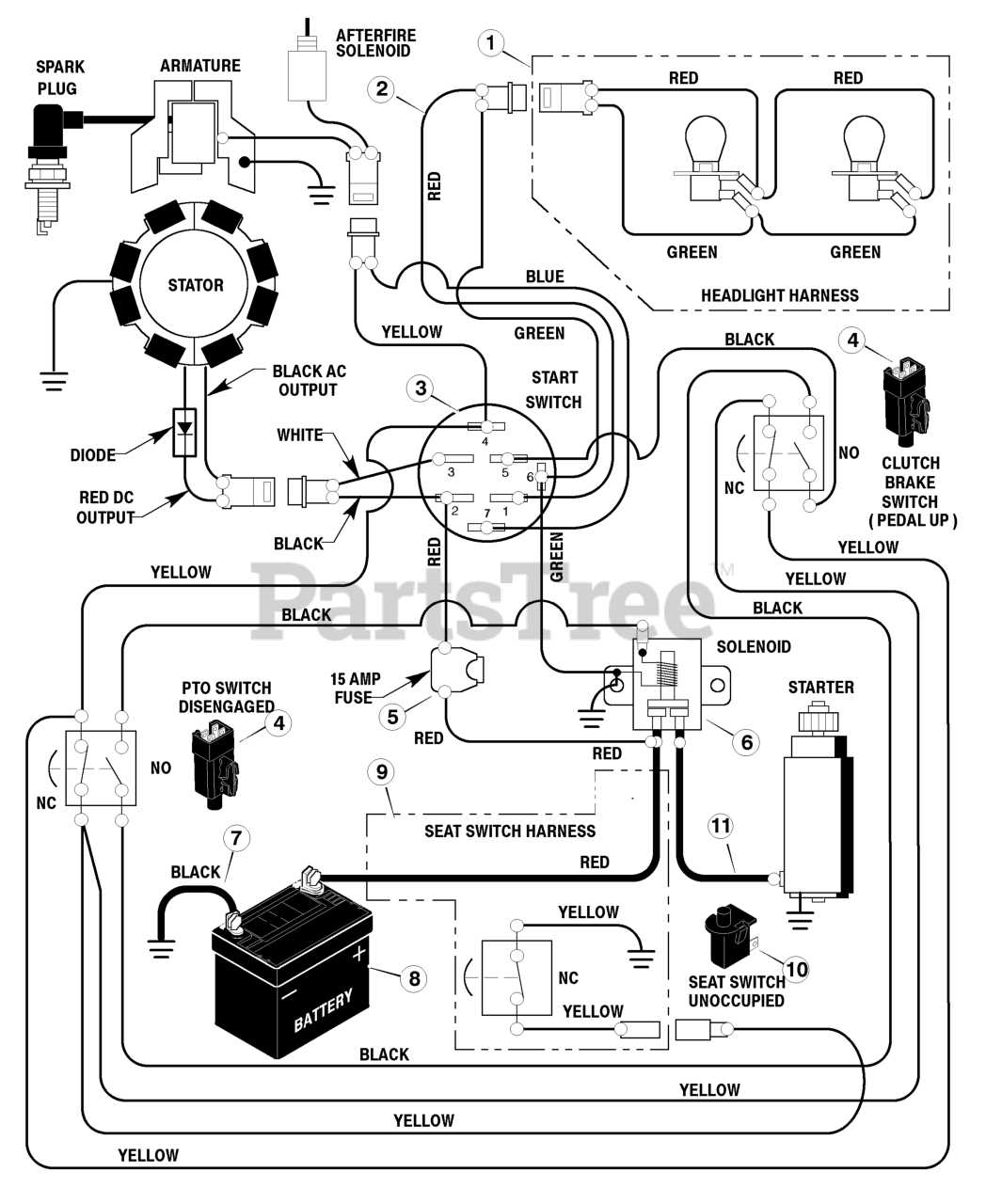

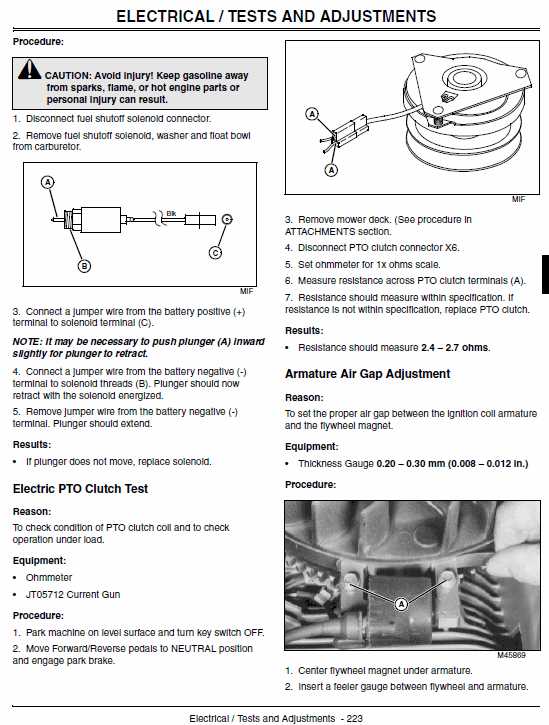

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations provide an overview of the elements involved, their relationships, and their functions within a specific system. By grasping the layout and symbols used, users can navigate through the complexities of the structure more efficiently.

Begin by familiarizing yourself with the symbols and legends used in the representation. Each icon typically corresponds to a particular item or function. Take note of any labels or annotations that clarify the roles of different elements. This will aid in connecting the visual cues to the actual components.

Next, pay attention to the arrangement of the components. The spatial organization often reflects how parts interact with one another. Understanding the connections helps in diagnosing issues and planning for repairs. Observe any lines or arrows that indicate pathways or flows, as these signify how energy or materials move through the system.

Lastly, refer to accompanying documentation for additional context. Often, detailed descriptions or specifications accompany the visual guide, providing deeper insights into each element’s role. Combining visual interpretation with supplementary information enhances comprehension and equips users with the knowledge needed for successful operations.

Common Replacement Parts Needed

Regular maintenance often requires the replacement of specific components to ensure optimal performance of lawn care machinery. Understanding which items are frequently needed can help in planning and minimizing downtime during repairs. Below are some essential items typically sought after for upkeep.

Essential Components

These are some of the most commonly replaced items that contribute to the efficiency and longevity of equipment:

| Component | Description |

|---|---|

| Blades | Critical for achieving a clean cut, blades wear over time and need replacement to maintain cutting performance. |

| Belt | Connecting various parts, belts can wear down or break, requiring timely replacement to ensure smooth operation. |

| Air Filter | Filters out debris and dust, helping to maintain engine efficiency; should be checked and replaced regularly. |

| Oil Filter | Essential for keeping the engine clean; a clogged oil filter can lead to performance issues. |

| Battery | Powering electric start systems, batteries may lose their ability to hold charge and need to be swapped out. |

Maintaining Performance

Proactive replacement of these components not only enhances the functioning of the equipment but also extends its lifespan. Regular inspections and timely changes can prevent unexpected breakdowns, ensuring your machinery remains reliable throughout its use.

Assembly Instructions for Scotts 1642H

When it comes to assembling your equipment, following clear guidelines is essential for ensuring optimal performance and safety. This section provides step-by-step instructions to help you navigate the assembly process efficiently.

Preparation Steps

- Gather all necessary tools and components before starting.

- Review the instruction manual to familiarize yourself with each part.

- Ensure you have a clean workspace to avoid losing small items.

Assembly Process

- Begin by connecting the main chassis components. Align the parts and secure them with screws.

- Attach the power unit, ensuring all connections are tight and secure.

- Install the control panel, following the provided orientation guidelines.

- Double-check all connections and ensure there are no loose wires.

- Finally, perform a visual inspection to confirm that all parts are correctly assembled before use.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of any equipment. Implementing a regular maintenance routine can prevent wear and tear, enhance performance, and ultimately save costs on repairs or replacements. Below are some effective strategies to promote durability and efficiency.

Regular Inspections

Conducting routine assessments helps identify potential issues before they escalate. Look for the following:

- Signs of rust or corrosion

- Loose or damaged components

- Fluid leaks

- Worn-out belts or hoses

Cleaning and Lubrication

Keeping machinery clean and well-lubricated is vital for smooth operation. Consider these steps:

- Remove debris and dirt from surfaces regularly.

- Apply appropriate lubricants to moving parts as needed.

- Check and replace air filters to maintain airflow.

Troubleshooting Common Issues

When working with outdoor machinery, it’s common to encounter various challenges that can affect performance. Identifying and resolving these issues promptly can ensure optimal functionality and longevity of the equipment. Below are some frequent problems and suggested solutions to help you address them effectively.

Engine Problems

Engine-related difficulties can manifest in several ways, such as stalling or failing to start. Here are some common causes:

- Fuel Issues: Ensure the fuel is fresh and not contaminated.

- Battery Problems: Check the battery connections and charge status.

- Air Filter Blockage: Clean or replace the air filter as needed.

Cutting Performance Issues

Poor cutting performance can result from a variety of factors. Consider the following when troubleshooting:

- Blade Condition: Inspect the blades for dullness or damage; sharpen or replace if necessary.

- Height Adjustment: Verify that the cutting height is set appropriately for the grass type.

- Deck Cleanliness: Remove any grass clippings or debris from the deck.

Where to Find Genuine Parts

When seeking authentic components for your equipment, it’s essential to know the right places to look. Reliable sources ensure you receive high-quality items that meet the specifications of your machinery. Below are some of the best options for acquiring these genuine components.

- Authorized Dealers: Purchasing from certified sellers guarantees that you are getting original items designed specifically for your model.

- Manufacturer’s Website: Many manufacturers provide online catalogs where you can order directly from them, ensuring authenticity.

- Specialty Retailers: Stores that focus on outdoor equipment often carry a selection of genuine components and can assist in finding the right fit.

- Online Marketplaces: Websites that specialize in outdoor equipment parts frequently offer genuine options, but always check seller ratings and reviews.

- Local Repair Shops: Many repair facilities maintain a stock of original components or can order them for you, often providing expert advice in the process.

Exploring these options can help you find the exact components you need to maintain the performance and reliability of your machinery.

Comparison with Other Models

This section explores the distinctions and similarities among various equipment types within the same category. By examining key features, performance capabilities, and design elements, users can gain a better understanding of how different machines meet specific needs.

Key Features

- Engine power variations that affect performance.

- Cutting widths available across different models.

- Control mechanisms and user interface differences.

- Attachment compatibility for enhanced functionality.

Performance Analysis

- Comparative efficiency in various terrain types.

- Maintenance requirements and ease of access to components.

- Durability assessments based on user feedback.

- Fuel consumption rates and environmental impact.

FAQs About Scotts 1642H Parts

This section addresses common inquiries regarding components and accessories associated with a specific model of equipment. Understanding these elements can enhance user experience and ensure proper maintenance and functionality.

Common Questions

Users often seek clarification on the availability and compatibility of various elements for their machinery. Below are some frequent queries:

| Question | Answer |

|---|---|

| Where can I find replacement components? | Replacement items can be sourced from authorized retailers or online marketplaces that specialize in outdoor equipment. |

| Are the components interchangeable with other models? | Many elements may vary between models, so it’s crucial to verify compatibility before making a purchase. |

| What should I do if a part is missing? | If a component is missing, consult the user manual for specific details on the required item and how to obtain it. |

| Can I perform repairs on my own? | Basic repairs can often be done independently; however, consulting a professional is advisable for complex issues. |

Maintenance Tips

Regular upkeep is essential to prolong the lifespan of your equipment. Here are a few suggestions:

- Check for wear and tear on components periodically.

- Follow the manufacturer’s guidelines for maintenance schedules.

- Utilize only recommended items for replacements to ensure optimal performance.