In the world of vintage firearms, proper maintenance and a clear understanding of each component’s function are essential for both collectors and enthusiasts. Familiarity with the internal structure and how different elements interact allows for a better grasp of how to restore or repair a timeless piece. This guide provides an in-depth look into the essential mechanical elements of one such historic model.

As we explore the various mechanisms and design features, it’s important to recognize how each piece contributes to the overall functionality of the firearm. Whether you’re restoring or simply studying the design, the precise arrangement of moving parts plays a crucial role in maintaining the firearm’s accuracy and reliability.

By breaking down each section of the firearm, this guide aims to give you a comprehensive overview of the intricate system that makes it work. Understanding the purpose and placement of every detail will enhance your ability to troubleshoot issues or perform upgrades on the rifle.

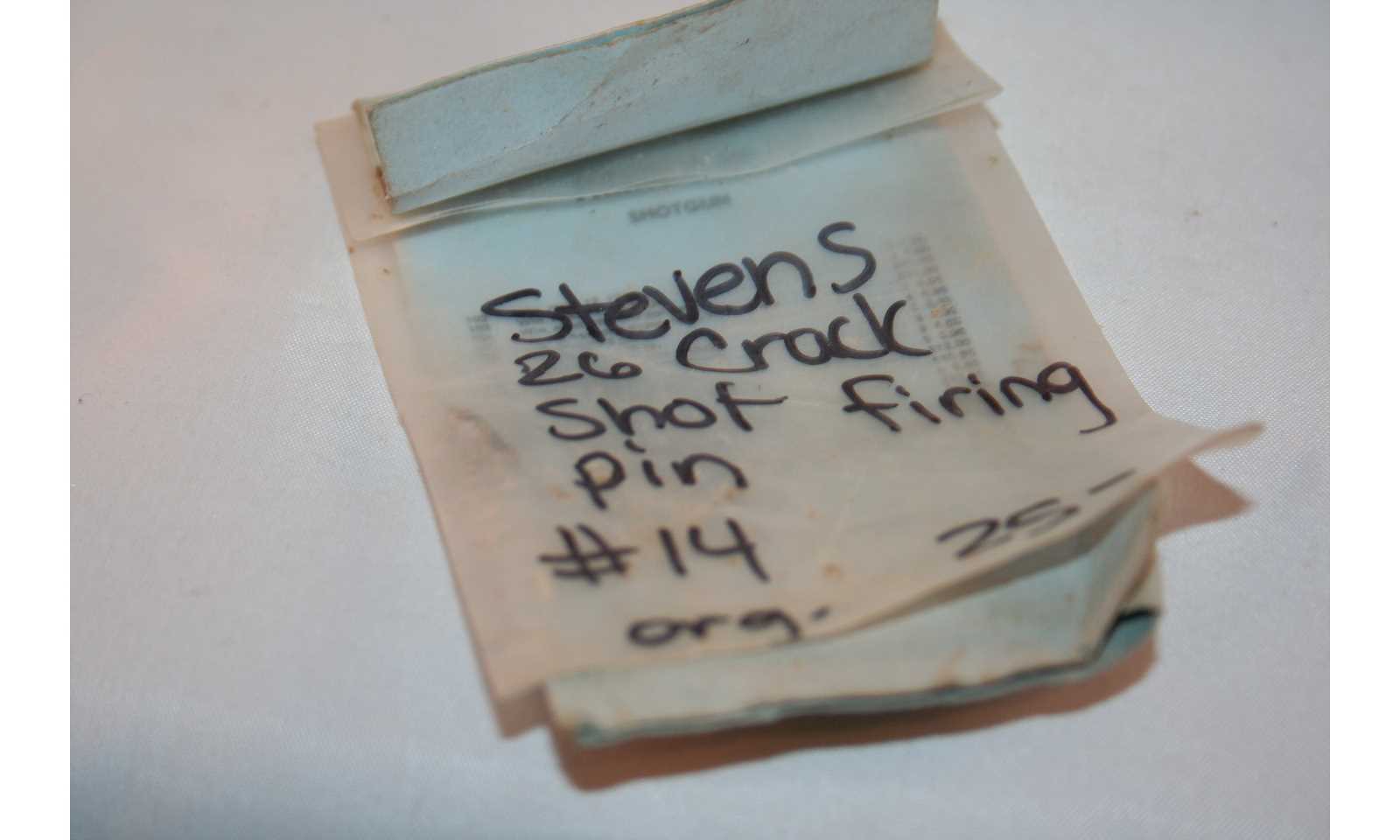

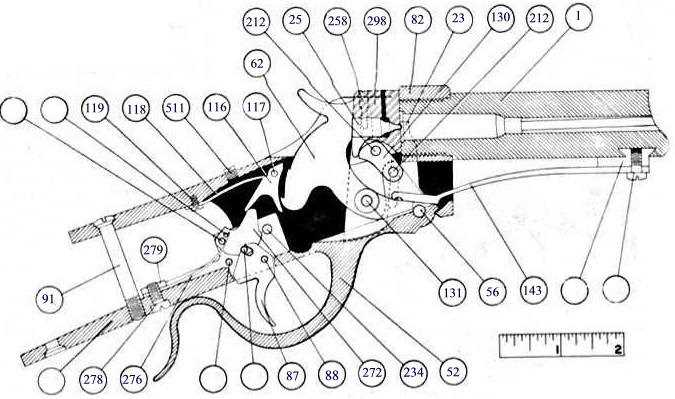

Stevens Crackshot 26: Component Breakdown

In this section, we’ll explore the internal structure and main elements that compose this classic firearm. Each part serves a distinct role, ensuring the smooth operation and reliability that users expect. By understanding how these pieces work together, you can gain a deeper appreciation for the craftsmanship and design behind the mechanism.

Main Mechanisms

- Barrel Assembly: The central part responsible for directing the bullet’s path with precision. Its length and material significantly impact the firearm’s accuracy.

- Trigger Group: This mechanism allows for the controlled release of the hammer, initiating the firing sequence. Proper maintenance is essential to ensure safety and function.

- Hammer: A key component that strikes the firing pin, igniting the cartridge. It must be durable and operate smoothly for reliable performance.

Additional Components

- Stock: Provides stability and support to the user, enhancing control and aim during use. Typically made of

Exploring the Trigger Mechanism

The trigger mechanism is a critical component in any firearm, responsible for releasing the hammer and firing the projectile. Its design and function directly affect both the safety and accuracy of the shooting experience. Understanding how this system works can provide valuable insight into the overall performance of the weapon, allowing for smoother operation and better control.

In essence, the trigger assembly consists of several interconnected parts that work in unison. When the shooter pulls the trigger, the sear releases the hammer, which strikes the firing pin to ignite the cartridge. Proper alignment and maintenance of these components are essential for reliable performance and ensuring the smooth discharge of the firearm. With attention to detail, the entire process can be optimized to provide a crisp, clean break when firing, enhancing accuracy and control.

The construction of the trigger mechanism varies, but key components include the trigger, sear, hammer, and various springs. Each element plays a specific role in controlling the force required to fire and the overall feel of the trigger pull. Adjust

Barrel Assembly and Key Features

The barrel assembly plays a crucial role in the overall performance of a firearm, ensuring accuracy and durability. This section will outline the construction and characteristics that define this essential component, highlighting its impact on precision and reliability during use.

One of the key aspects of the barrel is its material, which directly influences the longevity and resistance to wear. High-quality steel is often employed to ensure both strength and corrosion resistance, making it suitable for various environments and conditions.

Another important feature is the rifling inside the barrel. The internal grooves are designed to stabilize the projectile, improving accuracy over long distances. The length and twist rate of the rifling are optimized to match specific ammunition, allowing for greater consistency in shots.

The barrel also includes mounting points for other essential elements, such as the sight system, which contributes to proper target alignment. Precision engineering in these areas ensures smooth integration with the overall mechanics of the firearm, enhancing ease of use and user control.

Finally, the barrel is typically designed with

Stock Overview: Material and Design

The stock is a crucial component of any firearm, serving as the foundation for both its ergonomics and overall appearance. Its material and design significantly impact the user experience, influencing the firearm’s balance, durability, and comfort. The structure is thoughtfully crafted to ensure a combination of strength, stability, and aesthetic appeal, making it not only functional but also visually appealing.

Materials Used in Construction

Modern stocks are crafted from a range of materials, each offering distinct advantages. Traditional options include high-quality woods like walnut, which provide a classic look and natural resilience. For those seeking enhanced durability, synthetic options such as polymer and fiberglass offer lightweight, weather-resistant alternatives, designed for use in rugged conditions.

Material Properties Advantages Wood (Walnut, Maple) Strong, How the Firing Pin Operates

The firing pin plays a crucial role in the mechanism of most firearms, ensuring that the bullet is discharged efficiently when the trigger is pulled. Its function revolves around initiating the ignition of the cartridge by delivering a precise impact to the primer, setting the entire firing sequence into motion. This action is key to the controlled explosion that propels the projectile forward.

When the hammer or striker is released, it strikes the firing pin with force. This force drives the firing pin forward, making contact with the cartridge primer. Upon impact, the primer ignites the gunpowder, creating a controlled explosion that generates the necessary pressure to launch the bullet from the barrel. The exact timing and precision of this operation are critical for the firearm’s performance and reliability.

After the firing pin completes its motion, it retracts to its resting position, either through spring tension or the movement of

Understanding the Extractor Function

The extractor plays a crucial role in the operation of firearms, ensuring the seamless ejection of spent casings after firing. This essential component is designed to grab hold of the cartridge case, allowing it to be removed from the chamber efficiently. Understanding how this mechanism works can enhance one’s appreciation for the overall functionality of a firearm.

How the Extractor Operates

When the trigger is pulled and a round is fired, the pressure generated within the chamber pushes the bullet down the barrel. Following this action, the extractor engages with the rim of the spent casing. As the bolt moves backward, the extractor pulls the casing out of the chamber and guides it towards the ejection port. This process is vital for preparing the firearm to chamber a new round, thereby maintaining its readiness for subsequent shots.

Common Issues and Maintenance

Like any mechanical part, the extractor can encounter problems that affect its performance. Issues such as wear, dirt accumulation, or improper alignment may hinder its ability to extract spent casings effectively. Regular maintenance, including cleaning and inspecting the extractor, is essential to ensure reliable operation. By addressing these concerns, firearm enthusiasts can prevent malfunctions and ensure consistent ejection with every shot.

Receiver: Structure and Purpose

The receiver serves as a crucial component in the mechanism of firearms, providing the foundation for the assembly and operation of various elements. It plays an essential role in the functionality and reliability of the weapon, housing vital parts that enable the firing process and facilitate user interaction.

Structurally, the receiver is designed to accommodate several integral features, including the trigger mechanism, safety systems, and the housing for the firing pin. This unit is typically constructed from durable materials to withstand the stresses of repeated use while ensuring a secure fit for other components. The shape and design of the receiver also allow for optimal alignment and support of the barrel, enhancing accuracy and overall performance.

In terms of purpose, the receiver not only provides structural integrity but also acts as the primary interface for the operator. It is where the user engages with the firearm, initiating the firing sequence through the trigger mechanism. Additionally, the receiver’s design can influence aspects such as weight distribution and balance, affecting handling and maneuverability during use.

Hammer Mechanism: A Closer Look

The hammer mechanism is a critical component in many firearms, responsible for initiating the firing sequence. Understanding its functionality can provide insights into the overall performance and reliability of the firearm. This section will delve into the intricacies of this essential mechanism, highlighting its design and operation.

At its core, the hammer mechanism serves to strike the firing pin or primer, igniting the cartridge. The following points outline the key features and functions:

- Components: The hammer assembly typically consists of the hammer itself, a sear, and a trigger. Each part plays a vital role in the firing process.

- Operation: When the trigger is pulled, it releases the sear, allowing the hammer to pivot and strike the firing pin with significant force.

- Spring Mechanism: A spring is usually employed to reset the hammer after firing, ensuring that it is ready for the next shot.

Additionally, variations in hammer design can influence the shooting experience:

- Single Action: Requires manual cocking of the hammer before each shot, enhancing safety but slowing the firing rate.

- Double Action: Allows the trigger pull to both cock and release the hammer, facilitating faster shooting sequences.

In conclusion, the hammer mechanism is an indispensable element that directly affects both safety and efficiency. Its design intricacies contribute significantly to the overall functionality of the firearm.

Disassembling the Breech Block

Taking apart the breech mechanism is a crucial step for maintenance and repair. This process allows for a thorough inspection and cleaning, ensuring the smooth operation of the firearm. Understanding the components involved and the method of disassembly will make this task straightforward and efficient.

Before you begin, gather the necessary tools to facilitate the process:

- Small screwdriver set

- Pin punch set

- Cloth for cleaning

- Lubricating oil

Follow these steps for effective disassembly:

- Ensure the firearm is unloaded and safe to handle.

- Remove any attached accessories that may obstruct access to the breech block.

- Locate and unscrew the retaining screws securing the breech block in place.

- Gently tap out any pins holding the block, using a pin punch if necessary.

- Carefully lift the breech block from its housing, taking note of how components fit together.

Once disassembled, clean each part thoroughly. Inspect for wear or damage, as this can impact performance. After completing the cleaning process, reassemble the breech block by reversing the disassembly steps, ensuring that all components are properly aligned and secured.

Sights and Accuracy Adjustments

Achieving precision in shooting is a fundamental aspect of firearm use, greatly influenced by the sighting mechanism and adjustment capabilities. Understanding how to properly utilize and modify these elements can enhance overall performance and accuracy during target practice or hunting. This section delves into the various types of sights available and the methods for making necessary adjustments to improve shooting precision.

Types of Sights: There are several sighting options that shooters can choose from, each offering unique advantages. Open sights, often featuring a front blade and a rear notch, are popular for their simplicity and quick target acquisition. Alternatively, scope sights provide magnification and enhanced clarity, allowing for improved focus on distant targets. Understanding the characteristics and benefits of each sight type is crucial for selecting the right one for specific shooting scenarios.

Adjustment Techniques: To achieve optimal accuracy, proper alignment and calibration of the sights are essential. Many firearms are equipped with adjustable rear sights that can be moved vertically and horizontally to accommodate for bullet drop and windage. Additionally, the front sight may also be adjusted or replaced to enhance visibility. Regularly checking and fine-tuning these settings ensures consistent performance and better groupings on the target.

Practice and Familiarity: Ultimately, consistent practice with adjustments in mind will lead to greater familiarity and skill. Engaging in regular shooting sessions allows shooters to understand how their adjustments impact performance and enables them to make informed corrections based on their experiences. Mastery of sight alignment and adjustment techniques is key to becoming a proficient marksman.

Buttplate: Design and Material Insights

The buttplate serves as a crucial interface between the shooter and the firearm, contributing significantly to comfort, stability, and aesthetics. Its design and material selection can greatly influence the overall performance and user experience. Understanding these aspects is essential for anyone looking to appreciate or modify their weapon.

Design Features

- Ergonomics: The contouring of the buttplate should align with the shoulder for enhanced comfort during use.

- Thickness: A well-balanced thickness can help absorb recoil, improving handling and aim.

- Texture: Grip-enhancing textures can prevent slippage, providing better control in various conditions.

Material Considerations

- Wood: Traditional and aesthetically pleasing, wood buttplates often offer good shock absorption but may require maintenance.

- Plastic: Lightweight and durable, plastic options can be molded into intricate designs and often come in various colors.

- Rubber: Known for its recoil-dampening properties, rubber buttplates enhance comfort during firing.

When choosing a buttplate, consider how the design and materials will affect both functionality and the overall look of the firearm. The right combination can lead to a more enjoyable shooting experience.

Replacing the Forearm Assembly

Replacing the forearm assembly of a firearm can enhance both its aesthetics and functionality. This process involves removing the existing forearm and installing a new one, ensuring a secure fit and optimal performance. Whether you are upgrading to a different style or replacing a worn-out component, understanding the steps involved is crucial for a successful outcome.

Necessary Tools and Preparations

Before starting the replacement process, gather the required tools. You will need a screwdriver set, a wrench, and possibly a pair of pliers. Additionally, ensure your workspace is clean and organized to avoid losing small parts. Always prioritize safety by ensuring the firearm is unloaded and properly secured before beginning any disassembly.

Step-by-Step Replacement Process

Begin by removing any screws or fasteners that hold the forearm in place. Carefully detach the assembly from the barrel, taking care not to damage any surrounding components. Once removed, compare the new forearm with the old one to ensure proper compatibility. Next, align the new assembly with the barrel and secure it using the original screws or fasteners. Finally, perform a functionality check to confirm that everything is operating smoothly.

By following these guidelines, you can effectively replace the forearm assembly, improving your firearm’s performance and extending its lifespan.

Maintenance Tips for Stevens Crackshot 26

Proper care and regular upkeep are essential for ensuring the longevity and reliable performance of your firearm. Following a structured maintenance routine not only enhances functionality but also promotes safety during use. Here are some important tips to keep in mind for effective care.

- Regular Cleaning: After each use, clean the firearm to remove dirt, debris, and residue. Use a cleaning rod and patches soaked in solvent to clean the barrel thoroughly.

- Lubrication: Apply a light coat of gun oil to moving parts to reduce friction and prevent wear. Be careful not to over-lubricate, as excess oil can attract dust and grime.

- Inspect Components: Periodically check all parts for signs of wear or damage. Pay attention to springs, screws, and the firing mechanism, ensuring everything is in good condition.

Routine maintenance can prevent potential issues and extend the lifespan of your equipment. Establishing a schedule for inspections and cleaning will help maintain optimal performance.

- Proper Storage: Store your firearm in a cool, dry place. Consider using a protective case to shield it from moisture and dust.

- Safety Checks: Always perform a safety check before and after use. Ensure that the firearm is unloaded and the safety mechanisms are functioning correctly.

- Seek Professional Help: If you notice any significant issues or uncertainties during maintenance, consult a qualified gunsmith for assistance.

By following these guidelines, you can ensure that your equipment remains in excellent working order, allowing for safe and enjoyable experiences.