When it comes to maintaining and enhancing the performance of your machinery, having a comprehensive understanding of its various elements is essential. Each component plays a vital role in ensuring optimal functionality, and knowing how they interconnect can significantly impact your overall experience.

Visual representation of these components not only simplifies the assembly process but also aids in troubleshooting common issues. By examining the layout and organization of these parts, users can quickly identify what may need attention or replacement.

Whether you’re a seasoned expert or a novice, delving into the intricacies of these essential elements will empower you to make informed decisions, ultimately leading to better maintenance and performance of your equipment.

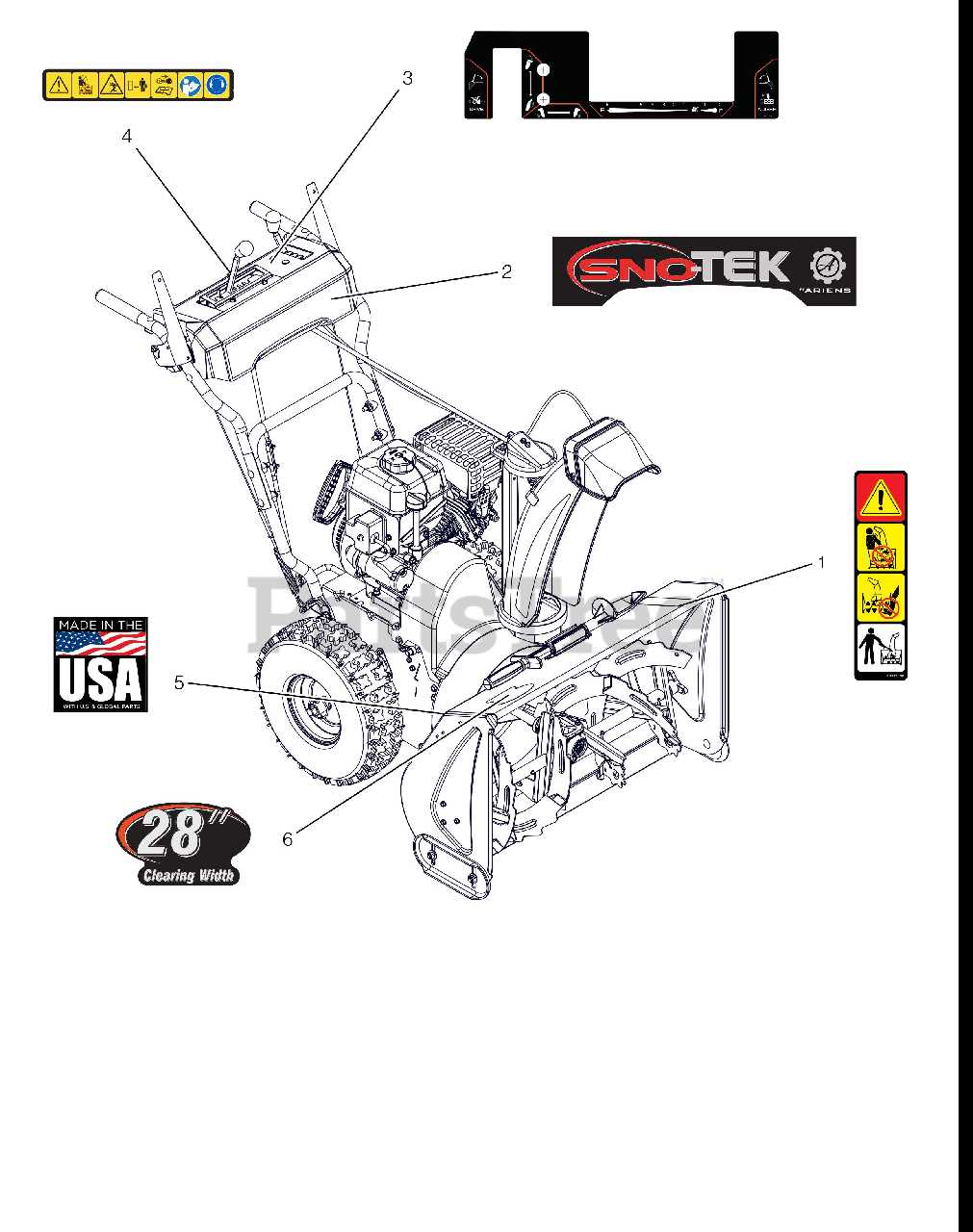

Sno Tek Parts Overview

This section provides a comprehensive insight into the components essential for optimal performance and maintenance of winter equipment. Understanding these elements helps users make informed decisions regarding repairs and enhancements.

Key Components

Each element plays a critical role in the functionality and durability of the machinery. Familiarity with these parts ensures better care and longevity.

| Component | Description |

|---|---|

| Engine | Powers the entire unit, providing the necessary force for operation. |

| Chassis | Framework that supports and houses various parts, ensuring stability. |

| Tracks | Provide traction and mobility on snowy terrain, crucial for maneuverability. |

Maintenance Tips

Regular upkeep of these components not only enhances performance but also prolongs the lifespan of the equipment. Periodic inspections and timely replacements are key to ultimate efficiency.

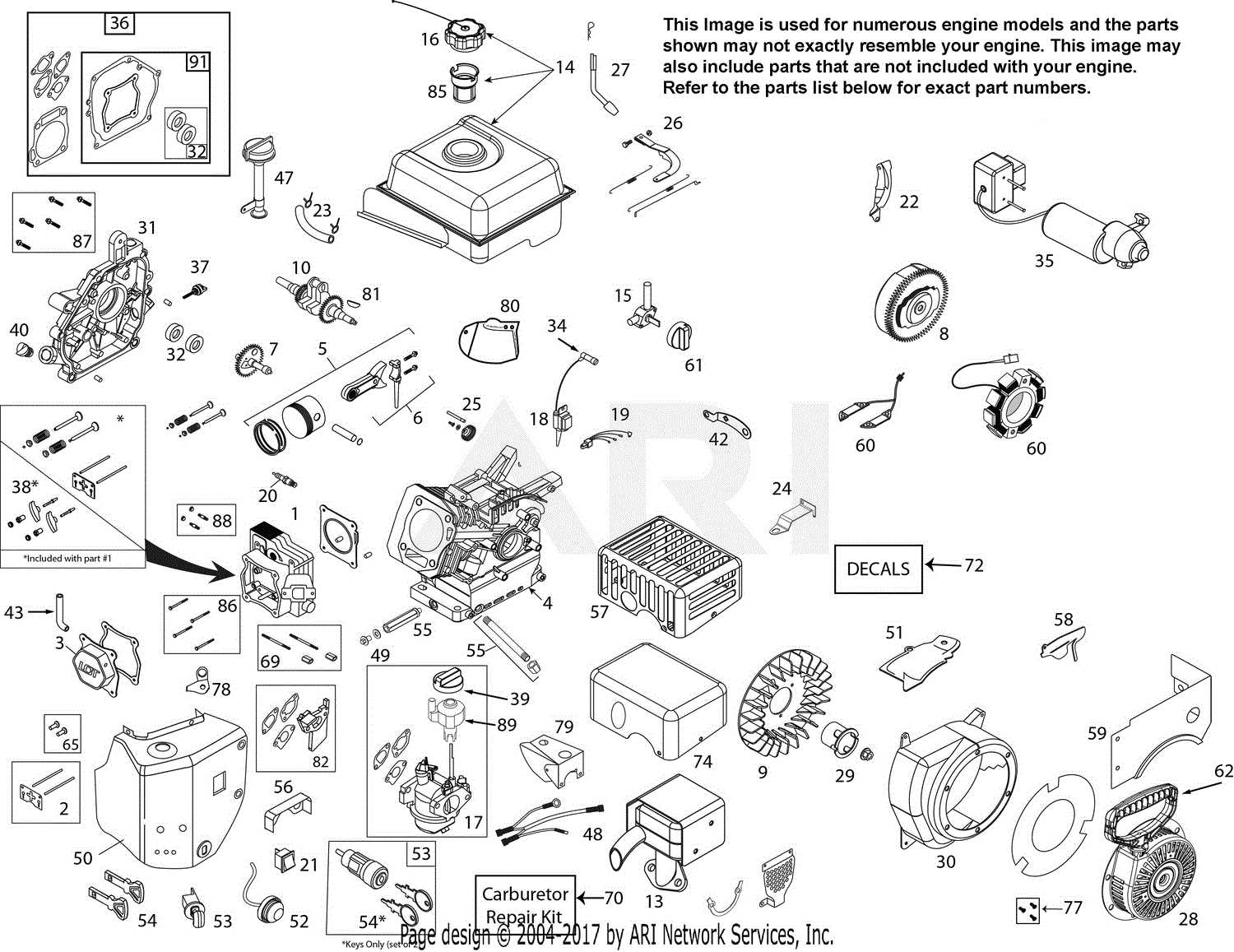

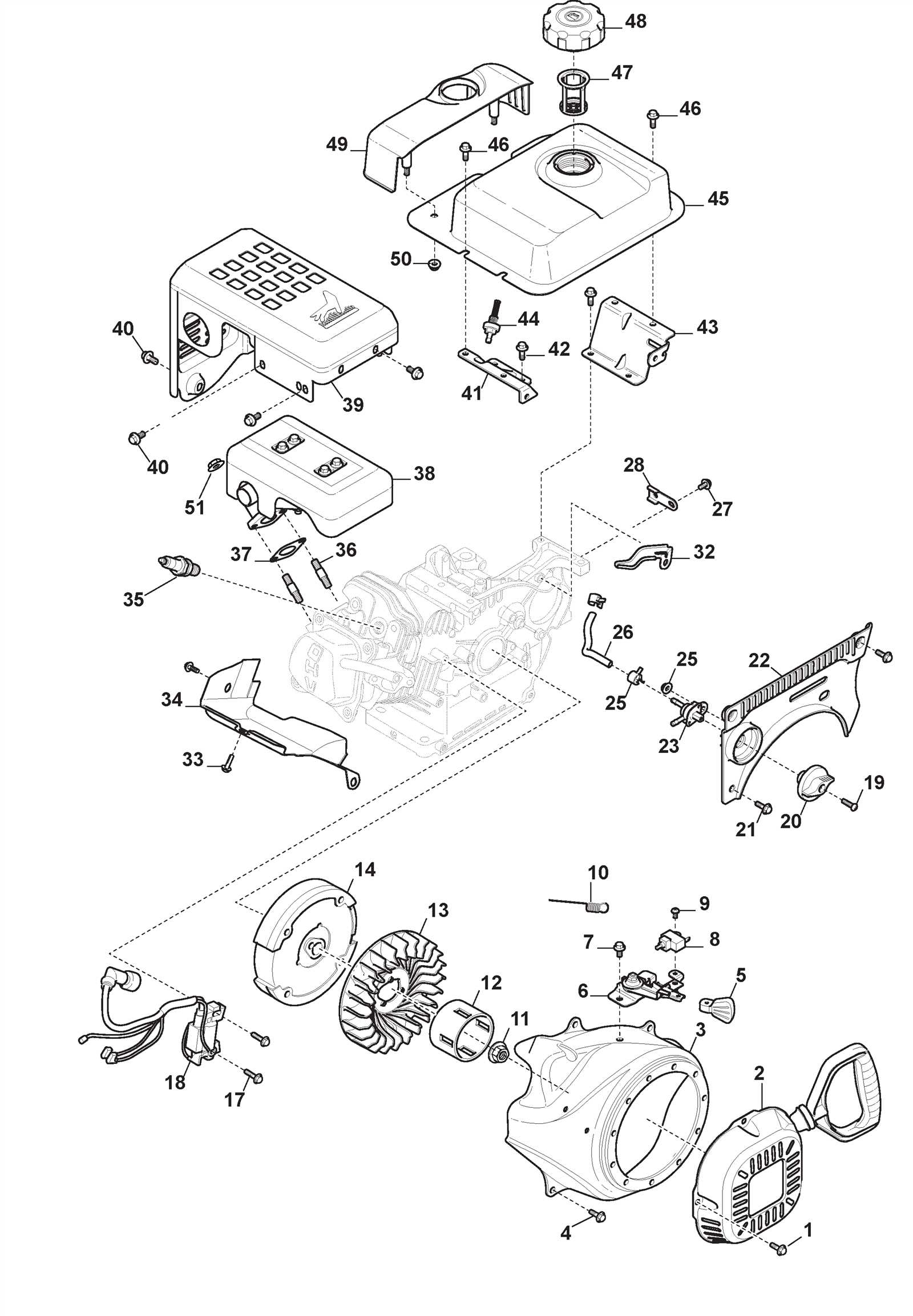

Understanding Parts Diagrams

Visual representations of components play a crucial role in simplifying complex mechanical systems. These illustrations serve as essential tools for identifying and categorizing various elements within a machine, making it easier for users to comprehend assembly and maintenance procedures. By breaking down intricate structures into more manageable visuals, one can efficiently navigate the myriad of parts involved.

The Importance of Clarity

Clear depictions facilitate understanding, ensuring that each segment is easily identifiable. This clarity aids not only in the assembly process but also in troubleshooting and repair, allowing users to quickly pinpoint issues and implement solutions. Comprehensive visuals often include labels and codes, which enhance communication and streamline workflows.

Benefits for Users

Utilizing these visual aids provides significant advantages for both novice and experienced technicians. They promote accuracy during repairs and modifications, reducing the likelihood of errors. Furthermore, such representations can serve as educational tools, empowering users with the knowledge to better understand the mechanics of their equipment.

Importance of Accurate Diagrams

Precise visual representations are crucial for understanding complex machinery and systems. They serve as essential tools for both maintenance and assembly, enabling technicians and users to navigate components effectively. Without accuracy, the risk of errors increases significantly, leading to inefficient repairs and potential damage.

Enhancing Efficiency

Clear illustrations streamline processes by providing straightforward guidance. When individuals can visualize arrangements and connections, they can perform tasks more swiftly and with greater confidence.

Minimizing Errors

Inaccurate visuals can lead to mistakes that may compromise functionality. By relying on dependable representations, users can avoid costly missteps, ensuring that everything operates smoothly.

| Benefit | Description |

|---|---|

| Clarity | Helps users comprehend system layouts effortlessly. |

| Time-Saving | Reduces the time spent on troubleshooting and repairs. |

| Safety | Enhances safety by minimizing the risk of improper handling. |

Common Components in Sno Tek Models

Understanding the essential elements of snow removal machinery is crucial for effective maintenance and operation. These components work together to enhance performance, durability, and user experience. Familiarity with these features can help users troubleshoot issues and ensure their equipment runs smoothly throughout the winter season.

Main Elements

- Engine: The powerhouse of the equipment, providing the necessary energy for operation.

- Auger: Responsible for breaking up and collecting snow, directing it towards the discharge chute.

- Chassis: The frame that supports all components and provides stability during use.

- Discharge Chute: Directs snow away from the path of the machine, allowing for efficient clearing.

- Controls: User interface that enables operation and adjustments for various conditions.

Additional Features

- Skids: Help maintain a consistent height above the ground, preventing damage to surfaces.

- Headlights: Enhance visibility during low-light conditions, improving safety.

- Wheels or Tracks: Provide mobility and traction on different types of terrain.

- Fuel System: Ensures the engine operates efficiently, impacting overall performance.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as valuable guides, providing insights into how various elements fit together and function within a larger system.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Each illustration uses specific icons and markings. Take time to learn what each symbol represents to avoid confusion.

- Identify Key Sections: Most visuals are divided into segments. Recognize these sections to understand how different components interact within their respective areas.

- Follow the Legend: A legend or key often accompanies these visuals, explaining the symbols used. Always refer to it for clarity.

- Trace Connections: Pay attention to lines and arrows that indicate how parts connect or relate to each other. This helps in visualizing the flow of operation.

- Review Assembly Order: If applicable, identify any numbered steps that indicate the sequence for assembly or disassembly, ensuring correct procedures are followed.

By following these guidelines, you can enhance your understanding and effectively utilize these visual tools for various applications.

Finding Replacement Parts Easily

Locating the necessary components for your machinery can often be a daunting task. However, with the right approach and resources, you can streamline the process and ensure that you get what you need promptly. This section will guide you through effective strategies for sourcing the right items with minimal hassle.

Utilizing Online Resources

One of the most efficient ways to find what you’re looking for is by leveraging digital platforms. Numerous websites specialize in offering detailed catalogs and user-friendly search options. Online marketplaces can also provide customer reviews that help in making informed decisions. Additionally, joining forums can connect you with experienced users who share valuable insights.

Consulting Local Dealers

Another option is reaching out to local suppliers. Visiting brick-and-mortar stores allows you to inspect items firsthand and ask questions. Establishing a relationship with a trusted dealer can often lead to better service and recommendations tailored to your needs. Don’t hesitate to inquire about inventory or potential alternatives that may serve your purpose.

Tips for Maintenance and Repair

Regular upkeep and timely fixes are essential for optimal performance and longevity of your equipment. By adhering to a structured approach, you can minimize breakdowns and enhance efficiency. Understanding key components and their functions is crucial to successful maintenance and repair tasks.

Routine Checks

Conduct frequent inspections to identify wear and tear early. Pay attention to moving parts and fluid levels, ensuring everything operates smoothly. Create a checklist to streamline your routine and prevent oversight.

Proper Cleaning

Keeping your machinery clean is vital for preventing debris buildup that can lead to malfunctions. Use appropriate cleaning agents and tools to maintain surfaces and components without causing damage. Regular cleaning extends the life of your equipment.

Comparing Models and Parts

When evaluating different machinery iterations, understanding the nuances between components is essential. Each variant may showcase distinct features that cater to specific requirements, influencing performance and usability.

Key factors such as compatibility, durability, and efficiency play a significant role in the selection process. By examining these elements, users can identify which versions offer the ultimate functionality for their needs.

Moreover, analyzing similarities and differences across models allows for informed decisions, ensuring optimal performance and longevity. This comparative approach helps enthusiasts and professionals alike to delve deeper into the mechanics behind each configuration.

Where to Purchase Parts

Finding the right components for your equipment is essential for maintaining its performance and longevity. Fortunately, there are various avenues to explore when seeking reliable sources for these essentials. Below are some recommended options to consider.

- Authorized Dealers:

Visiting an official distributor ensures that you receive genuine items. These dealers typically offer warranties and knowledgeable support.

- Online Retailers:

Many e-commerce platforms specialize in selling quality components. Here, you can compare prices and read customer reviews for informed choices.

- Local Repair Shops:

Local mechanics often have access to quality items and can provide personalized advice tailored to your specific needs.

- Manufacturer’s Website:

Checking the official website of your equipment’s maker can direct you to reliable purchasing options, including exclusive items.

- Second-Hand Markets:

Platforms like online classifieds or specialized forums can offer used components at lower prices. Just ensure you verify the condition and compatibility before purchasing.

Each of these sources provides unique benefits, making it easier to find the right components to keep your machinery in top shape.

Identifying Genuine Parts vs. Counterfeits

In the world of machinery and equipment, distinguishing authentic components from imitations is crucial for optimal performance and longevity. Counterfeit items often compromise safety and functionality, making awareness of key differences essential for consumers and professionals alike.

Visual Inspection Techniques

One of the simplest methods to identify authenticity is through careful visual examination. Genuine components typically feature high-quality materials and precise manufacturing standards. Look for consistent branding, clear logos, and any unique identifiers that may be present.

| Feature | Genuine Component | Counterfeit Component |

|---|---|---|

| Branding | Clear and consistent | Faded or misspelled |

| Material Quality | Durable and well-crafted | Inferior, flimsy |

| Packaging | Professional and informative | Poor quality, misleading |

Performance and Reliability

Beyond physical attributes, performance indicators can also reveal authenticity. Genuine components often undergo rigorous testing and meet specific industry standards. If a part exhibits unusual wear, failure, or subpar performance, it may be a sign of a counterfeit item.

Using Diagrams for Troubleshooting

Visual representations are invaluable tools when it comes to diagnosing issues in complex machinery. By breaking down intricate systems into understandable segments, these illustrations allow users to pinpoint malfunctioning components more effectively. A clear layout not only aids in identifying problems but also streamlines the repair process, minimizing downtime and enhancing efficiency.

Benefits of Visual Aids

Clarity and Precision: Illustrations provide a straightforward way to visualize connections and functions within a system. This clarity enables technicians to quickly assess which elements are operating correctly and which are not. Additionally, the use of labeled visuals helps to reduce the likelihood of errors during repairs.

Step-by-Step Troubleshooting

Utilizing visual aids can transform troubleshooting into a systematic procedure. By following a sequential approach depicted in these representations, users can methodically check each segment. This organized method not only simplifies the diagnosis but also ensures that no critical aspects are overlooked, ultimately leading to quicker resolutions.

Ultimate Benefits of Using Diagrams

Visual representations of complex systems play a crucial role in enhancing understanding and communication. They simplify intricate details, making it easier for individuals to grasp the overall structure and function of various components. By presenting information visually, these tools allow for quicker insights and foster effective problem-solving.

Enhanced Clarity

Utilizing visual aids significantly improves clarity. Stakeholders can quickly identify relationships and hierarchies within the information, reducing the potential for misunderstandings. This leads to more informed decision-making and efficient workflows.

Improved Collaboration

Visual tools encourage teamwork by providing a common reference point. Teams can delve into discussions with a clear focus, ultimately enhancing collaboration and productivity. This collective engagement often results in innovative solutions and a deeper understanding of the subject matter.