In the world of metalworking, a reliable apparatus for flame-related tasks is essential. These instruments enable precision in various applications, from welding to shaping materials. A thorough grasp of their structure is crucial for both beginners and seasoned professionals.

Every device consists of several integral elements, each contributing to its overall functionality. By examining these components, users can optimize performance and enhance safety. This knowledge empowers operators to troubleshoot issues effectively and maintain their equipment with confidence.

Furthermore, delving into the specifics of each segment reveals the ultimate relationship between design and performance. Understanding how these pieces work together fosters a deeper appreciation for the craft and improves overall outcomes.

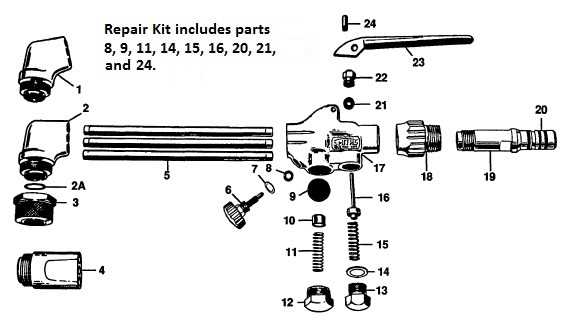

Understanding Victor Cutting Torch Components

Grasping the intricacies of a professional welding apparatus is essential for anyone working in metal fabrication. Each component plays a pivotal role in ensuring efficient operation and optimal performance. Familiarity with these elements not only enhances safety but also contributes to the quality of the finished product.

Essential Elements of the Equipment

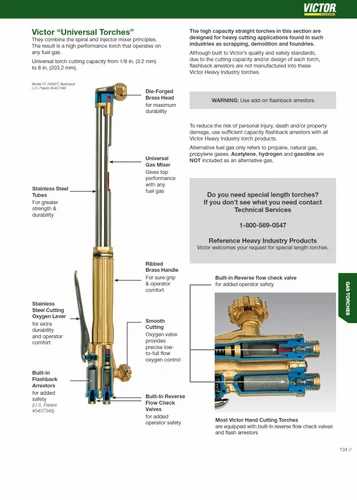

At the heart of this apparatus lies a mechanism designed to regulate the flow of gases, facilitating precise heat application. The handle serves as the operator’s point of control, housing essential valves and adjustments that govern performance. Additionally, the mixing chamber plays a crucial role in blending the gases, allowing for a consistent flame suitable for various tasks.

Safety and Maintenance Features

Incorporating safety mechanisms is vital to protect users from potential hazards. Features such as flashback arrestors prevent dangerous backflow of gases, while regulators ensure that pressure levels remain stable during operation. Regular maintenance of these components is essential to prolong the lifespan of the equipment and ensure reliable function.

Key Parts of a Cutting Torch

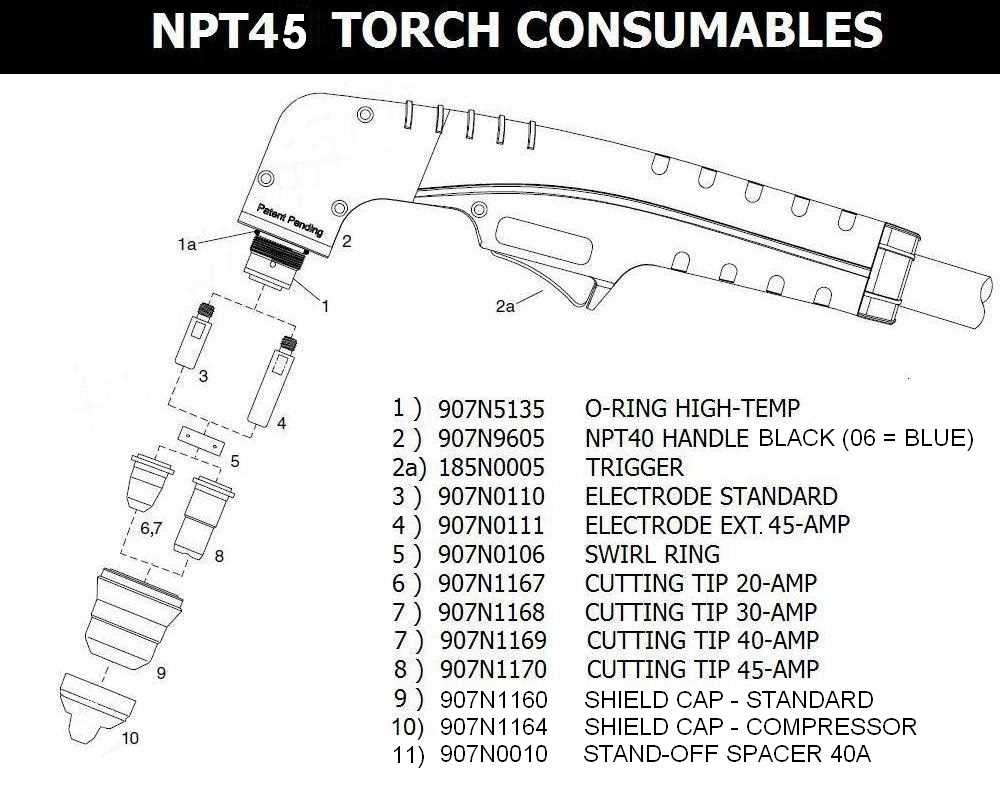

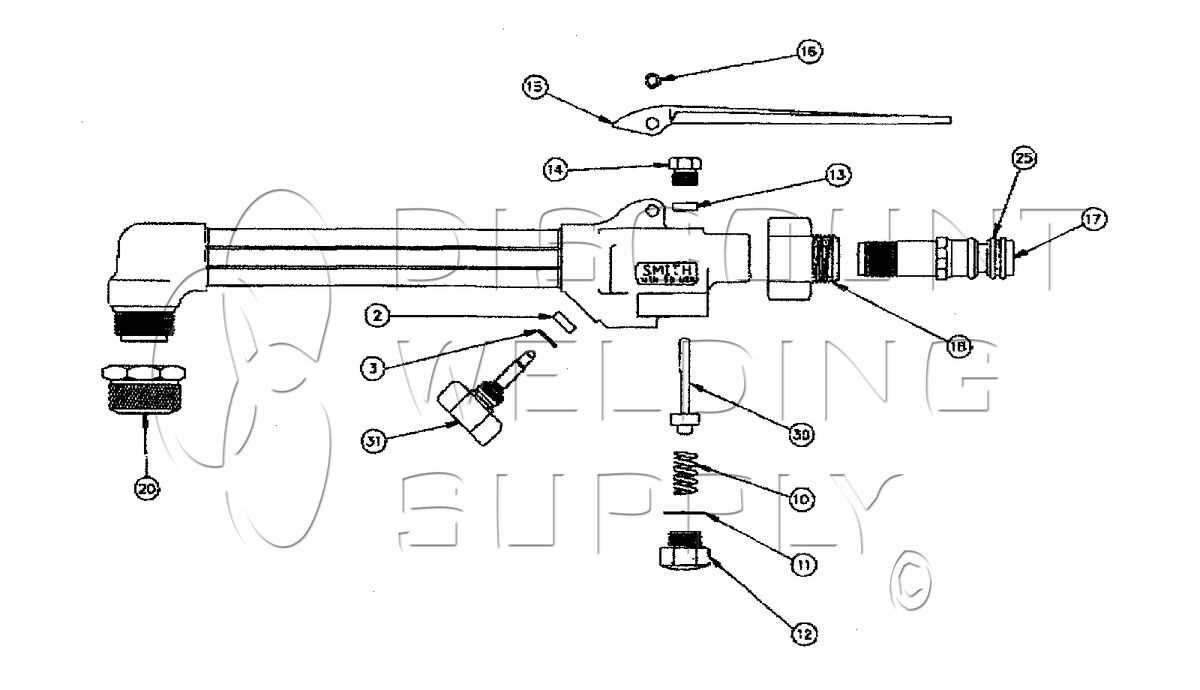

Understanding the essential components of a cutting device is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring that the tool functions properly, enabling precise and effective results in metalworking applications.

Main Components

The primary sections of a cutting apparatus include the following:

| Component | Description |

|---|---|

| Handle | The grip that allows the user to maneuver the tool with ease. |

| Mixing Chamber | Where fuel and oxygen are blended to create the cutting flame. |

| Tip | The part that focuses the flame and defines the cutting width. |

Additional Features

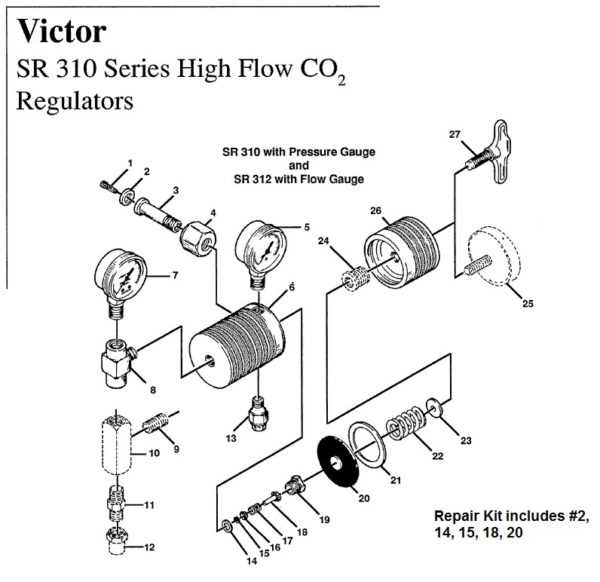

Beyond the main elements, several auxiliary components enhance functionality, such as valves for regulating gas flow and gauges for monitoring pressure levels, all contributing to the ultimate effectiveness of the tool.

Functionality of Each Component Explained

This section delves into the roles and responsibilities of the various elements that comprise a specialized tool for thermal applications. Each component contributes uniquely to the overall efficiency and effectiveness of the device, ensuring optimal performance during operation.

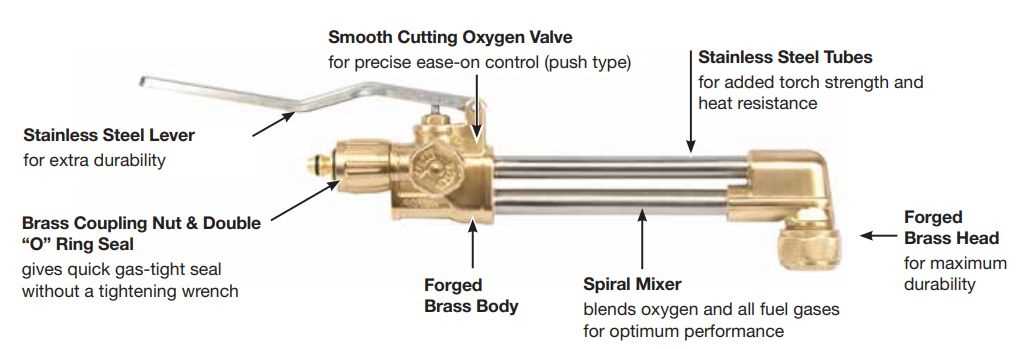

1. Fuel Gas Valve: This element regulates the flow of fuel, allowing the user to control the intensity of the flame. Its precision is crucial for achieving the desired temperature and ensuring safe operation.

2. Oxygen Valve: Similar to the fuel gas valve, this component manages the oxygen supply. A balanced mixture of fuel and oxygen is essential for creating the proper combustion environment, leading to effective cutting or welding.

3. Mixing Chamber: The mixing chamber serves as the site where fuel and oxygen combine before ignition. Its design is critical for achieving a consistent and stable flame, which directly impacts the quality of the work being performed.

4. Tip: The tip is the part where the flame emerges, and its configuration affects the shape and intensity of the flame. Different tips are available for various applications, enabling users to tailor their approach based on specific tasks.

5. Handle: This component provides ergonomics and control. A well-designed handle enhances user comfort and maneuverability, facilitating precision during intricate operations.

6. Hose Assembly: The hose assembly connects the fuel and oxygen sources to the main apparatus. Its durability and flexibility are essential for safe operation, preventing leaks and ensuring reliable performance.

Understanding the functionality of each component is vital for effective use, as it allows users to appreciate the intricate design and purpose behind the tool, ultimately enhancing their experience and results.

Common Issues with Torch Parts

In the realm of cutting equipment, various challenges can arise, impacting functionality and performance. Understanding these prevalent issues can significantly enhance the effectiveness of operations and extend the lifespan of the tools.

Wear and Tear: Over time, components may exhibit signs of degradation, affecting efficiency. Regular inspections can help identify early signs of wear.

Gas Leaks: A common concern is the potential for leaks in gas lines, which can lead to safety hazards. Ensuring proper connections and seal integrity is essential.

Inconsistent Flame Quality: Fluctuations in flame characteristics can occur due to blockages or improper adjustments. Regular maintenance and cleaning can mitigate this issue.

Misalignment: Components may become misaligned, causing operational inefficiencies. Proper alignment and calibration are crucial for optimal performance.

Component Compatibility: Using mismatched or incompatible components can lead to malfunctions. It’s vital to ensure all parts are designed to work together seamlessly.

Maintenance Tips for Cutting Torches

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By following a few simple guidelines, you can enhance performance and minimize issues. This section outlines crucial practices to keep your tools in top condition.

1. Clean After Use: Always wipe down the exterior and remove any residue after every operation. This prevents buildup that can affect functionality.

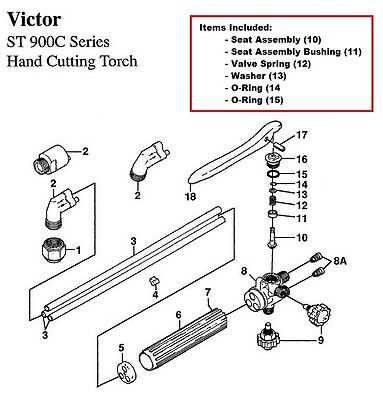

2. Inspect Components: Periodically check all elements for wear and tear. Look for cracks, leaks, or other signs of damage to avoid malfunctions during use.

3. Replace Worn Parts: When you notice any deterioration, replace the affected elements promptly. Using compromised components can lead to poor performance.

4. Store Properly: Keep your equipment in a dry, cool place to protect it from environmental damage. Ensure that it’s stored in a secure manner to prevent accidental damage.

5. Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance instructions. Adhering to these recommendations ensures optimal performance and safety.

Choosing the Right Torch Model

Selecting the appropriate model for your needs is crucial for ensuring efficiency and effectiveness in your tasks. With a wide array of options available, understanding the key features and applications can help you make an informed decision. Considerations such as fuel type, size, and intended use play a significant role in identifying the most suitable equipment for your projects.

Factors to Consider

When evaluating different models, several factors should be taken into account:

| Factor | Description |

|---|---|

| Fuel Type | Determine whether you prefer acetylene, propane, or another fuel source based on availability and compatibility. |

| Size and Portability | Consider the weight and dimensions of the model, especially if you need to transport it frequently. |

| Application | Identify whether you will use it for light tasks or heavy-duty operations to select a model with the appropriate capacity. |

Matching Your Needs

Assessing your specific requirements will guide you toward a model that aligns with your working conditions. Whether for professional or hobbyist purposes, a tailored selection can enhance your overall experience and productivity.

Safety Precautions During Use

Ensuring safety while operating high-temperature tools is crucial to prevent accidents and injuries. Awareness of potential hazards and adherence to safety guidelines can significantly reduce risks in the workspace.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and flame-resistant clothing.

- Ensure proper ventilation in the working area to avoid inhaling harmful fumes.

- Keep flammable materials away from the work zone to minimize fire hazards.

- Regularly inspect equipment for any signs of damage or wear before use.

- Follow manufacturer guidelines for safe operation and maintenance of the tool.

By implementing these precautions, users can foster a safer environment and enhance their overall experience with these high-energy instruments.

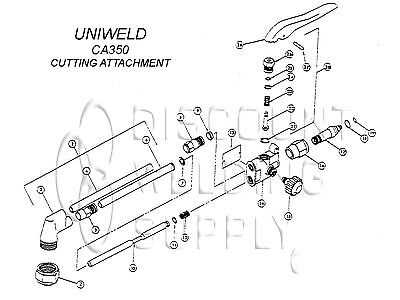

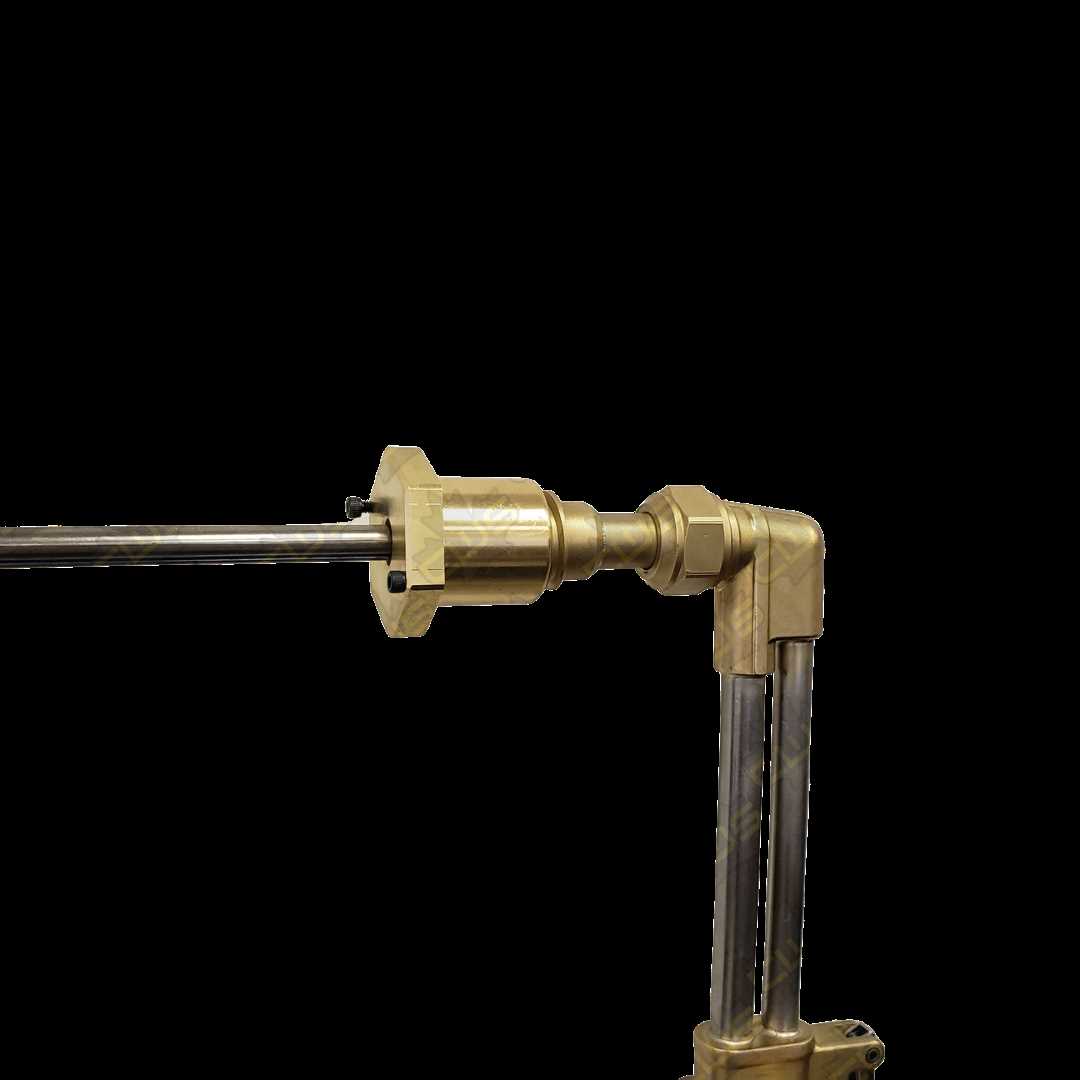

How to Assemble Your Torch Properly

Proper assembly of your equipment is essential for optimal performance and safety. Understanding the components and their arrangement is crucial for achieving the desired results. This section provides a step-by-step guide to ensure everything is put together correctly.

Essential Components

| Component | Description |

|---|---|

| Handle | The main part used to control the device. |

| Mixing Chamber | Where gases combine before ignition. |

| Nozzle | Focuses the flame for precision work. |

| Regulator | Controls the gas flow and pressure. |

Assembly Steps

Begin by securing the handle firmly. Next, attach the mixing chamber, ensuring it fits snugly. Then, connect the nozzle, making sure it is aligned properly. Finally, install the regulator, checking that all connections are tight and leak-free. Regular inspections will help maintain efficiency and safety during use.

Upgrading Your Torch Components

Enhancing your equipment can significantly improve performance and efficiency. By selecting superior components, you can ensure better precision and longevity, ultimately leading to more effective results in your projects. This section explores essential upgrades that can transform your setup into a more powerful tool.

Choosing High-Quality Nozzles

Investing in advanced nozzles can optimize the flow and distribution of fuel. High-quality options can provide a more uniform flame, allowing for cleaner cuts and reduced material waste. Evaluate the materials and designs available to find the best match for your needs.

Improving Regulators and Hoses

Upgrading regulators and hoses is crucial for maintaining consistent pressure and safety. Durable, flexible hoses can withstand higher temperatures and pressures, while reliable regulators ensure steady gas delivery. Prioritize components that enhance overall performance and minimize risk during operation.

Comparison of Popular Torch Models

This section delves into a comparative analysis of widely used models in the realm of thermal cutting tools. By examining various options, we aim to highlight their unique features, advantages, and limitations, enabling users to make informed decisions based on their specific requirements.

Model A: Features and Benefits

Model A stands out with its ergonomic design and advanced technology. Users appreciate its lightweight construction, which enhances maneuverability during operations. Additionally, the reliability of this model ensures consistent performance, making it a favored choice among professionals seeking efficiency.

Model B: Strengths and Limitations

Model B is known for its robust build and high durability, ideal for heavy-duty applications. However, its weight can be a drawback for some users, especially in prolonged tasks. Despite this, its cutting precision remains unmatched, proving to be the ultimate solution for demanding environments.

Resources for Further Learning

Expanding your knowledge in the field of fabrication and metalworking can greatly enhance your skills and understanding. There are numerous materials available to deepen your expertise and provide insights into various tools and techniques.

- Books:

- “Welding Essentials” by William L. Galvery

- “The Metal Fabrication Handbook” by Timothy J. McGrail

- “Oxy-Fuel Welding and Cutting” by David J. Davy

- Online Courses:

- Coursera: Metalworking Fundamentals

- Udemy: Introduction to Welding Techniques

- edX: Advanced Fabrication Methods

- Video Tutorials:

- YouTube: Channels dedicated to welding and fabrication

- Skillshare: Courses on metalworking techniques

- Vimeo: Expert demonstrations and workshops

- Forums and Communities:

- Reddit: r/Welding

- WeldingWeb: Online community for metalworkers

- Facebook Groups: Metalworking enthusiasts

Utilizing these resources will help you gain practical knowledge and refine your craft, allowing for greater proficiency and confidence in your projects.