Understanding the intricate components of machinery is crucial for effective maintenance and repair. A well-structured overview of these elements aids users in identifying specific parts and their functions within the system. By grasping the layout and organization of the components, individuals can enhance their troubleshooting and operational efficiency.

This section provides a comprehensive look at the essential elements found within the machinery, detailing their arrangement and interconnections. Recognizing how each part contributes to overall functionality is key for both novice and experienced users alike. A clear depiction of these components will facilitate informed decisions regarding repairs and replacements.

Equipped with this knowledge, users can approach maintenance tasks with greater confidence. Whether for routine upkeep or addressing specific issues, having a solid understanding of the layout and function of each component will lead to improved performance and longevity of the machinery.

This section outlines a comprehensive framework for an informative piece centered around a specific mechanical assembly. The focus will be on various components, their functionalities, and the overall structure that contributes to efficient operation. Each heading will delve into different aspects, providing valuable insights into the intricate design and engineering behind the assembly.

- Introduction to the Mechanical Assembly

- Key Components and Their Functions

- Assembly Overview and Configuration

- Maintenance Tips for Optimal Performance

- Common Issues and Troubleshooting Techniques

- Replacement Procedures for Essential Parts

- Compatibility with Various Models

- Tools Required for Assembly and Repair

- Safety Guidelines for Handling Components

- Upgrades and Customization Options

- Resources for Further Reading and Support

Essential Components of K61

The functionality and efficiency of the K61 model rely heavily on its crucial elements. Understanding these components is vital for anyone looking to maintain or enhance the performance of this machinery. Each part plays a significant role in ensuring smooth operation and longevity.

Main Functional Parts

- Transmission System: Facilitates power transfer and speed control.

- Engine Assembly: Provides the necessary power for operation.

- Cooling System: Maintains optimal temperatures during use.

Supporting Components

- Fuel System: Ensures efficient fuel delivery to the engine.

- Electrical System: Powers various functions and controls.

- Chassis: Provides structural integrity and support for all components.

Each of these elements must work harmoniously to achieve peak performance. Regular inspection and maintenance of these components are essential for optimal functionality and to prevent unexpected failures.

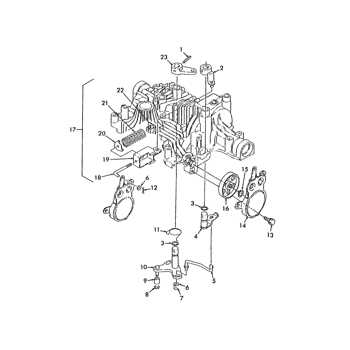

Understanding the Parts Diagram

The visual representation of components is essential for comprehending the assembly and functionality of machinery. It serves as a valuable tool for both maintenance and repair, allowing users to identify individual elements and their specific roles. By familiarizing oneself with this illustration, one can gain insights into the overall structure and operation of the equipment.

Key Components Explained

Each element in the visual representation plays a vital role in the machine’s performance. Here are some common components:

- Housing: The protective casing that contains all internal parts.

- Shaft: A rotating component that transmits power.

- Bearings: Support structures that facilitate smooth movement.

- Gears: Elements that interlock to transmit motion and force.

Benefits of Familiarity

Being knowledgeable about the individual components offers numerous advantages:

- Improved troubleshooting capabilities.

- Streamlined maintenance procedures.

- Enhanced understanding of the machinery’s functionality.

- Increased efficiency in repairs.

Common Issues with K61 Parts

When dealing with mechanical systems, various challenges can arise that impact functionality and performance. Understanding these typical complications is essential for effective maintenance and troubleshooting.

Here are some frequent problems encountered in these systems:

- Wear and Tear: Over time, components may degrade due to regular usage, leading to inefficiencies.

- Fluid Leaks: Seals and gaskets can become damaged, resulting in leaks that affect performance.

- Alignment Issues: Misalignment of components can cause abnormal wear and operational failures.

- Clogging: Debris can accumulate in filters or hoses, obstructing fluid flow and reducing efficiency.

Addressing these issues promptly can extend the lifespan of the system and enhance its overall performance.

How to Read the Diagram

Understanding a schematic representation is crucial for effectively working with mechanical systems. These visual aids provide essential information about the components and their relationships within a specific assembly. Familiarizing yourself with the elements represented in such visuals can significantly enhance your troubleshooting and maintenance efforts.

Key Components Explained

Each symbol and line in the representation conveys specific information. The shapes typically indicate different parts, while the connections illustrate how these elements interact. Take note of any labels or annotations, as they often describe the function or specifications of the respective components.

Step-by-Step Approach

Start by identifying the major sections within the visual guide. Focus on the flow of the system and how various elements are linked. Utilize color coding or numbering systems to track your understanding, ensuring that you grasp the overall layout before diving into the details of individual parts.

Replacement Parts for K61

When maintaining a mechanical system, sourcing quality components is crucial for ensuring optimal performance and longevity. This section explores the various elements available for restoration and upkeep of a specific model, highlighting the importance of compatibility and reliability.

Essential Components

Among the key items necessary for effective maintenance are filters, belts, and bearings. Each component plays a vital role in the overall functionality, contributing to smooth operation and efficiency. Choosing the right replacements ensures that the machine operates as intended, preventing unnecessary wear and tear.

Where to Find Quality Replacements

Quality replacements can often be found through authorized distributors or online retailers specializing in mechanical components. It is recommended to verify that the sourced items meet the specifications of the model to guarantee proper fit and functionality.

Tools Needed for Maintenance

Proper upkeep of machinery requires a selection of essential tools to ensure efficiency and longevity. Understanding which instruments are necessary can facilitate smooth operation and help prevent potential issues. Having the right equipment on hand allows for timely interventions, thereby maintaining optimal performance.

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten or loosen bolts and nuts. |

| Screwdriver Set | For securing or removing screws. |

| Oil Can | To lubricate moving parts. |

| Socket Set | For various sizes of fasteners. |

| Cleaning Brush | To remove dirt and debris from components. |

| Multimeter | To check electrical connections and voltage. |

| Safety Gear | To ensure personal protection while working. |

Assembly Process for K61

The assembly procedure for this specific model involves a series of systematic steps aimed at ensuring optimal functionality and durability. Each component plays a crucial role in the overall performance, making it essential to follow the guidelines accurately.

Begin by gathering all necessary components and tools. This preparation phase is vital for a smooth assembly experience. Ensure that the workspace is clean and organized to prevent any mix-ups during the process.

Start with the foundation, carefully attaching the main structure. Secure each part firmly, using the recommended fasteners. Pay attention to alignment, as precise positioning is critical for seamless operation.

Next, integrate the additional components, ensuring that each one fits properly. Utilize the correct tools for tightening and adjustments, avoiding over-tightening, which can lead to damage. Follow the sequence of assembly as outlined in the guidelines to maintain consistency.

Once all elements are in place, conduct a thorough inspection to verify that everything is securely attached and functioning as intended. Testing the assembled unit will help identify any potential issues before putting it into service.

By adhering to these assembly steps, you can achieve a well-constructed unit that meets performance expectations and extends the longevity of the machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any machinery. Regular attention and care can prevent premature wear and ensure that the equipment operates efficiently. Here are some valuable suggestions to maintain optimal performance.

Regular Inspections

- Conduct routine checks to identify any signs of wear or damage.

- Inspect belts, seals, and connections for tightness and integrity.

- Monitor fluid levels and look for leaks that could indicate underlying issues.

Scheduled Servicing

- Establish a regular maintenance schedule to keep your equipment in top shape.

- Replace filters and fluids according to the manufacturer’s recommendations.

- Clean components regularly to prevent buildup of debris and dirt.

By adhering to these maintenance practices, you can enhance the longevity and reliability of your machinery, ensuring it continues to perform effectively over time.

Where to Buy Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. There are various avenues to explore when seeking high-quality replacements or accessories. Knowing where to look is essential to ensure you obtain genuine items that meet the required specifications.

Authorized Retailers

One of the most reliable options is to visit authorized dealers. These retailers are equipped with the necessary knowledge and inventory to assist you in selecting the appropriate components. They often have direct access to the manufacturer’s resources, ensuring authenticity and compliance with quality standards.

Online Marketplaces

Online platforms provide a convenient alternative for sourcing necessary components. Websites specializing in equipment supplies often have extensive catalogs featuring a wide range of options. When shopping online, ensure that the seller is reputable and check customer reviews to confirm the quality of the items being offered. Look for warranties or return policies to safeguard your purchase.

Customer Reviews on K61 Performance

This section explores the feedback from users regarding the performance of a specific engine model. Reviews highlight various aspects of functionality, reliability, and overall satisfaction, providing valuable insights for potential buyers.

User Satisfaction

Many users express high levels of satisfaction with the engine’s efficiency and power delivery. They appreciate its ability to handle various terrains effortlessly, making it a preferred choice for both residential and commercial applications. The reliable performance under demanding conditions has been a common point of praise.

Areas for Improvement

While the overall response is positive, some customers mention areas that could benefit from enhancement. Issues such as maintenance requirements and noise levels are discussed, suggesting that improvements in these areas could further elevate user experience. Feedback emphasizes the importance of ongoing support and availability of replacement components for maintaining optimal functionality.