Understanding the internal structure of home cleaning systems is essential for both maintenance and repairs. By familiarizing yourself with the layout of the different elements, you can quickly identify any potential issues and resolve them efficiently. This guide offers a clear view into the arrangement of all necessary elements, helping users gain confidence when it comes to handling their equipment.

Efficient system management starts with knowing how various elements are interconnected. Whether you’re troubleshooting a malfunction or simply conducting routine upkeep, visualizing the organization of the system’s components will help streamline your efforts. Each part plays a role, and knowing their placement ensures you’re well-prepared for any task.

In this detailed breakdown, we’ll explore the structure of the system and its various components, emphasizing their roles and connections. With a clear understanding of these elements, users can ensure smoother operation and better maintenance.

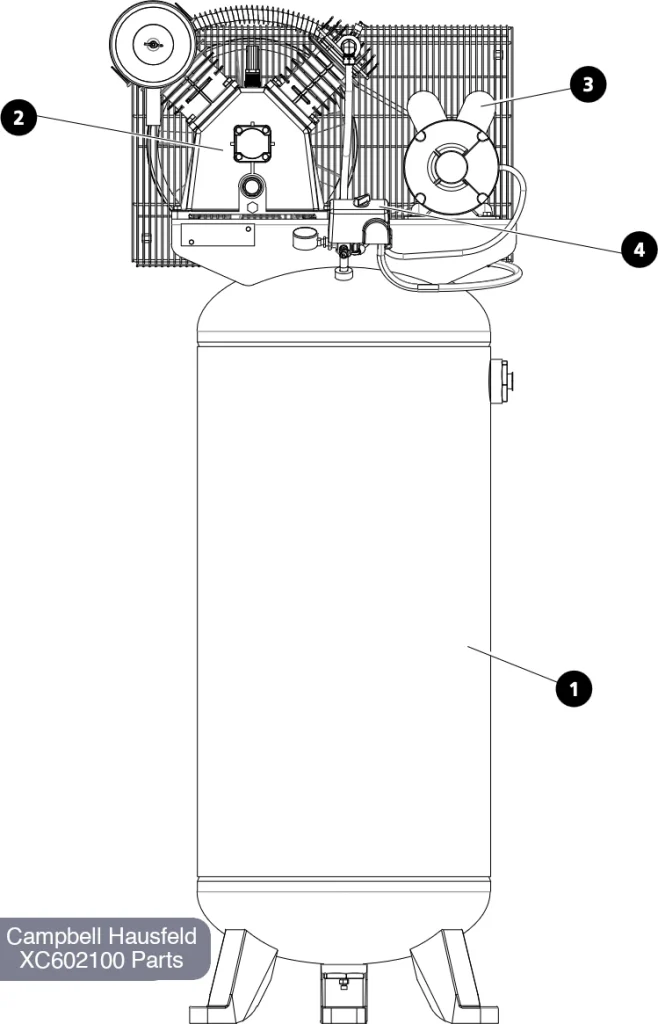

Understanding the Structure of Vacuflo 560

The system’s layout is designed for efficiency and seamless operation. It consists of several key components working in harmony to provide optimal performance. By understanding how these elements interact, users can gain a clearer perspective on the inner workings of this device, making it easier to maintain and troubleshoot.

The central unit serves as the heart of the system, responsible for generating the necessary force to move air and debris. It is complemented by various filters and tubing that channel the airflow throughout the connected spaces.

Additionally, strategically placed connectors and attachments allow for a versatile configuration, ensuring compatibility with different areas. Every element has its role, from the intake points to the exhaust outlets, contributing to the smooth operation of the overall setup.

Key Components of the Vacuflo 560 System

Understanding the crucial elements of this central cleaning unit allows users to maintain and optimize its performance effectively. Each component plays a vital role in the overall functionality, ensuring efficient operation and reliability. Below is an overview of the primary components that make up this system, focusing on their function and importance.

- Main Power Unit: This central element generates the necessary suction, driving the cleaning process and ensuring debris is collected effectively.

- Filtration System: Designed to trap dust and particles, this mechanism ensures clean air output while maintaining the efficiency of the unit.

- Inlet Valves: Strategically placed around the space, these access points allow for the connection of hoses and attachments, directing airflow to the main unit.

- Piping Network: The system of tubes that transports debris from the cleaning area to the main unit, ensuring an uninterrupted flow throughout the operation.

- Cleaning Attachments: A variety of

How the Vacuum Motor Operates

The operation of a vacuum motor is based on creating airflow that generates suction. By utilizing a rotating mechanism, the motor pulls in air through an intake, directing it through a series of internal components. This process is crucial for producing the pressure difference required for efficient suction, ensuring debris and dust are captured effectively.

At the heart of the system is a fan or impeller connected to the motor’s shaft. As it spins, the impeller accelerates the air, creating a low-pressure zone. This pressure imbalance causes air from the surrounding area to rush into the system, drawing particles along with it. The air is then expelled, completing the cycle and maintaining continuous suction power.

Key elements, such as bearings and brushes, work together to ensure smooth operation of the motor. These components reduce friction and wear, helping to extend the lifespan of the system. Regular maintenance is essential to keep the motor functioning efficiently, preventing blockages and mechanical failure over time.

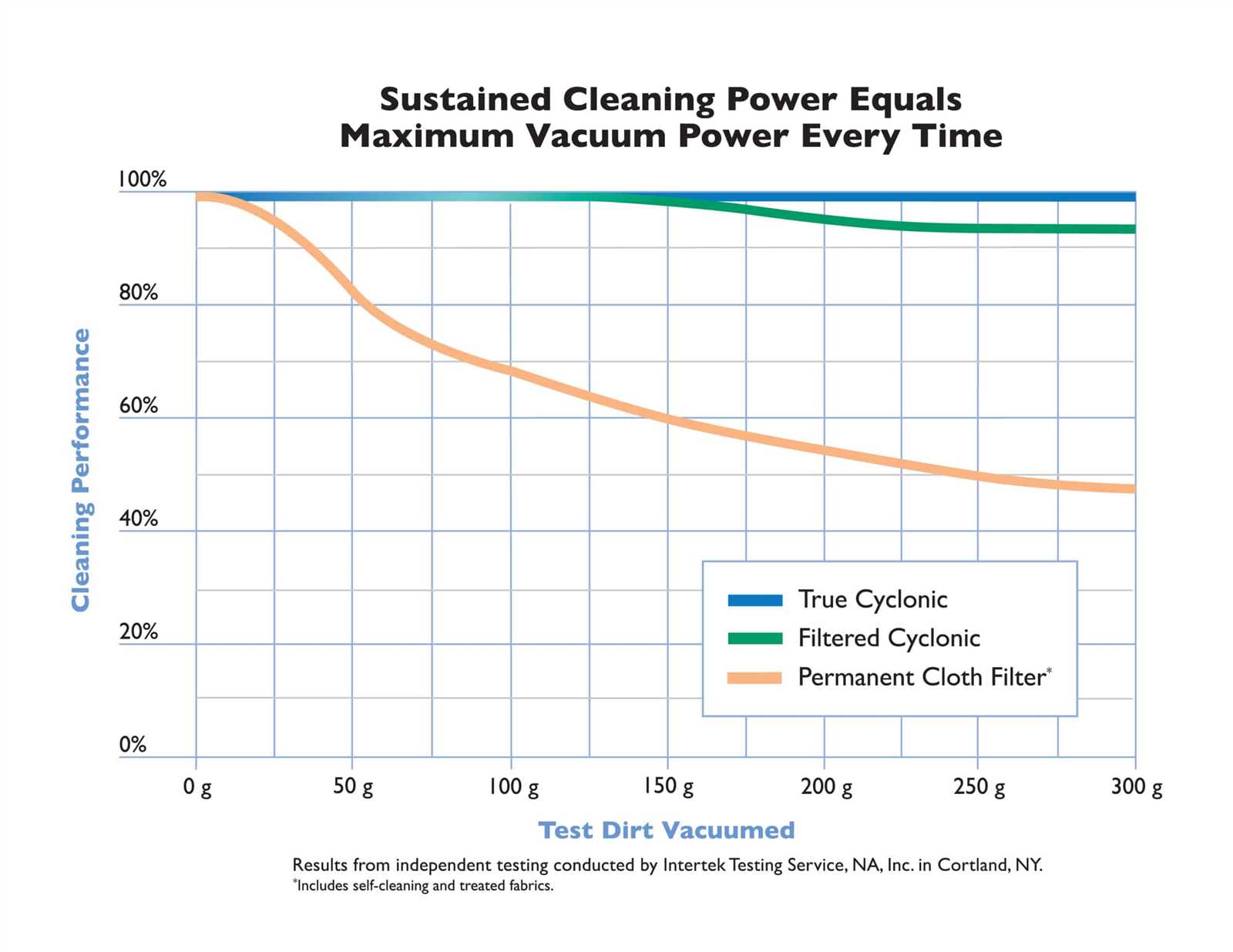

Significance of the Filtration Mechanism

The filtration system plays a crucial role in maintaining the efficiency and longevity of cleaning devices. It ensures that dust, dirt, and other particles are effectively captured, preventing them from being reintroduced into the air. A well-designed filtration mechanism helps in improving air quality, enhancing the overall performance of the equipment, and reducing maintenance needs over time.

Enhanced Air Quality

A key benefit of a strong filtration mechanism is its ability to improve indoor air quality. By trapping fine particles, allergens, and pollutants, it keeps the environment cleaner and healthier. This is especially important for individuals with allergies or respiratory issues, as clean air promotes better health and comfort.

Durability and Maintenance

In addition to improving air quality, the filtration system extends the lifespan of the device. By capturing harmful debris before it reaches critical components, it reduces wear and tear, minimizing the risk of breakdowns and costly repairs. Regularly maintaining the filter also ensures optimal performance, keeping the system running smoothly and efficiently.

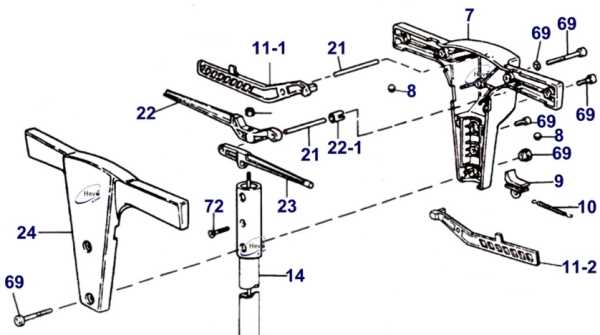

Examining the Tubing and Connections

Understanding the system of tubes and their connectors is crucial for ensuring efficient airflow and overall functionality. These components form the backbone of any vacuum system, facilitating the smooth transfer of air and debris through the network.

Key Aspects of Tubing

The tubing in this setup is responsible for guiding air through the various sections. It must be properly aligned and secured to avoid any leaks or drops in performance. Durability and resistance to wear and tear are essential for long-lasting use.

- Ensure that all sections of the tubing are securely fastened to avoid any gaps.

- Regular inspections of the tubing can prevent clogging and buildup of debris.

- Opt for tubing materials that are resistant to cracks and tears, which can compromise efficiency.

Connections and Fittings

The joints where tubes meet need to be tightly sealed to maintain airflow integrity. Using appropriate fittings ensures that the system operates without interruptions or loss of suct

Identifying and Replacing Key Seals

Maintaining optimal performance in your vacuum system often involves careful attention to essential components that can wear out over time. Among these components, seals play a crucial role in ensuring airtight connections, preventing leaks, and enhancing the overall efficiency of the unit. Understanding how to identify and replace these key seals can significantly extend the lifespan of your system and improve its functionality.

Identifying Seals

To begin, it’s important to recognize the different types of seals used in your device. Common types include O-rings, gaskets, and flat seals. Inspecting these components regularly for signs of wear, such as cracks, deformation, or discoloration, can help you determine when a replacement is necessary. Pay special attention to areas where two parts meet, as these are often the most susceptible to damage.

Replacing Seals

When it comes to replacement, ensure you have the correct size and type of seal on hand. Carefully remove the old seal, taking care not to damage the surrounding components. Before installing the new seal, clean the surfaces to remove any debris or old adhesive that may affect the seal’s effectiveness. Apply the new seal, ensuring it fits snugly and evenly in its designated groove. Finally, reassemble the components, taking care to avoid over-tightening, which can lead to further damage.

Regular maintenance and prompt replacement of worn seals can prevent air leaks and maintain the efficiency of your vacuum system. By being proactive in this regard, you can enjoy a more effective and long-lasting device.

Electrical System Overview in Vacuflo 560

The electrical framework within this model plays a crucial role in its operational efficiency. Understanding its components and functionality is essential for optimal performance and maintenance. This section will provide insights into the key elements that comprise the electrical system, their interconnections, and their significance in the overall functioning of the unit.

Main Components

- Power Source: The primary supply that energizes the entire system.

- Control Circuit: Manages the operation of various elements based on user input and system requirements.

- Motor Assembly: Converts electrical energy into mechanical motion, enabling the device to function effectively.

- Switching Mechanism: Facilitates the activation and deactivation of the system, allowing for user control.

System Functionality

The electrical setup operates through a series of interactions between its components. When the power source is engaged, it feeds energy into the control circuit, which directs the flow to the motor assembly. This process initiates the suction mechanism, creating the necessary force for the device’s intended purpose. Additionally, the switching mechanism allows users to easily control the system, enhancing user experience.

Regular maintenance of the electrical components is vital to ensure longevity and efficiency. Understanding the layout and function of each part will aid in troubleshooting and repairs, contributing to sustained performance over time.

Maintenance Tips for Longer Component Life

Proper upkeep is essential for ensuring the longevity and efficiency of your cleaning system’s components. By adhering to specific maintenance practices, you can prevent premature wear and ensure optimal performance over time. This section outlines several strategies that can help extend the lifespan of your equipment.

Regular Cleaning and Inspection

Routine cleaning is vital to keep the system functioning smoothly. Accumulation of dirt and debris can lead to reduced efficiency and potential damage. Regular inspections allow you to identify worn parts early, preventing further issues. Pay close attention to the following components:

Component Maintenance Tip Filters Clean or replace regularly to maintain airflow. Hoses Check for blockages and leaks; replace if necessary. Brushes Inspect for wear; clean bristles to ensure effective cleaning. Motor Ensure proper lubrication to prevent overheating. Scheduled Maintenance

Implementing a scheduled maintenance routine can significantly improve the durability of your equipment. Create a timetable for deep cleaning and replacement of critical parts. This proactive approach not only enhances performance but also reduces the risk of unexpected breakdowns.

Common Issues with Vacuum Parts

Understanding frequent complications associated with cleaning equipment components can greatly enhance maintenance efficiency and prolong the lifespan of the devices. Identifying these issues early allows for timely interventions, ensuring optimal functionality and performance.

Common Problems Encountered

- Clogs: Accumulation of debris can obstruct airflow, reducing suction power and leading to overheating.

- Wear and Tear: Regular usage can cause components to degrade, impacting performance and efficiency.

- Loose Connections: Over time, joints may become loose, resulting in air leaks and diminished suction capabilities.

Preventive Measures

- Regularly clean filters to maintain airflow.

- Inspect hoses for cracks or blockages.

- Tighten all connections to ensure a secure fit.

Compatibility of Spare Parts

The interchangeability of replacement components is essential for maintaining the efficiency and longevity of any vacuum system. Understanding which items can be utilized across different models ensures users can find suitable alternatives, reducing downtime and enhancing performance. This section will explore how various elements work together seamlessly, offering insights into compatibility factors.

Identifying Compatible Components

When searching for replacement elements, it’s crucial to consider the specifications and functionalities that align with your existing setup. Many components share similar characteristics, making them interchangeable among various models. Always check compatibility charts or consult with specialists to confirm that the replacements will function effectively within your system.

Benefits of Using Compatible Items

Utilizing compatible elements not only simplifies the repair process but also can lead to cost savings. Quality components designed to meet or exceed original specifications can enhance performance and ensure reliability. Investing in high-quality replacements can significantly improve the overall efficiency of the vacuum system, leading to better results and extended service life.

Safety Features in the Vacuflo 560 Design

The design of modern central vacuum systems incorporates a variety of safety mechanisms aimed at ensuring user protection and operational efficiency. These innovations not only enhance the overall experience but also minimize potential hazards during use.

- Overheat Protection: The system is equipped with sensors that detect excessive heat. If temperatures rise beyond a safe threshold, the vacuum automatically shuts down to prevent damage and ensure user safety.

- Automatic Shut-off: In the event of blockages or malfunctions, this feature halts operation to avoid potential harm to both the device and the user.

- Safe Electrical Design: The electrical components are designed to meet rigorous safety standards, reducing the risk of electrical failures and ensuring that the system operates reliably.

- Child Safety Locks: Many models include safety locks to prevent unauthorized use, providing peace of mind for families with young children.

- Air Filtration Systems: Advanced filtration minimizes allergens and dust particles, contributing to a healthier indoor environment while ensuring that the system functions efficiently.

These carefully considered features not only enhance the overall functionality of the system but also prioritize the safety of users in various settings.

Tools Required for Component Repairs

When addressing issues with various components of a vacuum system, having the right tools is essential for effective and efficient repairs. Proper tools not only simplify the process but also ensure that each task is completed with precision and care.

Here are some common tools you might need:

- Screwdrivers: A set of flathead and Phillips screwdrivers for removing screws and securing components.

- Pliers: Needle-nose and regular pliers to grip and manipulate small parts.

- Wrenches: Adjustable wrenches for loosening or tightening nuts and bolts.

- Socket Set: A variety of sockets to fit different bolt sizes for quick removal and installation.

- Utility Knife: For cutting through materials like tape or insulation.

- Multimeter: To measure voltage, current, and resistance for troubleshooting electrical components.

In addition to these basic tools, having a clean workspace and organization for your components will enhance the repair experience, making it easier to keep track of parts and ensure that everything is properly reassembled.

Where to Find Authentic Replacement Parts

Ensuring the longevity and efficiency of your vacuum system requires using genuine components. Authentic replacements are crucial for maintaining optimal performance and compatibility with your equipment. Below are some reliable sources to obtain these essential items.

One of the best places to start your search is through the manufacturer’s official website. They often provide a dedicated section for replacements, featuring a comprehensive selection of items tailored specifically for their models. This ensures that you receive high-quality, compatible components.

In addition to the manufacturer’s site, authorized retailers and specialty stores can be valuable resources. These establishments typically offer a range of genuine replacements, alongside knowledgeable staff who can assist with finding the right parts for your specific model.

Lastly, consider reputable online marketplaces that focus on home appliances. Look for sellers with positive reviews and a track record of providing authentic products. Always verify the product descriptions to ensure compatibility with your vacuum system.

Investing time in sourcing genuine components will not only enhance the performance of your equipment but also prolong its lifespan, ensuring that it serves you well for years to come.