Understanding the internal structure of certain mechanical systems is crucial for effective maintenance and repair. Every element plays a key role in ensuring smooth operation, and having a clear visual representation of each piece allows for a more precise approach to troubleshooting and replacement.

By examining the full arrangement of individual mechanisms, users can gain insight into the relationships between different elements. This knowledge empowers technicians to address potential issues swiftly, ensuring the longevity and efficiency of the entire setup.

With proper identification and categorization of various elements, maintaining optimal performance becomes significantly easier. This not only simplifies the repair process but also helps in preemptively identifying wear and tear that could lead to future problems.

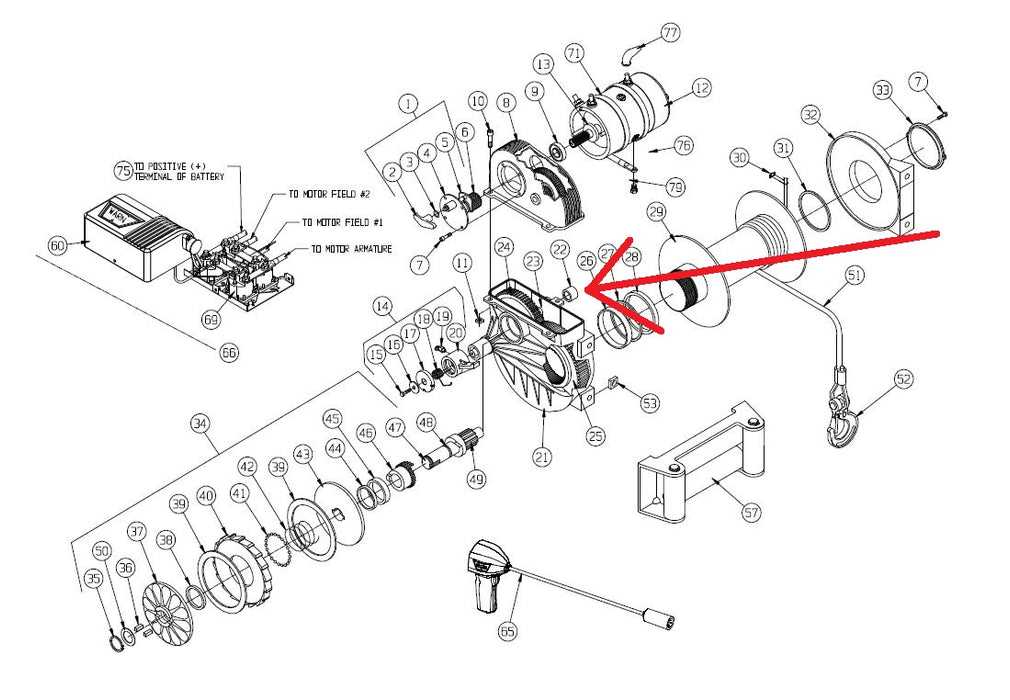

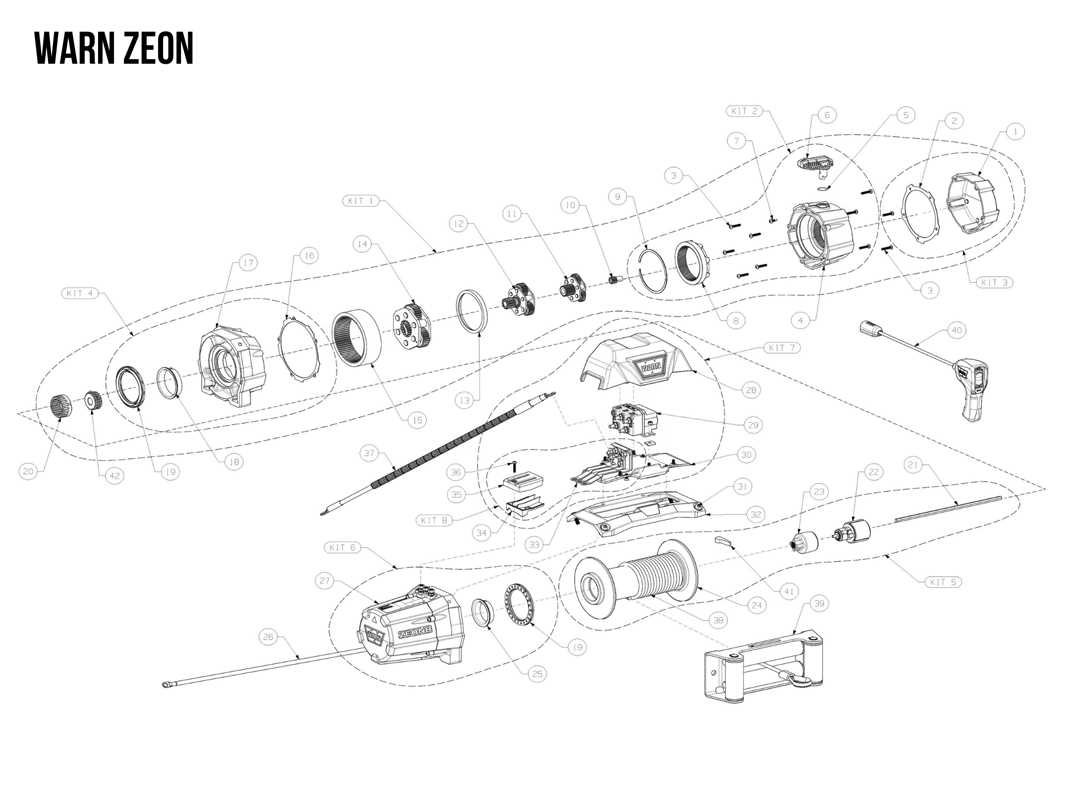

Overview of Key Components

The essential elements of this mechanical system are designed to work together seamlessly, each playing a crucial role in its operation. By understanding the core functions of these components, users can maintain and troubleshoot effectively.

Motor Assembly

The motor is the driving force, providing the necessary power to handle heavy loads. Its robust construction ensures durability, while the electric or hydraulic variations offer flexibility for different applications.

Drum and Cable Mechanism

The drum, coupled with a strong cable, is vital for securing and moving weight. Its rotation allows for controlled spooling, ensuring that the cable remains tight and responsive during operation. This system provides both strength and precision.

Internal Mechanism Layout

The internal structure is designed with precision to ensure reliable performance and durability. Each component inside the mechanism plays a crucial role in the overall operation, working together to achieve seamless functionality. The layout focuses on efficient power transfer, controlled movement, and enhanced stability, providing a dependable experience in demanding situations.

- Gear System: The gear assembly facilitates smooth and controlled torque transmission, ensuring consistent performance under load.

- Brake Assembly: A specialized braking system ensures safety by maintaining control over movement, particularly during high-tension situations.

- Drum and Cable Management: The

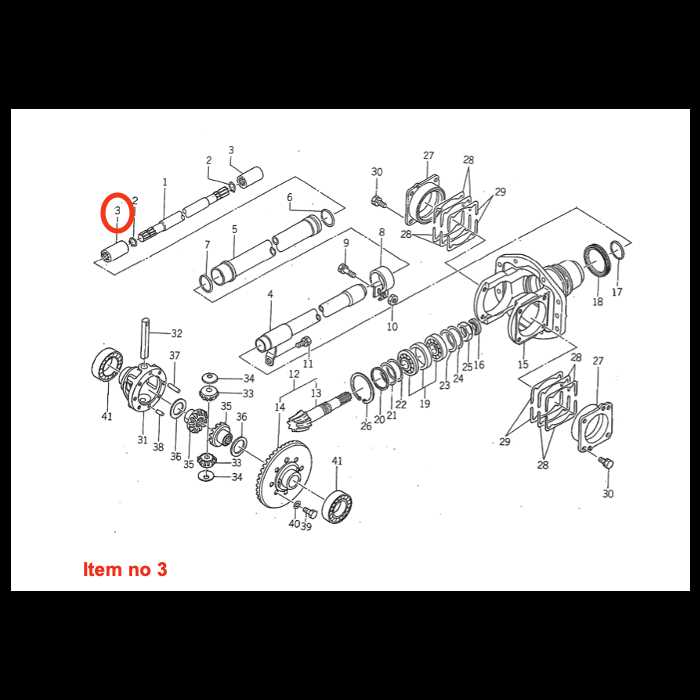

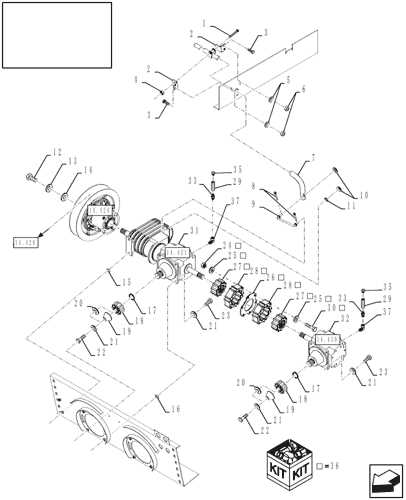

Exploded View of Gear Assembly

An exploded view offers a clear representation of how various components in the gear mechanism are interconnected. It is a practical tool for understanding the intricate structure of the system and how each element fits together. This breakdown reveals the relationships between moving and stationary parts, allowing users to grasp the detailed composition of the assembly without needing to disassemble the unit manually.

Core Components and Their Functions

The key elements within the gear system include a series of interlocking wheels, shafts, and support structures. Each component serves a specific purpose, whether transmitting torque, reducing speed, or supporting rotational movement. Understanding how these elements interact is crucial for effective maintenance and repairs.

Sequential Arrangement and Fitting

Electrical Wiring and Connections

The electrical system is essential for ensuring efficient power distribution and proper operation of the equipment. Understanding the wiring layout and the role of various connections helps maintain stability and functionality across all components. Properly configured circuits and secure connections reduce the risk of malfunctions and enhance overall safety.

Key connection points in the system include power input lines, grounding terminals, and control wiring. Each of these plays a critical role in the overall electrical flow. It is important to inspect wiring regularly for signs of wear, loose connections, or corrosion, as any disruption can lead to performance issues or potential hazards.

When assembling or maintaining the setup, always ensure that cables are routed correctly and securely fastened. This prevents unnecessary strain on the wires and helps avoid accidental disconnections. Using appropriate connectors and protective coverings further safeguards the integrity of the electrical system.

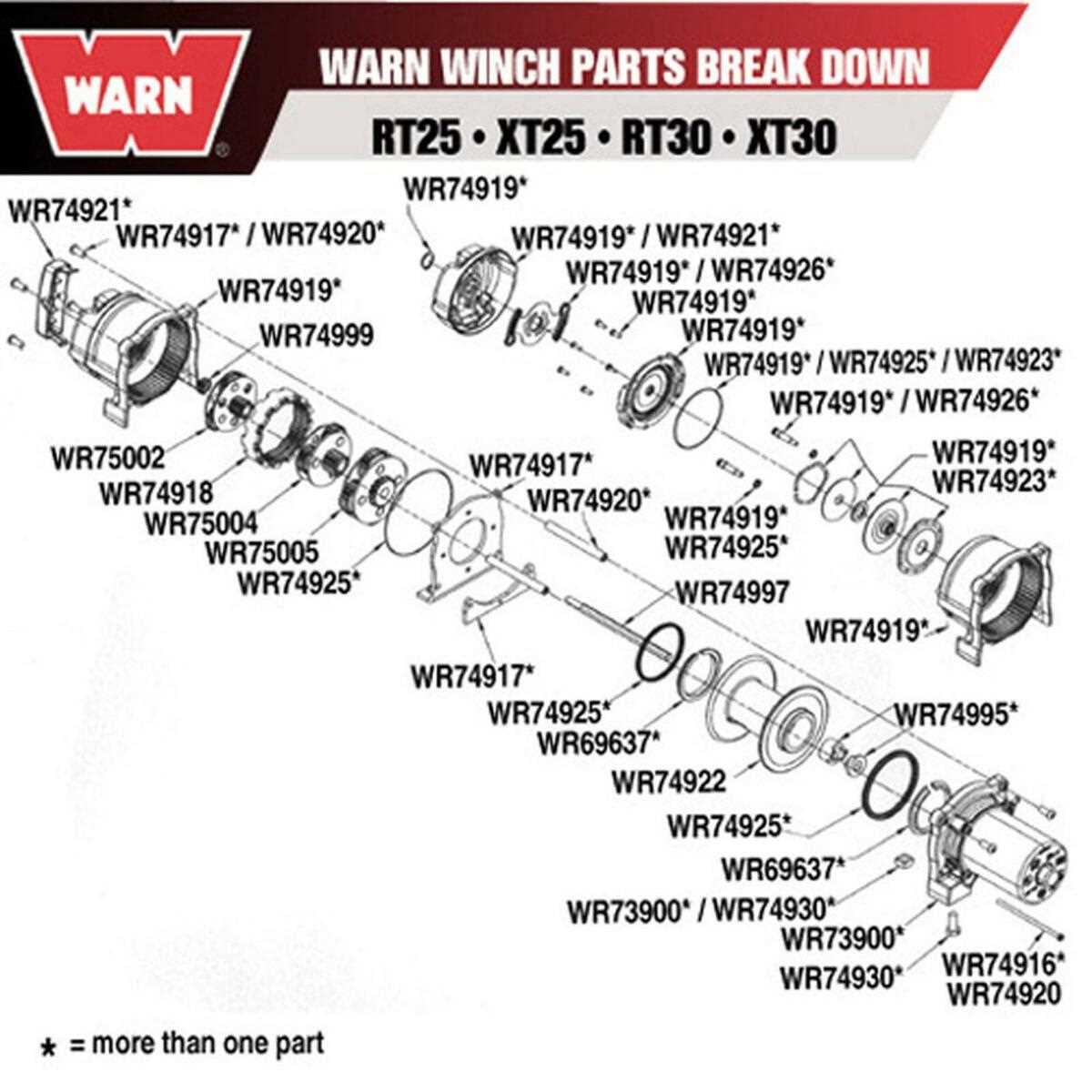

Motor and Drive System Breakdown

The motor and drive assembly is crucial for the operation of any lifting and pulling mechanism. This section examines the key components, detailing their roles and how they interconnect to ensure efficient functionality. Understanding these elements is essential for maintaining performance and troubleshooting issues in the system.

- Electric Motor: Powers the entire system, converting electrical energy into mechanical force. Its efficiency directly impacts the speed and torque generated.

- Gear Train: A series of gears that reduces motor speed while increasing torque. This ensures the system can handle heavy loads without overstraining the motor.

- Clutch Assembly: Allows for manual control of the mechanism. When disengaged, it lets the operator freely spool the cable without engaging the motor.

- Brake Mechanism: Automatically activates when the power is cut, holding the load in place and preventing unwinding under pressure

Mounting Brackets and Fasteners

The selection of mounting brackets and fasteners is crucial for ensuring the stability and functionality of equipment. Properly chosen components provide secure attachment points, allowing for optimal performance in various applications. Understanding the characteristics and specifications of these elements helps in achieving a reliable setup.

Brackets are essential for supporting equipment, as they determine the positioning and orientation of the installed components. They come in various designs and materials to accommodate specific requirements. Selecting the appropriate bracket type can significantly influence the overall effectiveness and safety of the installation.

Fasteners play a vital role in holding everything together. These elements need to be compatible with the chosen brackets and should withstand the operational conditions they will face. Utilizing the correct fasteners ensures that connections remain secure, preventing any potential failure during use.

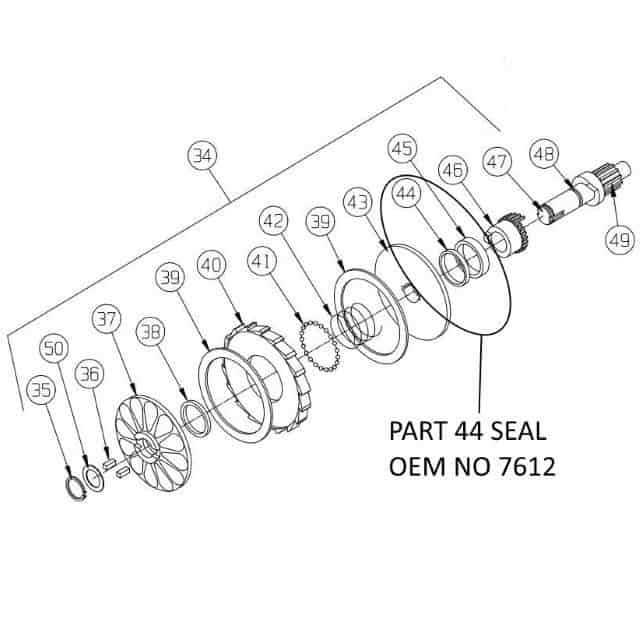

Clutch Assembly Structure

The clutch assembly is a crucial component in the operation of a winch system, facilitating the engagement and disengagement of power transmission. Understanding its structure is essential for effective maintenance and performance optimization. This assembly typically consists of various elements that work in harmony to ensure smooth functionality.

Main Components

The operation of the clutch assembly involves precise coordination between its components. When engaged, the friction discs come into contact with the pressure plates, creating a secure bond that transmits power effectively. Disengaging the clutch requires the release mechanism to pull back the pressure plates, allowing the friction discs to separate, thereby interrupting power flow.

Brake System Components

The braking mechanism is crucial for the safety and performance of any vehicle. It consists of various elements that work together to ensure effective stopping power and control. Understanding these components can help in maintaining the system and enhancing its functionality.

Key Elements of the Braking Mechanism

Several essential parts comprise the braking system, each serving a specific purpose. Among these are the brake pads, which create friction against the rotor, and the calipers, which house the pads and exert pressure to initiate braking. Additionally, the brake lines facilitate the transfer of hydraulic fluid, enabling the system to function efficiently.

Importance of Regular Maintenance

Regular inspection and maintenance of the braking components are vital for optimal performance. Neglecting these parts can lead to reduced efficiency and potential safety hazards. Periodic checks on the pads, calipers, and lines can help identify wear and tear, ensuring that the braking system operates smoothly and reliably.

Cable Drum Configuration

The arrangement of the cable drum plays a vital role in the efficient operation of a winching system. Proper configuration ensures that the cable is wound uniformly, minimizing wear and tear while maximizing performance. This setup affects the overall functionality, reliability, and longevity of the equipment.

Key Components: The cable drum typically includes several essential elements, such as the spool, flanges, and guide rollers. Each of these components contributes to the effective management of the cable, allowing for smooth deployment and retrieval.

Considerations: When configuring the cable drum, factors such as the diameter of the drum, cable material, and intended load capacity must be taken into account. Adhering to these considerations promotes optimal operation and reduces the risk of malfunction.

Control Unit Parts

The control unit is a crucial component that manages the overall operation of the system. It ensures seamless functionality and coordination between different elements, contributing to optimal performance.

Component Description Processor Executes commands and processes data for efficient operation. Input Module Receives signals from various sensors and devices. Output Module Delivers commands to the actuators and other components. Power Supply Provides the necessary energy for the unit’s functionality. Connector Pins Facilitate secure connections between the unit and other components. Lubrication Points and Maintenance Areas

Proper upkeep of mechanical equipment is essential for optimal performance and longevity. Regular lubrication helps prevent wear and tear on moving components, ensuring smooth operation. Identifying key areas for maintenance is crucial for preserving functionality and avoiding costly repairs.

- Gearbox: Regularly check and apply grease to the gearbox to maintain efficiency.

- Bearings: Lubricate bearings frequently to minimize friction and enhance durability.

- Winch Drum: Inspect and oil the winch drum to facilitate smooth cable operation.

- Chain and Sprockets: Ensure the chain and sprockets are adequately lubricated to reduce wear.

- Seals and Gaskets: Examine seals for signs of damage and apply appropriate lubricant to prevent leaks.

Implementing a consistent maintenance schedule that includes these lubrication points will significantly improve the reliability and lifespan of the equipment. Regular inspections are essential for identifying potential issues before they escalate.

Aftermarket Replacement

Aftermarket options provide an excellent opportunity for individuals seeking to enhance or restore their winching systems. These alternatives often offer comparable quality to original components while potentially delivering cost savings.

When considering aftermarket replacements, several factors should be taken into account:

- Compatibility: Ensure the chosen components are designed to fit the specific model and system requirements.

- Quality: Look for reputable manufacturers that guarantee durability and performance.

- Warranty: Check for warranties or guarantees that accompany the aftermarket products, as this can indicate reliability.

- Reviews: Research customer feedback and reviews to gauge the effectiveness and longevity of the replacements.

In summary, opting for aftermarket solutions can be a practical choice for those aiming to maintain or upgrade their winching setups. By thoroughly researching and selecting high-quality components, users can achieve satisfactory results without compromising performance.