The intricate world of machinery requires a deep understanding of its various elements and how they interact. Each component plays a vital role in ensuring optimal functionality and performance. Gaining insight into these elements can significantly enhance maintenance and repair processes.

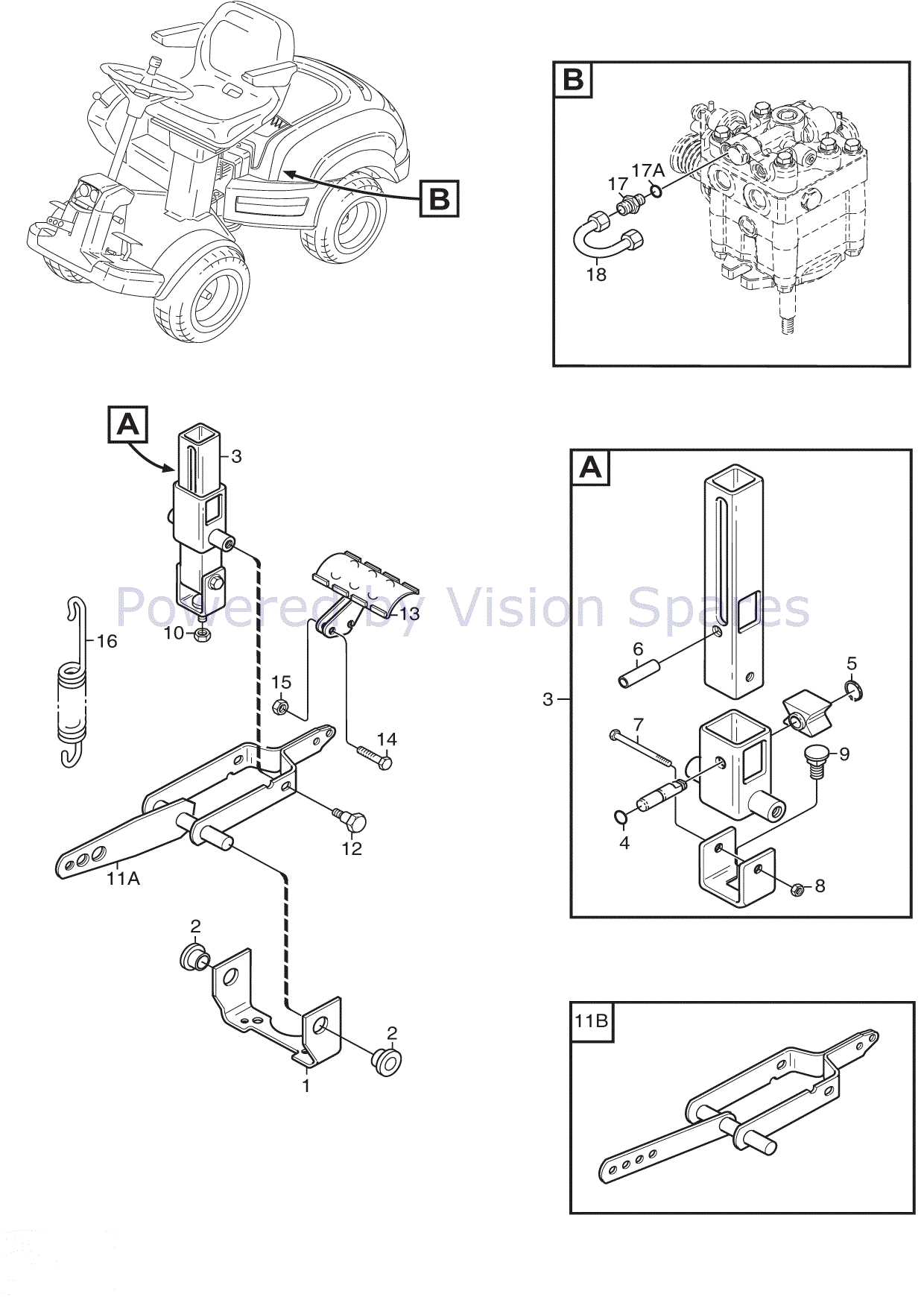

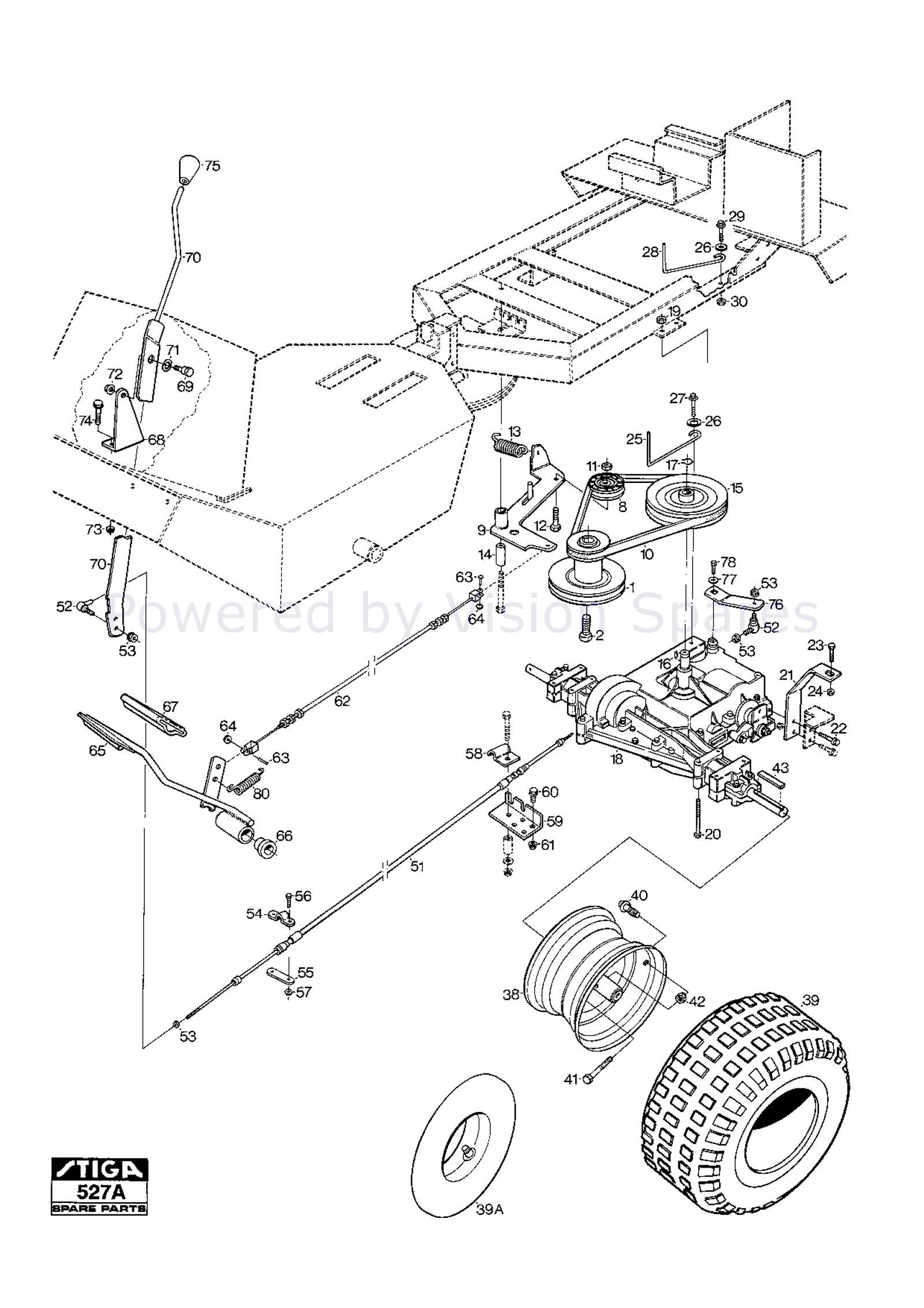

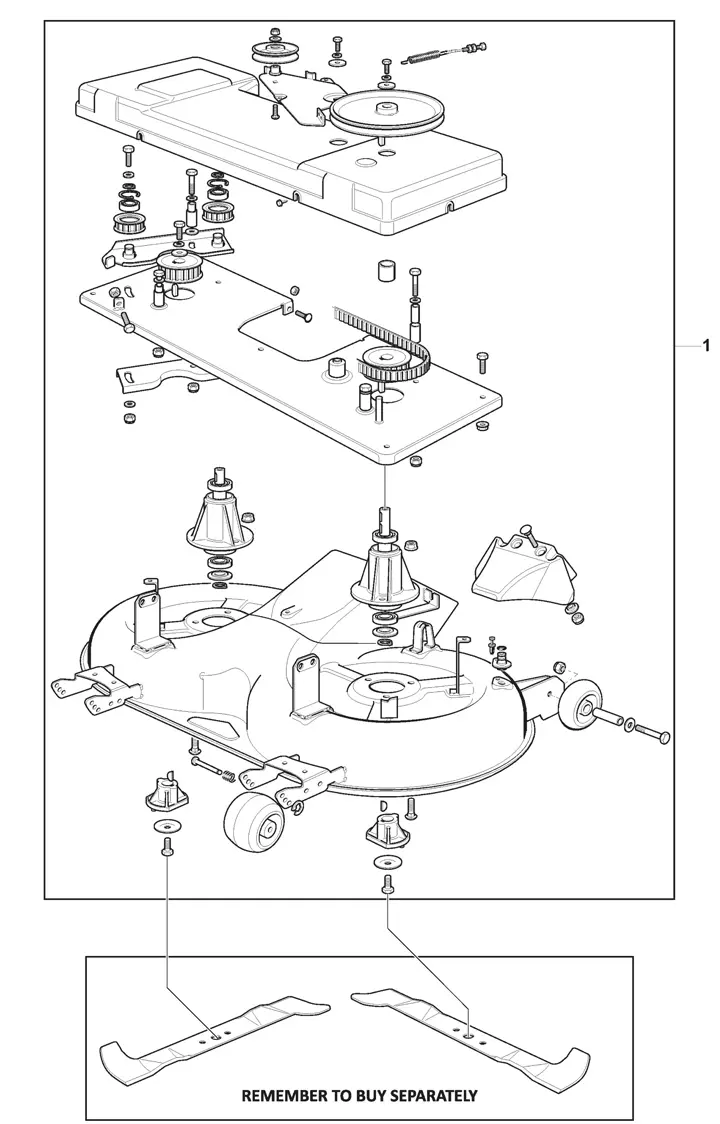

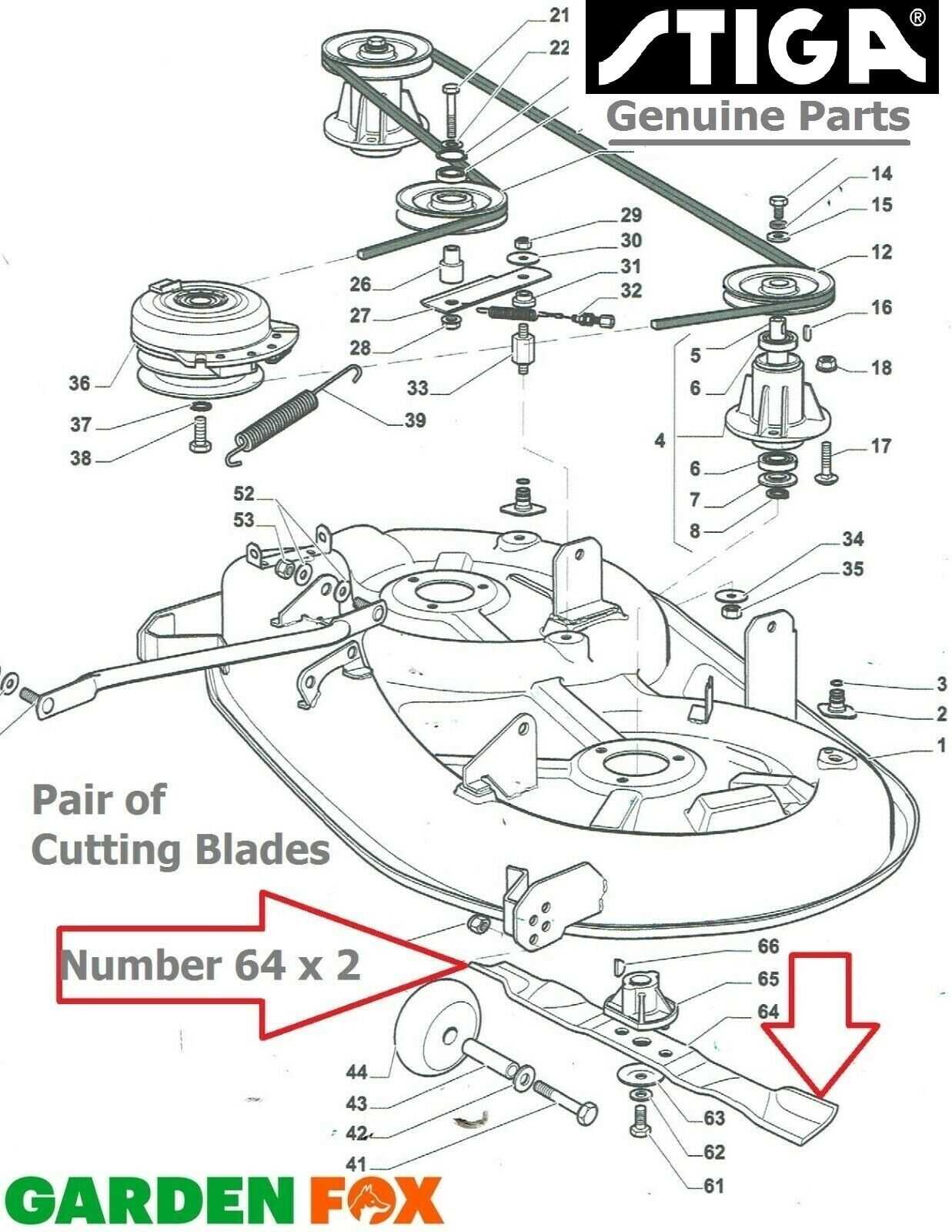

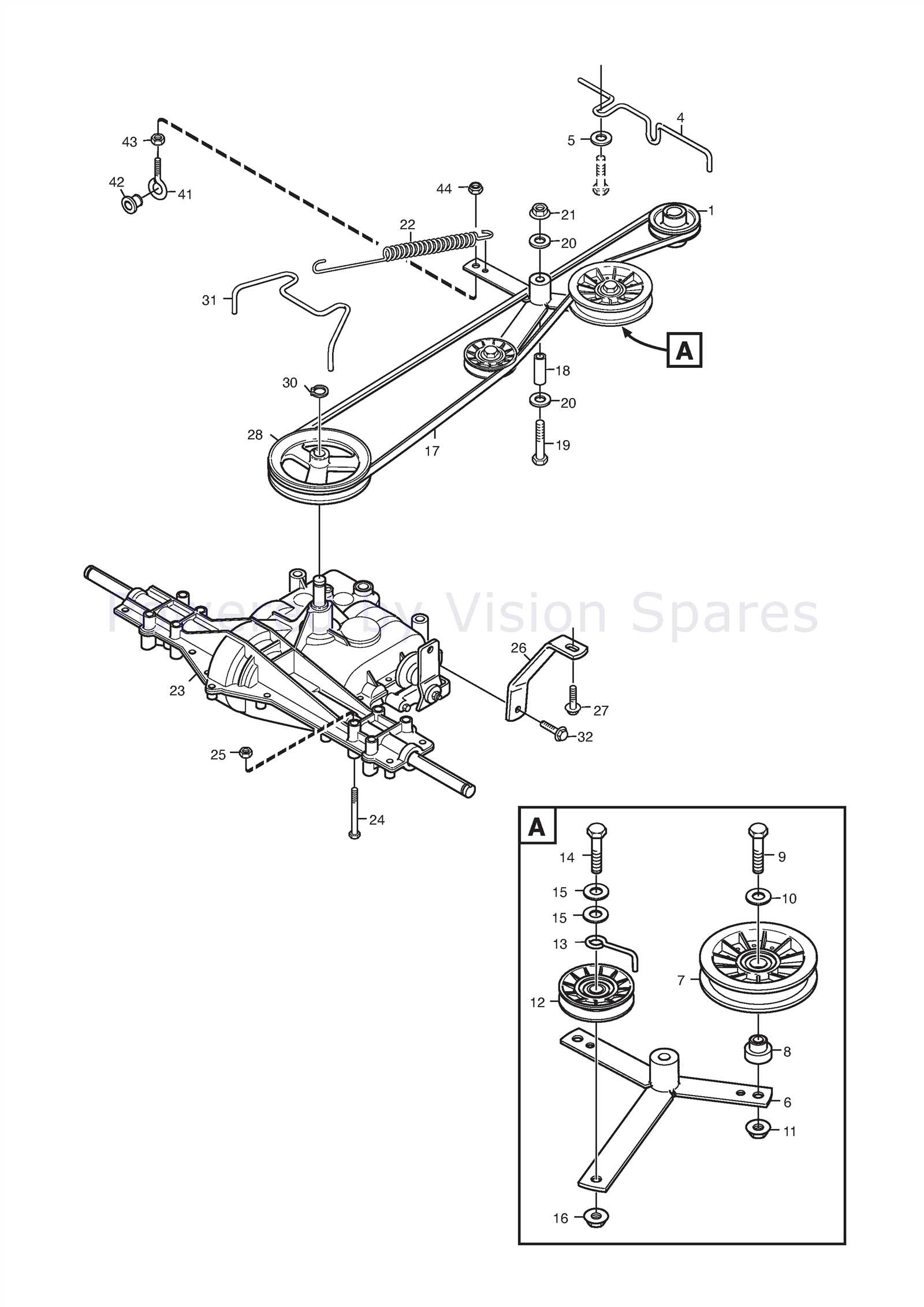

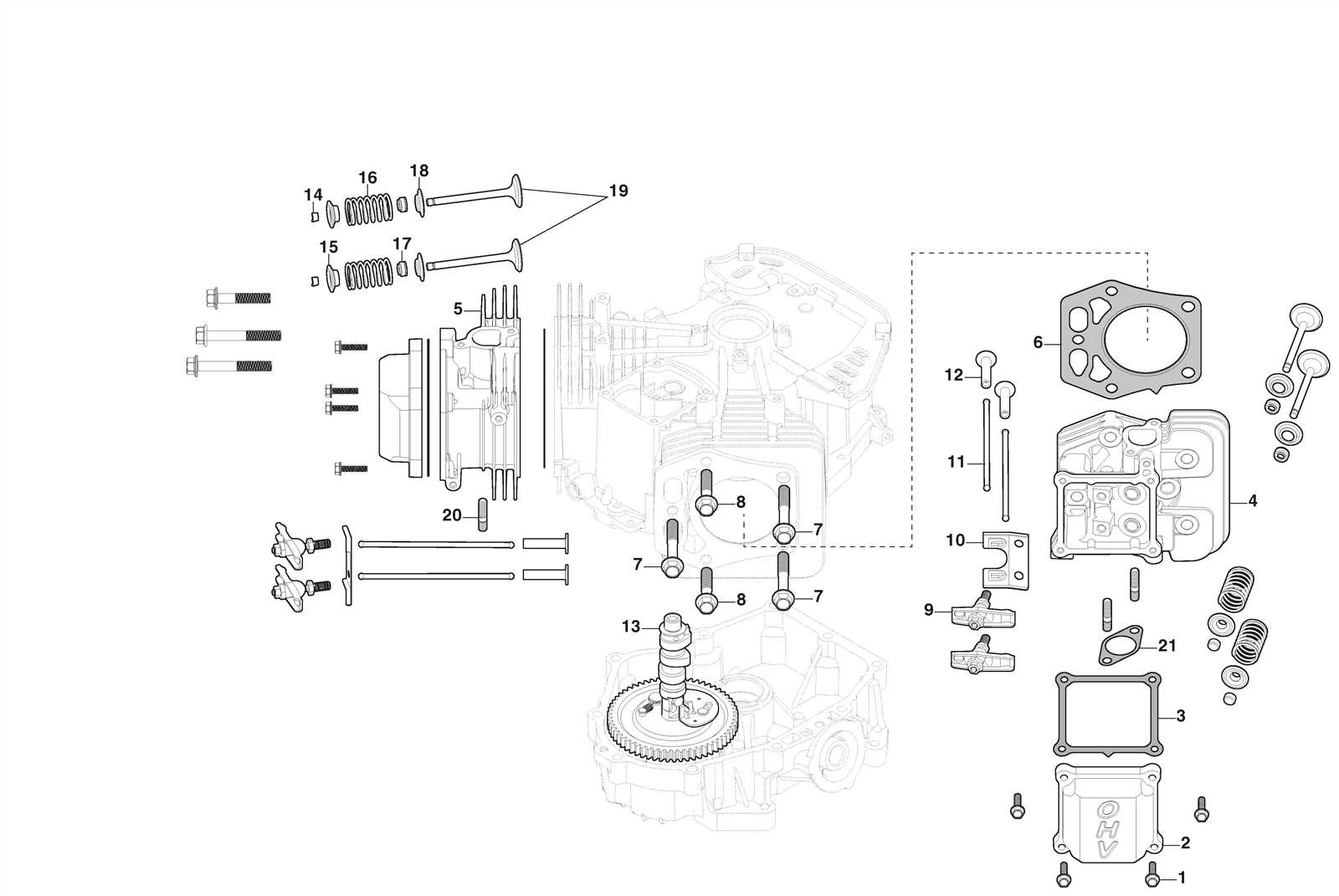

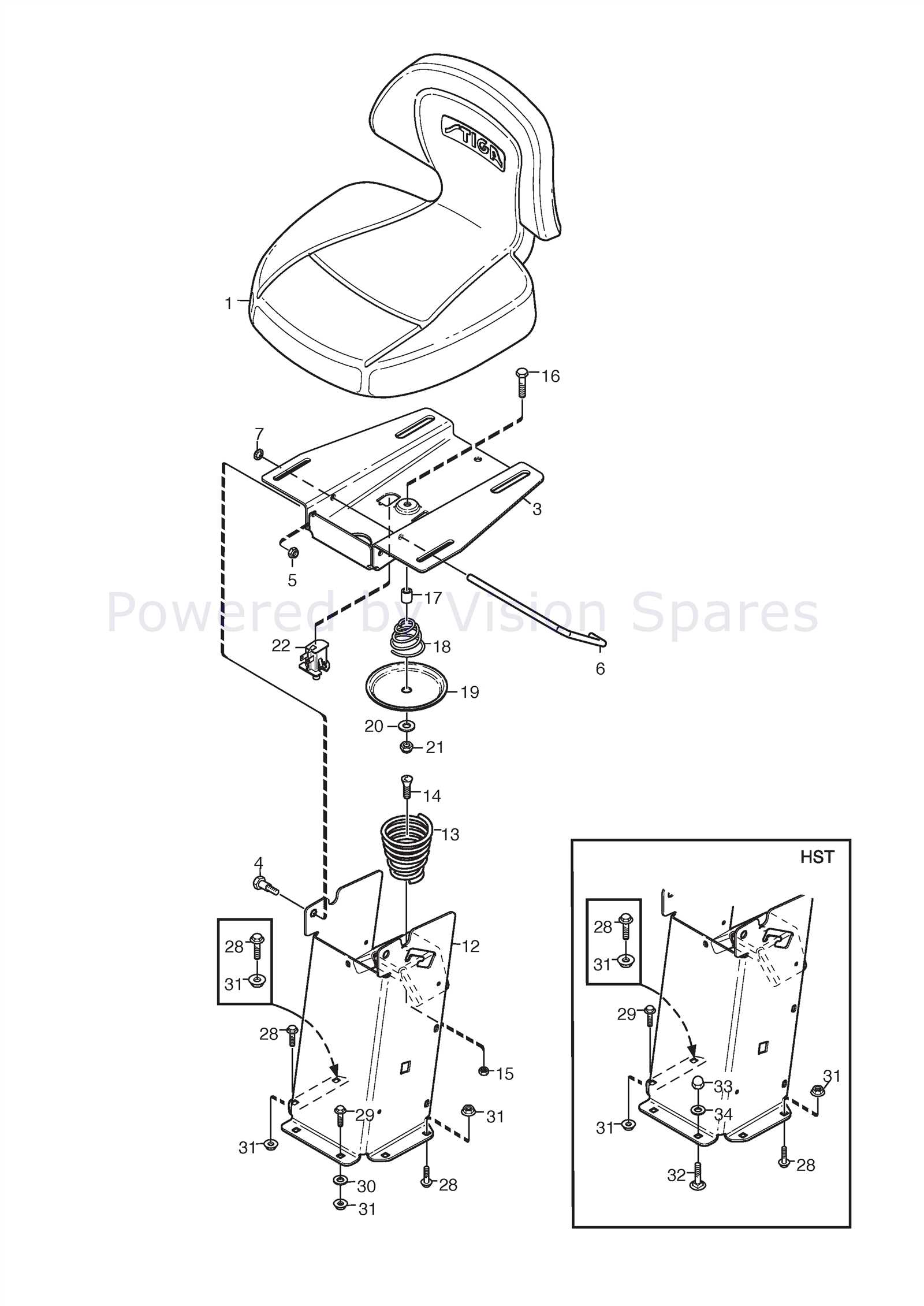

Visual representations of these components can serve as invaluable tools for technicians and enthusiasts alike. They not only clarify the relationships between different parts but also provide a roadmap for troubleshooting and assembly. Such illustrations can transform a daunting task into a manageable one, simplifying complex procedures.

By exploring these visual aids, users can become more proficient in handling their equipment, leading to improved longevity and efficiency. Whether you are a seasoned professional or a novice, understanding the layout and functions of each element will empower you to take control of your machinery.

Understanding Stiga Parts Diagrams

Grasping the layout of components is essential for effective maintenance and repair. These visual representations offer insights into the assembly and functionality of various elements, enabling users to identify specific sections quickly. A thorough comprehension can ultimately enhance efficiency in troubleshooting and restoration tasks.

Each representation typically includes a detailed breakdown of the elements, highlighting connections and interdependencies. This clarity assists in ensuring that every piece is accounted for, minimizing the risk of errors during assembly. Familiarity with these visuals empowers users to make informed decisions, fostering a deeper understanding of the machinery.

Additionally, the use of these illustrations aids in communication with suppliers or service technicians, as they provide a common reference point. By delving into the specifics of each element, one can ascertain the appropriate replacements or adjustments needed, enhancing the overall performance and longevity of the equipment.

Importance of Accurate Parts Identification

Proper identification of components is crucial for effective maintenance and repair tasks. Without precise recognition, the entire process can lead to inefficiencies, increased costs, and potential equipment failure.

Understanding the significance of accurate identification involves several key factors:

- Efficiency: Correctly identifying components streamlines the repair process, allowing for quicker resolution of issues.

- Cost-effectiveness: By ensuring the right items are used, unnecessary expenditures on incorrect or duplicate components can be avoided.

- Safety: Using the right parts is vital for maintaining safety standards, preventing accidents that could arise from faulty repairs.

- Longevity: Properly matched components contribute to the durability and longevity of equipment, reducing the frequency of repairs.

Moreover, maintaining a well-organized reference for component identification can enhance the overall workflow:

- Regularly updating manuals and references can prevent confusion.

- Training staff on the importance of precise identification ensures everyone is on the same page.

- Implementing technology solutions can facilitate faster searches for needed components.

In conclusion, the accurate recognition of components plays a fundamental role in the maintenance ecosystem, ultimately leading to better performance and reliability of equipment.

Common Components in Stiga Products

When exploring the essentials of outdoor equipment, understanding the various elements that contribute to performance and functionality is crucial. Each machine comprises several key components that work harmoniously to deliver efficiency and reliability. Familiarity with these elements can enhance maintenance practices and improve overall user experience.

Engines serve as the heart of any outdoor machinery, providing the necessary power to perform various tasks. Their efficiency is pivotal, and regular checks can ensure longevity and optimal performance.

Blades are vital for cutting and trimming applications. Different designs cater to specific needs, whether for grass, hedges, or other vegetation. Maintaining sharpness and integrity is essential for achieving precise results.

Wheels and treads play a significant role in maneuverability. The right selection can enhance traction and stability, especially on uneven surfaces, making them a critical aspect of outdoor operations.

Handles and controls are designed with user comfort in mind. Ergonomically designed grips reduce fatigue during extended use, while intuitive controls facilitate ease of operation.

Finally, chassis and framework provide structural integrity to the equipment. A robust design not only enhances durability but also impacts the overall performance of the machine in various conditions.

Understanding these fundamental components can significantly impact maintenance strategies and help users make informed decisions when selecting or servicing their outdoor machinery.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide valuable insights into the structure and functionality of various elements, enabling users to identify and source the necessary items with ease.

Identifying Key Features

Begin by familiarizing yourself with the main sections of the illustration. Look for labels and numbers that correspond to specific components. Each part is typically marked clearly, allowing for quick reference. Pay attention to any accompanying notes or legends that explain the symbols used, as these can clarify the relationships between different elements.

Navigating the Layout

The arrangement of the visual representation often follows a logical order, reflecting the assembly or disassembly process. Observe how components are grouped and whether they are displayed in a linear fashion or clustered together. Understanding this layout will enhance your ability to locate the required items and comprehend their connections within the overall system.

Tip: Always keep a reference or manual on hand for additional context, as it can significantly aid in your understanding of the visual materials.

Finding Replacement Parts Easily

Locating the right components for your equipment can often feel like a daunting task. However, with a structured approach, you can simplify the process and ensure that you acquire the necessary items without unnecessary hassle. This section offers insights into effective strategies for identifying and sourcing the right replacements.

Utilizing Online Resources

The internet is a powerful tool for finding the components you need. Many manufacturers provide extensive online catalogs that include detailed listings of available items. Additionally, there are various platforms dedicated to parts exchanges and sales, where you can search by model or specific requirements. Make use of search filters and comparison tools to streamline your search.

Consulting User Manuals

User manuals are often overlooked but are invaluable resources when looking for replacements. These documents typically include diagrams, part numbers, and maintenance tips that can significantly aid in identifying the exact items required. If you don’t have a physical copy, many manufacturers offer digital versions online. Taking the time to reference these manuals can save you both time and money in the long run.

Tips for Maintenance and Repair

Regular upkeep and timely repairs are essential for extending the lifespan of your outdoor equipment. By following a few simple guidelines, you can ensure optimal performance and avoid unnecessary breakdowns.

1. Regular Inspections: Make it a habit to inspect your machinery periodically. Look for signs of wear, loose components, or any unusual noises that could indicate a problem.

2. Cleanliness Matters: Keeping your equipment clean can prevent dirt buildup, which may hinder performance. Regularly remove debris from filters and other critical areas.

3. Lubrication: Ensure all moving parts are adequately lubricated. This reduces friction and helps maintain efficiency.

4. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance schedules and repair procedures. Adhering to these can significantly enhance the durability of your equipment.

5. Safety First: When performing repairs, prioritize safety. Disconnect power sources and use protective gear to prevent accidents.

By incorporating these practices, you can delve deeper into effective maintenance and enjoy the ultimate reliability of your equipment.

Stiga Model Variations Explained

This section provides an overview of the diverse models available in the lineup, highlighting key differences and features that cater to various user needs. Understanding these variations is essential for making informed decisions and maximizing performance.

Key Differences in Design

The range of models showcases distinct design elements tailored for specific tasks. Some are engineered for compactness and ease of use, while others prioritize power and durability, appealing to both casual users and professionals alike.

Performance Features

Each model offers unique performance attributes, such as engine power, cutting width, and maneuverability. By examining these features, potential users can delve into which variant aligns best with their requirements, ensuring optimal results.

Where to Access Diagrams Online

Finding detailed visual aids for various equipment can significantly enhance your understanding and maintenance efforts. Numerous platforms offer access to these valuable resources, ensuring users can easily locate the information they need for effective repairs and servicing.

| Source | Description | Link |

|---|---|---|

| Manufacturer Website | Official sites often provide comprehensive resources, including user manuals and schematics. | Visit Here |

| Online Retailers | Many retailers feature sections dedicated to product details, including diagrams for reference. | Visit Here |

| Community Forums | Forums can be rich sources of shared resources and links to various visual guides. | Visit Here |

| YouTube | Video tutorials often include visuals that are helpful for understanding assembly and parts. | Visit Here |

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functionality. Understanding these elements can enhance your experience and ensure optimal performance.

What should I do if I can’t find the specific component I need? Consider checking online resources or contacting customer support for assistance.

How can I ensure I’m purchasing the right replacement? Always refer to your model’s specifications and consult available manuals for guidance.

Are there any tips for maintaining these components? Regular cleaning and inspection can significantly prolong their lifespan.

What warranty options are available for replacements? Review the manufacturer’s policy, as many offer warranties on their products.

Comparing Diagrams Across Models

Understanding the relationships and components among different models can enhance the maintenance and repair process. By analyzing the visual representations that illustrate the assembly and layout of parts, users can identify similarities and differences, leading to better decision-making in servicing various units.

| Model | Common Features | Unique Aspects |

|---|---|---|

| Model A | Component X, Y, Z | Distinct Layout A |

| Model B | Component X, Y | Enhanced Component B |

| Model C | Component Y, Z | Improved Design C |

Using Diagrams for Troubleshooting

Visual representations can be invaluable when diagnosing issues in mechanical equipment. They provide a clear overview of components and their interrelations, making it easier to pinpoint where problems may arise. By referring to these illustrations, users can systematically approach repairs and maintenance, ensuring that no aspect is overlooked.

Enhancing Understanding of Components

These visual aids offer detailed insights into individual elements of a machine, helping users comprehend their functions and locations. When a malfunction occurs, a well-crafted illustration can guide the user to specific parts, making it simpler to identify potential faults. This clarity reduces the time spent troubleshooting and enhances overall efficiency.

Streamlining the Repair Process

By utilizing these resources, technicians can follow step-by-step procedures for disassembly and reassembly. Clear visual instructions minimize the risk of errors, allowing for a more organized repair process. Furthermore, this approach can help in ordering the correct replacements, ensuring that repairs are carried out effectively and promptly.

Benefits of DIY Repairs with Diagrams

Engaging in self-repairs offers a myriad of advantages, particularly when utilizing visual guides. These resources empower individuals to take control of their maintenance tasks, enhancing both skill and confidence.

- Cost Savings: Performing repairs independently significantly reduces expenses associated with professional services.

- Understanding Mechanisms: Visual aids provide insight into how components interact, fostering a deeper comprehension of the equipment.

- Skill Development: DIY repairs enhance problem-solving abilities and practical skills, making future tasks easier.

- Personal Satisfaction: Successfully completing a repair instills a sense of achievement and pride in one’s capabilities.

By delving into these resources, enthusiasts can navigate repairs more effectively, leading to improved performance and longevity of their equipment.

Expert Advice on Parts Selection

Choosing the right components for maintenance and repair is crucial for ensuring optimal performance and longevity of your equipment. With various options available, it is essential to understand the factors that influence your selection process. This guide provides valuable insights to help you make informed decisions when sourcing essential items for your machinery.

Understand Compatibility

Before making any purchase, verify that the items you select are compatible with your equipment. This includes checking model numbers and specifications to avoid any mismatches that could lead to performance issues. Utilizing manufacturer resources can also provide clarity on which components are suitable for your specific needs.

Prioritize Quality

Investing in high-quality components is vital for the long-term functionality of your machinery. While it might be tempting to opt for cheaper alternatives, these options often compromise durability and reliability. Look for trusted brands and consider customer reviews to ensure you choose items that meet rigorous standards.