The intricate design of a stitching machine encompasses various elements that work in harmony to ensure optimal functionality. Each component plays a significant role in the machine’s operation, contributing to its overall performance and reliability. A thorough understanding of these elements can aid users in troubleshooting issues and enhancing their sewing experience.

By familiarizing oneself with the layout and function of the different sections, individuals can easily identify the key parts essential for the machine’s effective operation. This knowledge not only empowers users to maintain their equipment but also facilitates repairs and replacements when necessary.

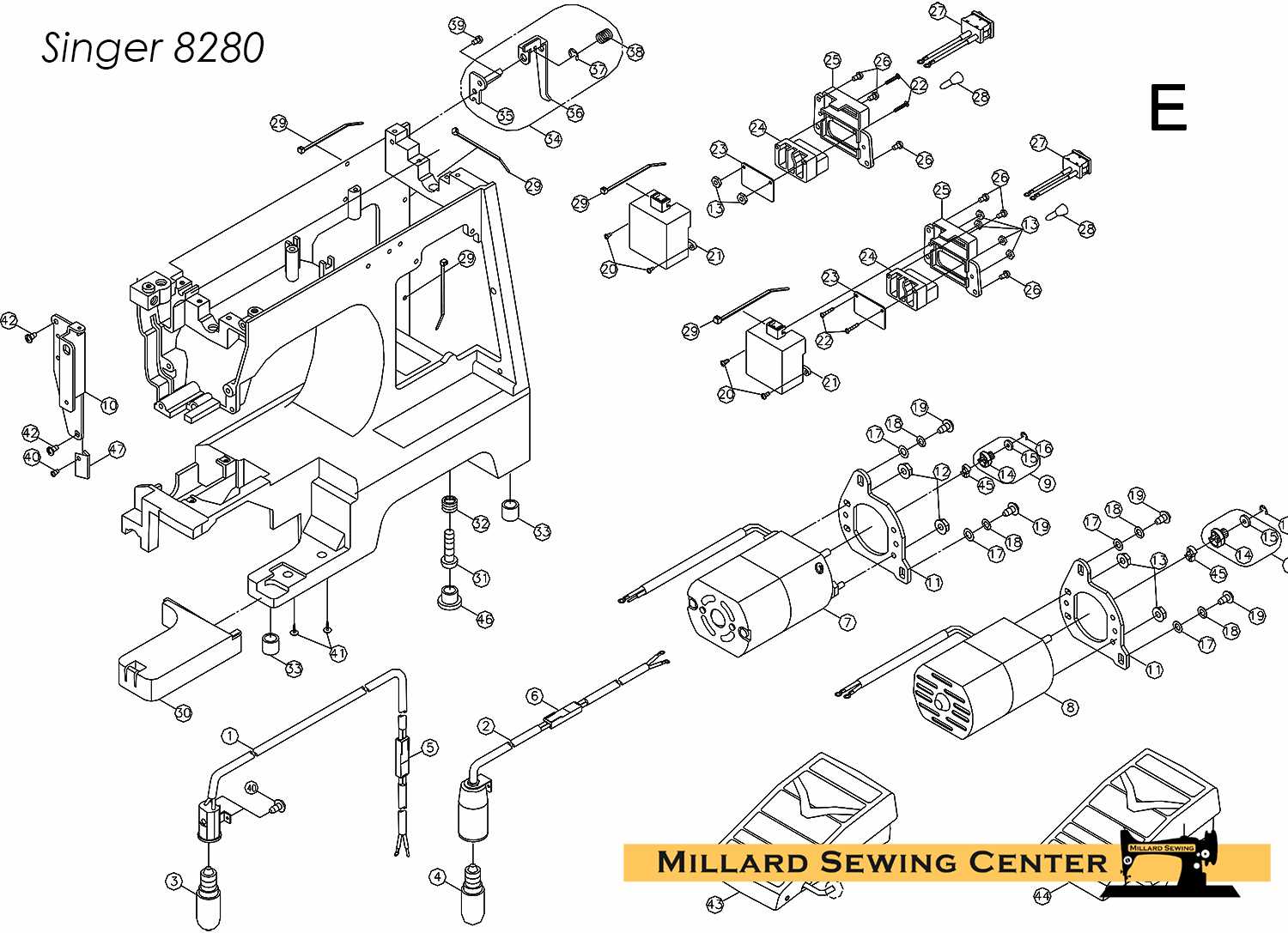

Utilizing a visual reference that outlines these components can greatly enhance comprehension, making it simpler to grasp the machine’s intricate workings. Such resources provide clarity and enable users to navigate their sewing machines with confidence and skill.

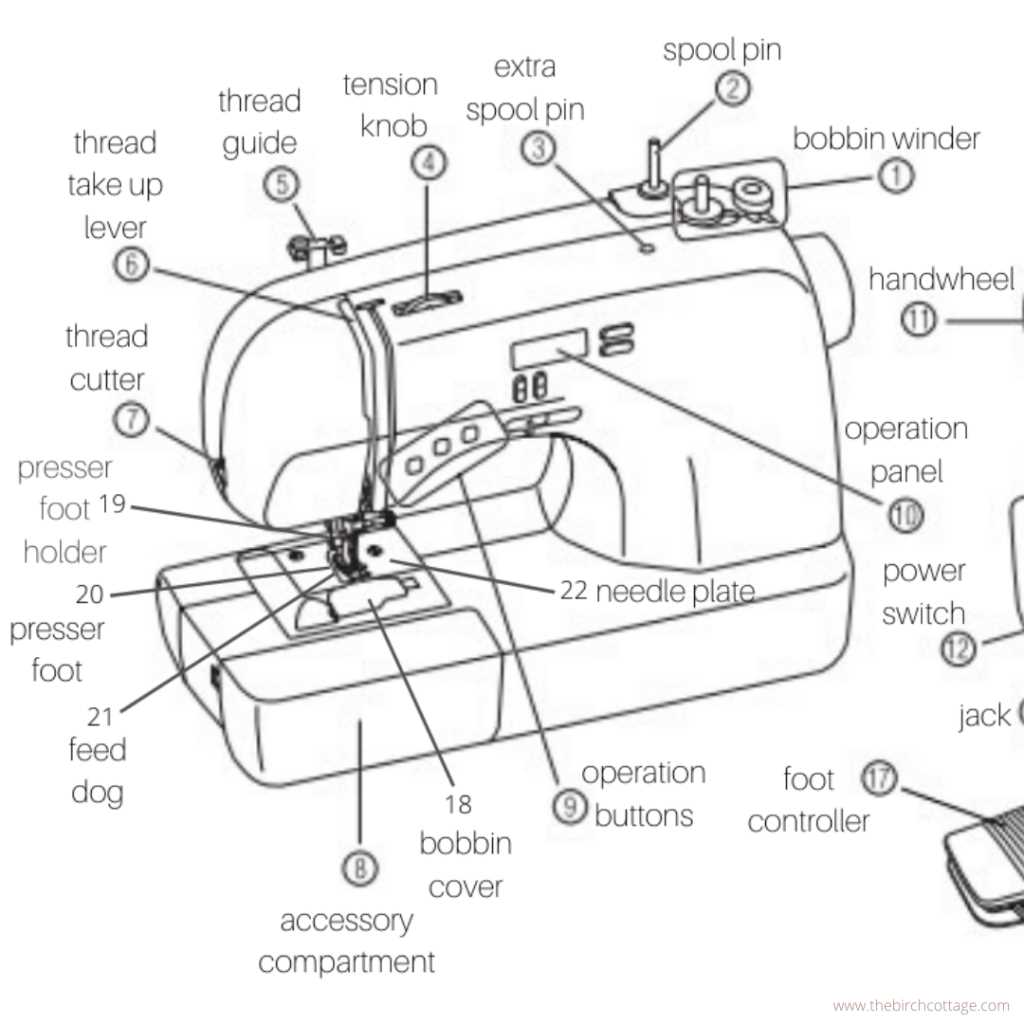

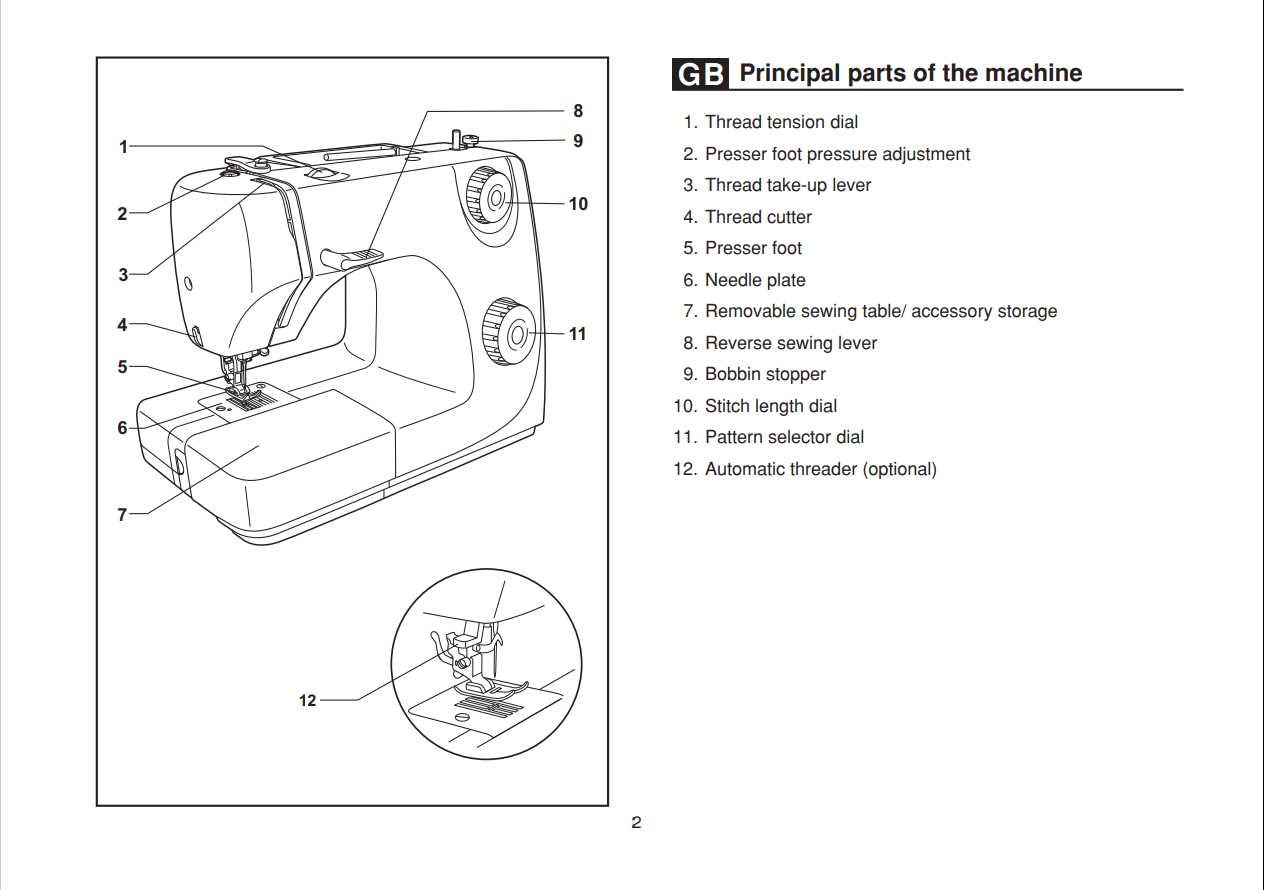

Key Components of the Sewing Machine

The sewing machine consists of several essential elements that work together to create precise stitches and facilitate various sewing tasks. Understanding these critical components can help users maintain their equipment effectively and enhance their sewing skills.

Mechanical Structure

The mechanical structure forms the foundation of the device, supporting all other parts. This includes the frame, which provides stability, and the base, ensuring the machine remains stationary during operation. Additionally, the mechanisms that control the movement of the needle and fabric feed play a vital role in achieving smooth stitching.

Stitching Mechanism

The stitching mechanism is responsible for creating the various stitch types. This includes the needle, which penetrates the fabric, and the bobbin assembly, which supplies the thread from beneath. The tension controls and presser foot are also integral to achieving the desired stitch quality and ensuring that the fabric feeds properly through the machine.

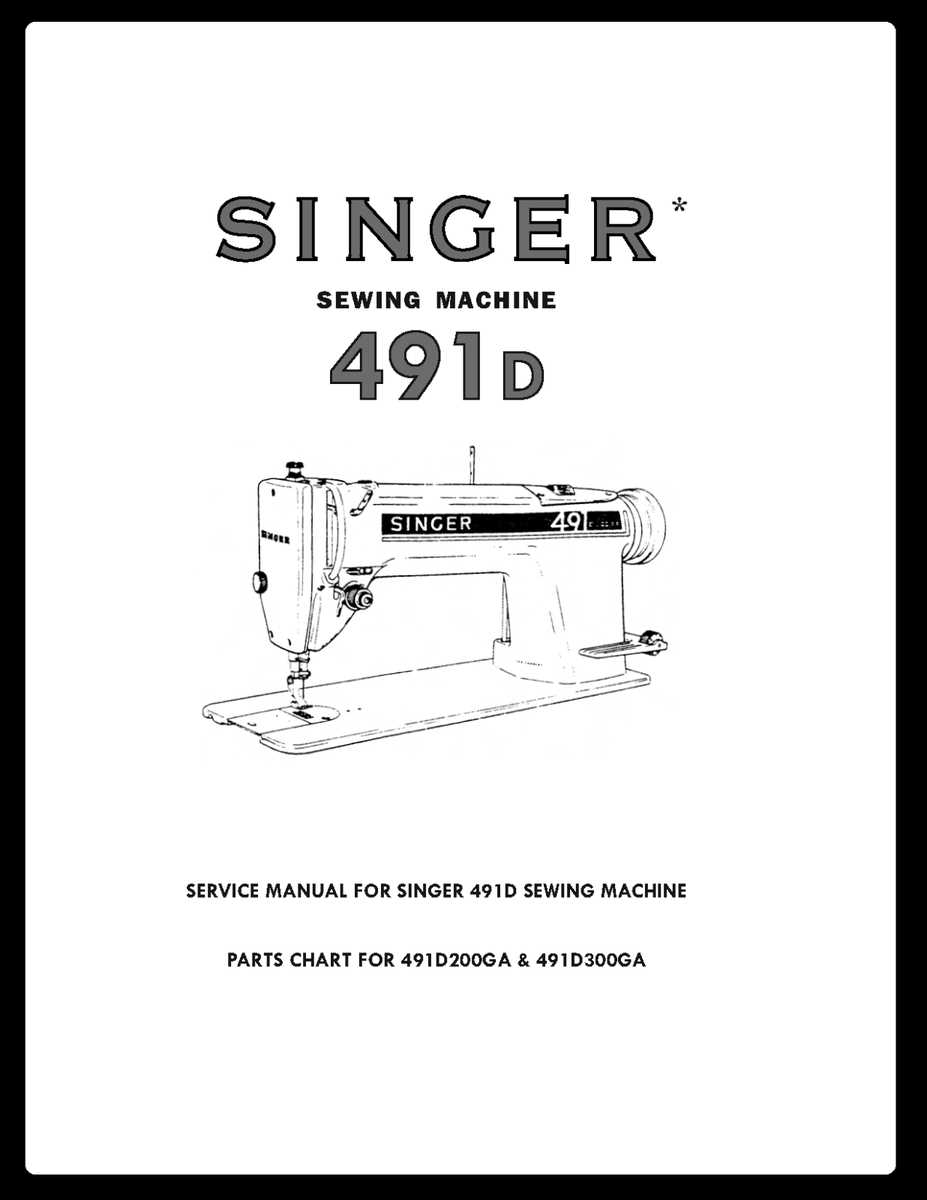

Understanding the Parts Diagram

Grasping the layout of a sewing machine’s components is essential for effective maintenance and troubleshooting. A comprehensive visual representation can greatly aid users in identifying each element and its function, enhancing their overall sewing experience. This overview will delve into the significance of familiarizing oneself with the intricate assembly of a sewing device.

When working with a sewing mechanism, recognizing various sections allows for more informed decisions regarding repairs or upgrades. Each segment plays a crucial role in the machine’s functionality, and understanding these can lead to improved performance and longevity.

| Component | Description |

|---|---|

| Needle Holder | Secures the needle in place for stitching. |

| Thread Tension Disc | Regulates the tension of the thread for even stitching. |

| Feed Dog | Moves the fabric under the needle during sewing. |

| Bobbin Case | Holds the bobbin and allows the thread to unwind properly. |

| Stitch Selector | Allows the user to choose different stitch patterns. |

Essential Features of Singer 8280

This remarkable sewing machine offers a combination of user-friendly characteristics and advanced technology, making it an ideal choice for both beginners and experienced sewers. Its intuitive design ensures ease of use, while its robust construction guarantees long-lasting performance. The appliance is equipped with various functionalities that cater to diverse sewing needs, enhancing creativity and efficiency in projects.

| Feature | Description |

|---|---|

| Stitch Options | Includes multiple stitch patterns for versatile sewing tasks. |

| Adjustable Tension | Allows customization of thread tension for different fabrics. |

| Automatic Needle Threader | Streamlines the threading process, saving time and effort. |

| Built-in Lighting | Illuminates the workspace for better visibility while sewing. |

| Lightweight Design | Easy to transport, making it suitable for classes and travel. |

Maintenance Tips for Longevity

Ensuring the durability of your sewing machine requires regular care and attention. By following simple maintenance practices, you can significantly extend its lifespan and keep it operating smoothly. This section provides essential tips to help you maintain your equipment effectively.

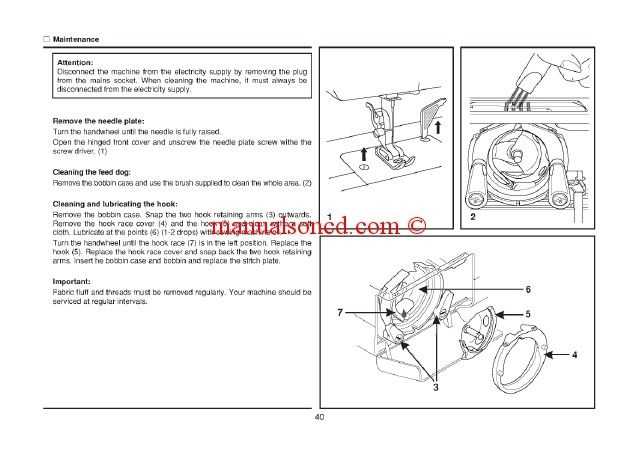

Regular Cleaning

Keep your machine clean by regularly removing lint and dust from the feed dogs and bobbin area. Use a soft brush or a vacuum attachment designed for delicate surfaces. Regular cleaning prevents the buildup of debris that can hinder performance and lead to malfunctions.

Proper Oiling

Lubricate your machine according to the manufacturer’s guidelines. Use high-quality oil specifically designed for sewing machines. Proper lubrication reduces friction between moving parts, enhancing efficiency and preventing wear over time. Ensure that all moving components are well-oiled to maintain optimal functionality.

Common Issues and Solutions

This section addresses typical challenges users may encounter with their sewing machines, along with practical solutions to enhance their performance and longevity. Understanding these issues can significantly improve your experience and help you maintain your device in optimal condition.

Thread Tension Problems

Improper thread tension can lead to various complications, such as uneven stitches or fabric puckering. It’s crucial to adjust the tension settings correctly to achieve a smooth sewing experience.

Needle and Fabric Compatibility

Using the wrong needle type or size for a specific fabric can cause skipped stitches or damage to the material. Selecting the appropriate needle is essential for successful sewing projects.

| Issue | Possible Cause | Solution |

|---|---|---|

| Uneven Stitches | Incorrect thread tension | Adjust the tension dial to find the correct setting. |

| Skipped Stitches | Improper needle choice | Use a needle suited for the fabric type. |

| Puckering Fabric | Excessive tension or wrong stitch settings | Reduce tension and check stitch length settings. |

| Thread Breakage | Old or poor-quality thread | Replace with high-quality, appropriate thread. |

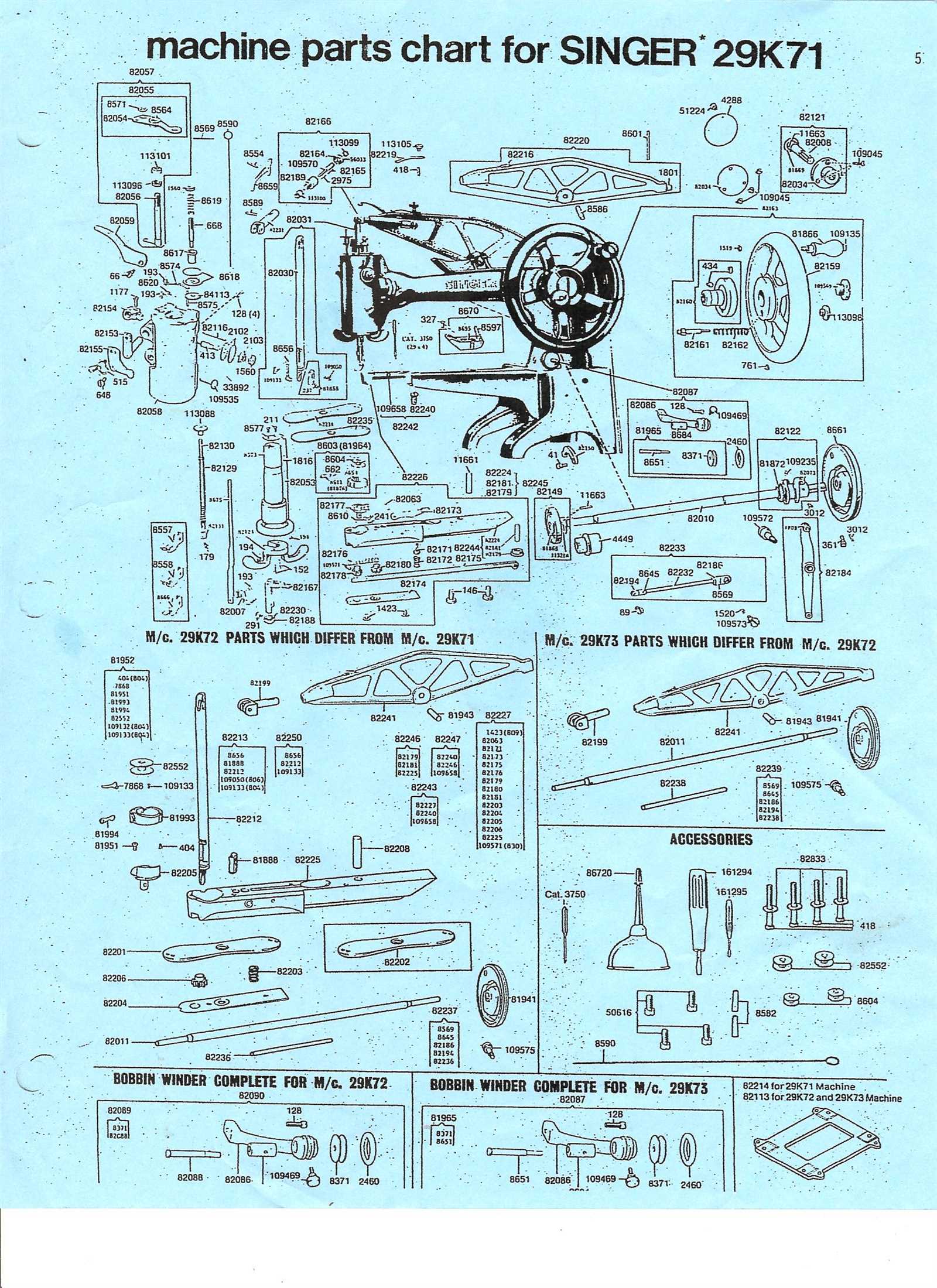

Replacement Parts Availability

Ensuring the longevity and efficient operation of your sewing machine often requires access to suitable components. Availability of these elements is crucial for users looking to maintain or enhance the functionality of their equipment. Fortunately, many resources exist for acquiring the necessary items, whether through online retailers, specialized stores, or authorized distributors.

When seeking components, it is essential to consider various factors such as compatibility, quality, and cost. Users can explore a variety of options to find the best fit for their needs. Below is a summary of common sources where you can find suitable components:

| Source | Description |

|---|---|

| Online Retailers | Numerous websites specialize in offering a wide selection of sewing machine components, often at competitive prices. |

| Local Sewing Shops | These shops may carry a range of essential components and can provide personalized assistance. |

| Authorized Dealers | Obtaining items from authorized dealers ensures quality and compatibility with your specific model. |

| Second-Hand Markets | Exploring second-hand platforms may yield affordable options, although quality should be assessed carefully. |

How to Identify Broken Components

Recognizing malfunctioning elements in a device is crucial for maintaining its functionality and longevity. By systematically examining various parts, users can determine which components may need repair or replacement. This process not only enhances performance but also saves time and resources.

To start, visual inspection is essential. Look for signs of wear, such as cracks, discoloration, or missing pieces. These indicators often reveal the overall condition of the elements and can point to specific issues that require attention.

Next, functional tests can help pinpoint problematic areas. By operating the machine and observing its performance, you can identify any irregularities, such as unusual noises or failure to function correctly. Documenting these anomalies will provide a clearer picture of which components are not performing as expected.

Additionally, using a multimeter can be beneficial for electrical components. This tool allows you to measure voltage, resistance, and continuity, helping to confirm whether a particular element is functioning properly. If measurements fall outside the normal range, this could indicate a defect.

Lastly, consulting manufacturer manuals or online resources can provide insights into common issues associated with specific elements. These guides often include troubleshooting steps and recommendations for resolving common problems, making it easier to identify and address faulty parts.

Tools Needed for Repairs

When undertaking maintenance tasks on your sewing machine, having the right tools is essential for ensuring efficient repairs and optimal performance. A well-equipped toolkit not only simplifies the process but also enhances accuracy and safety during the procedure.

Here is a list of essential tools to consider:

- Screwdrivers: A set of both flathead and Phillips screwdrivers in various sizes is crucial for loosening and tightening screws.

- Pliers: Needle-nose pliers can assist in grasping small components and making precise adjustments.

- Seam Ripper: This handy tool is invaluable for removing stitches and correcting mistakes with minimal damage.

- Cleaning Brushes: Soft brushes are useful for removing lint and debris from hard-to-reach areas.

- Oiling Tools: A small oil applicator or bottle helps maintain smooth operation by lubricating moving parts.

Additional accessories that may enhance your repair efforts include:

- Measuring Tools: A ruler or measuring tape for precise adjustments.

- Fabric Scissors: Sharp scissors ensure clean cuts and prevent fraying.

- Work Light: Adequate lighting helps illuminate intricate details during repairs.

Having these tools readily available can significantly improve the effectiveness of your repair tasks and prolong the lifespan of your equipment.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing common issues with sewing machines. By following these steps, you can diagnose problems and restore your device to optimal working condition. Whether you’re dealing with minor adjustments or more significant repairs, a structured method can simplify the process and enhance your confidence in handling machine maintenance.

Identifying the Problem

The first step in any repair is to determine the exact issue. Listen for unusual sounds, check for any visible wear or damage, and ensure all components are functioning as intended. Take note of any error messages or performance irregularities, as these can provide valuable clues.

Gathering Necessary Tools

Before beginning the repair, assemble all required tools and materials. Commonly needed items include screwdrivers, replacement parts, lubricants, and cleaning supplies. Having everything ready at hand will streamline the repair process and minimize interruptions.